PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1928857

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1928857

Furniture Plastic Market by Plastic Type (Virgin Grade, Compounded Grade), Composition (Unfilled, Mineral Filled, Glass Fiber Reinforced, Other Compositions), Furniture Type, Application, End-use Industry, and Region - Global Forecast to 2030

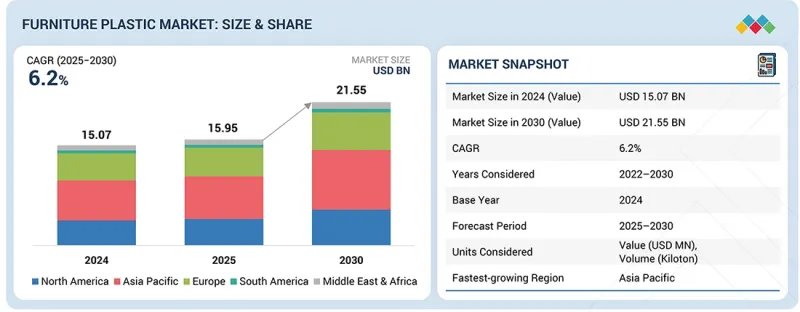

The furniture plastic market is projected to reach USD 21.55 billion by 2030 from USD 15.95 billion in 2025, at a CAGR of 6.2% during the forecast period.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million) and Volume (Kiloton) |

| Segments | Plastic Type, Composition, Furniture Type, Application, End-Use Industry, and Region. |

| Regions covered | North America, Asia Pacific, Europe, Middle East & Africa, and South America |

Furniture plastics have penetrated various sectors like residential housing, offices, hospitality, healthcare, and educational facilities, the trend being supported by ever-changing safety, durability, and sustainability requirements. Manufacturers are moving to materials such as polypropylene (PP), polyethylene (PE), ABS, and engineered plastic compounds to give the customers the benefits of a light product, unlimited design possibilities, water resistance, and a longer service life. These materials open up the possibilities in furniture components such as chairs, tables, storage units, modular furniture systems, and indoor and outdoor furnishings, with the areas of maintenance simplicity and high-volume manufacturability being the most addressed.

The observance of international product safety and material standards such as ISO, ASTM, and EN regulations also acts as a further incentive for the use of plastic materials of a certain standard in furniture production. Besides that, industry and sustainability guidelines recognize the importance of plastics in enabling the reduction of material usage, cutting of transportation emissions through lightweighting, and bettering production efficiency, thus being a major factor behind their rise in significance across global furniture manufacturing value chains.

"Virgin grade are projected to be the fastest-growing plastic type in the furniture plastic market during the forecast period."

Virgin-grade plastics are anticipated to become the furniture plastics market segment, contributing most to the market growth of plastic types during the forecast period. It is to be expected that the shift towards a continuous material quality, a better mechanical performance and a firm safety and durability standard compliance will be the key drivers for this growth. For the applications that require precise molding, uniform surface finish, and long service life, especially in residential and institutional furniture, furniture manufacturers are now using more and more virgin polypropylene, polyethylene, and ABS. As compared with recycled ones, virgin-grade plastics offer larger impact resistance, better color stability, and more predictable processing behavior, thus, they are the primary choice in high-volume injection molding and complex furniture geometries. Besides, the adherence to global material and product safety standards such as ISO, ASTM, and EN norms is another factor that paves the way for the use of virgin-grade plastics in furniture production worldwide.

"Residential is projected to be the fastest-growing end-use industry in the furniture plastic market during the forecast period."

The residential segment is expected to be the leading end-use industry in the furniture plastics market, with the fastest growth rate over the forecast period. The main factors that contribute to the rapid development of this market segment are urbanization, affordable housing expansion, and increasing consumer preference for lightweight and space-efficient furniture. Plastic furniture is becoming more and more popular among households thanks to its waterproof feature, simple maintenance, and compatibility with modular and ready-to-assemble formats. The rise of e-commerce furniture sales and the direct-to-consumer delivery model have a major impact on residential demand growth, which is further augmented by the advantages of plastic furniture in cutting transportation costs and lessening the occurrence of damage. Besides, the accelerated replacement cycles that are mostly due to the changing interior design trends and lifestyle upgrades act as a continuous consumption driver in the urban and semi-urban residential markets.

"Asia Pacific is projected to be the fastest-growing region in the furniture plastic market during the forecast period."

Asia Pacific is set to outpace the rest of the world in the furniture plastics market in terms of growth over the forecast period. The key factors that have led to this situation include large-scale urban development, population growth, and the expanding middle-class consumption. The demand for cost-efficient furniture is very strong in areas like China, India, Indonesia, and Vietnam, where the residential, commercial, and institutional sectors are booming. The region has a full-fledged plastics manufacturing base, which is supported by the availability of the raw materials and cost-competitive production. All these are good conditions for the region to keep up the momentum of high-volume furniture manufacturing. The governments' efforts to promote housing development, infrastructure expansion, and domestic manufacturing not only speed up the market growth but also make Asia Pacific one of the most important future global furniture plastics market hubs.

By Company Type: Tier 1: 40%, Tier 2: 30%, and Tier 3: 30%

By Designation: Directors: 30%, Managers: 20%, and Others: 50%

By Region: North America: 20%, Europe: 10%, Asia Pacific: 40%, South America: 10%, and the Middle East & Africa 20%

Notes: Others include sales, marketing, and product managers.

Tier 1: >USD 1 Billion; Tier 2: USD 500 Million-1 Billion; and Tier 3: <USD 500 Million

Companies Covered: Keter (Israel), Nilkamal (India), The Supreme Industries Limited (India), Tramontina (Brazil), Cello (India), Inter IKEA Systems B.V. (Netherlands), MillerKnoll, Inc. (US), Grosfillex (France), Poly-Wood, LLC (US), NARDI S.p.A. (Italy) and Harwal Group of Companies (UAE) are covered in the report.

The study includes an in-depth competitive analysis of these key players in the furniture plastic market, with their company profiles, recent developments, and key market strategies.

Research Coverage

This research report categorizes the furniture plastic market based on plastic type (virgin grade, compounded grade), composition (unfilled, mineral filled, glass fiber reinforced, other compositions) , furniture type (garden furniture, household, institutional furniture, residential furniture), application (indoor, outdoor), and end-use industry (residential, commercial, institutional). The report's scope covers detailed information regarding the drivers, restraints, challenges, and opportunities influencing the growth of the furniture plastic market. A detailed analysis of the key industry players has been done to provide insights into their business overview, products offered, and key strategies, such as mergers, acquisitions, product launches, and expansions, associated with the furniture plastic market. This report covers a competitive analysis of upcoming startups in the furniture plastic market ecosystem.

