PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1871092

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1871092

Root Blower Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

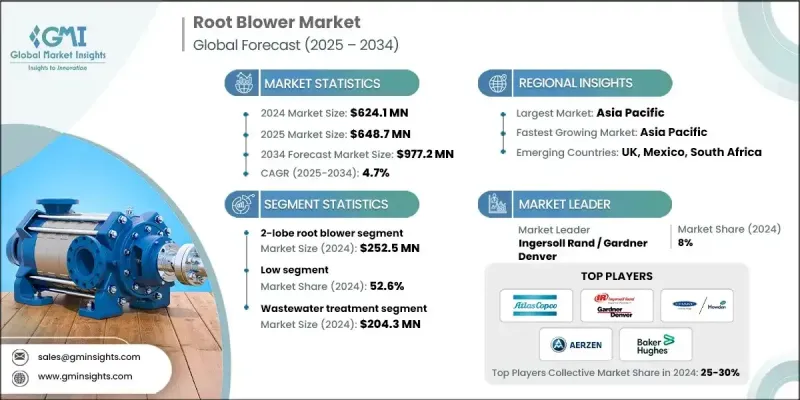

The Global Root Blower Market was valued at USD 624.1 million in 2024 and is estimated to grow at a CAGR of 4.7% to reach USD 977.2 million by 2034.

The steady growth is driven by its essential use in both industrial and municipal sectors. Root blowers are widely adopted for their robust performance and ability to deliver high air volumes at a constant pressure, making them ideal for various processes such as food production, water treatment, and more. Increasing demand across industries, including cement, chemicals, power generation, and steel production, continues to boost market growth. These blowers play a critical role in aeration, pneumatic conveying, and supplying combustion air. Rising infrastructure investments and environmental initiatives across developed regions are creating strong demand for cost-effective and specialized air movement systems. Municipal upgrades, especially in sewage and water treatment, are key contributors to this momentum. Technological advancements are also reshaping the landscape, with manufacturers focusing on compact, low-noise, and energy-efficient designs that meet evolving industry regulations. The integration of smart features like IoT-based monitoring and predictive maintenance is further improving system performance and helping operators minimize downtime and operational costs.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $624.1 Million |

| Forecast Value | $977.2 Million |

| CAGR | 4.7% |

In 2024, the 2-lobe root blower segment generated USD 252.5 million. Its dependable operation, simple mechanics, and ability to maintain uninterrupted air flow make it a popular option across numerous industrial settings. With a design that incorporates two lobes rotating in opposite directions, this blower type ensures a steady airflow without internal compression. These features make it well-suited for operations in sectors such as cement manufacturing, wastewater treatment, and chemicals, where it is employed for tasks like aeration, combustion air supply, and material handling, due to its durability and effectiveness under varying conditions.

The low-pressure segment held a 52.6% share in 2024. Designed for operating pressures up to 15 PSI, low-pressure root blowers are commonly utilized in applications where a steady, low-pressure airflow is essential. These include aquaculture, municipal wastewater treatment, and several light industrial processes. Their non-pulsating air delivery is especially useful in biological treatment applications, as well as in the pneumatic conveying of grains, powders, and other lightweight materials where higher pressure is not necessary, but continuous airflow is critical to the process.

United States Root Blower Market held a 78.4% share and generated USD 145.6 million in 2024. The market is experiencing stable expansion driven by the need to upgrade outdated water treatment systems and increasing enforcement of environmental regulations. With regulatory bodies tightening emission and discharge standards, municipalities and industries are turning to reliable equipment like root blowers to meet compliance standards. These systems are vital in processes like sludge handling and aeration, both of which are integral to efficient and compliant wastewater treatment.

Leading companies operating in the Global Root Blower Market include Robuschi/Gardner Denver, KlimatVentMash, AERZEN, Baker Hughes, Ventinform, Izhvent, Howden/Chart Industries, Roots, VENTPROM, Atlas Copco, Gardner Denver/Ingersoll Rand, Ukrventsystems, Azvetra, Kaeser, and TMC Fluid Systems. Companies in the Global Root Blower Market are focusing on innovation, energy efficiency, and digital integration to strengthen their competitive positioning. Many are developing compact, low-noise blowers with enhanced energy-saving features to meet modern industrial requirements. Incorporating smart technologies like IoT for remote monitoring and predictive maintenance is a key strategy to improve equipment lifespan and reduce operational downtime. To expand their customer base, manufacturers are also tailoring products for specific applications in water treatment, cement, and power industries.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Bearing type

- 2.2.4 Sealing technology

- 2.2.5 Pressure output

- 2.2.6 Application

- 2.2.7 Distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Industrial demand expansion

- 3.2.1.2 Technological advancements

- 3.2.1.3 Urban infrastructure & utility upgrades

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High energy consumption

- 3.2.2.2 Regulatory compliance pressure

- 3.2.3 Opportunities

- 3.2.3.1 Smart manufacturing & industry 4.0 integration

- 3.2.3.2 Energy-efficient and eco-friendly designs

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021 - 2034 (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 2-lobe root blowers

- 5.3 3-lobe root blowers

- 5.4 4-lobe root blowers

- 5.5 Multi-stage root blowers

Chapter 6 Market Estimates and Forecast, By Bearing Type, 2021 - 2034 (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Rolling element bearing

- 6.3 Sleeve bearing

- 6.4 Magnetic bearing

Chapter 7 Market Estimates and Forecast, By Sealing Technology, 2021 - 2034 (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Mechanical seals

- 7.3 Labyrinth seals

- 7.4 Contact seals

Chapter 8 Market Estimates and Forecast, By Pressure Output, 2021 - 2034 (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Low (upto 15 PSI)

- 8.3 Medium (15 PSI-30 PSI)

- 8.4 High (above 30 PSI)

Chapter 9 Market Estimates and Forecast, By Application, 2021 - 2034 (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 Wastewater treatment

- 9.3 Pneumatic conveying systems

- 9.4 Cement production

- 9.5 Chemical processing

- 9.6 Power generation

- 9.7 Others

Chapter 10 Market Estimates and Forecast, By Distribution Channel, 2021 - 2034 (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 Direct sales

- 10.3 Indirect sales

Chapter 11 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Million) (Thousand Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 Germany

- 11.3.2 UK

- 11.3.3 France

- 11.3.4 Italy

- 11.3.5 Spain

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 Japan

- 11.4.3 India

- 11.4.4 Australia

- 11.4.5 South Korea

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.5.3 Argentina

- 11.6 Middle East and Africa

- 11.6.1 South Africa

- 11.6.2 Saudi Arabia

- 11.6.3 UAE

Chapter 12 Company Profiles

- 12.1 AERZEN

- 12.2 Atlas Copco

- 12.3 Azvetra

- 12.4 Baker Hughes

- 12.5 Gardner Denver/Ingersoll Rand

- 12.6 Howden/Chart Industries

- 12.7 Izhvent

- 12.8 Kaeser

- 12.9 KlimatVentMash

- 12.10 Robuschi/Gardner Denver

- 12.11 Roots

- 12.12 TMC Fluid Systems

- 12.13 Ukrventsystemy

- 12.14 VENTPROM

- 12.15 Ventinform