PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1883932

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1883932

Thin-Film Electrode Market by Material, Manufacturing Facility, End-Use Industry - Global Forecast to 2030

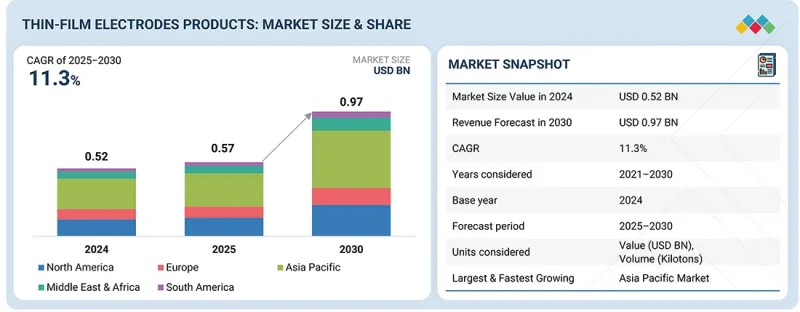

The thin-film electrode market is projected to reach USD 0.97 billion in 2030, at a CAGR of 11.3% from USD 0.57 billion in 2025.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million/Billion), Volume (Kiloton) |

| Segments | Material, Manufacturing Technology, End-Use Industry, and Region |

| Regions covered | Asia Pacific, North America, Europe, Middle East & Africa, and South America |

The thin-film electrode market is driven by the growing demand for miniaturized, lightweight, and high-performance electronic devices across consumer and industrial applications. As devices such as smartphones, wearables, sensors, and microchips continue to shrink in size while increasing in functionality, the need for precise, reliable, and conductive thin-film electrodes has become essential. A significant market opportunity exists in the ongoing advancements of Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) technologies. These innovations enable manufacturers to produce ultra-thin, uniform, and defect-free electrode films with improved scalability and material diversity.

"Boron-doped diamond was the fastest-growing material segment of the thin-film electrode market in terms of value."

Boron-doped diamond (BDD) materials are the fastest-growing segment in the thin-film electrode market due to their exceptional chemical stability, wide potential window, and resistance to fouling, which make them ideal for demanding electrochemical applications. Unlike traditional metal or carbon electrodes, BDD electrodes can operate in highly corrosive environments and under extreme potentials without degrading, enabling their use in advanced industries such as wastewater treatment, electrochemical oxidation, and environmental monitoring. The unique diamond lattice structure, doped with boron, imparts both high electrical conductivity and mechanical hardness, allowing these electrodes to maintain their performance over long operational cycles. Additionally, BDD thin films exhibit low background current and high signal sensitivity, which makes them increasingly preferred in analytical and sensing applications, including biosensors, pharmaceutical analysis, and industrial water purification systems.

"Chemical vapor deposition is the fastest-growing manufacturing facility segment of the thin-film electrode market in terms of value."

Chemical vapor deposition (CVD) is the fastest-growing manufacturing technology in the thin-film electrode market due to its ability to produce high-purity, uniform, and conformal thin films with excellent mechanical and electrochemical properties. CVD allows precise control over the film's composition, thickness, and crystal structure, which is particularly advantageous for advanced materials such as boron-doped diamond (BDD) and carbon-based electrodes. These materials require atomic-level uniformity and strong adhesion to the substrate qualities that CVD delivers more effectively than traditional techniques. As a result, the technology is becoming increasingly preferred for applications demanding extreme chemical stability and long operational lifespans, such as wastewater treatment, electrochemical oxidation, and high-performance sensing systems. Furthermore, recent innovations in plasma-enhanced and low-temperature CVD processes have enabled the deposition of thin films on temperature-sensitive and flexible substrates, thereby expanding the application of CVD in wearable sensors and biomedical devices.

"Healthcare & biotechnology is the fastest-growing end-use industry segment of the thin-film electrode market in terms of value."

The healthcare and biotechnology industry is the fastest-growing end-use segment in the thin-film electrode market, driven by the increasing demand for advanced biosensing, diagnostic, and neuroelectronic devices. Thin-film electrodes offer exceptional sensitivity, flexibility, and biocompatibility, making them ideal for applications such as electrochemical biosensors, neural interfaces, wearable health monitors, and implantable medical devices. Their ability to detect minute biological signals and chemical reactions with high accuracy is driving their adoption in point-of-care testing, glucose monitoring, and brain-computer interface research. As healthcare systems worldwide move toward personalized and real-time diagnostics, the need for reliable, miniaturized, and non-invasive sensing technologies continues to accelerate. Advancements in biocompatible materials (like gold, platinum, and boron-doped diamond) and flexible thin-film fabrication techniques (such as low-temperature CVD and sputtering on polymer substrates) have enabled the integration of electrodes into wearable and implantable biomedical systems.

"Asia Pacific is the fastest-growing market for thin-film electrodes."

