PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1750298

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1750298

Thin Wall Packaging Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

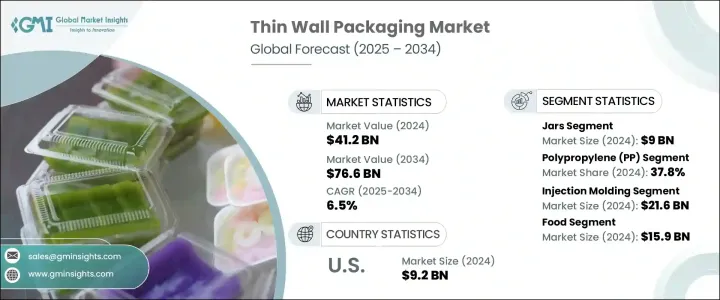

The Global Thin Wall Packaging Market was valued at USD 41.2 billion in 2024 and is estimated to grow at a CAGR of 6.5% to reach USD 76.6 billion by 2034, driven by shifting lifestyle patterns, increasing demand for convenience food options, and expanding foodservice channels. As urban centers grow and consumer routines become more hectic, the appeal of lightweight, durable, and cost-efficient packaging formats has intensified. Thin-wall packaging enables quicker production turnaround and reduced material use while delivering product integrity. It also supports modern supply chain needs with formats that fit today's fast-paced retail and food delivery ecosystems.

With rising demand for portable, microwaveable, and resealable containers, thin wall formats have become indispensable across urban food consumption. These packages align with consumers' preference for on-the-go meals and instant snacks, especially in high-density regions. Thanks to their barrier properties and structural integrity, thin wall containers help extend shelf life while supporting sustainability goals. They're now widely chosen for packaging dairy, frozen entrees, and snack foods. Consumers gravitate toward these options for practicality, especially as packaging trends lean more toward minimalism and eco-consciousness. Jars are popular for their reusable nature and suitability across personal care, household goods, and food applications. They offer an effective seal that maintains freshness while being easy to handle.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $41.2 Billion |

| Forecast Value | $76.6 Billion |

| CAGR | 6.5% |

The jars segment generated USD 9 billion in 2024, marking its dominance within the thin wall packaging landscape. These containers are extensively used across food, personal care, and household product categories due to their lightweight structure, reduced material usage, and cost-effective production. Jars offer an ideal packaging solution for a wide range of applications, providing both manufacturers and consumers with versatility and functionality. Their growing popularity stems not only from their affordability but also from consumer-driven preferences for convenience, ease of use, and sustainability. Reusability and easy storage make jars a preferred option, especially for products that require repeated access or portion control.

The polypropylene (PP) segment held a 37.8% share in 2024. This polymer's blend of strength, light weight, and affordability makes it ideal for thin wall packaging, especially in fast-cycle injection molding. Its moisture resistance and chemical stability make it a preferred choice for food-grade applications. Enhanced PP formulations allow thinner walls without compromising durability, enabling companies to reduce carbon footprints while meeting regulatory pressures.

United States Thin Wall Packaging Market generated USD 9.2 billion in 2024. Increased consumption of prepared meals and snacks has fueled demand for lightweight, protective packaging solutions. Additionally, the rise of e-commerce and home delivery services has prompted packaging innovations that prioritize material reduction and environmental compliance. This trend is further accelerated by growing consumer awareness and government-led sustainability initiatives.

Leading companies in the Global Thin Wall Packaging Industry comprise ILIP S.r.l., Paccor GmbH, Amcor plc, Greiner Packaging International GmbH, and Berry Global Inc. Key players in the Global Thin Wall Packaging Market are investing heavily in sustainable innovation, strategic mergers, and regional expansion to enhance market presence. Companies are focusing on lightweight design technologies and adopting recyclable materials like bio-based polypropylene to align with green packaging mandates. Several have partnered with food and beverage brands to offer customized solutions that improve shelf appeal and extend freshness. Expanding production capacity in high-growth regions such as North America and Asia Pacific is a top priority, alongside adopting advanced injection molding machinery to improve speed and efficiency.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Profit margin analysis

- 3.5 Key news & initiatives

- 3.6 Regulatory landscape

- 3.7 Impact forces

- 3.7.1 Growth drivers

- 3.7.1.1 Surge in demand for convenience and ready-to-eat foods

- 3.7.1.2 Growth in sustainability and lightweighting initiatives

- 3.7.1.3 Rise of food delivery and QSR channels

- 3.7.1.4 Rapid urbanization in emerging economies

- 3.7.1.5 Increasing advancements in injection molding and in-mold labeling (IML)

- 3.7.2 Industry pitfalls & challenges

- 3.7.2.1 Stringent environmental regulations on plastic use

- 3.7.2.2 Limited barrier properties for perishable goods

- 3.7.1 Growth drivers

- 3.8 Growth potential analysis

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Product Type, 2021-2034 (USD Million & Units)

- 5.1 Key trends

- 5.2 Cups

- 5.3 Tubs

- 5.4 Trays

- 5.5 Jars

- 5.6 Lids

- 5.7 Other containers

Chapter 6 Market Estimates & Forecast, By Material Type, 2021-2034 (USD Million & Units)

- 6.1 Key trends

- 6.2 Polypropylene (PP)

- 6.3 Polyethylene (PE)

- 6.3.1 High-density polyethylene (HDPE)

- 6.3.2 Low-density polyethylene (LDPE)

- 6.4 Polystyrene (PS)

- 6.5 Polyethylene terephthalate (PET)

- 6.6 Polyvinyl chloride (PVC)

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By Production Process, 2021-2034 (USD Million & Units)

- 7.1 Key trends

- 7.2 Thermoforming

- 7.3 Injection molding

- 7.4 Others

Chapter 8 Market Estimates & Forecast, By Application, 2021-2034 (USD Million & Units)

- 8.1 Key trends

- 8.2 Food

- 8.2.1 Dairy products

- 8.2.2 Ready-to-eat meals

- 8.2.3 Bakery & confectionery

- 8.2.4 Meat, poultry & seafood

- 8.3 Beverages

- 8.4 Personal care & cosmetics

- 8.5 Household products

- 8.6 Electrical & electronics

- 8.7 Pharmaceuticals & nutraceuticals

- 8.8 Industrial

Chapter 9 Market Estimates & Forecast, By Region, 2021-2034 (USD Million & Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Russia

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.6 MEA

- 9.6.1 South Africa

- 9.6.2 Saudi Arabia

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 ALPLA Group

- 10.2 Akshar Plastic

- 10.3 Amcor Plc

- 10.4 Berry Global Inc.

- 10.5 Borouge

- 10.6 Chemco Plast

- 10.7 Cosmo Films

- 10.8 Double H Plastics

- 10.9 EVCO Plastics

- 10.10 Greiner Packaging International GmbH

- 10.11 ILIP S.r.l.

- 10.12 IPL Plastics Inc.

- 10.13 Mold-Masters

- 10.14 Paccor

- 10.15 Prabhoti Plastic Industries

- 10.16 SABIC

- 10.17 SP International Industries Pvt. Ltd.