Reasons to Buy the Report

The report will offer the market leaders/new entrants with information on the closest approximations of the revenue numbers for the overall furniture plastic market and the subsegments. It will help stakeholders understand the competitive landscape, gain more insights into positioning their businesses better, and plan suitable go-to-market strategies. The report will help stakeholders understand the pulse of the market and provide them with information on key market drivers, restraints, challenges, and opportunities.

The report provides insights into the following points.

- Analysis of key drivers (Rapid urbanization and growth in affordable housing, Rising demand for modular and ready-to-assemble (RTA) furniture, Cost, weight, and logistics advantages over wood and metal), restraints (Environmental concerns and plastic waste perception, and Stringent regulations on plastics and recyclability), opportunities (Adoption of recycled and bio-based plastics, Growth of e-commerce and flat-pack furniture, and Expansion of commercial and institutional infrastructure), and challenges (Recycling and end-of-life management of mixed plastics and Balancing durability, aesthetics, and sustainability).

- Product Development/Innovation: Detailed insights into upcoming technologies, research & development activities, and product & service launches in the furniture plastic market.

- Market Development: Comprehensive information about profitable markets - the report analyzes the furniture plastic market across varied regions.

- Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in the furniture plastic market.

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players such as Keter Group (Israel), Nilkamal (India), The Supreme Industries Limited (India), Tramontina (Brazil), Cello (India), Inter IKEA Systems B.V. (Netherlands), MillerKnoll, Inc. (US), Grosfillex (France), Poly-Wood, LLC (US), NARDI S.p.A. (Italy) and Harwal Group of Companies (UAE).

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKET SEGMENTATION & REGIONAL SCOPE

- 1.3.2 INCLUSIONS & EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.3.4 UNITS CONSIDERED

- 1.3.4.1 Currency/Value unit

- 1.3.4.2 Volume unit

- 1.4 STAKEHOLDERS

2 EXECUTIVE SUMMARY

- 2.1 KEY INSIGHTS & MARKET HIGHLIGHTS

- 2.2 KEY MARKET PARTICIPANTS: SHARE INSIGHTS AND STRATEGIC DEVELOPMENTS

- 2.3 DISRUPTIVE TRENDS SHAPING MARKET

- 2.4 HIGH-GROWTH SEGMENTS & EMERGING FRONTIERS

- 2.5 SNAPSHOT: GLOBAL MARKET SIZE, GROWTH RATE, AND FORECAST

3 PREMIUM INSIGHTS

- 3.1 ATTRACTIVE OPPORTUNITIES FOR FURNITURE PLASTIC MARKET PLAYERS

- 3.2 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE AND COUNTRY

- 3.3 FURNITURE PLASTIC MARKET, BY COMPOSITION

- 3.4 FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY

- 3.5 FURNITURE PLASTIC MARKET, BY APPLICATION

- 3.6 FURNITURE PLASTIC MARKET, BY FURNITURE TYPE

- 3.7 FURNITURE PLASTIC MARKET, BY COUNTRY

4 MARKET OVERVIEW

- 4.1 INTRODUCTION

- 4.2 MARKET DYNAMICS

- 4.2.1 DRIVERS

- 4.2.1.1 Rapid urbanization and growth in affordable housing

- 4.2.1.2 Rising demand for modular and ready-to-assemble furniture

- 4.2.1.3 Cost, weight, and logistics advantages over wood and metal

- 4.2.2 RESTRAINTS

- 4.2.2.1 Environmental concerns and plastic waste perception

- 4.2.2.2 Stringent regulations on plastics and recyclability

- 4.2.3 OPPORTUNITIES

- 4.2.3.1 Adoption of recycled and bio-based plastics

- 4.2.3.2 Growth of e-commerce and flat-pack furniture

- 4.2.3.3 Expansion of commercial and institutional infrastructure

- 4.2.4 CHALLENGES

- 4.2.4.1 Recycling and end-of-life management of mixed plastics

- 4.2.4.2 Balancing durability, aesthetics, and sustainability

- 4.2.1 DRIVERS

5 INDUSTRY TRENDS

- 5.1 PORTER'S FIVE FORCES ANALYSIS

- 5.1.1 THREAT OF NEW ENTRANTS

- 5.1.2 THREAT OF SUBSTITUTES

- 5.1.3 BARGAINING POWER OF SUPPLIERS

- 5.1.4 BARGAINING POWER OF BUYERS

- 5.1.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.2 MACROECONOMIC OUTLOOK

- 5.2.1 INTRODUCTION

- 5.2.2 GDP TRENDS AND FORECASTS

- 5.3 VALUE CHAIN ANALYSIS

- 5.4 ECOSYSTEM ANALYSIS

- 5.4.1 ROLE IN ECOSYSTEM

- 5.5 PRICING ANALYSIS

- 5.5.1 AVERAGE SELLING PRICE OF FURNITURE PLASTICS, BY END-USE INDUSTRY, 2024

- 5.5.2 AVERAGE SELLING PRICE TREND OF FURNITURE PLASTICS, BY REGION, 2022-2024

- 5.6 TRADE ANALYSIS

- 5.6.1 EXPORT DATA FOR HS CODE 940370, 2020-2024

- 5.6.2 IMPORT DATA FOR HS CODE 940370, 2020-2024

- 5.7 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.8 TRENDS/DISRUPTIONS IMPACTING CUSTOMER'S BUSINESS

- 5.9 INVESTMENT & FUNDING SCENARIO

- 5.10 CASE STUDY ANALYSIS

- 5.10.1 EMECO & THE COCA-COLA COMPANY (111 NAVY CHAIR - RECYCLED PET FURNITURE)

- 5.10.2 BASF & EMECO (PETRA THERMOPLASTIC POLYESTER FOR SUSTAINABLE CHAIRS)

- 5.10.3 GLOBAL FURNITURE TRENDS (VITRA, KARTELL, HERMAN MILLER - RECYCLED PP/PE FURNITURE)

