PUBLISHER: Allied Market Research | PRODUCT CODE: 1365595

PUBLISHER: Allied Market Research | PRODUCT CODE: 1365595

Automotive Silicone Market By Type (Elastomers, Resins, Gels, Others), By Application (Interior and Exterior, Engines, Electrical Systems, Others): Global Opportunity Analysis and Industry Forecast, 2023-2032

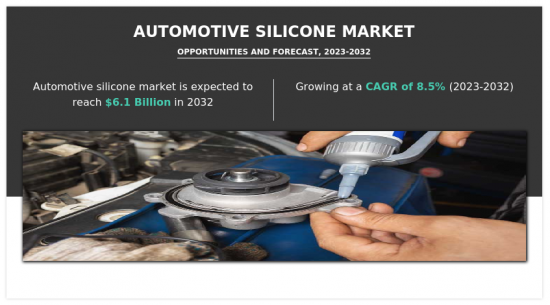

According to a new report published by Allied Market Research, titled, "Automotive Silicone Market," The automotive silicone market was valued at $2.7 billion in 2022, and is estimated to reach $6.1 billion by 2032, growing at a CAGR of 8.5% from 2023 to 2032.

Automotive silicone is a specific type of silicone material that is majorly designed for use in automotive applications. Silicone is a flexible polymer renowned for its excellent electrical insulation properties, temperature resistance, and durability. In the automotive industry, silicone is majorly used owing to its unique properties and benefits. The temperature resistance property of silicone can withstand extreme temperatures, both high and low, without losing its physical properties. It remains stable and flexible across an extensive temperature range, making it appropriate for automotive applications.

Automotive weight reduction is a constant goal for automakers as they seek to improve overall performance and fuel economy. Vehicle design is increasingly incorporating lightweight components including carbon fiber composites, high-strength steel, aluminum, and plastics. Because they may replace heavy materials and have a low density, silicone-based materials including adhesives, silicone foams, and sealants are a crucial step in the process of making automotive products lighter. These lightweight silicone materials are opted in various applications, such as seals, gaskets, electrical components, and thermal management systems, to reduce overall vehicle weight. Silicone-based adhesives, sealants, and gaskets are used in powertrain components, including transmissions, engines, and exhaust systems, to improve performance and reduce energy losses.

Silicon is a non-renewable resource that is used to make automotive silicone, and the procedures used to make silicone consume a lot of energy. In addition, silicone products are not easily biodegradable, leading to possible waste management challenges. As governments and regulatory bodies implement strict environmental regulations, automotive manufactures may face consequences and can diverge towards using more sustainable materials in comparison to silicone. Volatile organic compounds (VOCs) can be discharged as a result of the usage and manufacture of products with silicone as a base. VOCs are dangerous compounds that can harm human health and contribute to air pollution. Limits on VOC emissions are frequently imposed by stringent environmental laws, which may have an effect on the creation and application of automotive silicone. Moreover, the growing emphasis on sustainability has increased the demand for eco-friendly alternatives to silicone. The automotive industry is exploring and adopting greener solutions such as bio-based polymers and recyclable materials to reduce their environmental footprints. This is expected to restrain market growth during the forecast period.

As electric vehicle production surges globally, the demand for silicone-based materials is expected to surge. This provides an opportunity for automotive silicone manufacturers to develop innovative solutions, increase their product offerings, and cater to the specific needs of the EV industry. Electric vehicles generate heat during operation, particularly in the battery and powertrain systems. Silicone-based thermal management solutions, such as gels, thermal interface materials, and adhesives, can effectively manage and dissipate heat, ensuring ideal performance and safety of EV components. Moreover, silicone materials possess excellent electrical insulation properties, making them suitable for applications like cable and wire insulation, connectors, and gaskets in electric vehicles. As Evs incorporate advanced electronics and electrical systems, the demand for reliable and high-performance electrical insulation materials will increase.

The COVID-19 pandemic had both positive and negative impacts on various industries, including the automotive silicone industry. The pandemic caused disruptions in global supply chains, affecting the availability of raw materials, equipment, and components necessary for automotive production. This hampered the production of automotive globally. The automotive industry experienced a significant decline in demand during the initial stage of the pandemic owing to lockdowns, travel restrictions, and economic instability. Moreover, as a result automotive manufacturers scaled back production, leading to reduced demand for automotive silicone and other related materials.

