PUBLISHER: Aviation & Defense Market Reports (A&D) | PRODUCT CODE: 1927662

PUBLISHER: Aviation & Defense Market Reports (A&D) | PRODUCT CODE: 1927662

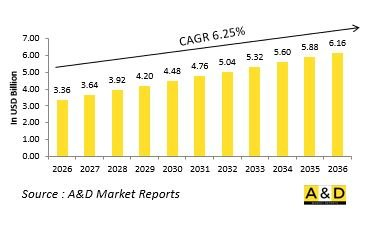

Global Copper demand in Aerospace & Defense Industry 2026-2036

The Global Copper demand in Aerospace & Defense Industry market is estimated at USD 3.36 billion in 2026, projected to grow to USD 6.16 billion by 2036 at a Compound Annual Growth Rate (CAGR) of 6.25% over the forecast period 2026-2036.

Introduction to Global Copper Demand in Aerospace & Defense Industry

Copper is a critical material in aerospace and defense applications, valued for its excellent electrical and thermal conductivity, corrosion resistance, and mechanical strength. Its widespread use spans aircraft wiring, power distribution systems, avionics, radar systems, and communication networks. In defense systems, copper is essential for high-reliability electronics, sensors, and missile systems where operational failure is not an option. The increasing complexity of modern military platforms, including unmanned aerial vehicles, electronic warfare systems, and satellite technologies, has intensified copper requirements. Additionally, the aerospace sector relies on copper for propulsion systems, energy management, and thermal control in both commercial and military aircraft. Industrial focus on lightweight, durable, and high-performance materials ensures that copper remains central to achieving operational efficiency and system reliability. Supply chain stability is a major consideration due to geopolitical factors affecting sourcing and refining. Recycling and alternative sourcing strategies are gaining importance to meet rising demand while managing cost and sustainability. Overall, copper's unique properties, versatility, and critical role in mission-critical systems make it indispensable for modern aerospace and defense industries, directly influencing technological innovation, system performance, and strategic planning.

Technology Impact in Global Copper Demand in Aerospace & Defense Industry

Technological advancements in aerospace and defense systems have significantly influenced the demand for copper, as modern platforms require high-performance electrical, thermal, and communication components. Emerging technologies such as electric propulsion, hybrid aircraft systems, high-capacity energy storage, and advanced avionics increase the volume and quality requirements for copper. Electronic warfare and radar systems rely on copper for efficient signal transmission and heat dissipation, while satellite communications and space-based sensors depend on reliable copper conductors for uninterrupted operations. Additive manufacturing and precision machining allow copper to be formed into complex components, enhancing design flexibility while maintaining conductivity and thermal performance. Integration of copper in compact electronics and miniaturized systems supports the trend toward lighter, more efficient aircraft and defense platforms. Materials science innovations, including copper alloys and coatings, improve corrosion resistance, durability, and performance under extreme conditions. Cybersecurity and reliability considerations in defense electronics further necessitate high-quality copper components to prevent failures. As new propulsion, energy, and sensor technologies evolve, the reliance on copper as a foundational material grows, making technological trends a central driver of its demand across aerospace and defense sectors.

Key Drivers in Copper Demand in Aerospace & Defense Industry

Several factors drive global copper demand in aerospace and defense sectors. The growing sophistication of aircraft and defense systems, including unmanned aerial platforms, radar networks, and communication systems, necessitates high-quality copper for reliable performance. Increasing adoption of electric and hybrid propulsion technologies, along with advanced energy storage and power management solutions, amplifies material requirements. Defense modernization initiatives and procurement programs in multiple regions focus on upgrading fleets, integrating advanced electronics, and enhancing system resilience, further boosting copper consumption. Technological progress in sensor systems, avionics, and satellite communications requires high-precision copper components. Reliability, durability, and thermal management in critical systems make copper indispensable in high-stakes operational environments. Supply chain considerations, including raw material sourcing and quality assurance, influence procurement and strategic inventory planning. Additionally, environmental regulations and sustainability initiatives encourage recycling and reuse of copper, indirectly affecting market dynamics. The intersection of operational necessity, technological evolution, and strategic defense priorities collectively underpins sustained growth in copper demand, reinforcing its status as a core material in aerospace and defense applications globally.

Regional Trends in Copper Demand in Aerospace & Defense Industry

Regional demand for copper in aerospace and defense varies according to industrial capabilities, defense priorities, and technological adoption. North America emphasizes high-performance copper for advanced aircraft, unmanned systems, and space-based defense technologies, driven by robust research and development infrastructure. Europe focuses on integrating copper in multi-role aircraft, radar networks, and collaborative defense programs, often balancing performance with sustainability considerations. Asia-Pacific demonstrates rapid growth due to expanding military modernization programs, increasing commercial aviation activity, and development of indigenous aerospace technologies. Middle Eastern nations prioritize copper for high-tech defense systems, including missiles, surveillance platforms, and strategic aircraft, often sourcing components through international partnerships. African and South American markets show selective growth, focusing on cost-efficient deployment in air, naval, and communication systems while gradually adopting advanced materials. Across all regions, trends in electrification, miniaturization, and networked defense systems drive higher copper utilization. Recycling initiatives and secure sourcing practices influence regional strategies, ensuring that copper availability aligns with long-term operational and industrial goals. Variations in regional industrial capacity, technological adoption, and strategic priorities shape copper demand while reflecting global advancements in aerospace and defense capabilities.