- 5.11 IMPACT OF 2025 US TARIFF ON FURNITURE PLASTIC MARKET

- 5.11.1 KEY TARIFF RATES

- 5.11.2 PRICE IMPACT ANALYSIS

- 5.11.3 IMPACT ON COUNTRY/REGION

- 5.11.3.1 US

- 5.11.3.2 China

- 5.11.3.3 Europe

- 5.11.3.4 Mexico

- 5.11.4 IMPACT ON END-USE INDUSTRY

6 STRATEGIC DISRUPTION THROUGH TECHNOLOGY, PATENTS, DIGITAL, AND AI ADOPTIONS

- 6.1 KEY EMERGING TECHNOLOGIES

- 6.1.1 BIO-BASED AND RECYCLED POLYMER TECHNOLOGIES

- 6.1.2 ADVANCED INJECTION MOLDING AND LIGHTWEIGHT STRUCTURAL TECHNOLOGIES

- 6.1.3 UV-STABILIZATION, WEATHER-RESISTANCE, AND FUNCTIONAL ADDITIVE SYSTEMS

- 6.2 COMPLEMENTARY TECHNOLOGIES

- 6.2.1 ADVANCED COMPOUNDING AND MASTERBATCH TECHNOLOGIES

- 6.2.2 SURFACE FINISHING, TEXTURE, AND DECORATIVE TECHNOLOGIES

- 6.2.3 AUTOMATION, ROBOTICS, AND DIGITAL MANUFACTURING SYSTEMS

- 6.3 ADJACENT TECHNOLOGIES

- 6.3.1 CIRCULAR ECONOMY AND ADVANCED RECYCLING TECHNOLOGIES

- 6.3.2 ADDITIVE MANUFACTURING AND TOOLING TECHNOLOGIES

- 6.3.3 SMART MATERIALS AND EMBEDDED FUNCTIONALITY

- 6.4 TECHNOLOGY/PRODUCT ROADMAP

- 6.4.1 SHORT-TERM (2025-2027) | FOUNDATION & EARLY COMMERCIALIZATION

- 6.4.2 MID-TERM (2027-2030) | EXPANSION & INTEGRATION

- 6.4.3 LONG-TERM (2030-2035+) | MATURITY & ADVANCED SYSTEMS

- 6.5 PATENT ANALYSIS

- 6.5.1 INTRODUCTION

- 6.5.2 METHODOLOGY

- 6.5.3 FURNITURE PLASTIC MARKET: PATENT ANALYSIS, 2015-2024

- 6.5.4 LIST OF KEY PATENTS

- 6.6 FUTURE APPLICATIONS

- 6.6.1 SMART AND FUNCTIONAL PLASTICS FOR INDUSTRY 4.0 FURNITURE

- 6.6.2 ECO-FRIENDLY AND RECYCLED PLASTICS

- 6.6.3 HIGH-PERFORMANCE ENGINEERED PLASTICS

- 6.6.4 FUNCTIONAL ADDITIVES AND COATINGS FOR SPECIALIZED USES

- 6.7 IMPACT OF AI/GEN AI ON FURNITURE PLASTIC MARKET

- 6.7.1 TOP USE CASES AND MARKET POTENTIAL

- 6.7.2 BEST PRACTICES IN FURNITURE PLASTIC MANUFACTURING

- 6.7.3 CASE STUDIES OF AI IMPLEMENTATION IN FURNITURE PLASTIC MARKET

- 6.7.4 INTERCONNECTED ADJACENT ECOSYSTEM AND IMPACT ON MARKET PLAYERS

- 6.7.5 CLIENTS' READINESS TO ADOPT GENERATIVE AI IN FURNITURE PLASTIC MARKET

- 6.8 SUCCESS STORIES AND REAL-WORLD APPLICATIONS

- 6.8.1 KARTELL-AI-DESIGNED CHAIR ("A.I. CHAIR")

- 6.8.2 AI-DRIVEN PRODUCTION AND MATERIAL EFFICIENCY IN FURNITURE

- 6.8.3 AI-ASSISTED QUALITY AND PRODUCTION OPTIMIZATION

- 6.8.4 INDUSTRY-WIDE AI PRODUCTIVITY GAINS IN FURNITURE PRODUCTION

7 SUSTAINABILITY AND REGULATORY LANDSCAPE

- 7.1 REGIONAL REGULATIONS & COMPLIANCE

- 7.1.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 7.1.2 INDUSTRY STANDARDS

- 7.2 SUSTAINABILITY INITIATIVES

- 7.2.1 MATERIAL PERFORMANCE, ENVIRONMENT, AND SAFETY INITIATIVES

- 7.2.1.1 Carbon impact reduction and eco-material strategies

- 7.2.1.2 Eco applications

- 7.2.1 MATERIAL PERFORMANCE, ENVIRONMENT, AND SAFETY INITIATIVES

- 7.3 SUSTAINABILITY IMPACT & REGULATORY POLICY INITIATIVES

- 7.4 CERTIFICATIONS, LABELING, AND ECO-STANDARDS

8 CUSTOMER LANDSCAPE & BUYER BEHAVIOR

- 8.1 DECISION-MAKING PROCESS

- 8.2 BUYER STAKEHOLDERS & BUYING EVALUATION CRITERIA

- 8.2.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 8.2.2 BUYING CRITERIA