The key players profiled in this report include: Shin Etsu, Wacker Chemie, Siltech, Elkem Silicones, Momentive Performance Materials, Primasil Silicones, Dowdupont, Evonik, KCC Corporation, and Henkel AG & Co. The market players are continuously striving to achieve a dominant position in this competitive market using strategies such as collaborations and acquisitions.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the automotive silicone market analysis from 2022 to 2032 to identify the prevailing automotive silicone market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the automotive silicone market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global automotive silicone market trends, key players, market segments, application areas, and market growth strategies.

Additional benefits you will get with this purchase are:

- Quarterly Update and* (only available with a corporate license, on listed price)

- 5 additional Company Profile of client Choice pre- or Post-purchase, as a free update.

- Free Upcoming Version on the Purchase of Five and Enterprise User License.

- 16 analyst hours of support* (post-purchase, if you find additional data requirements upon review of the report, you may receive support amounting to 16 analyst hours to solve questions, and post-sale queries)

- 15% Free Customization* (in case the scope or segment of the report does not match your requirements, 20% is equivalent to 3 working days of free work, applicable once)

- Free data Pack on the Five and Enterprise User License. (Excel version of the report)

- Free Updated report if the report is 6-12 months old or older.

- 24-hour priority response*

- Free Industry updates and white papers.

Possible Customization with this report (with additional cost and timeline talk to the sales executive to know more)

- Investment Opportunities

- Technology Trend Analysis

- New Product Development/ Product Matrix of Key Players

- Regulatory Guidelines

- Strategic Recommedations

- Additional company profiles with specific to client's interest

- Additional country or region analysis- market size and forecast

- Criss-cross segment analysis- market size and forecast

- Expanded list for Company Profiles

- Historic market data

- Key player details (including location, contact details, supplier/vendor network etc. in excel format)

- List of customers/consumers/raw material suppliers- value chain analysis

- SWOT Analysis

Key Market Segments

By Type

- Elastomers

- Resins

- Gels

- Others

By Application

- Interior and Exterior

- Engines

- Electrical Systems

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- Germany

- Italy

- Spain

- UK

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia-Pacific

- LAMEA

- Brazil

- Morocco

- South Africa

- Argentina

- Rest of LAMEA

Key Market Players:

