PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1885848

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1885848

Petrochemical Recycling Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

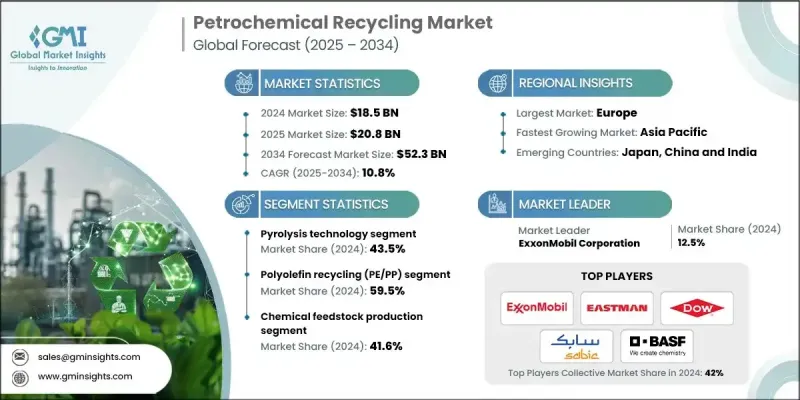

The Global Petrochemical Recycling Market was valued at USD 18.5 billion in 2024 and is estimated to grow at a CAGR of 10.8% to reach USD 52.3 billion by 2034.

The market's rapid rise reflects the growing need for sustainable solutions to manage plastic waste and the increasing refinement of advanced chemical recycling technologies. Rising environmental pressures and stricter global waste regulations are pushing industries and governments to accelerate innovation and expand recycling capacity. Chemical recycling is gaining traction as it provides a viable pathway for converting mixed and contaminated plastic waste into usable outputs that traditional mechanical systems cannot process effectively. As plastic consumption continues to climb worldwide, the gap between waste generation and recycling capacity highlights the urgent demand for scalable chemical recycling alternatives. Progress across major regions, combined with strong policy backing and substantial industrial investments, is reshaping the global landscape and positioning petrochemical recycling as a critical component of the circular economy.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $18.5 Billion |

| Forecast Value | $52.3 Billion |

| CAGR | 10.8% |

The pyrolysis technology segment held 43.5% share in 2024 and is anticipated to grow at a CAGR of 10.4% through 2034. Its dominance stems from its high commercial readiness and ability to break down complex polymer structures under oxygen-free conditions, yielding hydrocarbon products that can be refined. Its flexibility with mixed and contaminated plastics makes it essential for processing waste streams that mechanical recycling cannot accommodate. Its growing network of facilities and consistent investment support confirm its strong industry acceptance.

The polyolefin recycling segment accounted for a 59.5% share in 2024 and is expected to grow at a CAGR of 10.5% from 2025 to 2034. Materials such as polyethylene and polypropylene maintain a leading position due to their heavy use in global packaging production. Their thermoplastic properties make them highly compatible with conversion technologies such as pyrolysis and gasification, facilitating efficient transformation into valuable hydrocarbon derivatives.

North America Petrochemical Recycling Market held a 24.8% share in 2024. This region benefits from reliable waste collection systems, industry investments, and supportive regulatory measures that encourage recycled content adoption. Policies aimed at strengthening producer responsibility and reducing landfill waste reinforce market growth and stimulate long-term demand for chemically recycled materials.

Key companies in the Petrochemical Recycling Market include PETRONAS Chemicals Group, Quantafuel ASA, ExxonMobil Corporation, Plastic Energy, LyondellBasell Industries, Recycling Technologies Ltd., BASF SE, Eastman Chemical Company, Agilyx Corporation, Brightmark LLC, Pyrowave Inc., Dow Inc., Carbios SA, and SABIC (Saudi Basic Industries Corporation). Companies in the Petrochemical Recycling Market enhance their competitive standing by investing in advanced depolymerization technologies, expanding plant capacity, and forming long-term feedstock agreements to ensure stable input supply. Many firms pursue collaborations with packaging producers and petrochemical manufacturers to integrate recycled outputs directly into product value chains. Strategic partnerships accelerate technology development and support commercialization at scale. Organizations also increase R&D spending to improve process efficiency, reduce energy consumption, and enhance the purity of recycled hydrocarbons.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Technology type

- 2.2.3 Feedstock type

- 2.2.4 Application

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Extended producer responsibility (EPR) mandates

- 3.2.1.2 Recycled content requirements & regulations

- 3.2.1.3 Plastic waste crisis & environmental concerns

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High capital investment requirements

- 3.2.2.2 Technical challenges & quality constraints

- 3.2.3 Market opportunities

- 3.2.3.1 Government funding & investment programs

- 3.2.3.2 Emerging market expansion in Asia-Pacific

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By technology type

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) ( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Technology Type, 2021-2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Pyrolysis technology

- 5.2.1 Conventional pyrolysis systems

- 5.2.2 Advanced pyrolysis with catalysts

- 5.2.3 Microwave-assisted pyrolysis

- 5.3 Depolymerization (chemolysis)

- 5.3.1 Solvolysis processes

- 5.3.2 Glycolysis for PET recycling

- 5.3.3 Enzymatic depolymerization

- 5.3.4 Catalytic depolymerization

- 5.4 Gasification technology

- 5.4.1 Air-blown gasification systems

- 5.4.2 Oxygen-blown gasification

- 5.4.3 Steam gasification processes

- 5.4.4 Plasma gasification technology

- 5.5 Dissolution & solvent-based recycling

- 5.5.1 Selective dissolution technologies

- 5.5.2 Solvent recovery & purification

Chapter 6 Market Estimates and Forecast, By Feedstock Type, 2021-2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Polyolefin recycling (PE/PP)

- 6.2.1 High-density polyethylene (HDPE) recycling

- 6.2.2 Low-density polyethylene (LDPE) recycling

- 6.2.3 Polypropylene (pp) recycling

- 6.2.4 Mixed polyolefin streams

- 6.3 PET recycling

- 6.3.1 Bottle-to-bottle recycling

- 6.3.2 Fiber-to-fiber applications

- 6.3.3 Food-grade PET recycling

- 6.3.4 Colored PET processing

- 6.4 Mixed plastic waste recycling

- 6.4.1 Multi-layer packaging materials

- 6.4.2 Contaminated plastic streams

- 6.4.3 Electronic waste plastics

- 6.4.4 Automotive plastic components

- 6.5 Specialty polymer recycling

- 6.5.1 Engineering plastics recycling

- 6.5.2 Thermoset plastic processing

- 6.5.3 Composite material recycling

- 6.5.4 Bio-based polymer recycling

Chapter 7 Market Estimates and Forecast, By Application, 2021-2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Chemical feedstock production

- 7.3 Fuel production applications

- 7.4 New polymer production

- 7.5 Specialty product manufacturing

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 ExxonMobil Corporation

- 9.2 Eastman Chemical Company

- 9.3 Dow Inc.

- 9.4 SABIC (Saudi Basic Industries Corporation)

- 9.5 BASF SE

- 9.6 LyondellBasell Industries

- 9.7 PETRONAS Chemicals Group

- 9.8 Plastic Energy

- 9.9 Agilyx Corporation

- 9.10 Pyrowave Inc.

- 9.11 Recycling Technologies Ltd

- 9.12 Brightmark LLC

- 9.13 Quantafuel ASA

- 9.14 Carbios SA