Asia Pacific is the fastest-growing region in the thin-film electrode market due to its strong industrial base, rapid technological advancements, and expanding electronics and semiconductor manufacturing ecosystem. Countries such as China, Japan, South Korea, and Taiwan are global leaders in electronics production, driving large-scale demand for high-performance thin-film electrodes used in sensors, integrated circuits, and microelectronic devices. The region also benefits from massive investments in R&D and fabrication facilities, particularly in the areas of semiconductors, biosensors, and flexible electronics, which rely heavily on thin-film electrode technologies for precision, efficiency, and miniaturization. Moreover, the growing healthcare and biotechnology sectors in countries such as India, China, and Japan are increasingly adopting thin-film electrodes for medical diagnostics, neural implants, and wearable health monitoring devices, further accelerating market growth.

In-depth interviews were conducted with Chief Executive Officers (CEOs), marketing directors, other innovation and technology directors, and executives from various key organizations operating in the thin-film electrode market, and information was gathered from secondary research to determine and verify the market size of several segments.

- By Company Type: Tier 1 - 50%, Tier 2 - 30%, and Tier 3 - 20%

- By Designation: Managers - 15%, Directors - 20%, and Others - 65%

- By Region: North America - 30%, Europe - 25%, Asia Pacific - 35%, the Middle East & Africa -5%, and South America - 5%

The thin-film electrode market comprises BASi Research Products, Inc. (US), MicruX Technologies (Spain), Merck KGaA (Germany), Flex Medical Solutions Ltd (Scotland), PalmSens (Netherlands), MSE Supplies LLC (US), and Metrohm DropSens (Spain). The study includes in-depth competitive analysis of these key players in the thin-film electrode market, with their company profiles, recent developments, and key market strategies.

Research Coverage

This report segments the thin-film electrode market on the basis of material, manufacturing technology, end-use industry, and region, and provides estimations for the overall value of the market across various regions. A detailed analysis of key industry players has been conducted to provide insights into their business overviews, products & services, key strategies, and expansions associated with the thin-film electrode market.

Key benefits of buying this report

This research report is focused on various levels of analysis - industry analysis (industry trends), market ranking analysis of top players, and company profiles, which together provide an overall view of the competitive landscape; emerging and high-growth segments of the thin-film electrode market; high-growth regions; and market drivers, restraints, opportunities, and challenges.

The report provides insights into the following pointers:

- Analysis of drivers (Growing demand for flexible and wearable technology), restraints (Material limitations and degradation concerns), opportunities (Expanding market for flexible and transparent electronic applications), and challenges (Achieving sustained stability and biocompatibility for thin-film electrodes in practical settings), influencing the growth of the thin-film electrode market.

- Market Penetration: Comprehensive information on the thin-film electrode offered by top players in the global thin-film electrode market.

- Product Development/Innovation: Detailed insights on upcoming technologies, expansions, and partnerships in the thin-film electrode market.

- Market Development: Comprehensive information about lucrative emerging markets, the report analyzes the markets for the thin-film electrode market across regions.

- Market Capacity: Production capacity of the companies is provided wherever available, with upcoming capacities for the thin-film electrode market.

- Competitive Assessment: In-depth assessment of market shares, strategies, products, and manufacturing capabilities of leading players in the thin-film electrode market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKETS COVERED AND REGIONAL SNAPSHOT

- 1.3.2 INCLUSIONS & EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 CURRENCY CONSIDERED

- 1.3.5 UNITS CONSIDERED

- 1.4 LIMITATIONS

- 1.5 STAKEHOLDERS

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 Key primary sources

- 2.1.2.3 Key participants for primary interviews

- 2.1.2.4 Breakdown of primary interviews

- 2.1.2.5 Key industry insights

- 2.1.1 SECONDARY DATA

- 2.2 BASE NUMBER CALCULATION

- 2.2.1 SUPPLY-SIDE ANALYSIS

- 2.2.2 DEMAND-SIDE ANALYSIS

- 2.3 GROWTH FORECAST

- 2.3.1 SUPPLY SIDE

- 2.3.2 DEMAND SIDE

- 2.4 MARKET SIZE ESTIMATION

- 2.4.1 BOTTOM-UP APPROACH

- 2.4.2 TOP-DOWN APPROACH

- 2.5 DATA TRIANGULATION

- 2.6 RESEARCH ASSUMPTIONS

- 2.7 GROWTH FORECAST

- 2.8 RISK ASSESSMENT

- 2.9 FACTOR ANALYSIS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN THIN-FILM ELECTRODE MARKET

- 4.2 THIN-FILM ELECTRODE MARKET, BY MATERIAL

- 4.3 THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY

- 4.4 THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY

- 4.5 THIN-FILM ELECTRODE MARKET, BY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Growing demand for flexible and wearable technology

- 5.2.1.2 Miniaturization in sensors and biosensors

- 5.2.1.3 Growth in renewable energy technologies

- 5.2.2 RESTRAINTS

- 5.2.2.1 Elevated production costs and challenges in scaling manufacturing processes

- 5.2.2.2 Material limitations and degradation concerns

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Expanding market for flexible and transparent electronic applications

- 5.2.3.2 Potential for cost savings through adoption of carbon-based electrode materials

- 5.2.4 CHALLENGES

- 5.2.4.1 Achieving sustained stability and biocompatibility for thin-film electrodes in practical settings

