PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1406111

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1406111

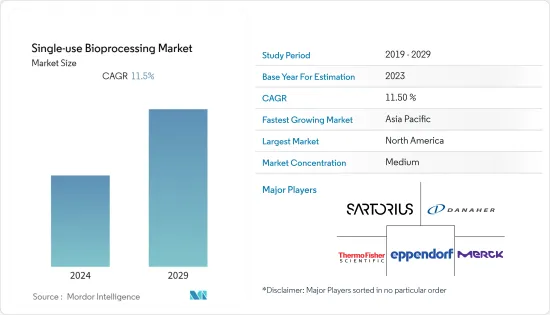

Single-use Bioprocessing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts 2024 - 2029

The single-use bioprocessing market is anticipated to register a CAGR of 11.5% during the forecast period.

The initial phase of the pandemic substantially impacted the growth of the single-use bioprocessing market owing to the significant decline in manufacturing processes and restricted demand and supply of drugs. However, single-use technology (SUT) became a leading technology in pre-commercial manufacturing, including preclinical and clinical scales. With the increasing number of COVID-19 cases, the demand for effective drugs and many vaccines increased. It also increased the adoption of biopharmaceutical companies' single-use bioprocessing systems and technology due to fewer chances of contamination and reduced sterilization tests between the batches. Also, drug discovery using single-use technologies became a major focus for managing the pandemic. For instance, according to an article published in the National Library of Medicine in November 2022, it was observed that the pandemic accelerated the growing demand for single-use devices for the rapid production of drugs and vaccines. Due to the increased infection rates, most COVID-19 vaccine research is based on single-use technologies. Thus, these efforts involve using novel approaches, such as mRNA and DNA technologies. Hence, the studied market witnessed significant growth during the COVID-19 pandemic.

Factors such as faster implementation and lower risk of product cross-contamination, increasing demand for biopharmaceuticals, lower costs, and lesser environmental impact of single-use bioprocessing technologies are expected to boost the market growth.

The demand for biopharmaceuticals increased due to the high population suffering from chronic diseases. It raises the need for effective drugs and products for their treatment, which is anticipated to fuel the demand for single-use technologies and related products, thereby propelling market growth. For instance, according to the data published by the FDA, in February 2023, about 14 biologics were approved for treating various chronic diseases in 2022. The pharmaceutical industry is expected to increase the utilization and adoption of single-use bioprocessing technologies and systems over the forecast period.

The ability to deploy single-use monitoring tools and improvements in sensing technologies allow producers more control over their processes, which increases their adoption. Also, adopting single-use technologies and systems helps biopharmaceutical companies overcome the challenges of eradicating contamination risks, thus lowering the need for sterilization between batches and increasing productivity. In addition, single-use bioreactors and fermentors provide high flexibility, making it easier to experiment with various designs to optimize the process. The system offers reduced energy consumption, water consumption, and the plant's environmental footprint over conventional bioprocessing systems. It makes them a preferred choice across the pharmaceutical industry. Also, the increasing focus of the companies on developing a new single-use system that is utilized in both upstream and downstream processing of the production of biopharmaceuticals is expected to fuel market growth.

Furthermore, adopting big data-based machine learning in single-use systems increases the product or drug yield while achieving maximum productivity and efficiency in terms of process, and the use of mainstream strategy by many biopharmaceutical manufacturers is also contributing to the market growth.

Moreover, the rising adoption of various business strategies such as collaborations, partnerships, new product launches, and other company initiatives are also expected to propel the market growth. For instance, in May 2021, Qosina entered into a distribution agreement with Nordson MEDICAL to support Single-Use Bioprocess Integrators and Medical Device Manufacturers. Also, in March 2021, Thermo Fisher launched 3,000 and 5,000 L HyPerforma DynaDrive Single-use Bioreactors. These bioreactors offer features that support cell culture performance across scales, accommodate high-density and next-generation cell culture processes, and reduce overall costs through reduced capital investment, operational expenses, and higher-output processes. DynaDrive S.U.B.s also provide superior turn-down in stirred tank reactors, which lowers the number of vessels needed for seed-train scale-up. The new systems offer increased scalability, improved turn-down ratio, and improved mixing.