- 8.3 ADOPTION BARRIERS & INTERNAL CHALLENGES

- 8.4 UNMET NEEDS FROM VARIOUS END-USE INDUSTRIES

- 8.5 MARKET PROFITABILITY

- 8.5.1 REVENUE POTENTIAL

- 8.5.2 COST DYNAMICS

- 8.5.3 MARGIN OPPORTUNITIES BY END-USE INDUSTRY

9 FURNITURE PLASTIC MARKET, BY PLASTIC TYPE

- 9.1 INTRODUCTION

- 9.2 VIRGIN GRADE

- 9.2.1 POLYPROPYLENE

- 9.2.2 POLYCARBONATE

- 9.2.3 ACRYLONITRILE BUTADIENE STYRENE

- 9.2.4 POLYSTYRENE

- 9.2.5 POLYAMIDE

- 9.2.6 POLYMETHYL METHACRYLATE

- 9.2.7 OTHER VIRGIN-GRADE PLASTICS

- 9.3 COMPOUNDED GRADE

- 9.3.1 POLYCARBONATE

- 9.3.2 ACRYLONITRILE BUTADIENE STYRENE

- 9.3.3 OTHER COMPOUNDED-GRADE PLASTICS

10 FURNITURE PLASTIC MARKET, BY COMPOSITION

- 10.1 INTRODUCTION

- 10.2 UNFILLED

- 10.3 MINERAL FILLED

- 10.4 GLASS FIBER REINFORCED

- 10.5 OTHER COMPOSITIONS

11 FURNITURE PLASTIC MARKET, BY FURNITURE TYPE

- 11.1 INTRODUCTION

- 11.2 GARDEN FURNITURE

- 11.2.1 OUTDOOR CHAIRS & TABLES

- 11.2.2 OUTDOOR POTS & JARS

- 11.3 HOUSEHOLD FURNITURE

- 11.3.1 CLEANING & SERVICE TOOLS

- 11.3.2 DESIGN ACCESSORIES & HOOKS

- 11.3.3 KITCHEN TOOLS

- 11.3.4 POTS & JARS

- 11.4 INSTITUTIONAL FURNITURE

- 11.4.1 OFFICE CHAIRS & TABLES

- 11.4.2 SCHOOL, INSTITUTIONAL, AND STADIA SEATING

- 11.5 RESIDENTIAL FURNITURE

- 11.5.1 INDOOR CHAIRS & TABLES

- 11.5.2 OTHER RESIDENTIAL FURNITURE

12 FURNITURE PLASTIC MARKET, BY APPLICATION

- 12.1 INTRODUCTION

- 12.2 INDOOR

- 12.3 OUTDOOR

13 FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY

- 13.1 INTRODUCTION

- 13.2 RESIDENTIAL

- 13.3 COMMERCIAL

- 13.4 INSTITUTIONAL

14 FURNITURE PLASTIC MARKET, BY REGION

- 14.1 INTRODUCTION

- 14.2 NORTH AMERICA

- 14.2.1 US

- 14.2.1.1 Strong industrial base, regulatory oversight, and sustainability to drive furniture plastic demand

- 14.2.2 CANADA

- 14.2.2.1 Sustainability regulation, urban development, and manufacturing standards to support market growth

- 14.2.3 MEXICO

- 14.2.3.1 Urbanization, manufacturing strength, and sustainability policies to propel furniture plastic adoption

- 14.2.1 US

- 14.3 EUROPE

- 14.3.1 GERMANY

- 14.3.1.1 Focus on durability, industrial innovation, and circular design to positively influence furniture plastic demand

- 14.3.2 FRANCE

- 14.3.2.1 Sustainability-led lifestyles and design-driven consumption to reshape furniture plastic demand

- 14.3.3 UK

- 14.3.3.1 Sustainability-driven consumption, strong DIY culture, and durability needs to spur market demand

- 14.3.4 ITALY

- 14.3.4.1 Manufacturing strength, design-led innovation, and circular economy adoption to drive market

- 14.3.5 SPAIN

- 14.3.5.1 Urban living, hospitality demand, and sustainability initiatives to augment market growth

- 14.3.6 POLAND

- 14.3.6.1 Strong plastic compounding base and well-developed furniture manufacturing sector to fuel market demand

- 14.3.7 REST OF EUROPE

- 14.3.1 GERMANY

- 14.4 SOUTH AMERICA

- 14.4.1 BRAZIL

- 14.4.1.1 Urban growth and favorable government initiatives to drive demand for construction plastics

- 14.4.2 ARGENTINA

- 14.4.2.1 Local manufacturing recovery and public infrastructure to reshape Argentina furniture plastic market

- 14.4.3 REST OF SOUTH AMERICA

- 14.4.1 BRAZIL

- 14.5 ASIA PACIFIC

- 14.5.1 CHINA

- 14.5.1.1 Manufacturing scale, urban housing demand, and circular-economy policy to reinforce Chinese leadership

- 14.5.2 JAPAN

- 14.5.2.1 Demographic transition, compact living, and circular-economy policy to reshape market

- 14.5.3 INDIA

- 14.5.3.1 Urban expansion, affordability needs, and policy-led infrastructure development to accelerate market growth

- 14.5.4 SOUTH KOREA

- 14.5.4.1 Aging demographics, compact urban living, and circular economy policies to accelerate furniture plastic demand

- 14.5.5 REST OF ASIA PACIFIC

- 14.5.1 CHINA

- 14.6 MIDDLE EAST & AFRICA

- 14.6.1 GCC COUNTRIES

- 14.6.1.1 Kingdom of Saudi Arabia

- 14.6.1.1.1 Urban megaprojects, housing expansion, and climate resilience to drive market demand

- 14.6.1.2 UAE

- 14.6.1.2.1 Urban real estate expansion, sustainability mandates, and climate-adapted living to drive market demand

- 14.6.1.3 Rest of GCC Countries

- 14.6.1.4 South Africa

- 14.6.1.4.1 Urban housing demand, public infrastructure upgrades, and affordability pressures to favor market growth

- 14.6.1.1 Kingdom of Saudi Arabia

- 14.6.2 REST OF MIDDLE EAST & AFRICA

- 14.6.1 GCC COUNTRIES

15 COMPETITIVE LANDSCAPE

- 15.1 INTRODUCTION

- 15.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 15.3 REVENUE ANALYSIS, 2020-2024

- 15.4 MARKET SHARE ANALYSIS, 2024

- 15.5 PRODUCT COMPARISON

- 15.6 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 15.6.1 STARS

- 15.6.2 EMERGING LEADERS

- 15.6.3 PERVASIVE PLAYERS

- 15.6.4 PARTICIPANTS

- 15.6.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 15.6.5.1 Company footprint

- 15.6.5.2 Region footprint

- 15.6.5.3 Plastic type footprint

- 15.6.5.4 Composition footprint

- 15.6.5.5 Furniture type footprint

- 15.6.5.6 Application footprint

- 15.6.5.7 End-use industry footprint

- 15.7 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 15.7.1 PROGRESSIVE COMPANIES

- 15.7.2 RESPONSIVE COMPANIES

- 15.7.3 DYNAMIC COMPANIES

- 15.7.4 STARTING BLOCKS

- 15.7.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 15.7.5.1 Detailed list of key startups/SMEs