- Dowdupont

- Elkem ASA

- Evonik

- Henkel AG & Co

- KCC Corporation

- Momentive

- Primasil Silicones

- Shin Etsu

- Siltech Corporation

- Wacker Chemie

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION

- 1.1. Report description

- 1.2. Key market segments

- 1.3. Key benefits to the stakeholders

- 1.4. Research Methodology

- 1.4.1. Primary research

- 1.4.2. Secondary research

- 1.4.3. Analyst tools and models

CHAPTER 2: EXECUTIVE SUMMARY

- 2.1. CXO Perspective

CHAPTER 3: MARKET OVERVIEW

- 3.1. Market definition and scope

- 3.2. Key findings

- 3.2.1. Top impacting factors

- 3.2.2. Top investment pockets

- 3.3. Porter's five forces analysis

- 3.4. Market dynamics

- 3.4.1. Drivers

- 3.4.2. Restraints

- 3.4.3. Opportunities

- 3.5. COVID-19 Impact Analysis on the market

- 3.6. Market Share Analysis

- 3.7. Value Chain Analysis

- 3.8. Regulatory Guidelines

- 3.9. Key Regulation Analysis

- 3.10. Patent Landscape

CHAPTER 4: AUTOMOTIVE SILICONE MARKET, BY TYPE

- 4.1. Overview

- 4.1.1. Market size and forecast

- 4.2. Elastomers

- 4.2.1. Key market trends, growth factors and opportunities

- 4.2.2. Market size and forecast, by region

- 4.2.3. Market share analysis by country

- 4.3. Resins

- 4.3.1. Key market trends, growth factors and opportunities

- 4.3.2. Market size and forecast, by region

- 4.3.3. Market share analysis by country

- 4.4. Gels

- 4.4.1. Key market trends, growth factors and opportunities

- 4.4.2. Market size and forecast, by region

- 4.4.3. Market share analysis by country

- 4.5. Others

- 4.5.1. Key market trends, growth factors and opportunities

- 4.5.2. Market size and forecast, by region

- 4.5.3. Market share analysis by country

CHAPTER 5: AUTOMOTIVE SILICONE MARKET, BY APPLICATION

- 5.1. Overview

- 5.1.1. Market size and forecast

- 5.2. Interior and Exterior

- 5.2.1. Key market trends, growth factors and opportunities

- 5.2.2. Market size and forecast, by region

- 5.2.3. Market share analysis by country

- 5.3. Engines

- 5.3.1. Key market trends, growth factors and opportunities

- 5.3.2. Market size and forecast, by region

- 5.3.3. Market share analysis by country

- 5.4. Electrical Systems

- 5.4.1. Key market trends, growth factors and opportunities

- 5.4.2. Market size and forecast, by region

- 5.4.3. Market share analysis by country

- 5.5. Others

- 5.5.1. Key market trends, growth factors and opportunities

- 5.5.2. Market size and forecast, by region

- 5.5.3. Market share analysis by country

CHAPTER 6: AUTOMOTIVE SILICONE MARKET, BY REGION

- 6.1. Overview

- 6.1.1. Market size and forecast By Region

- 6.2. North America

- 6.2.1. Key trends and opportunities

- 6.2.2. Market size and forecast, by Type

- 6.2.3. Market size and forecast, by Application

- 6.2.4. Market size and forecast, by country

- 6.2.4.1. U.S.

