PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1766271

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1766271

High Entropy Alloy Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

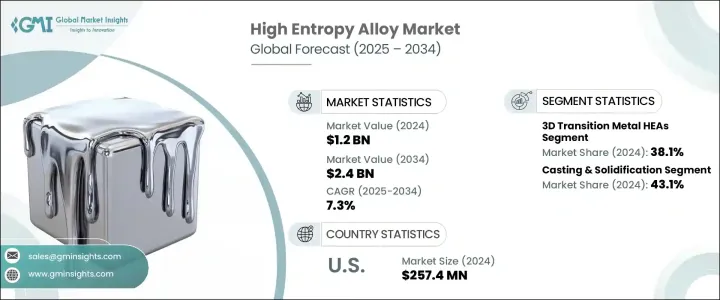

The Global High Entropy Alloy Market was valued at USD 1.2 billion in 2024 and is estimated to grow at a CAGR of 7.3% to reach USD 2.4 billion by 2034. These alloys are composed of five or more principal elements mixed in near-equal ratios, offering a unique combination of mechanical strength, corrosion resistance, and thermal stability. Their growing popularity stems from their performance advantages over conventional alloys, especially in environments that demand resilience to wear, heat, and structural fatigue. This increasing adoption across multiple sectors is backed by a surge in research and development, as manufacturers look for ways to improve material durability, reduce weight, and enhance component longevity.

The focus on developing lighter, stronger, and more temperature-tolerant materials is critical as industries prioritize energy efficiency and long-term performance. As a result, high entropy alloys are quickly becoming essential in next-generation component manufacturing, where advanced material properties are non-negotiable. These materials are showing strong potential in both traditional and emerging applications, ranging from mobility systems and heavy-duty infrastructure to components used in energy-intensive equipment. With growing investment in material innovation and the need to meet evolving performance benchmarks, the market is witnessing a steady shift toward widespread industrial deployment.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.2 Billion |

| Forecast Value | $2.4 Billion |

| CAGR | 7.3% |

In 2024, 3D transition metal high entropy alloys accounted for 38.1% of the overall market share by alloy type. These alloys, typically made using elements such as Fe, Ni, Co, Cr, and Mn, are well-known for their mechanical resilience, corrosion resistance, and economic viability, making them ideal for applications across various industries. Their compatibility with powder metallurgy and additive manufacturing processes further broadens their usability. These methods enable the production of complex parts and streamline prototyping, which is valuable in industries that demand quick development cycles and durable prototypes. Additionally, these alloys exhibit excellent radiation tolerance and high thermal conductivity, making them suitable for systems exposed to extreme temperatures and operating conditions.

By manufacturing method, casting and solidification processes led the market with a 43.1% share in 2024. This dominance is driven by the scalability and cost-efficiency of these techniques, especially when integrated into existing metallurgical systems. The process not only supports mass production but also plays a vital role in refining grain structure and stabilizing phases, which are essential for ensuring long-term material performance under high thermal and mechanical stress. Although powder metallurgy and additive manufacturing continue to gain traction, casting remains the most cost-effective approach for producing bulk components with intricate designs.

When categorized by property, alloys with superior mechanical characteristics held the largest market share in 2024. These properties-such as high tensile strength, impact resistance, and ductility-allow components to endure continuous mechanical loading without degradation. The unique atomic structure of high entropy alloys contributes to their solid-solution strengthening and resistance to deformation, which is why they are heavily used in applications that require structural integrity under cyclic stress and intense operational conditions. Their ability to maintain performance while reducing component weight helps manufacturers meet demanding regulatory and safety standards.

In terms of application, structural uses represented the largest share of the market in 2024. These alloys are frequently chosen for components that must bear significant load or operate in high-stress environments due to their fatigue resistance and mechanical stability. The materials' multi-phase structures offer enhanced toughness, which helps prevent failure during high-impact use. As a result, these alloys are gaining ground in systems designed for durability, structural endurance, and long service life across multiple heavy-use applications.

Looking at end-use industries, aerospace and defense led the global market in 2024. This dominance reflects the sector's ongoing demand for materials that combine lightweight characteristics with high mechanical strength and thermal resistance. Components that operate in rapidly changing thermal environments require enhanced oxidation and creep resistance, which these alloys can provide. Their proven reliability in harsh conditions continues to drive investment and innovation in the sector, particularly for mission-critical systems.