- 15.7.5.2 Competitive benchmarking of key startups/SMEs

- 15.8 COMPANY VALUATION & FINANCIAL METRICS

- 15.8.1 FINANCIAL METRICS

- 15.8.2 COMPANY VALUATION

- 15.8.3 ENTERPRISE VALUATION

- 15.9 COMPETITIVE SCENARIO

- 15.9.1 PRODUCT LAUNCHES

- 15.9.2 DEALS

- 15.9.3 EXPANSIONS

16 COMPANY PROFILES

- 16.1 KEY PLAYERS

- 16.1.1 KETER GROUP

- 16.1.1.1 Business overview

- 16.1.1.2 Products/Solutions/Services offered

- 16.1.1.3 MnM view

- 16.1.1.3.1 Right to win

- 16.1.1.3.2 Strategic choices

- 16.1.1.3.3 Weaknesses & competitive threats

- 16.1.2 NILKAMAL

- 16.1.2.1 Business overview

- 16.1.2.2 Products/Solutions/Services offered

- 16.1.2.3 Recent developments

- 16.1.2.3.1 Expansions

- 16.1.2.4 MnM view

- 16.1.2.4.1 Right to win

- 16.1.2.4.2 Strategic choices

- 16.1.2.4.3 Weaknesses & competitive threats

- 16.1.3 THE SUPREME INDUSTRIES LIMITED

- 16.1.3.1 Business overview

- 16.1.3.2 Products/Solutions/Services offered

- 16.1.3.3 MnM view

- 16.1.3.3.1 Right to win

- 16.1.3.3.2 Strategic choices

- 16.1.3.3.3 Weaknesses & competitive threats

- 16.1.4 TRAMONTINA

- 16.1.4.1 Business overview

- 16.1.4.2 Products/Solutions/Services offered

- 16.1.4.3 Recent developments

- 16.1.4.4 MnM view

- 16.1.4.4.1 Right to win

- 16.1.4.4.2 Strategic choices

- 16.1.4.4.3 Weaknesses & competitive threats

- 16.1.5 CELLO

- 16.1.5.1 Business overview

- 16.1.5.2 Products/Solutions/Services offered

- 16.1.5.3 MnM view

- 16.1.5.3.1 Right to win

- 16.1.5.3.2 Strategic choices

- 16.1.5.3.3 Weaknesses & competitive threats

- 16.1.6 INTER IKEA SYSTEMS B.V.

- 16.1.6.1 Business overview

- 16.1.6.2 Products/Solutions/Services offered

- 16.1.6.3 MnM view

- 16.1.7 MILLERKNOLL, INC.

- 16.1.7.1 Business overview

- 16.1.7.2 Products/Solutions/Services offered

- 16.1.7.3 Recent developments

- 16.1.7.3.1 Product launches

- 16.1.7.3.2 Deals

- 16.1.7.3.3 Expansions

- 16.1.7.4 MnM view

- 16.1.8 GROSFILLEX

- 16.1.8.1 Business overview

- 16.1.8.2 Products/Solutions/Services offered

- 16.1.8.3 MnM view

- 16.1.9 POLY-WOOD, LLC

- 16.1.9.1 Business overview

- 16.1.9.2 Products/Solutions/Services offered

- 16.1.9.3 MnM view

- 16.1.10 NARDI S.P.A.

- 16.1.10.1 Business overview

- 16.1.10.2 Products/Solutions/Services offered

- 16.1.10.3 MnM view

- 16.1.11 HARWAL GROUP OF COMPANIES

- 16.1.11.1 Business overview

- 16.1.11.2 Products/Solutions/Services offered

- 16.1.11.3 MnM view

- 16.1.1 KETER GROUP

- 16.2 OTHER PLAYERS

- 16.2.1 PRIMA PLASTICS

- 16.2.2 VONDOM

- 16.2.3 SOTUFAB PLAST.

- 16.2.4 OTOBI

- 16.2.5 MODERN INDUSTRIES

- 16.2.6 GRACIOUS LIVING

- 16.2.7 METE PLASTIK

- 16.2.8 KAYALAR MUTFAK

- 16.2.9 C.R. PLASTIC PRODUCTS

- 16.2.10 KARTELL S.P.A.

- 16.2.11 KING OF PLASTIC

- 16.2.12 RESOL

- 16.2.13 GRUPO DUNA SA DE CV

- 16.2.14 MARMAX RECYCLED PLASTIC PRODUCTS

17 RESEARCH METHODOLOGY

- 17.1 RESEARCH DATA

- 17.1.1 SECONDARY DATA

- 17.1.1.1 Key data from secondary sources

- 17.1.2 PRIMARY DATA

- 17.1.2.1 Key data from primary sources

- 17.1.2.2 Key industry insights

- 17.1.2.3 Breakdown of primary interviews

- 17.1.1 SECONDARY DATA

- 17.2 MARKET SIZE ESTIMATION

- 17.2.1 BOTTOM-UP APPROACH

- 17.2.2 TOP-DOWN APPROACH

- 17.3 DATA TRIANGULATION

- 17.4 STUDY ASSUMPTIONS

- 17.5 RESEARCH LIMITATIONS

18 APPENDIX

- 18.1 DISCUSSION GUIDE

- 18.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 18.3 CUSTOMIZATION OPTIONS

- 18.4 RELATED REPORTS

- 18.5 AUTHOR DETAILS

List of Tables

- TABLE 1 FURNITURE PLASTIC MARKET: INCLUSIONS & EXCLUSIONS

- TABLE 3 MONTHLY NEW RESIDENTIAL CONSTRUCTION AS OF SEPTEMBER 2025

- TABLE 4 INTERCONNECTED MARKETS AND CROSS-SECTOR OPPORTUNITIES IN FURNITURE PLASTIC MARKET

- TABLE 5 FURNITURE PLASTIC MARKET: PORTER'S FIVE FORCES

- TABLE 6 GLOBAL GDP GROWTH PROJECTION, BY REGION, 2021-2028 (USD TRILLION)

- TABLE 7 ROLES OF COMPANIES IN FURNITURE PLASTIC ECOSYSTEM

- TABLE 8 AVERAGE SELLING PRICE OF FURNITURE PLASTICS, BY END-USE INDUSTRY, 2024 (USD/KG)

- TABLE 9 AVERAGE SELLING PRICE TREND OF FURNITURE PLASTICS, BY REGION, 2022-2024 (USD/KG)

- TABLE 10 EXPORT DATA FOR HS CODE 940370, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 11 IMPORT DATA FOR HS CODE 940370, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 12 LIST OF MAJOR CONFERENCES AND EVENTS IN FURNITURE PLASTIC MARKET, JANUARY 2025-DECEMBER 2026

- TABLE 13 CASE STUDY 1: EMECO & THE COCA-COLA COMPANY (111 NAVY CHAIR - RECYCLED PET FURNITURE)