- 6.2.4.1.1. Key market trends, growth factors and opportunities

- 6.2.4.1.2. Market size and forecast, by Type

- 6.2.4.1.3. Market size and forecast, by Application

- 6.2.4.2. Canada

- 6.2.4.2.1. Key market trends, growth factors and opportunities

- 6.2.4.2.2. Market size and forecast, by Type

- 6.2.4.2.3. Market size and forecast, by Application

- 6.2.4.3. Mexico

- 6.2.4.3.1. Key market trends, growth factors and opportunities

- 6.2.4.3.2. Market size and forecast, by Type

- 6.2.4.3.3. Market size and forecast, by Application

- 6.3. Europe

- 6.3.1. Key trends and opportunities

- 6.3.2. Market size and forecast, by Type

- 6.3.3. Market size and forecast, by Application

- 6.3.4. Market size and forecast, by country

- 6.3.4.1. France

- 6.3.4.1.1. Key market trends, growth factors and opportunities

- 6.3.4.1.2. Market size and forecast, by Type

- 6.3.4.1.3. Market size and forecast, by Application

- 6.3.4.2. Germany

- 6.3.4.2.1. Key market trends, growth factors and opportunities

- 6.3.4.2.2. Market size and forecast, by Type

- 6.3.4.2.3. Market size and forecast, by Application

- 6.3.4.3. Italy

- 6.3.4.3.1. Key market trends, growth factors and opportunities

- 6.3.4.3.2. Market size and forecast, by Type

- 6.3.4.3.3. Market size and forecast, by Application

- 6.3.4.4. Spain

- 6.3.4.4.1. Key market trends, growth factors and opportunities

- 6.3.4.4.2. Market size and forecast, by Type

- 6.3.4.4.3. Market size and forecast, by Application

- 6.3.4.5. UK

- 6.3.4.5.1. Key market trends, growth factors and opportunities

- 6.3.4.5.2. Market size and forecast, by Type

- 6.3.4.5.3. Market size and forecast, by Application

- 6.3.4.6. Rest of Europe

- 6.3.4.6.1. Key market trends, growth factors and opportunities

- 6.3.4.6.2. Market size and forecast, by Type

- 6.3.4.6.3. Market size and forecast, by Application

- 6.4. Asia-Pacific

- 6.4.1. Key trends and opportunities

- 6.4.2. Market size and forecast, by Type

- 6.4.3. Market size and forecast, by Application

- 6.4.4. Market size and forecast, by country

- 6.4.4.1. China

- 6.4.4.1.1. Key market trends, growth factors and opportunities

- 6.4.4.1.2. Market size and forecast, by Type

- 6.4.4.1.3. Market size and forecast, by Application

- 6.4.4.2. Japan

- 6.4.4.2.1. Key market trends, growth factors and opportunities

- 6.4.4.2.2. Market size and forecast, by Type

- 6.4.4.2.3. Market size and forecast, by Application

- 6.4.4.3. India

- 6.4.4.3.1. Key market trends, growth factors and opportunities

- 6.4.4.3.2. Market size and forecast, by Type

- 6.4.4.3.3. Market size and forecast, by Application

- 6.4.4.4. South Korea

- 6.4.4.4.1. Key market trends, growth factors and opportunities

- 6.4.4.4.2. Market size and forecast, by Type

- 6.4.4.4.3. Market size and forecast, by Application

- 6.4.4.5. Australia

- 6.4.4.5.1. Key market trends, growth factors and opportunities

- 6.4.4.5.2. Market size and forecast, by Type

- 6.4.4.5.3. Market size and forecast, by Application

- 6.4.4.6. Rest of Asia-Pacific

- 6.4.4.6.1. Key market trends, growth factors and opportunities

- 6.4.4.6.2. Market size and forecast, by Type

- 6.4.4.6.3. Market size and forecast, by Application

- 6.5. LAMEA

- 6.5.1. Key trends and opportunities

- 6.5.2. Market size and forecast, by Type

- 6.5.3. Market size and forecast, by Application

- 6.5.4. Market size and forecast, by country

- 6.5.4.1. Brazil

- 6.5.4.1.1. Key market trends, growth factors and opportunities

- 6.5.4.1.2. Market size and forecast, by Type

- 6.5.4.1.3. Market size and forecast, by Application

- 6.5.4.2. Morocco

- 6.5.4.2.1. Key market trends, growth factors and opportunities

- 6.5.4.2.2. Market size and forecast, by Type

- 6.5.4.2.3. Market size and forecast, by Application

- 6.5.4.3. South Africa

- 6.5.4.3.1. Key market trends, growth factors and opportunities

- 6.5.4.3.2. Market size and forecast, by Type

- 6.5.4.3.3. Market size and forecast, by Application

- 6.5.4.4. Argentina

- 6.5.4.4.1. Key market trends, growth factors and opportunities

- 6.5.4.4.2. Market size and forecast, by Type

- 6.5.4.4.3. Market size and forecast, by Application

- 6.5.4.5. Rest of LAMEA

- 6.5.4.5.1. Key market trends, growth factors and opportunities

- 6.5.4.5.2. Market size and forecast, by Type

- 6.5.4.5.3. Market size and forecast, by Application

CHAPTER 7: COMPETITIVE LANDSCAPE

- 7.1. Introduction

- 7.2. Top winning strategies

- 7.3. Product Mapping of Top 10 Player

- 7.4. Competitive Dashboard

- 7.5. Competitive Heatmap

- 7.6. Top player positioning, 2022

CHAPTER 8: COMPANY PROFILES

- 8.1. Shin Etsu

- 8.1.1. Company overview

- 8.1.2. Key Executives

- 8.1.3. Company snapshot

- 8.2. Wacker Chemie

- 8.2.1. Company overview

- 8.2.2. Key Executives

- 8.2.3. Company snapshot

- 8.3. Siltech Corporation

- 8.3.1. Company overview

- 8.3.2. Key Executives

- 8.3.3. Company snapshot

- 8.4. Elkem ASA

- 8.4.1. Company overview

- 8.4.2. Key Executives

- 8.4.3. Company snapshot

- 8.5. Momentive

- 8.5.1. Company overview

- 8.5.2. Key Executives

- 8.5.3. Company snapshot

- 8.6. Primasil Silicones

- 8.6.1. Company overview

- 8.6.2. Key Executives

- 8.6.3. Company snapshot

- 8.7. Dowdupont

- 8.7.1. Company overview

- 8.7.2. Key Executives

- 8.7.3. Company snapshot

- 8.8. Evonik

- 8.8.1. Company overview

- 8.8.2. Key Executives

- 8.8.3. Company snapshot

- 8.9. KCC Corporation

- 8.9.1. Company overview

- 8.9.2. Key Executives

- 8.9.3. Company snapshot

- 8.10. Henkel AG & Co

- 8.10.1. Company overview

- 8.10.2. Key Executives

- 8.10.3. Company snapshot

LIST OF TABLES

- TABLE 01. GLOBAL AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 02. AUTOMOTIVE SILICONE MARKET FOR ELASTOMERS, BY REGION, 2022-2032 ($MILLION)