- 5.2.1 DRIVERS

- 5.3 IMPACT OF GENERATIVE AI ON THIN-FILM ELECTRODE MARKET

- 5.3.1 INTRODUCTION

- 5.3.2 CHEMICAL COMPANIES EMBRACING AI ACROSS VARIOUS BUSINESS AREAS

- 5.3.3 USE OF GENERATIVE AI IN THIN-FILM ELECTRODE MARKET

- 5.3.4 IMPACT OF GENERATIVE AI ON THIN-FILM ELECTRODE MARKET

6 INDUSTRY TRENDS

- 6.1 INTRODUCTION

- 6.2 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 6.3 SUPPLY CHAIN ANALYSIS

- 6.3.1 RAW MATERIAL SOURCING

- 6.3.2 MANUFACTURING & PROCESSING

- 6.3.3 DISTRIBUTION & LOGISTICS

- 6.3.4 END-USE APPLICATIONS & UTILIZATION

- 6.4 IMPACT OF 2025 US TARIFFS-THIN-FILM ELECTRODE MARKET

- 6.4.1 INTRODUCTION

- 6.4.2 KEY TARIFF RATES

- 6.4.3 PRICE IMPACT ANALYSIS

- 6.4.4 KEY IMPACT ON VARIOUS REGIONS

- 6.4.4.1 US

- 6.4.4.2 Europe

- 6.4.4.3 Asia Pacific

- 6.4.5 END-USE INDUSTRY IMPACT

- 6.5 PRICING ANALYSIS

- 6.5.1 AVERAGE SELLING PRICE TREND, BY REGION, 2021-2024

- 6.5.2 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODES, BY FORM, 2021-2024

- 6.5.3 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODES OFFERED BY KEY PLAYERS, BY FORM, 2021-2024

- 6.6 INVESTMENT AND FUNDING SCENARIO

- 6.7 ECOSYSTEM ANALYSIS

- 6.8 TECHNOLOGY ANALYSIS

- 6.8.1 KEY TECHNOLOGIES

- 6.8.2 COMPLEMENTARY TECHNOLOGIES

- 6.9 PATENT ANALYSIS

- 6.9.1 METHODOLOGY

- 6.9.2 PATENTS GRANTED, 2015-2024

- 6.9.3 PATENT PUBLICATION TRENDS

- 6.9.4 INSIGHTS

- 6.9.5 LEGAL STATUS OF PATENTS

- 6.9.6 JURISDICTION ANALYSIS

- 6.9.7 TOP APPLICANTS

- 6.9.8 LIST OF MAJOR PATENTS

- 6.10 TRADE ANALYSIS

- 6.10.1 EXPORT SCENARIO (HS CODE 831110)

- 6.10.2 IMPORT SCENARIO (HS CODE 831110)

- 6.11 KEY CONFERENCES AND EVENTS, 2025-2026

- 6.12 TARIFF AND REGULATORY LANDSCAPE

- 6.12.1 TARIFF, 2024

- 6.12.2 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 6.12.3 REGULATIONS RELATED TO THIN-FILM ELECTRODES

- 6.13 PORTER'S FIVE FORCES ANALYSIS

- 6.13.1 THREAT OF NEW ENTRANTS

- 6.13.2 THREAT OF SUBSTITUTES

- 6.13.3 BARGAINING POWER OF SUPPLIERS

- 6.13.4 BARGAINING POWER OF BUYERS

- 6.13.5 INTENSITY OF COMPETITIVE RIVALRY

- 6.14 KEY STAKEHOLDERS AND BUYING CRITERIA

- 6.14.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 6.14.2 BUYING CRITERIA