Key Copper demand in Aerospace & Defense Industry Program:

U.S. Defense Logistics Agency Allocates $1 Million to Copper Industry for Advanced Casting Technology. The Defense Logistics Agency supports the global logistics requirements of the U.S. Department of Defense, serving the Military Departments and Unified Combatant Commands. Its mission is to deliver cost-effective, reliable logistics support to U.S. Armed Forces worldwide, ensuring continuous readiness during both peacetime and conflict.

Table of Contents

Copper Component In The Aerospace And Defense Market - Table of Contents

Copper Component In The Aerospace And Defense Market Report Definition

Copper Component In The Aerospace And Defense Market Segmentation

By Component

By Process

By Region

By Alloy

Copper Component In The Aerospace And Defense Market Analysis for next 10 Years

The 10-year Copper Component In The Aerospace And Defense market analysis would give a detailed overview of Copper Component In The Aerospace And Defense market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Access Control Market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Access Control Market Forecast

The 10-year access control market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Access Control Market Trends & Forecast

The regional access control market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Access Control Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Access Control Market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Access Control Market Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2026-2036

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2026-2036

- Table 18: Scenario Analysis, Scenario 1, By Component, 2026-2036

- Table 19: Scenario Analysis, Scenario 1, By Alloy, 2026-2036

- Table 20: Scenario Analysis, Scenario 2, By Region, 2026-2036

- Table 21: Scenario Analysis, Scenario 2, By Component, 2026-2036

- Table 22: Scenario Analysis, Scenario 2, By Alloy, 2026-2036

List of Figures

- Figure 1: Global Copper Demand A&D Market Forecast, 2026-2036

- Figure 2: Global Copper Demand A&D Market Forecast, By Region, 2026-2036

- Figure 3: Global Copper Demand A&D Market Forecast, By Component, 2026-2036

- Figure 4: Global Copper Demand A&D Market Forecast, By Alloy, 2026-2036

- Figure 5: North America, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 6: Europe, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 7: Middle East, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 8: APAC, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 9: South America, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 10: United States, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 11: United States, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 12: Canada, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 13: Canada, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 14: Italy, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 15: Italy, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 16: France, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 17: France, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 18: Germany, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 19: Germany, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 20: Netherlands, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 21: Netherlands, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 22: Belgium, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 23: Belgium, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 24: Spain, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 25: Spain, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 26: Sweden, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 27: Sweden, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 28: Brazil, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 29: Brazil, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 30: Australia, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 31: Australia, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 32: India, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 33: India, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 34: China, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 35: China, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 36: Saudi Arabia, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 37: Saudi Arabia, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 38: South Korea, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 39: South Korea, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 40: Japan, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 41: Japan, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 42: Malaysia, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 43: Malaysia, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 44: Singapore, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 45: Singapore, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 46: United Kingdom, Copper Demand A&D Market, Technology Maturation, 2026-2036

- Figure 47: United Kingdom, Copper Demand A&D Market, Market Forecast, 2026-2036

- Figure 48: Opportunity Analysis, Copper Demand A&D Market, By Region (Cumulative Market), 2026-2036

- Figure 49: Opportunity Analysis, Copper Demand A&D Market, By Region (CAGR), 2026-2036

- Figure 50: Opportunity Analysis, Copper Demand A&D Market, By Component (Cumulative Market), 2026-2036

- Figure 51: Opportunity Analysis, Copper Demand A&D Market, By Component (CAGR), 2026-2036

- Figure 52: Opportunity Analysis, Copper Demand A&D Market, By Alloy (Cumulative Market), 2026-2036

- Figure 53: Opportunity Analysis, Copper Demand A&D Market, By Alloy (CAGR), 2026-2036

- Figure 54: Scenario Analysis, Copper Demand A&D Market, Cumulative Market, 2026-2036

- Figure 55: Scenario Analysis, Copper Demand A&D Market, Global Market, 2026-2036

- Figure 56: Scenario 1, Copper Demand A&D Market, Total Market, 2026-2036

- Figure 57: Scenario 1, Copper Demand A&D Market, By Region, 2026-2036

- Figure 58: Scenario 1, Copper Demand A&D Market, By Component, 2026-2036

- Figure 59: Scenario 1, Copper Demand A&D Market, By Alloy, 2026-2036

- Figure 60: Scenario 2, Copper Demand A&D Market, Total Market, 2026-2036

- Figure 61: Scenario 2, Copper Demand A&D Market, By Region, 2026-2036

- Figure 62: Scenario 2, Copper Demand A&D Market, By Component, 2026-2036

- Figure 63: Scenario 2, Copper Demand A&D Market, By Alloy, 2026-2036

- Figure 64: Company Benchmark, Copper Demand A&D Market, 2026-2036