PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1871172

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1871172

Precision Fermentation Bioreactors Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

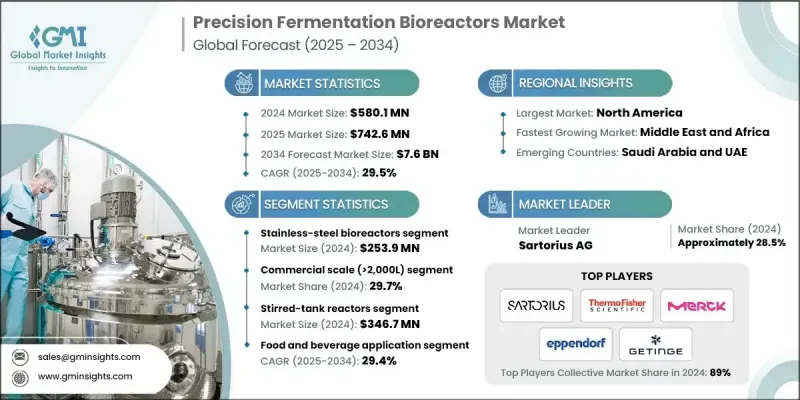

The Global Precision Fermentation Bioreactors Market was valued at USD 580.1 million in 2024 and is estimated to grow at a CAGR of 29.5% to reach USD 7.6 Billion by 2034.

Market expansion is propelled by the increasing preference for sustainable and animal-free production of proteins and enzymes. As consumers increasingly choose plant-based and ethical alternatives, precision fermentation has emerged as a sustainable and scalable solution for producing high-value ingredients such as dairy analogs and protein isolates without relying on animals. The growing emphasis on environmental responsibility and ethical sourcing is accelerating adoption in both food and biotechnology sectors. Furthermore, the technology's ability to deliver consistent product quality and reduce the carbon footprint of traditional protein production strengthens its position as a key enabler of the future food ecosystem. Continuous progress in microbial strain engineering and real-time process monitoring is also improving the precision, efficiency, and yield of fermentation systems, creating favorable conditions for rapid industry growth. Additionally, technological integration, automation, and data analytics are helping companies scale from pilot to commercial operations efficiently, supporting the shift toward mass production of fermentation-derived ingredients.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $580.1 million |

| Forecast Value | $7.6 Billion |

| CAGR | 29.5% |

The commercial-scale segment > 2,000L was valued at USD 235.6 million in 2024 and is expected to register a CAGR of 29.7% during 2025-2034. Large-volume bioreactors have become essential for industrial-scale precision fermentation, facilitating consistent, high-quality, and cost-effective manufacturing processes. The steady rise in commercial-scale deployment demonstrates the industry's transition from research and prototype phases toward large-scale, market-ready production. The move toward industrial scalability reflects the growing confidence of producers in achieving economic feasibility and regulatory compliance, supporting widespread adoption across various industries.

The food & beverage sector remains one of the leading application areas, driven by increasing demand for animal-free proteins, enzymes, and flavoring agents produced through precision fermentation. Rising consumer awareness regarding sustainability, combined with a shift toward alternative proteins, has encouraged broader adoption of fermentation-based technologies. Pilot-scale experiments are rapidly evolving into commercial production lines as producers recognize the long-term potential of this method for creating cleaner, more sustainable food products.

United States Precision Fermentation Bioreactors Market held a significant share in 2024, supported by advanced R&D capabilities, strong industrial collaboration, and a favorable innovation ecosystem. The country's biotechnology and food-tech industries are actively advancing the commercialization of lab-cultured proteins, dairy substitutes, and enzymes, with universities and private firms collaborating to refine fermentation technologies. The integration of automation and digital process control is improving the reliability, productivity, and consistency of fermentation systems.