- 6.15 MACROECONOMIC OUTLOOK

- 6.15.1 GDP TRENDS AND FORECASTS, BY COUNTRY

- 6.16 CASE STUDY ANALYSIS

- 6.16.1 THIN-FILM ELECTRODES FOR ANODIC STRIPPING VOLTAMMETRY

7 THIN-FILM ELECTRODE MARKET, BY MATERIAL

- 7.1 INTRODUCTION

- 7.2 METAL BASED

- 7.2.1 ADVANCING ELECTRICAL CONDUCTIVITY AND INDUSTRIAL MANUFACTURING COMPATIBILITY

- 7.3 BORON-DOPED DIAMOND

- 7.3.1 ENABLING HIGH CHEMICAL STABILITY AND LONG-TERM ELECTROCHEMICAL PRECISION

- 7.4 CARBON BASED

- 7.4.1 SUPPORTING HIGH SURFACE AREA, FLEXIBILITY, AND EMERGING PRINTED ELECTRONICS APPLICATIONS

- 7.5 OTHER MATERIALS

- 7.5.1 POLYMER BASED

- 7.5.2 OXIDE BASED

8 THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY

- 8.1 INTRODUCTION

- 8.2 PHYSICAL VAPOR DEPOSITION

- 8.2.1 HIGH PRECISION AND SCALABILITY FOR SEMICONDUCTOR AND FLEXIBLE ELECTRONICS MANUFACTURING

- 8.3 CHEMICAL VAPOR DEPOSITION

- 8.3.1 ENABLING HIGH-QUALITY CARBON-BASED AND SPECIALTY ELECTRODE COATINGS

- 8.4 ELECTROCHEMICAL DEPOSITION/ELECTROPLATING

- 8.4.1 COST-EFFECTIVE METALLIZATION FOR BATTERIES, SENSORS, AND PRINTED ELECTRONICS

- 8.5 OTHER MANUFACTURING TECHNOLOGIES

- 8.5.1 SCREEN PRINTING

- 8.5.2 PHOTOLITHOGRAPHY

9 THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY

- 9.1 INTRODUCTION

- 9.2 HEALTHCARE & BIOTECHNOLOGY

- 9.2.1 ENABLING ADVANCED MONITORING, DIAGNOSTICS, AND BIO-INTERFACE

- 9.3 ELECTRONICS & SEMICONDUCTOR

- 9.3.1 SUPPORTING MINIATURIZATION AND HIGH-PERFORMANCE INTEGRATED ELECTRONICS

- 9.4 ENERGY & POWER

- 9.4.1 ACCELERATING GROWTH IN BATTERIES, FUEL CELLS, AND ELECTROCHEMICAL ENERGY SYSTEMS

- 9.5 CHEMICAL & PETROCHEMICAL

- 9.5.1 IMPROVING PROCESS MONITORING, CORROSION DETECTION, AND REAL-TIME SENSING

- 9.6 OTHER END-USE INDUSTRIES

- 9.6.1 WATER & WASTEWATER TREATMENT

- 9.6.2 INDUSTRIAL

10 THIN-FILM ELECTRODE MARKET -REGION

- 10.1 INTRODUCTION

- 10.2 ASIA PACIFIC

- 10.2.1 CHINA

- 10.2.1.1 Huge electronics manufacturing and rapid semiconductor expansion innovation to drive market

- 10.2.2 JAPAN

- 10.2.2.1 Electronics leadership and advanced healthcare sector to drive market

- 10.2.3 INDIA

- 10.2.3.1 Strong policy support, expanding semiconductor and electronics base, and rising healthcare innovation collectively to drive market

- 10.2.4 SOUTH KOREA

- 10.2.4.1 Semiconductor advancement and technological innovations in electronics to drive market

- 10.2.5 TAIWAN

- 10.2.5.1 Semiconductor leadership, high-tech manufacturing, and growing applications in healthcare sector to drive market

- 10.2.6 REST OF ASIA PACIFIC

- 10.2.1 CHINA

- 10.3 NORTH AMERICA

- 10.3.1 US

- 10.3.1.1 Rising healthcare investments and rapid semiconductor expansion to drive market

- 10.3.2 CANADA

- 10.3.2.1 Growing healthcare, semiconductors, and clean energy to drive market

- 10.3.3 MEXICO

- 10.3.3.1 Rapid industrialization, robust semiconductor ecosystem, and growing healthcare and energy infrastructure to drive market

- 10.3.1 US

- 10.4 EUROPE

- 10.4.1 GERMANY

- 10.4.1.1 Strong semiconductor, pharmaceutical, and energy sectors to support market

- 10.4.2 FRANCE

- 10.4.2.1 Synergistic growth across semiconductors, electronics, and healthcare to strengthen by large-scale investments

- 10.4.3 UK

- 10.4.3.1 Focus on healthcare innovation, semiconductor expansion backed by strong R&D funding, and industrial collaborations

- 10.4.4 ITALY

- 10.4.4.1 Cutting-edge healthcare demand, electronics innovation, and semiconductor investment to drive market

- 10.4.5 SPAIN

- 10.4.5.1 Expanding electronics manufacturing and chemical industry to drive market

- 10.4.6 REST OF EUROPE

- 10.4.1 GERMANY

- 10.5 SOUTH AMERICA

- 10.5.1 BRAZIL

- 10.5.1.1 Strong government backing and thriving manufacturing base to drive market

- 10.5.2 ARGENTINA

- 10.5.2.1 Rising healthcare investment, renewable energy initiatives, and broader transition toward advanced materials and high-tech manufacturing to drive market

- 10.5.3 REST OF SOUTH AMERICA

- 10.5.1 BRAZIL

- 10.6 MIDDLE EAST & AFRICA

- 10.6.1 SAUDI ARABIA

- 10.6.1.1 Expanding renewable projects and healthcare industries to drive market

- 10.6.2 UAE

- 10.6.2.1 Huge investments in renewable energy and healthcare innovation to drive market

- 10.6.3 REST OF GCC COUNTRIES

- 10.6.4 SOUTH AFRICA

- 10.6.4.1 Expanding renewable energy projects and advanced healthcare applications to drive market

- 10.6.5 REST OF MIDDLE EAST & AFRICA

- 10.6.1 SAUDI ARABIA

11 COMPETITIVE LANDSCAPE

- 11.1 INTRODUCTION

- 11.2 KEY PLAYER STRATEGIES/RIGHT TO WIN (JANUARY 2021-AUGUST 2025)

- 11.3 MARKET SHARE ANALYSIS, 2024

- 11.3.1 MARKET SHARE OF KEY PLAYERS

- 11.4 REVENUE ANALYSIS, 2021-2025

- 11.5 BRAND COMPARISON

- 11.5.1 BASI RESEARCH PRODUCTS, INC

- 11.5.2 MICRUX TECHNOLOGIES

- 11.5.3 MERCK KGAA

- 11.5.4 FLEX MEDICAL SOLUTIONS LTD

- 11.5.5 METROHM DROPSENS

- 11.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 11.6.1 STARS

- 11.6.2 EMERGING LEADERS

- 11.6.3 PERVASIVE PLAYERS

- 11.6.4 PARTICIPANTS

- 11.6.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 11.6.5.1 Company footprint