- TABLE 03. AUTOMOTIVE SILICONE MARKET FOR RESINS, BY REGION, 2022-2032 ($MILLION)

- TABLE 04. AUTOMOTIVE SILICONE MARKET FOR GELS, BY REGION, 2022-2032 ($MILLION)

- TABLE 05. AUTOMOTIVE SILICONE MARKET FOR OTHERS, BY REGION, 2022-2032 ($MILLION)

- TABLE 06. GLOBAL AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 07. AUTOMOTIVE SILICONE MARKET FOR INTERIOR AND EXTERIOR, BY REGION, 2022-2032 ($MILLION)

- TABLE 08. AUTOMOTIVE SILICONE MARKET FOR ENGINES, BY REGION, 2022-2032 ($MILLION)

- TABLE 09. AUTOMOTIVE SILICONE MARKET FOR ELECTRICAL SYSTEMS, BY REGION, 2022-2032 ($MILLION)

- TABLE 10. AUTOMOTIVE SILICONE MARKET FOR OTHERS, BY REGION, 2022-2032 ($MILLION)

- TABLE 11. AUTOMOTIVE SILICONE MARKET, BY REGION, 2022-2032 ($MILLION)

- TABLE 12. NORTH AMERICA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 13. NORTH AMERICA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 14. NORTH AMERICA AUTOMOTIVE SILICONE MARKET, BY COUNTRY, 2022-2032 ($MILLION)

- TABLE 15. U.S. AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 16. U.S. AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 17. CANADA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 18. CANADA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 19. MEXICO AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 20. MEXICO AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 21. EUROPE AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 22. EUROPE AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 23. EUROPE AUTOMOTIVE SILICONE MARKET, BY COUNTRY, 2022-2032 ($MILLION)

- TABLE 24. FRANCE AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 25. FRANCE AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 26. GERMANY AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 27. GERMANY AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 28. ITALY AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 29. ITALY AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 30. SPAIN AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 31. SPAIN AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 32. UK AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 33. UK AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 34. REST OF EUROPE AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 35. REST OF EUROPE AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 36. ASIA-PACIFIC AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 37. ASIA-PACIFIC AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 38. ASIA-PACIFIC AUTOMOTIVE SILICONE MARKET, BY COUNTRY, 2022-2032 ($MILLION)

- TABLE 39. CHINA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 40. CHINA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 41. JAPAN AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 42. JAPAN AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 43. INDIA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 44. INDIA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 45. SOUTH KOREA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 46. SOUTH KOREA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 47. AUSTRALIA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 48. AUSTRALIA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 49. REST OF ASIA-PACIFIC AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 50. REST OF ASIA-PACIFIC AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 51. LAMEA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 52. LAMEA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 53. LAMEA AUTOMOTIVE SILICONE MARKET, BY COUNTRY, 2022-2032 ($MILLION)

- TABLE 54. BRAZIL AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 55. BRAZIL AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 56. MOROCCO AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 57. MOROCCO AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 58. SOUTH AFRICA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 59. SOUTH AFRICA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 60. ARGENTINA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 61. ARGENTINA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 62. REST OF LAMEA AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022-2032 ($MILLION)

- TABLE 63. REST OF LAMEA AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022-2032 ($MILLION)