Leading players operating in the Global Precision Fermentation Bioreactors Market include Merck KGaA (MilliporeSigma), Thermo Fisher Scientific, Sartorius AG, Getinge AB, and Eppendorf AG. Key strategies adopted by companies in the Precision Fermentation Bioreactors Market focus on innovation, scalability, and strategic collaboration. Major manufacturers are investing heavily in R&D to enhance process control, energy efficiency, and fermentation yield. Strategic partnerships with food-tech and biotech firms are helping expand application areas and accelerate market commercialization. Companies are also emphasizing modular bioreactor designs that allow flexible scaling from laboratory to industrial production. Integration of automation, AI-driven monitoring, and digital twin technologies is improving system precision and reducing operational costs.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Scale

- 2.2.4 Technology

- 2.2.5 Application

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Supply chain complexity

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021- 2034 (USD Million, Units)

- 5.1 Key trends

- 5.2 Single-use bioreactors

- 5.3 Stainless steel bioreactors

- 5.4 Glass bioreactors

- 5.5 Hybrid bioreactors

- 5.6 Stirred-tank bioreactors

- 5.7 Others

Chapter 6 Market Estimates and Forecast, By Scale, 2021- 2034 (USD Million, Units)

- 6.1 Key trends

- 6.2 Laboratory scale (<50L)

- 6.3 Pilot scale (50L - 2,000L)

- 6.4 Commercial scale (>2,000L)

- 6.4.1 Small commercial (2,000L - 10,000L)

- 6.4.2 Large commercial (>10,000L)

Chapter 7 Market Estimates and Forecast, By Technology, 2021 - 2034 (USD Million, , Units)

- 7.1 Key trends

- 7.2 Stirred-tank reactors

- 7.3 Wave/rocking bioreactors

- 7.4 Bubble column reactors

- 7.5 Other technologies

Chapter 8 Market Estimates and Forecast, By Application, 2021 - 2034 (USD Million, , Units)

- 8.1 Key trends

- 8.2 Food and beverage

- 8.2.1 Alternative proteins

- 8.2.1.1 Dairy proteins

- 8.2.1.2 Meat proteins

- 8.2.1.3 Egg proteins

- 8.2.2 Food ingredients

- 8.2.2.1 Enzymes

- 8.2.2.2 Vitamins

- 8.2.2.3 Flavors and preservatives

- 8.2.3 Functional foods

- 8.2.3.1 Probiotics and prebiotics

- 8.2.3.2 Nutritional supplements

- 8.2.1 Alternative proteins

- 8.3 Pharmaceutical

- 8.3.1 Therapeutic proteins

- 8.3.2 Vaccines and biologics

- 8.3.3 Pharmaceutical enzymes

- 8.4 Industrial and chemical

- 8.4.1 Industrial enzymes

- 8.4.2 Specialty chemicals

- 8.4.3 Biofuels and energy

- 8.5 Others

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Million, Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East & Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East & Africa

Chapter 10 Company Profiles

- 10.1 Sartorius AG

- 10.2 Thermo Fisher Scientific Inc.

- 10.3 Merck KGaA

- 10.4 Eppendorf AG

- 10.5 Getinge AB

- 10.6 Pall Corporation (Danaher)

- 10.7 ABEC Inc.

- 10.8 Applikon Biotechnology

- 10.9 Solaris Biotechnology

- 10.10 Pierre Guerin Technologies

- 10.11 Perfect Day Inc.

- 10.12 Impossible Foods Inc.

- 10.13 TurtleTree Labs

- 10.14 The EVERY Company

- 10.15 Motif FoodWorks

- 10.16 Geltor Inc.

- 10.17 Clara Foods (The EVERY Company)

- 10.18 Novonesis (formerly Novozymes)

- 10.19 Ginkgo Bioworks

- 10.20 Zymergen (Ginkgo Bioworks)

- 10.21 Synthetic Biologics Inc.

- 10.22 Amyris Inc.

- 10.23 Formo (formerly LegenDairy Foods)

- 10.24 Change Foods

- 10.25 New Culture Inc.

- 10.26 Remilk Ltd.

- 10.27 Imagindairy Ltd.

- 10.28 Shiru Inc.

- 10.29 Tetra Pak

- 10.30 Culture Biosciences