- 11.6.5.2 Region footprint

- 11.6.5.3 Material footprint

- 11.6.5.4 End-use industry footprint

- 11.6.6 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 11.6.6.1 Detailed list of key startups/SMEs, 2024

- 11.6.7 VALUATION AND FINANCIAL METRICS OF KEY THIN-FILM ELECTRODE VENDORS

- 11.7 COMPETITIVE SCENARIO

- 11.7.1 PRODUCT LAUNCHES

- 11.7.2 DEALS

- 11.7.3 OTHER DEVELOPMENTS

12 COMPANY PROFILES

- 12.1 KEY PLAYERS

- 12.1.1 BASI RESEARCH PRODUCTS, INC

- 12.1.1.1 Business overview

- 12.1.1.2 Products/Solutions/Services offered

- 12.1.1.3 MnM view

- 12.1.1.3.1 Right to win

- 12.1.1.3.2 Strategic choices

- 12.1.1.3.3 Weaknesses and competitive threats

- 12.1.2 MICRUX TECHNOLOGIES

- 12.1.2.1 Business overview

- 12.1.2.2 Products/Solutions/Services offered

- 12.1.2.3 Recent developments

- 12.1.2.3.1 Product launches

- 12.1.2.4 MnM view

- 12.1.2.4.1 Right to win

- 12.1.2.4.2 Strategic choices

- 12.1.2.4.3 Weaknesses and competitive threats

- 12.1.3 MERCK KGAA

- 12.1.3.1 Business overview

- 12.1.3.2 Products/Solutions/Services offered

- 12.1.3.3 Recent developments

- 12.1.3.3.1 Deals

- 12.1.3.4 MnM view

- 12.1.3.4.1 Right to win

- 12.1.3.4.2 Strategic choices

- 12.1.3.4.3 Weaknesses and competitive threats

- 12.1.4 FLEX MEDICAL SOLUTIONS LTD

- 12.1.4.1 Business overview

- 12.1.4.2 Products/Solutions/Services offered

- 12.1.4.3 Recent developments

- 12.1.4.3.1 Deals

- 12.1.4.4 MnM view

- 12.1.4.4.1 Right to win

- 12.1.4.4.2 Strategic choices

- 12.1.4.4.3 Weaknesses and competitive threats

- 12.1.5 PALMSENS

- 12.1.5.1 Business overview

- 12.1.5.2 Products/Solutions/Services offered

- 12.1.5.3 MnM view

- 12.1.5.3.1 Right to win

- 12.1.5.3.2 Strategic choices

- 12.1.5.3.3 Weaknesses and competitive threats

- 12.1.6 MSE SUPPLIES LLC

- 12.1.6.1 Business overview

- 12.1.6.2 Products/Solutions/Services offered

- 12.1.6.3 Recent developments

- 12.1.6.3.1 Deals

- 12.1.6.3.2 Others

- 12.1.6.4 MnM view

- 12.1.6.4.1 Right to win

- 12.1.6.4.2 Strategic choices

- 12.1.6.4.3 Weaknesses and competitive threats

- 12.1.7 METROHM DROPSENS

- 12.1.7.1 Business overview

- 12.1.7.2 Products/Solutions/Services offered

- 12.1.7.3 Recent developments

- 12.1.7.3.1 Product launches

- 12.1.7.4 MnM view

- 12.1.7.4.1 Right to win

- 12.1.7.4.2 Strategic choices

- 12.1.7.4.3 Weaknesses and competitive threats

- 12.1.1 BASI RESEARCH PRODUCTS, INC

13 APPENDIX

- 13.1 DISCUSSION GUIDE

- 13.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 13.3 CUSTOMIZATION OPTIONS

- 13.4 RELATED REPORTS

- 13.5 AUTHOR DETAILS

List of Tables

- TABLE 1 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODE, BY REGION, 2021-2024 (USD/KILOGRAM)

- TABLE 2 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODE, BY FORM, 2021-2024 (USD/KILOGRAM)

- TABLE 3 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODES, OFFERED BY KEY PLAYERS, BY FORM, 2021-2024 (USD/KILOGRAM)

- TABLE 4 THIN-FILM ELECTRODE MARKET: ROLE IN ECOSYSTEM

- TABLE 5 KEY TECHNOLOGIES IN THIN-FILM ELECTRODE

- TABLE 6 COMPLEMENTARY TECHNOLOGIES IN THIN-FILM ELECTRODE

- TABLE 7 THIN-FILM ELECTRODE MARKET: TOTAL NUMBER OF PATENTS

- TABLE 8 THIN-FILM ELECTRODE: LIST OF MAJOR PATENT OWNERS, 2015-2024

- TABLE 9 THIN-FILM ELECTRODE: LIST OF MAJOR PATENTS, 2015-2024

- TABLE 10 EXPORT DATA OF HS CODE 831110-COMPLIANT PRODUCTS, BY COUNTRY, 2021-2024 (USD THOUSAND)

