PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1801844

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1801844

Pharmaceutical Robots Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

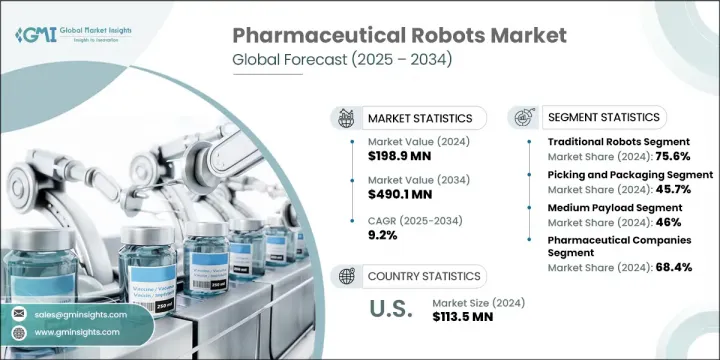

The Global Pharmaceutical Robots Market was valued at USD 198.9 million in 2024 and is estimated to grow at a CAGR of 9.2% to reach USD 490.1 million by 2034. This robust growth is being fueled by increasing automation across pharmaceutical manufacturing processes, heightened investments in R&D, and the expanding use of collaborative robotics within drug production facilities. Pharmaceutical robots are being utilized across a broad range of functions, including drug testing, cleanroom applications, and production workflows.

The rising adoption of collaborative robotic systems is primarily driven by the need for enhanced workplace safety, solutions to address labor shortages, and efficiency in sterile compounding and other complex pharmaceutical processes. At the same time, significant advancements in next-generation therapies and increasing R&D investments are prompting pharmaceutical companies to accelerate the automation of their operations. This is fostering demand for robotics systems that offer scalability, safety, and consistent precision. Industry innovation combined with government support is laying the foundation for widespread adoption of pharmaceutical robots, further advancing the automation trend within the sector.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $198.9 Million |

| Forecast Value | $490.1 Million |

| CAGR | 9.2% |

In 2024, the traditional robots segment held a 75.6% share, driven by their unmatched accuracy, speed, and effectiveness in high-end manufacturing environments. Among these, articulated robotic systems are widely deployed due to their versatility in operations such as material handling and packaging. Their flexible payload capacities and efficiency make them suitable for diverse pharmaceutical applications. Leading industry players are actively working to expand the application scope of these robots to serve pharmaceutical manufacturing needs.

The picking and packaging application segment held a 45.7% share in 2024. The demand for robotic systems in packaging functions continues to grow as pharma manufacturers seek compact, space-saving solutions that can streamline operations. These systems also improve efficiency by optimizing workspace utilization. Companies are partnering with automation solution providers to develop customized systems that align with evolving pharmaceutical production demands. The focus remains on speeding up packaging workflows and enhancing operational output across production facilities.

United States Pharmaceutical Robots Market was valued at USD 113.5 million in 2024. The presence of major pharmaceutical players such as Pfizer, AbbVie, Johnson & Johnson, and Bristol Myers Squibb plays a crucial role in fueling this growth. U.S.-based firms are also investing in modernizing their supply chains through robotics and digital transformation to improve transparency and operational efficiency while minimizing costs. This focus on efficiency is boosting the demand for robotic systems across pharmaceutical production lines nationwide.

Key market participants in the Pharmaceutical Robots Market include FANUC, OMRON AUTOMATION, EPSON, UNIVERSAL ROBOTS, STAUBLI, ABB, MITSUBISHI ELECTRIC, DENSO WAVE, YASKAWA, KAWASAKI Robotics, and KUKA. Top companies in the pharmaceutical robots market are prioritizing automation advancements and smart manufacturing integration to solidify their market foothold. They are investing in R&D to develop collaborative robots with enhanced safety features and precision, tailored to pharmaceutical-specific requirements. Companies are expanding their product portfolios to support cleanroom standards and sterile environments. Strategic partnerships with pharma manufacturers enable co-development of customized solutions for packaging, material handling, and drug formulation. Vendors are also leveraging AI and machine learning to create intelligent robotic systems capable of adapting to complex processes. In addition, global expansion and after-sales service networks are being strengthened to ensure customer support and long-term reliability.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional trends

- 2.2.2 Product type trends

- 2.2.3 Application trends

- 2.2.4 Payload trends

- 2.2.5 End use trends

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing demand for automation in pharmaceutical manufacturing

- 3.2.1.2 Increasing pharmaceutical research and development investments and production volumes

- 3.2.1.3 Technological advancements in robotic systems

- 3.2.1.4 Surging adoption of collaborative robots in pharma manufacturing facilities

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High initial investment and maintenance

- 3.2.2.2 Lack of skilled personnel to work in automated units

- 3.2.3 Market opportunities

- 3.2.3.1 Integration of AI and machine learning in robotics

- 3.2.3.2 Expansion in emerging markets

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.5 Technological advancements

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Value chain analysis

- 3.7 Pharmaceutical robots market in terms of Volume (Units), 2021 -2034

- 3.7.1 Global

- 3.7.2 North America

- 3.7.3 Europe

- 3.7.4 Asia Pacific

- 3.7.5 Latin America

- 3.7.6 MEA

- 3.8 Pricing analysis, 2024

- 3.9 Market evolution and historical context

- 3.10 Porter's analysis

- 3.11 PESTEL analysis

- 3.12 Future market trends

- 3.13 Gap analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 Global

- 4.2.2 North America

- 4.2.3 Europe

- 4.2.4 Asia Pacific

- 4.2.5 Latin America

- 4.2.6 MEA

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers and acquisitions

- 4.6.2 Partnerships and collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021 - 2034 ($ Mn)

- 5.1 Key trends

- 5.2 Traditional robots

- 5.2.1 Articulated robots

- 5.2.2 SCARA robots

- 5.2.3 Delta/Parallel robots

- 5.2.4 Cartesian robots

- 5.2.5 Dual-arm robots

- 5.3 Collaborative robots

Chapter 6 Market Estimates and Forecast, By Application, 2021 - 2034 ($ Mn)

- 6.1 Key trends

- 6.2 Picking and packaging

- 6.3 Pharmaceutical drugs inspection

- 6.4 Laboratory applications

- 6.5 Other applications

Chapter 7 Market Estimates and Forecast, By Payload, 2021 - 2034 ($ Mn)

- 7.1 Key trends

- 7.2 Low (Upto 5 kg)

- 7.3 Medium (6-15 kg)

- 7.4 High (more than 15 kg)

Chapter 8 Market Estimates and Forecast, By End Use, 2021 - 2034 ($ Mn)

- 8.1 Key trends

- 8.2 Pharmaceutical companies

- 8.3 Research laboratories

- 8.4 Other end use

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 ($ Mn)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Netherlands

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 Japan

- 9.4.3 India

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 Middle East and Africa

- 9.6.1 South Africa

- 9.6.2 Saudi Arabia

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 ABB

- 10.2 DENSO WAVE

- 10.3 EPSON

- 10.4 FANUC

- 10.5 KAWASAKI Robotics

- 10.6 KUKA

- 10.7 MITSUBISHI ELECTRIC

- 10.8 OMRON AUTOMATION

- 10.9 STAUBLI

- 10.10 UNIVERSAL ROBOTS

- 10.11 YASKAWA