- TABLE 14 CASE STUDY 2: BASF & EMECO (PETRA THERMOPLASTIC POLYESTER FOR SUSTAINABLE CHAIRS)

- TABLE 15 CASE STUDY 3: GLOBAL FURNITURE TRENDS (VITRA, KARTELL, HERMAN MILLER - RECYCLED PP/PE FURNITURE)

- TABLE 16 LIST OF KEY PATENTS IN FURNITURE PLASTIC MARKET, 2022-2024

- TABLE 17 TOP USE CASES AND MARKET POTENTIAL IN FURNITURE PLASTIC MARKET

- TABLE 18 BEST PRACTICES FOR COMPANIES IMPLEMENTING USE CASES

- TABLE 19 FURNITURE PLASTIC MARKET: CASE STUDIES RELATED TO GEN AI IMPLEMENTATION

- TABLE 20 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 21 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 22 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 23 MIDDLE EAST & AFRICA: REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 24 SOUTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, INDUSTRY ASSOCIATIONS, AND OTHER ORGANIZATIONS

- TABLE 25 GLOBAL INDUSTRY STANDARDS IN FURNITURE PLASTIC MARKET

- TABLE 26 CERTIFICATIONS, LABELING, AND ECO-STANDARDS IN FURNITURE PLASTIC MARKET

- TABLE 27 INFLUENCE OF KEY STAKEHOLDERS ON BUYING PROCESS, BY END-USE INDUSTRY (%)

- TABLE 28 KEY BUYING CRITERIA, BY END-USE INDUSTRY

- TABLE 29 UNMET NEEDS IN FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY

- TABLE 30 FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (USD MILLION)

- TABLE 31 FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (USD MILLION)

- TABLE 32 FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (KILOTON)

- TABLE 33 FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (KILOTON)

- TABLE 34 FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (USD MILLION)

- TABLE 35 FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (USD MILLION)

- TABLE 36 FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (KILOTON)

- TABLE 37 FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (KILOTON)

- TABLE 38 FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (USD MILLION)

- TABLE 39 FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (USD MILLION)

- TABLE 40 FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (KILOTON)

- TABLE 41 FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (KILOTON)

- TABLE 42 FURNITURE PLASTIC MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 43 FURNITURE PLASTIC MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 44 FURNITURE PLASTIC MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 45 FURNITURE PLASTIC MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 46 FURNITURE PLASTIC MARKET SIZE, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 47 FURNITURE PLASTIC MARKET SIZE, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 48 FURNITURE PLASTIC MARKET SIZE, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 49 FURNITURE PLASTIC MARKET SIZE, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 50 FURNITURE PLASTIC MARKET, BY REGION, 2022-2024 (USD MILLION)

- TABLE 51 FURNITURE PLASTIC MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 52 FURNITURE PLASTIC MARKET, BY REGION, 2022-2024 (KILOTONS)

- TABLE 53 FURNITURE PLASTIC MARKET, BY REGION, 2025-2030 (KILOTONS)

- TABLE 54 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 55 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 56 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 57 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 58 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (USD MILLION)

- TABLE 59 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (USD MILLION)

- TABLE 60 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (KILOTON)

- TABLE 61 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (KILOTON)

- TABLE 62 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (USD MILLION)

- TABLE 63 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (USD MILLION)

- TABLE 64 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (KILOTON)

- TABLE 65 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (KILOTON)

- TABLE 66 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (USD MILLION)

- TABLE 67 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (USD MILLION)

- TABLE 68 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (KILOTON)

- TABLE 69 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (KILOTON)

- TABLE 70 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 71 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 72 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 73 NORTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 74 US: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 75 US: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 76 US: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 77 US: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 78 CANADA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 79 CANADA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 80 CANADA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 81 CANADA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 82 MEXICO: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 83 MEXICO: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 84 MEXICO: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 85 MEXICO: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 86 EUROPE: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 87 EUROPE: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 88 EUROPE: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (KILOTONS)

- TABLE 89 EUROPE: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (KILOTONS)

- TABLE 90 EUROPE: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (USD MILLION)

- TABLE 91 EUROPE: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (USD MILLION)

- TABLE 92 EUROPE: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (KILOTON)

- TABLE 93 EUROPE: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (KILOTON)

- TABLE 94 EUROPE: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (USD MILLION)

- TABLE 95 EUROPE: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (USD MILLION)

- TABLE 96 EUROPE: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (KILOTON)

- TABLE 97 EUROPE: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (KILOTON)

- TABLE 98 EUROPE: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (USD MILLION)

- TABLE 99 EUROPE: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (USD MILLION)

- TABLE 100 EUROPE: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (KILOTON)

- TABLE 101 EUROPE: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (KILOTON)

- TABLE 102 EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 103 EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 104 EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 105 EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 106 GERMANY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 107 GERMANY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 108 GERMANY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 109 GERMANY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 110 FRANCE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 111 FRANCE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 112 FRANCE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 113 FRANCE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 114 UK: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 115 UK: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 116 UK: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 117 UK: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 118 ITALY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 119 ITALY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 120 ITALY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 121 ITALY: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 122 SPAIN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 123 SPAIN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 124 SPAIN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 125 SPAIN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 126 POLAND: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 127 POLAND: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 128 POLAND: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 129 POLAND: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 130 REST OF EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 131 REST OF EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 132 REST OF EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 133 REST OF EUROPE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 134 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 135 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 136 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (KILOTONS)

- TABLE 137 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (KILOTONS)

- TABLE 138 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (USD MILLION)

- TABLE 139 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (USD MILLION)

- TABLE 140 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (KILOTON)

- TABLE 141 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (KILOTON)

- TABLE 142 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (USD MILLION)

- TABLE 143 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (USD MILLION)

- TABLE 144 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (KILOTON)

- TABLE 145 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (KILOTON)

- TABLE 146 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (USD MILLION)

- TABLE 147 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (USD MILLION)

- TABLE 148 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (KILOTON)

- TABLE 149 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (KILOTON)

- TABLE 150 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 151 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 152 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 153 SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 154 BRAZIL: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 155 BRAZIL: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 156 BRAZIL: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 157 BRAZIL: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 158 ARGENTINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 159 ARGENTINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 160 ARGENTINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 161 ARGENTINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 162 REST OF SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 163 REST OF SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 164 REST OF SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 165 REST OF SOUTH AMERICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 166 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 167 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 168 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (KILOTONS)