Therefore, owing to the factors above, such as the high demand for biopharmaceutical products, several advantages offered by single-use systems, and the increasing company activities, the studied market is anticipated to grow over the forecast period. However, the issues related to leachable and extractable are likely to restrain the market growth over the forecast period.

Single-use Bioprocessing Market Trends

Biopharmaceutical Manufacturer Segment is Expected to Witness Significant Growth Over the Forecast Period

The biopharmaceutical segment is expected to grow significantly in the single-use bioprocessing market over the forecast period. It is due to the rising adoption of single-use technologies and systems, increasing demand for biologics, and growing company activities. In addition, some of the advantages offered by single-use technologies and products, such as reduced initial investment and research and development costs, low labor and material costs, and easy disposal over conventional bioprocessing methods, are also increasing their adoption across the biopharmaceutical industry. Additionally, these single-use bioprocessing plants produce a 35% more favorable carbon dioxide (CO2) balance than stainless steel reactors used in conventional bioprocessing and are highly adopted by the manufacturer.

The rising number of biologics approvals is also contributing to the increased demand for single-use bioreactors and technologies. For instance, in February 2023, the United States FDA approved Bioverativ Therapeutics's ALTUVIIIO, a first-in-class, high-sustained factor VIII replacement therapy. It is indicated for routine prophylaxis, on-demand treatment to control bleeding episodes, and perioperative management (surgery) for adults and children with hemophilia A. Also, in January 2022, Moderna, Inc., a biotechnology company pioneering messenger RNA (mRNA) therapeutics and vaccines, received approval for the Biologics License Application for SPIKEVAX (COVID-19 Vaccine, mRNA) from the FDA to prevent COVID-19 in individuals 18 years of age and older.

Furthermore, the companies' rising focus on adopting key strategies such as collaborations, new product launches, and other initiatives are also expected to fuel the segment growth. For instance, in May 2022, ILC Dover LP launched liquid single-use bioprocessing bags to handle and supply sterile liquids for the biotherapeutics market. Also, the companies are opening up single-use bioprocessing plants to expand their protein, cell line, and process development services. For instance, in April 2022, Thermo Fisher Scientific opened a 55,000 sq ft single-use technology (SUT) facility in Ogden. It is to increase the production of single-use bioprocess containers for developing vaccines and therapies. The plant provides additional capacity to produce various techniques and materials needed to develop emerging vaccines and breakthrough therapies. The facility manufactures customizable bioprocess container (BPC) systems for the delivery, processing, separation, storage, and transportation of liquids. Also, in February 2021, WuXi Biologics MFG5 Drug Substance (DS) manufacturing facility in China launched a GMP operation with a capacity of 36,000 l, deploying nine 4,000 l single-use bioreactors. This launch increased the company's current capacity to 90,000 l.

Therefore, the studied segment is expected to grow significantly over the forecast period due to the above factors.

North America is Expected to Hold the Significant Market Share Over the Forecast Period

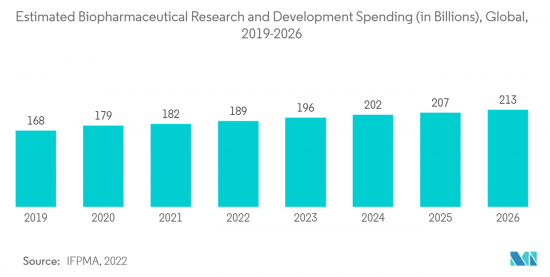

North America is expected to hold a significant market share over the forecast period. It is due to increasing research and development spending, large manufacturing unit presence, the growing popularity of disposables, increasing healthcare expenditure, and well-established healthcare infrastructure presence.

The government is investing enormously in developing biopharmaceutical products, which is expected to drive the market for single-use bioreactors, containers, media, filtration assemblies, and others, propelling the market growth. For instance, according to the data published by the Government of Canada in July 2021, it was observed that the Canadian government invested more than USD 1.2 billion to reestablish national vaccination, therapeutic, and biomanufacturing capacity. In addition, the Honourable Francois-Philippe Champagne, Minister of Innovation, Science, and Industry, and the Honourable Patty Hajdu, Minister of Health, launched the Biomanufacturing and Life Sciences Strategy. Over seven years, more than USD 2.2 billion was invested to continue growing a robust and competitive sector for facing future pandemics.