- TABLE 11 IMPORT DATA OF HS CODE 831110-COMPLIANT PRODUCTS, BY COUNTRY, 2021-2024 (USD THOUSAND)

- TABLE 12 THIN-FILM ELECTRODE MARKET: KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 13 TARIFFS RELATED TO THIN-FILM ELECTRODE MARKET, 2024

- TABLE 14 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 15 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 16 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 17 MIDDLE EAST & AFRICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 18 SOUTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 19 REGULATIONS FOR PLAYERS IN THIN-FILM ELECTRODE MARKET

- TABLE 20 THIN-FILM ELECTRODE MARKET: IMPACT OF FIVE PORTER FORCES

- TABLE 21 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- TABLE 22 KEY BUYING CRITERIA FOR TOP THREE END-USE INDUSTRIES

- TABLE 23 GDP TRENDS AND FORECASTS, BY COUNTRY, 2023-2025 (USD MILLION)

- TABLE 24 THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (USD MILLION)

- TABLE 25 THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (USD MILLION)

- TABLE 26 THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (TON)

- TABLE 27 THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (TON)

- TABLE 28 THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (USD MILLION)

- TABLE 29 THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (USD MILLION)

- TABLE 30 THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (TON)

- TABLE 31 THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (TON)

- TABLE 32 THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 33 THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 34 THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 35 THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 36 THIN-FILM ELECTRODE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 37 THIN-FILM ELECTRODE MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 38 THIN-FILM ELECTRODE MARKET, BY REGION, 2021-2024 (TON)

- TABLE 39 THIN-FILM ELECTRODE MARKET, BY REGION, 2025-2030 (TON)

- TABLE 40 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 41 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 42 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (TON)

- TABLE 43 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 44 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (USD MILLION)

- TABLE 45 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (USD MILLION)

- TABLE 46 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (TON)

- TABLE 47 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (TON)

- TABLE 48 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (USD MILLION)

- TABLE 49 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (USD MILLION)

- TABLE 50 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (TON)

- TABLE 51 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (TON)

- TABLE 52 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION) INDUSTRY

- TABLE 53 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 54 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 55 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 56 CHINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION) INDUSTRY

- TABLE 57 CHINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 58 CHINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 59 CHINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 60 JAPAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 61 JAPAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 62 JAPAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 63 JAPAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 64 INDIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 65 INDIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 66 INDIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 67 INDIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 68 SOUTH KOREA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 69 SOUTH KOREA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 70 SOUTH KOREA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 71 SOUTH KOREA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 72 TAIWAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 73 TAIWAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 74 TAIWAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 75 TAIWAN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 76 REST OF ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 77 REST OF ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 78 REST OF ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 79 REST OF ASIA PACIFIC: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 80 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 81 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 82 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (TON)

- TABLE 83 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 84 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (USD MILLION)

- TABLE 85 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (USD MILLION)

- TABLE 86 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (TON)

- TABLE 87 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (TON)

- TABLE 88 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (USD MILLION)

- TABLE 89 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (USD MILLION)

- TABLE 90 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (TON)

- TABLE 91 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (TON)

- TABLE 92 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 93 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 94 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 95 NORTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 96 US: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 97 US: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 98 US: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 99 US: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 100 CANADA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 101 CANADA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 102 CANADA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 103 CANADA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 104 MEXICO: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 105 MEXICO: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 106 MEXICO: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 107 MEXICO: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 108 EUROPE: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 109 EUROPE: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 110 EUROPE: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (TON)

- TABLE 111 EUROPE: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 112 EUROPE: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (USD MILLION)

- TABLE 113 EUROPE: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (USD MILLION)

- TABLE 114 EUROPE: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (TON)

- TABLE 115 EUROPE: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (TON)

- TABLE 116 EUROPE: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (USD MILLION)

- TABLE 117 EUROPE: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (USD MILLION)

- TABLE 118 EUROPE: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (TON)

- TABLE 119 EUROPE: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (TON)

- TABLE 120 EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 121 EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 122 EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 123 EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 124 GERMANY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 125 GERMANY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 126 GERMANY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 127 GERMANY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 128 FRANCE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 129 FRANCE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 130 FRANCE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 131 FRANCE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 132 UK: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 133 UK: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 134 UK: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 135 UK: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 136 ITALY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 137 ITALY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 138 ITALY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 139 ITALY: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 140 SPAIN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 141 SPAIN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 142 SPAIN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 143 SPAIN: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 144 REST OF EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 145 REST OF EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 146 REST OF EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 147 REST OF EUROPE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 148 SOUTH AMERICA: THIN-FILM ELECTRODES MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 149 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 150 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (TON)

- TABLE 151 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 152 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (USD MILLION)

- TABLE 153 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (USD MILLION)

- TABLE 154 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (TON)

- TABLE 155 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (TON)

- TABLE 156 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (USD MILLION)

- TABLE 157 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (USD MILLION)

- TABLE 158 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (TON)

- TABLE 159 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (TON)