- TABLE 169 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (KILOTONS)

- TABLE 170 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (USD MILLION)

- TABLE 171 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (USD MILLION)

- TABLE 172 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (KILOTON)

- TABLE 173 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (KILOTON)

- TABLE 174 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (USD MILLION)

- TABLE 175 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (USD MILLION)

- TABLE 176 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (KILOTON)

- TABLE 177 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (KILOTON)

- TABLE 178 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (USD MILLION)

- TABLE 179 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (USD MILLION)

- TABLE 180 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (KILOTON)

- TABLE 181 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (KILOTON)

- TABLE 182 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 183 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 184 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 185 ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 186 CHINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 187 CHINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 188 CHINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 189 CHINA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 190 JAPAN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 191 JAPAN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 192 JAPAN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 193 JAPAN: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 194 INDIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 195 INDIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 196 INDIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 197 INDIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 198 SOUTH KOREA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 199 SOUTH KOREA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 200 SOUTH KOREA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 201 SOUTH KOREA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 202 REST OF ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 203 REST OF ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 204 REST OF ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 205 REST OF ASIA PACIFIC: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 206 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 207 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 208 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2022-2024 (KILOTONS)

- TABLE 209 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COUNTRY, 2025-2030 (KILOTONS)

- TABLE 210 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (USD MILLION)

- TABLE 211 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (USD MILLION)

- TABLE 212 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2022-2024 (KILOTON)

- TABLE 213 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY PLASTIC TYPE, 2025-2030 (KILOTON)

- TABLE 214 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (USD MILLION)

- TABLE 215 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (USD MILLION)

- TABLE 216 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2022-2024 (KILOTON)

- TABLE 217 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY COMPOSITION, 2025-2030 (KILOTON)

- TABLE 218 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (USD MILLION)

- TABLE 219 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (USD MILLION)

- TABLE 220 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2022-2024 (KILOTON)

- TABLE 221 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY FURNITURE TYPE, 2025-2030 (KILOTON)

- TABLE 222 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 223 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 224 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 225 MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 226 GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 227 GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 228 GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 229 GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 230 KINGDOM OF SAUDI ARABIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 231 KINGDOM OF SAUDI ARABIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 232 KINGDOM OF SAUDI ARABIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 233 KINGDOM OF SAUDI ARABIA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 234 UAE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 235 UAE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 236 UAE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 237 UAE: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 238 REST OF GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 239 REST OF GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 240 REST OF GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 241 REST OF GCC COUNTRIES: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 242 SOUTH AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 243 SOUTH AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 244 SOUTH AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 245 SOUTH AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 246 REST OF MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 247 REST OF MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 248 REST OF MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTONS)

- TABLE 249 REST OF MIDDLE EAST & AFRICA: FURNITURE PLASTIC MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTONS)

- TABLE 250 KEY STRATEGIES ADOPTED BY MAJOR PLAYERS IN FURNITURE PLASTIC MARKET

- TABLE 251 FURNITURE PLASTIC MARKET: DEGREE OF COMPETITION, 2024

- TABLE 252 FURNITURE PLASTIC MARKET: REGION FOOTPRINT

- TABLE 253 FURNITURE PLASTIC MARKET: PLASTIC TYPE FOOTPRINT

- TABLE 254 FURNITURE PLASTIC MARKET: COMPOSITION FOOTPRINT

- TABLE 255 FURNITURE PLASTIC MARKET: FURNITURE TYPE FOOTPRINT

- TABLE 256 FURNITURE PLASTIC MARKET: APPLICATION FOOTPRINT

- TABLE 257 FURNITURE PLASTIC MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 258 FURNITURE PLASTIC MARKET: DETAILED LIST OF KEY STARTUPS/SME PLAYERS

- TABLE 259 FURNITURE PLASTIC MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SME PLAYERS, BY PLASTIC TYPE, COMPOSITION, AND END-USE INDUSTRY

- TABLE 260 FURNITURE PLASTIC MARKET: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SME PLAYERS, BY FURNITURE TYPE AND REGION

- TABLE 261 FURNITURE PLASTIC MARKET: PRODUCT LAUNCHES, JANUARY 2020-DECEMBER 2025

- TABLE 262 FURNITURE PLASTIC MARKET: DEALS, JANUARY 2020-DECEMBER 2025

- TABLE 263 FURNITURE PLASTIC MARKET: EXPANSIONS, JANUARY 2020-DECEMBER 2025

- TABLE 264 KETER GROUP: COMPANY OVERVIEW

- TABLE 265 KETER GROUP: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 266 NILKAMAL: COMPANY OVERVIEW

- TABLE 267 NILKAMAL: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 268 NILKAMAL: EXPANSIONS, JANUARY 2020-DECEMBER 2025

- TABLE 269 THE SUPREME INDUSTRIES LIMITED: COMPANY OVERVIEW

- TABLE 270 THE SUPREME INDUSTRIES LIMITED: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 271 TRAMONTINA: COMPANY OVERVIEW

- TABLE 272 TRAMONTINA: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 274 CELLO: COMPANY OVERVIEW

- TABLE 275 CELLO: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 276 INTER IKEA SYSTEMS B.V.: COMPANY OVERVIEW

- TABLE 277 INTER IKEA SYSTEMS B.V.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 278 MILLERKNOLL, INC.: COMPANY OVERVIEW

- TABLE 279 MILLERKNOLL, INC.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 280 MILLERKNOLL, INC.: PRODUCT LAUNCHES, JANUARY 2020-DECEMBER 2025

- TABLE 281 MILLERKNOLL, INC.: DEALS, JANUARY 2020-DECEMBER 2025

- TABLE 282 MILLERKNOLL, INC.: EXPANSIONS, JANUARY 2020-DECEMBER 2025

- TABLE 283 GROSFILLEX: COMPANY OVERVIEW

- TABLE 284 GROSFILLEX: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 285 POLY-WOOD, LLC: COMPANY OVERVIEW

- TABLE 286 POLY-WOOD, LLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 287 NARDI S.P.A.: COMPANY OVERVIEW

- TABLE 288 NARDI S.P.A.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 289 HARWAL GROUP OF COMPANIES: COMPANY OVERVIEW

- TABLE 290 HARWAL GROUP OF COMPANIES: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 291 PRIMA PLASTICS: COMPANY OVERVIEW