Furthermore, the rising company activities in establishing single-use bioprocessing plants and launching new products such as bioreactors, filtration assemblies, and other consumables are also contributing to the market growth in the region. For instance, in May 2022, ILC Dover Lp launched liquid single-use bioprocessing bags for handling and supplying sterile liquids for the biotherapeutics market. This launch assists the company in setting across the entire biotherapeutic and pharmaceutical manufacturing workflow, from powder containment and handling through sterile liquid handling and pre-filled liquid and powder bags. Also, in November 2021, Bionova opened a USD 25 million single-use plant in Fremont, California. The plant is equipped with a 1,000 l Cytiva XDR upstream train. Similarly, in October 2021, Agilitech launched an Agilitech bioreactor controller that simultaneously controls up to two single-use bioreactors from 30 l up to 2000 l. The design of the product allows for integration with any brand single-use bioreactor.

Therefore, owing to the factors above, the studied market is expected to grow significantly in the region over the forecast period.

Single-use Bioprocessing Industry Overview

The single-use bioprocessing market is moderately competitive and consists of several major players. The companies are focusing on adopting various business strategies such as collaboration, new product launches, and other initiatives to retain their market position. Some of the companies in the market are Sartorius AG, Thermo Fisher Scientific, Danaher Corporation (Cytiva), Eppendorf AG, Merck KGaA, Boehringer Ingelheim International GmbH, and PBS Biotech, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Faster Implementation and Lower Risk of Product Cross-contamination

- 4.2.2 Increasing Demand for Biopharmaceuticals

- 4.2.3 Lower Costs and Lesser Environmental Impact of Single-use Bioprocessing Technologies

- 4.3 Market Restraints

- 4.3.1 Issues Related to Leachables and Extractables

- 4.4 Industry Attractiveness - Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers/Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products

- 4.4.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size by Value in USD)

- 5.1 By Product

- 5.1.1 Filtration Assemblies

- 5.1.2 Media Bags and Containers

- 5.1.3 Disposable/Single-use Bioreactors

- 5.1.4 Disposable Mixers

- 5.1.5 Other Products

- 5.2 By Application

- 5.2.1 Filtration

- 5.2.2 Cell Culture

- 5.2.3 Purification

- 5.2.4 Other Applications

- 5.3 By End User

- 5.3.1 Biopharmaceutical Manufacturers

- 5.3.2 Academic and Clinical Research Institutes

- 5.3.3 Other End Users

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Italy

- 5.4.2.5 Spain

- 5.4.2.6 Rest of Europe

- 5.4.3 Asia Pacific

- 5.4.3.1 China

- 5.4.3.2 Japan

- 5.4.3.3 India

- 5.4.3.4 Australia

- 5.4.3.5 South Korea

- 5.4.3.6 Rest of Asia Pacific

- 5.4.4 Middle East and Africa

- 5.4.4.1 GCC

- 5.4.4.2 South Africa

- 5.4.4.3 Rest of Middle East and Africa

- 5.4.5 South America

- 5.4.5.1 Brazil

- 5.4.5.2 Argentina

- 5.4.5.3 Rest of South America

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Sartorius AG

- 6.1.2 Thermo Fisher Scientific

- 6.1.3 Danaher Corporation (Cytiva)

- 6.1.4 Eppendorf AG

- 6.1.5 Merck KGaA

- 6.1.6 3M

- 6.1.7 CESCO Bioengineering Co., Ltd.

- 6.1.8 PBS Biotech, Inc.

- 6.1.9 ABEC Inc.

- 6.1.10 Celltainer Biotech BV

- 6.1.11 Distek, Inc.

- 6.1.12 OmniBRx Biotechnologies

- 6.1.13 Boehringer Ingelheim International GmbH

7 MARKET OPPORTUNITIES AND FUTURE TRENDS