PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1716605

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1716605

Tamping Rammer Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

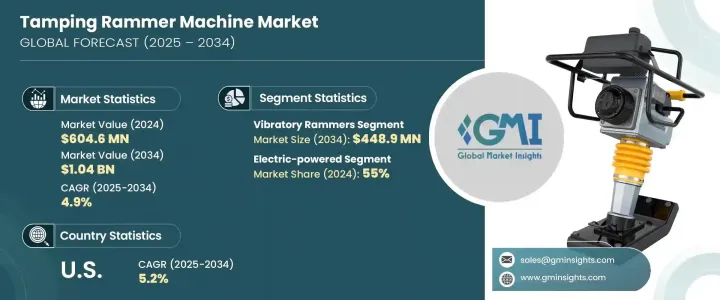

The Global Tamping Rammer Machine Market was valued at USD 604.6 million in 2024 and is expected to grow at a CAGR of 4.9% from 2025 to 2034. The rise in construction activities and infrastructure development is significantly contributing to the demand for tamping rammers. With urbanization and population growth, the need for constructing various types of infrastructure, including residential buildings, commercial complexes, and roads, continues to expand. Tamping rammers are critical in compacting gravel, soil, and asphalt, ensuring the stability and durability of these structures. The growth of the construction industry, particularly in emerging economies, is a key driver behind the increasing demand for these machines. As contractors strive for efficient compaction in their projects, tamping rammers provide an ideal solution for ensuring proper soil density, which is essential for structural integrity.

Tamping rammers are favored due to their efficiency, helping contractors minimize labor costs and project timelines. Their ability to quickly and effectively compact materials in tight or difficult-to-reach spaces is a major advantage. While alternative technologies such as vibratory plate compactors, walk-behind rollers, and trench rollers are also used for soil compaction, tamping rammers maintain their significance in the market. Despite the presence of such alternatives, tamping rammers offer exceptional value, particularly for tasks in confined spaces where larger machines cannot operate.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $604.6 Million |

| Forecast Value | $1.04 Billion |

| CAGR | 4.9% |

In terms of product type, the market is divided into percussion rammers, vibratory rammers, walk-behind rammers, and remote-controlled rammers. Vibratory rammers are expected to dominate, with a market value of USD 249.6 million in 2024, growing to USD 448.9 million by 2034. These machines are highly effective in cohesive and mixed soils, providing rapid compaction with minimal effort, which is ideal for medium-to-heavy tasks. Vibratory rammers also save time and energy compared to manual compaction methods, making them popular for small projects such as utility installations.

The market is segmented by power source, with electric-powered rammers leading the market with a 55% share in 2024. These machines are particularly suitable for indoor applications due to their zero emissions and low noise. Battery-powered rammers offer portability without the emissions of gasoline-powered models, making them versatile for both indoor and outdoor use. Gasoline-powered rammers remain useful in outdoor environments where electricity access is limited.

The construction sector is the largest end-use segment, accounting for over 30.86% of the market share in 2024, and it is expected to grow at a rate of 5.3% by 2034. These machines are essential for various tasks in roadwork, pavement laying, and trench backfilling, particularly in narrow or confined spaces. The market in the U.S. is projected to grow at a CAGR of 5.2% during the forecast period, driven by significant infrastructure investments.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.4.2.1 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Supplier landscape

- 3.3 Pricing analysis

- 3.4 Technology & innovation landscape

- 3.5 Key news & initiatives

- 3.6 Regulatory landscape

- 3.7 Manufacturers

- 3.8 Distributors

- 3.9 Impact forces

- 3.9.1 Growth drivers

- 3.9.1.1 Increasing construction activities

- 3.9.1.2 Infrastructure development

- 3.9.1.3 Growing demand for portable equipment

- 3.9.1.4 Technological advancements

- 3.9.2 Industry pitfalls & challenges

- 3.9.2.1 Competition from alternative technologies

- 3.9.2.2 Environmental concerns

- 3.9.1 Growth drivers

- 3.10 Growth potential analysis

- 3.11 Technological overview

- 3.12 Trade analysis (HS Code – 84306100)

- 3.13 Porter's analysis

- 3.14 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Product Type, 2021-2034 (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Vibratory rammers

- 5.3 Percussion rammers

- 5.4 Walk-behind rammers

- 5.5 Remote-controlled rammers

Chapter 6 Market Estimates & Forecast, By Power Source, 2021-2034 (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Gasoline-powered

- 6.3 Electric-powered

- 6.4 Battery-powered

Chapter 7 Market Estimates & Forecast, By Category, 2021-2034 (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Automatic

- 7.3 Manual

- 7.4 Semi-automatic

Chapter 8 Market Estimates & Forecast, By End Use, 2021-2034 (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Construction

- 8.3 Infrastructure

- 8.4 Mining

- 8.5 Landscaping and gardening

- 8.6 Agriculture

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021-2034 (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates & Forecast, By Region, 2021-2034 (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Ammann Group

- 11.2 Atlas Copco

- 11.3 Belle Group

- 11.4 Bomag GmbH

- 11.5 Caterpillar Inc.

- 11.6 Chicago Pneumatic

- 11.7 Doosan Corporation

- 11.8 Husqvarna Group

- 11.9 JCB

- 11.10 MBW Inc.

- 11.11 Mikasa Sangyo Co., Ltd.

- 11.12 Multiquip Inc.

- 11.13 Toro Company

- 11.14 Wacker Neuson

- 11.15 Weber MT