PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1876613

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1876613

3D Printed Surgical Instrument Materials Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

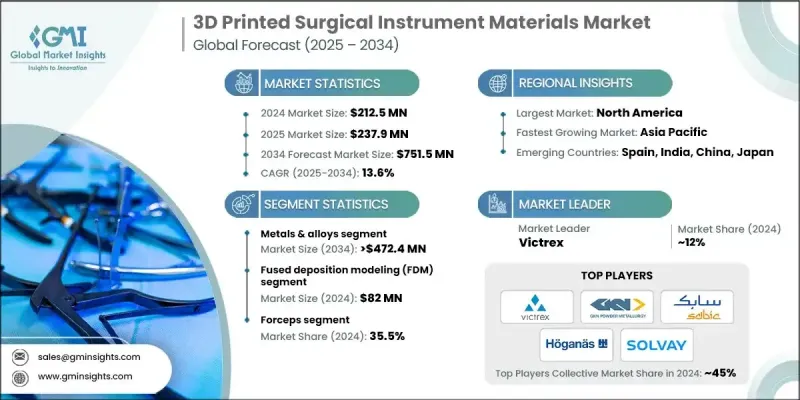

The Global 3D Printed Surgical Instrument Materials Market was valued at USD 212.5 million in 2024 and is estimated to grow at a CAGR of 13.6% to reach USD 751.5 million by 2034.

Market expansion is fueled by ongoing advancements in biocompatible and sterilizable materials, rising demand for patient-specific surgical instruments, increasing adoption of 3D printing across healthcare facilities, and the growing prevalence of minimally invasive and complex surgical procedures. 3D printed surgical instrument materials include metals, polymers, and composites used to fabricate tools such as scalpels, forceps, clamps, and retractors. These materials must ensure high mechanical strength, sterilizability, and biocompatibility. Surgeons are increasingly seeking customized instruments to enhance surgical accuracy and patient outcomes. Additive manufacturing enables precise design, ergonomic customization, and cost-effective production. Continuous innovation in lightweight, durable, and sterilizable metals, polymers, and composite materials is broadening the application of 3D printing in healthcare, supporting the rapid development of specialized surgical tools.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $212.5 Million |

| Forecast Value | $751.5 Million |

| CAGR | 13.6% |

The metals & alloys segment held a 62.6% share in 2024 owing to their exceptional mechanical strength, precision, and sterilization compatibility. Materials such as titanium, stainless steel, and cobalt-chrome offer superior tensile strength, wear resistance, and long-term durability, making them ideal for repeated surgical use. These properties ensure reliability in high-stress surgical environments, driving their widespread adoption.

The fused deposition modeling (FDM) segment was valued at USD 82 million in 2024 and is expected to grow at a CAGR of 13.5% through 2034. FDM is highly cost-effective, enabling rapid prototyping and early-stage production of surgical instruments. Its simplicity, low maintenance, and ease of integration into hospitals and surgical centers facilitate on-demand printing of customized tools, accelerating development while reducing costs.

North America 3D Printed Surgical Instrument Materials Market held a 42.2% share in 2024, supported by advanced healthcare infrastructure, well-equipped hospitals, and research institutions adopting additive manufacturing for surgical applications. Substantial investments by governments, academia, and private enterprises in 3D printing research, along with continuous innovation in biocompatible polymers and metal alloys, are driving regional growth.

Key players operating in the Global 3D Printed Surgical Instrument Materials Market include 3D SYSTEMS, Apium, Arkema, Ensinger, EOS, Evonik, Formlabs, GKN Powder Metallurgy, Hoganas, INDO-MIM, RENISHAW, SABIC, SOLVAY, Stratasys, and Victrex. Companies in the 3D Printed Surgical Instrument Materials Market are strengthening their position by investing in research and development to create advanced biocompatible and sterilizable materials. They are focusing on developing customizable, patient-specific solutions and expanding their product portfolios to cater to complex surgical requirements. Strategic collaborations with hospitals, medical device manufacturers, and academic institutions enhance market reach and adoption. Firms are also leveraging additive manufacturing innovations to reduce production costs, improve precision, and accelerate instrument development.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional trends

- 2.2.2 Material trends

- 2.2.3 Technology trends

- 2.2.4 Instruments trends

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing demand for customized and patient-specific surgical instruments

- 3.2.1.2 Advancements in biocompatible and sterilizable 3D printing materials

- 3.2.1.3 Increasing adoption of additive manufacturing in healthcare

- 3.2.1.4 Rising investments in medical 3D printing R&D

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Limited standardization and regulatory challenges

- 3.2.2.2 Mechanical strength limitations of certain polymers

- 3.2.3 Market opportunities

- 3.2.3.1 Expansion into emerging healthcare markets

- 3.2.3.2 Integration of AI and simulation tools in design optimization

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.5 Technology landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Consumer insights

- 3.7 Gap analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

- 3.10 Future market trends

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company matrix analysis

- 4.3 Company market share analysis

- 4.3.1 Global

- 4.3.2 North America

- 4.3.3 Europe

- 4.4 Competitive positioning matrix

- 4.5 Competitive analysis of major market players

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Material, 2021 - 2034 ($ Mn)

- 5.1 Key trends

- 5.2 Metals & alloys

- 5.3 Polymers

- 5.4 Biodegradable polymer

- 5.5 Other materials

Chapter 6 Market Estimates and Forecast, By Technology, 2021 - 2034 ($ Mn)

- 6.1 Key trends

- 6.2 Fused deposition modeling (FDM)

- 6.3 Selective laser sintering (SLS)

- 6.4 Stereolithography (SLA)

- 6.5 Other technologies

Chapter 7 Market Estimates and Forecast, By Instruments, 2021 - 2034 ($ Mn)

- 7.1 Key trends

- 7.2 Forceps

- 7.3 Clamps

- 7.4 Retractors

- 7.5 Scalpels

- 7.6 Other instruments

Chapter 8 Market Estimates and Forecast, By Region, 2021 - 2034 ($ Mn)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Netherlands

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 Japan

- 8.4.3 India

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 RoW

Chapter 9 Company Profiles

- 9.1 3D SYSTEMS

- 9.2 Apium

- 9.3 Arkema

- 9.4 Ensinger

- 9.5 EOS

- 9.6 Evonik

- 9.7 Formlabs

- 9.8 GKN Powder Metallurgy

- 9.9 Hoganas

- 9.10 INDO-MIM

- 9.11 RENISHAW

- 9.12 SABIC

- 9.13 SOLVAY

- 9.14 Stratasys

- 9.15 Victrex