- TABLE 160 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 161 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 162 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 163 SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 164 BRAZIL: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 165 BRAZIL: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 166 BRAZIL: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 167 BRAZIL: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 168 ARGENTINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 169 ARGENTINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 170 ARGENTINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 171 ARGENTINA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 172 REST OF SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 173 REST OF SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 174 REST OF SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 175 REST OF SOUTH AMERICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 176 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 177 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 178 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2021-2024 (TON)

- TABLE 179 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 180 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (USD MILLION)

- TABLE 181 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (USD MILLION)

- TABLE 182 MIDDLE EAST AND AFRICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2021-2024 (TON)

- TABLE 183 MIDDLE EAST AND AFRICA: THIN-FILM ELECTRODE MARKET, BY MATERIAL, 2025-2030 (TON)

- TABLE 184 MIDDLE EAST AND AFRICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (USD MILLION)

- TABLE 185 MIDDLE EAST AND AFRICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (USD MILLION)

- TABLE 186 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2021-2024 (TON)

- TABLE 187 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY MANUFACTURING TECHNOLOGY, 2025-2030 (TON)

- TABLE 188 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 189 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 190 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 191 MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 192 SAUDI ARABIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 193 SAUDI ARABIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 194 SAUDI ARABIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON) INDUSTRY

- TABLE 195 SAUDI ARABIA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 196 UAE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 197 UAE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 198 UAE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 199 UAE: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 200 REST OF GCC COUNTRIES: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 201 REST OF GCC COUNTRIES: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 202 REST OF GCC COUNTRIES: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 203 REST OF GCC COUNTRIES: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 204 SOUTH AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 205 SOUTH AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 206 SOUTH AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 207 SOUTH AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 208 REST OF MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 209 REST OF MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 210 REST OF MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2021-2024 (TON)

- TABLE 211 REST OF MIDDLE EAST & AFRICA: THIN-FILM ELECTRODE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 212 OVERVIEW OF STRATEGIES ADOPTED BY KEY THIN-FILM ELECTRODE MANUFACTURERS

- TABLE 213 THIN-FILM ELECTRODE MARKET: DEGREE OF COMPETITION

- TABLE 214 THIN-FILM ELECTRODE MARKET: REGION FOOTPRINT

- TABLE 215 THIN-FILM ELECTRODE MARKET: MATERIAL FOOTPRINT

- TABLE 216 THIN-FILM ELECTRODE MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 217 THIN-FILM ELECTRODE MARKET: DETAILED LIST OF KEY STARTUPS/SMES, 2024

- TABLE 218 THIN-FILM ELECTRODE MARKET: PRODUCT LAUNCHES, JANUARY 2021- NOVEMBER 2025

- TABLE 219 THIN-FILM ELECTRODE MARKET: DEALS, JANUARY 2021- NOVEMBER 2025

- TABLE 220 THIN-FILM ELECTRODE MARKET: OTHERS, JANUARY 2021-AUGUST 2025

- TABLE 221 BASI RESEARCH PRODUCTS, INC.: COMPANY OVERVIEW

- TABLE 222 BASI RESEARCH PRODUCTS, INC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 223 MICRUX TECHNOLOGIES: COMPANY OVERVIEW

- TABLE 224 MICRUX TECHNOLOGIES: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 225 MICRUX TECHNOLOGIES: PRODUCT LAUNCHES, 2021-2025

- TABLE 226 MERCK KGAA: COMPANY OVERVIEW

- TABLE 227 MERCK KGAA: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 228 MERCK KGAA: DEALS, 2021-2025

- TABLE 229 FLEX MEDICAL SOLUTIONS LTD: COMPANY OVERVIEW

- TABLE 230 FLEX MEDICAL SOLUTIONS LTD: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 231 FLEX MEDICAL SOLUTIONS LTD: DEALS, 2021-2025

- TABLE 232 PALMSENS: COMPANY OVERVIEW

- TABLE 233 PALMSENS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 234 MSE SUPPLIES LLC: COMPANY OVERVIEW

- TABLE 235 MSE SUPPLIES LLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 236 MSE SUPPLIES LLC: DEALS, 2021-2025

- TABLE 237 MSE SUPPLIES LLC: OTHERS, 2021-2025

- TABLE 238 METROHM DROPSENS: COMPANY OVERVIEW

- TABLE 239 METROHM DROPSENS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 240 METROHM DROPSENS: PRODUCT LAUNCHES, 2021-2025