- TABLE 64. SHIN ETSU: KEY EXECUTIVES

- TABLE 65. SHIN ETSU: COMPANY SNAPSHOT

- TABLE 66. WACKER CHEMIE: KEY EXECUTIVES

- TABLE 67. WACKER CHEMIE: COMPANY SNAPSHOT

- TABLE 68. SILTECH CORPORATION: KEY EXECUTIVES

- TABLE 69. SILTECH CORPORATION: COMPANY SNAPSHOT

- TABLE 70. ELKEM ASA: KEY EXECUTIVES

- TABLE 71. ELKEM ASA: COMPANY SNAPSHOT

- TABLE 72. MOMENTIVE: KEY EXECUTIVES

- TABLE 73. MOMENTIVE: COMPANY SNAPSHOT

- TABLE 74. PRIMASIL SILICONES: KEY EXECUTIVES

- TABLE 75. PRIMASIL SILICONES: COMPANY SNAPSHOT

- TABLE 76. DOWDUPONT: KEY EXECUTIVES

- TABLE 77. DOWDUPONT: COMPANY SNAPSHOT

- TABLE 78. EVONIK: KEY EXECUTIVES

- TABLE 79. EVONIK: COMPANY SNAPSHOT

- TABLE 80. KCC CORPORATION: KEY EXECUTIVES

- TABLE 81. KCC CORPORATION: COMPANY SNAPSHOT

- TABLE 82. HENKEL AG & CO: KEY EXECUTIVES

- TABLE 83. HENKEL AG & CO: COMPANY SNAPSHOT

LIST OF FIGURES

- FIGURE 01. AUTOMOTIVE SILICONE MARKET, 2022-2032

- FIGURE 02. SEGMENTATION OF AUTOMOTIVE SILICONE MARKET, 2022-2032

- FIGURE 03. AUTOMOTIVE SILICONE MARKET,2022-2032

- FIGURE 04. TOP INVESTMENT POCKETS IN AUTOMOTIVE SILICONE MARKET (2023-2032)

- FIGURE 05. BARGAINING POWER OF SUPPLIERS

- FIGURE 06. BARGAINING POWER OF BUYERS

- FIGURE 07. THREAT OF SUBSTITUTION

- FIGURE 08. THREAT OF SUBSTITUTION

- FIGURE 09. COMPETITIVE RIVALRY

- FIGURE 10. GLOBAL AUTOMOTIVE SILICONE MARKET:DRIVERS, RESTRAINTS AND OPPORTUNITIES

- FIGURE 11. REGULATORY GUIDELINES: AUTOMOTIVE SILICONE MARKET

- FIGURE 12. IMPACT OF KEY REGULATION: AUTOMOTIVE SILICONE MARKET

- FIGURE 13. PATENT ANALYSIS BY COMPANY

- FIGURE 14. PATENT ANALYSIS BY COUNTRY

- FIGURE 15. AUTOMOTIVE SILICONE MARKET, BY TYPE, 2022(%)

- FIGURE 16. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR ELASTOMERS, BY COUNTRY 2022-2032(%)

- FIGURE 17. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR RESINS, BY COUNTRY 2022-2032(%)

- FIGURE 18. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR GELS, BY COUNTRY 2022-2032(%)

- FIGURE 19. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR OTHERS, BY COUNTRY 2022-2032(%)

- FIGURE 20. AUTOMOTIVE SILICONE MARKET, BY APPLICATION, 2022(%)

- FIGURE 21. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR INTERIOR AND EXTERIOR, BY COUNTRY 2022-2032(%)

- FIGURE 22. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR ENGINES, BY COUNTRY 2022-2032(%)

- FIGURE 23. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR ELECTRICAL SYSTEMS, BY COUNTRY 2022-2032(%)

- FIGURE 24. COMPARATIVE SHARE ANALYSIS OF AUTOMOTIVE SILICONE MARKET FOR OTHERS, BY COUNTRY 2022-2032(%)

- FIGURE 25. AUTOMOTIVE SILICONE MARKET BY REGION, 2022

- FIGURE 26. U.S. AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 27. CANADA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 28. MEXICO AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 29. FRANCE AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 30. GERMANY AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 31. ITALY AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 32. SPAIN AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 33. UK AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 34. REST OF EUROPE AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 35. CHINA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 36. JAPAN AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 37. INDIA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 38. SOUTH KOREA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 39. AUSTRALIA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 40. REST OF ASIA-PACIFIC AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 41. BRAZIL AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 42. MOROCCO AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 43. SOUTH AFRICA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 44. ARGENTINA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 45. REST OF LAMEA AUTOMOTIVE SILICONE MARKET, 2022-2032 ($MILLION)

- FIGURE 46. TOP WINNING STRATEGIES, BY YEAR

- FIGURE 47. TOP WINNING STRATEGIES, BY DEVELOPMENT

- FIGURE 48. TOP WINNING STRATEGIES, BY COMPANY

- FIGURE 49. PRODUCT MAPPING OF TOP 10 PLAYERS

- FIGURE 50. COMPETITIVE DASHBOARD

- FIGURE 51. COMPETITIVE HEATMAP: AUTOMOTIVE SILICONE MARKET

- FIGURE 52. TOP PLAYER POSITIONING, 2022