Regionally, the United States recorded a market value of USD 257.4 million in 2024, leading North America. The country's strong foundation in federally funded research programs and the growing demand across aerospace, defense, energy, and automotive industries has driven widespread adoption. These sectors rely heavily on materials that perform consistently under mechanical and thermal loads, making high entropy alloys a strategic asset in advanced manufacturing.

The competitive landscape of the global high entropy alloy market is moderately fragmented, with several players holding niche positions. Companies are focusing on proprietary alloy formulations, next-generation processing techniques, and adherence to strict industry quality standards to stay ahead. Innovation, customization, and material performance remain the core areas influencing competitive positioning across the sector.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Trump administration tariffs

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Trade statistics (HS Code)Note: the above trade statistics will be provided for key countries only.

- 3.3.1 Major exporting countries

- 3.3.2 Major importing countries

- 3.4 Impact forces

- 3.4.1 Growth drivers

- 3.4.1.1 Rising demand for lightweight and high-strength materials in aerospace and defense sectors

- 3.4.1.2 Increased investment in advanced materials for nuclear reactor and energy storage applications

- 3.4.1.3 Expanding usage in electric vehicle components due to thermal stability and corrosion resistance

- 3.4.2 Industry pitfalls & challenges

- 3.4.2.1 High production costs due to complex alloy compositions and specialized processing techniques

- 3.4.2.2 Limited availability of commercial-scale production infrastructure and supply chain integration

- 3.4.2.3 Lack of standardization in testing and performance metrics across industries

- 3.4.3 Market opportunities

- 3.4.1 Growth drivers

- 3.5 Profit margin analysis

- 3.5.1 Manufacturing process analysis

- 3.5.2 Casting & solidification

- 3.5.3 Powder metallurgy

- 3.5.4 Additive manufacturing

- 3.5.5 Mechanical alloying

- 3.5.6 Other manufacturing methods

- 3.6 Technological advancements and innovations

- 3.7 Regulatory landscape

- 3.7.1 Material testing standards

- 3.7.2 Industry-specific certification requirements

- 3.7.3 Environmental regulations

- 3.7.4 Import/export regulations for advanced materials

- 3.8 Growth potential analysis

- 3.9 Pricing analysis (USD/Tons) 2021-2034

- 3.10 Porter's analysis

- 3.11 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic framework

- 4.3.1 Mergers & acquisition

- 4.3.2 Joint venture & collaborations

- 4.3.3 New product development

- 4.3.4 Expansion strategies

- 4.4 Competitive benchmarking

- 4.5 Vendor landscape

- 4.6 Competitive positioning matrix

- 4.7 Strategic dashboard

- 4.8 Patent analysis & Innovation assessment

- 4.9 Research & Development Intensity Analysis

Chapter 5 Market Estimates and Forecast, By Alloy Type, 2021–2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 3d transition metal HEAs

- 5.2.1 CoCrFeMnNi (cantor alloy)

- 5.2.2 CoCrFeNi

- 5.2.3 CoCrFeNiMn

- 5.2.4 Others

- 5.3 Refractory metal HEAs

- 5.3.1 NbMoTaW

- 5.3.2 VNbMoTaW

- 5.3.3 HfNbTaTiZr

- 5.3.4 Others

- 5.4 Light metal HEAs

- 5.4.1 AlMgLiCaZn

- 5.4.2 AlLiMgScTi

- 5.4.3 Others

- 5.5 Aluminum-containing HEAs

- 5.5.1 AlCoCrFeNi

- 5.5.2 AlCoCrCuFeNi

- 5.5.3 Others

- 5.6 Precious metal HEAs

- 5.7 Rare earth element-containing HEAs

- 5.8 Others

Chapter 6 Market Estimates and Forecast, By Manufacturing Method, 2021–2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Casting & solidification