List of Figures

- FIGURE 1 THIN-FILM ELECTRODE MARKET SEGMENTATION AND REGIONAL SNAPSHOT

- FIGURE 2 THIN-FILM ELECTRODE MARKET: RESEARCH DESIGN

- FIGURE 3 MARKET SIZE ESTIMATION METHODOLOGY: SUPPLY-SIDE APPROACH

- FIGURE 4 MARKET SIZE ESTIMATION METHODOLOGY: DEMAND-SIDE APPROACH

- FIGURE 5 MARKET SIZE ESTIMATION METHODOLOGY: REVENUE OF MARKET PLAYERS, 2024

- FIGURE 6 MARKET SIZE ESTIMATION METHODOLOGY: BOTTOM-UP APPROACH

- FIGURE 7 MARKET SIZE ESTIMATION METHODOLOGY: TOP-DOWN APPROACH

- FIGURE 8 THIN-FILM ELECTRODE MARKET: DATA TRIANGULATION

- FIGURE 9 METAL BASED SEGMENT TO DOMINATE MARKET IN 2025

- FIGURE 10 PHYSICAL VAPOR DEPOSITION SEGMENT TO DOMINATE MARKET DURING THE FORECAST PERIOD

- FIGURE 11 ELECTRONICS & SEMICONDUCTOR SEGMENT TO REGISTER HIGHEST GROWTH BETWEEN 2025 AND 2030

- FIGURE 12 ASIA PACIFIC TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 13 GROWING USE OF THIN-FILM ELECTRODE IN ELECTRONICS & SEMICONDUCTOR INDUSTRY TO CREATE LUCRATIVE OPPORTUNITIES FOR MARKET PLAYERS

- FIGURE 14 CARBON BASED SEGMENT TO REGISTER FASTEST GROWTH DURING FORECAST PERIOD

- FIGURE 15 PHYSICAL VAPOR DEPOSITION SEGMENT TO BE LARGEST SEGMENT IN 2025

- FIGURE 16 ELECTRONICS & SEMICONDUCTOR SEGMENT TO BE LARGEST SEGMENT IN 2025

- FIGURE 17 CHINA TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 18 THIN-FILM ELECTRODE MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 19 APPLICATION OF AI ACROSS VARIOUS BUSINESS AREAS IN CHEMICAL INDUSTRY

- FIGURE 20 APPLICATION OF GEN AI IN THIN-FILM ELECTRODE MARKET

- FIGURE 21 THIN-FILM ELECTRODE MARKET: TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 22 THIN-FILM ELECTRODE MARKET: SUPPLY CHAIN ANALYSIS

- FIGURE 23 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODE, BY REGION, 2021-2024 (USD/KILOGRAM)

- FIGURE 24 AVERAGE SELLING PRICE TREND OF THIN-FILM ELECTRODES, OFFERED BY KEY PLAYERS, BY MATERIAL, 2021-2024

- FIGURE 25 THIN-FILM ELECTRODE: INVESTMENT AND FUNDING SCENARIO

- FIGURE 26 THIN-FILM ELECTRODE: ECOSYSTEM ANALYSIS

- FIGURE 27 NUMBER OF PATENTS GRANTED (2015-2024)

- FIGURE 28 THIN-FILM ELECTRODE: LEGAL STATUS OF PATENTS

- FIGURE 29 PATENT ANALYSIS FOR THIN-FILM ELECTRODE, BY JURISDICTION, 2015-2024

- FIGURE 30 TOP 7 COMPANIES WITH HIGHEST NUMBER OF PATENTS IN LAST 10 YEARS

- FIGURE 31 EXPORT DATA OF HS CODE 831110-COMPLIANT PRODUCTS, BY COUNTRY, 2021-2024 (USD THOUSAND)

- FIGURE 32 IMPORT DATA OF HS CODE 831110-COMPLIANT PRODUCTS, BY COUNTRY, 2021-2024 (USD THOUSAND)

- FIGURE 33 THIN-FILM ELECTRODE MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 34 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS FOR TOP THREE END-USE INDUSTRIES

- FIGURE 35 KEY BUYING CRITERIA FOR TOP THREE APPLICATIONS

- FIGURE 36 METAL BASED WAS LARGEST SEGMENT OF THIN-FILM ELECTRODE MARKET IN 2024

- FIGURE 37 ELECTROCHEMICAL DEPOSITION/ELECTROPLATING TO LEAD THIN-FILM ELECTRODE MARKET DURING FORECAST PERIOD

- FIGURE 38 ELECTRONICS & SEMICONDUCTOR TO LEAD THIN-FILM ELECTRODE MARKET DURING FORECAST PERIOD

- FIGURE 39 ASIA PACIFIC TO BE FASTEST-GROWING MARKET DURING FORECAST PERIOD

- FIGURE 40 ASIA PACIFIC: THIN-FILM ELECTRODE MARKET SNAPSHOT

- FIGURE 41 NORTH AMERICA: THIN-FILM ELECTRODE MARKET SNAPSHOT

- FIGURE 42 EUROPE THIN-FILM ELECTRODE MARKET SNAPSHOT

- FIGURE 43 THIN-FILM ELECTRODE MARKET: SHARE OF KEY PLAYERS, 2024

- FIGURE 44 REVENUE ANALYSIS OF KEY PLAYERS, 2021-2025

- FIGURE 45 BRAND COMPARATIVE ANALYSIS, BY SEGMENT

- FIGURE 46 THIN-FILM ELECTRODE MARKET: COMPANY EVALUATION MATRIX, KEY PLAYERS, 2024

- FIGURE 47 THIN-FILM ELECTRODE MARKET: COMPANY FOOTPRINT

- FIGURE 48 EV/EBITDA OF KEY VENDORS

- FIGURE 49 YEAR-TO-DATE (YTD) PRICE TOTAL RETURN

- FIGURE 50 BASI RESEARCH PRODUCTS, INC.: COMPANY SNAPSHOT

- FIGURE 51 MERCK KGAA: COMPANY SNAPSHOT