- 6.2.1 Arc melting

- 6.2.2 Induction melting

- 6.2.3 Vacuum induction melting

- 6.3 Powder metallurgy

- 6.3.1 Gas atomization

- 6.3.2 Mechanical alloying

- 6.3.3 Spark plasma sintering

- 6.3.4 Hot isostatic pressing

- 6.3.5 Others

- 6.4 Additive manufacturing

- 6.4.1 Selective laser melting

- 6.4.2 Electron beam melting

- 6.4.3 Direct energy deposition

- 6.4.4 Others

- 6.5 Thin film deposition

- 6.5.1 Magnetron sputtering

- 6.5.2 Physical vapor deposition

- 6.6 Others

Chapter 7 Market Estimates and Forecast, By Property, 2021–2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Superior mechanical properties

- 7.2.1 High strength

- 7.2.2 High hardness

- 7.2.3 High ductility

- 7.2.4 Wear resistance

- 7.2.5 Others

- 7.3 Thermal stability

- 7.3.1 High-temperature strength

- 7.3.2 Creep resistance

- 7.3.3 Thermal expansion control

- 7.3.4 Others

- 7.4 Corrosion & oxidation resistance

- 7.4.1 Aqueous corrosion resistance

- 7.4.2 High-temperature oxidation resistance

- 7.4.3 Others

- 7.5 Magnetic properties

- 7.6 Electrical properties

- 7.7 Radiation resistance

- 7.8 Others

Chapter 8 Market Estimates and Forecast, By Application, 2021–2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 Structural applications

- 8.2.1 High-temperature structural components

- 8.2.2 Lightweight structural components

- 8.2.3 Others

- 8.3 Functional applications

- 8.3.1 Magnetic

- 8.3.2 Electrical

- 8.3.3 Catalytic

- 8.3.4 Others

- 8.4 Coatings & surface treatments

- 8.4.1 Wear-resistant coatings

- 8.4.2 Corrosion- resistant coatings

- 8.4.3 Thermal barrier coatings

- 8.4.4 Others

- 8.5 Extreme environment applications

- 8.5.1 Cryogenic

- 8.5.2 High temperature

- 8.5.3 Radiation-intensive

- 8.5.4 Others

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By End Use Industry, 2021–2034 (USD Billion) (Kilo Tons)

- 9.1 Key trends

- 9.2 Aerospace & defense

- 9.2.1 Aircraft components

- 9.2.2 Propulsion systems

- 9.2.3 Defense equipment

- 9.2.4 Space

- 9.2.5 Others

- 9.3 Automotive

- 9.3.1 Engine components

- 9.3.2 Exhaust systems

- 9.3.3 Structural components

- 9.3.4 Others

- 9.4 Energy

- 9.4.1 Nuclear energy

- 9.4.2 Fossil fuel power generation

- 9.4.3 Renewable energy

- 9.4.4 Others

- 9.5 Industrial equipment

- 9.5.1 Cutting tools

- 9.5.2 Machinery components

- 9.5.3 Others

- 9.6 Electronics & semiconductors

- 9.7 Chemical & petrochemical

- 9.8 Medical & healthcare

- 9.9 Research & academia

- 9.10 Others

Chapter 10 Market Estimates and Forecast, By Region, 2021–2034 (USD Billion) (Kilo Tons)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Spain

- 10.3.5 Italy

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 Middle East and Africa

- 10.6.1 Saudi Arabia

- 10.6.2 South Africa

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Alcoa Corporation

- 11.2 AMETEK Specialty Metal Products

- 11.3 Aperam S.A.

- 11.4 ATI Metals

- 11.5 Aubert & Duval

- 11.6 Carpenter Technology Corporation

- 11.7 Daido Steel

- 11.8 Eramet Group

- 11.9 H.C. Starck GmbH

- 11.10 Haynes International

- 11.11 High Entropy Alloys Inc.

- 11.12 Hitachi Metals

- 11.13 H?gan?s AB

- 11.14 IHI Corporation

- 11.15 Kennametal

- 11.16 Materion Corporation

- 11.17 Metalysis

- 11.18 Nippon Yakin Kogyo

- 11.19 Oerlikon Metco

- 11.20 Plansee SE

- 11.21 Praxair Surface Technologies

- 11.22 Questek Innovations

- 11.23 Sandvik AB

- 11.24 Special Metals Corporation

- 11.25 VDM Metals GmbH