- TABLE 292 VONDOM: COMPANY OVERVIEW

- TABLE 293 SOTUFAB PLAST.: COMPANY OVERVIEW

- TABLE 294 OTOBI: COMPANY OVERVIEW

- TABLE 295 MODERN INDUSTRIES: COMPANY OVERVIEW

- TABLE 296 GRACIOUS LIVING: COMPANY OVERVIEW

- TABLE 297 METE PLASTIK: COMPANY OVERVIEW

- TABLE 298 KAYALAR MUTFAK: COMPANY OVERVIEW

- TABLE 299 C.R. PLASTIC PRODUCTS: COMPANY OVERVIEW

- TABLE 300 KARTELL S.P.A.: COMPANY OVERVIEW

- TABLE 301 KING OF PLASTIC: COMPANY OVERVIEW

- TABLE 302 RESOL: COMPANY OVERVIEW

- TABLE 303 GRUPO DUNA SA DE CV: COMPANY OVERVIEW

- TABLE 304 MARMAX RECYCLED PLASTIC PRODUCTS: COMPANY OVERVIEW

List of Figures

- FIGURE 1 FURNITURE PLASTIC MARKET SEGMENTATION & REGIONAL SCOPE

- FIGURE 2 FURNITURE PLASTIC MARKET: YEARS CONSIDERED

- FIGURE 3 KEY INSIGHTS AND MARKET HIGHLIGHTS

- FIGURE 4 FURNITURE PLASTIC MARKET SIZE, 2022-2030 (USD MILLION)

- FIGURE 5 MAJOR STRATEGIES ADOPTED BY KEY PLAYERS IN FURNITURE PLASTIC MARKET (2020-2025)

- FIGURE 6 DISRUPTIVE TRENDS IMPACTING GROWTH OF FURNITURE PLASTIC MARKET DURING FORECAST PERIOD

- FIGURE 7 HIGH-GROWTH SEGMENTS & EMERGING FRONTIERS IN FURNITURE PLASTIC MARKET, 2025-2030

- FIGURE 8 ASIA PACIFIC TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 9 FURNITURE PLASTIC IN RESIDENTIAL AND COMMERCIAL SETTINGS TO CREATE LUCRATIVE OPPORTUNITIES FOR MARKET PLAYERS

- FIGURE 10 VIRGIN GRADE AND CHINA COMMANDED LARGEST MARKET SHARES IN 2024

- FIGURE 11 UNFILLED COMPOSITION COMMANDED LARGEST MARKET SHARE IN 2024

- FIGURE 12 RESIDENTIAL TO ACCOUNT FOR LARGEST SHARE IN FURNITURE PLASTIC END-USE INDUSTRY MARKET IN 2024

- FIGURE 13 INDOOR SEGMENT DOMINATED FURNITURE PLASTIC MARKET IN 2024

- FIGURE 14 RESIDENTIAL FURNITURE TO ACCOUNT FOR LARGEST MARKET SHARE IN 2024

- FIGURE 15 INDIA TO REGISTER HIGHEST CAGR DURING STUDY PERIOD

- FIGURE 16 FURNITURE PLASTIC MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 2 FURNITURE PLASTIC MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 3 FURNITURE PLASTIC MARKET: VALUE CHAIN ANALYSIS

- FIGURE 4 FURNITURE PLASTIC MARKET: ECOSYSTEM ANALYSIS

- FIGURE 5 AVERAGE SELLING PRICE OF FURNITURE PLASTICS, BY END-USE INDUSTRY, 2024 (USD/KG)

- FIGURE 6 AVERAGE SELLING PRICE TREND OF FURNITURE PLASTICS, BY REGION, 2022-2024 (USD/KG)

- FIGURE 7 EXPORT DATA FOR HS CODE 940370, BY COUNTRY, 2020-2024 (USD MILLION)

- FIGURE 8 IMPORT DATA FOR HS CODE 940370, BY COUNTRY, 2020-2024 (USD MILLION)

- FIGURE 9 TRENDS/DISRUPTIONS IMPACTING CUSTOMER'S BUSINESS IN FURNITURE PLASTIC MARKET

- FIGURE 10 FUNDING AND NUMBER OF DEALS IN FURNITURE PLASTIC MARKET, 2018-2024 (USD MILLION)

- FIGURE 11 LIST OF MAJOR PATENTS FOR FURNITURE PLASTIC, 2015-2024

- FIGURE 12 MAJOR PATENTS APPLIED AND GRANTED RELATED TO FURNITURE PLASTIC, BY COUNTRY/REGION, 2015-2024

- FIGURE 14 INFLUENCE OF KEY STAKEHOLDERS ON BUYING PROCESS, BY END-USE INDUSTRY

- FIGURE 15 KEY BUYING CRITERIA, BY END-USE INDUSTRY

- FIGURE 17 VIRGIN GRADE TO LEAD FURNITURE PLASTIC MARKET DURING STUDY PERIOD

- FIGURE 18 UNFILLED COMPOSITION ACCOUNTED FOR LARGEST MARKET SHARE IN 2025

- FIGURE 19 INSTITUTIONAL FURNITURE TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 20 OUTDOOR SEGMENT TO REGISTER HIGHER CAGR DURING STUDY PERIOD

- FIGURE 21 INSTITUTIONAL TO BE LEADING END-USE INDUSTRY OF FURNITURE PLASTIC MARKET FROM 2025 TO 2030

- FIGURE 22 INDIA TO BE FASTEST-GROWING MARKET FOR FURNITURE PLASTIC DURING FORECAST PERIOD

- FIGURE 23 NORTH AMERICA: FURNITURE PLASTIC MARKET SNAPSHOT

- FIGURE 24 EUROPE: FURNITURE PLASTIC MARKET SNAPSHOT

- FIGURE 25 ASIA PACIFIC: FURNITURE PLASTIC MARKET SNAPSHOT

- FIGURE 26 REVENUE ANALYSIS OF KEY PLAYERS IN FURNITURE PLASTIC MARKET, 2020-2024 (USD BILLION)

- FIGURE 27 FURNITURE PLASTIC MARKET SHARE ANALYSIS, 2024

- FIGURE 28 FURNITURE PLASTIC MARKET: PRODUCT COMPARATIVE ANALYSIS

- FIGURE 29 FURNITURE PLASTIC MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 30 FURNITURE PLASTIC MARKET: COMPANY FOOTPRINT

- FIGURE 31 FURNITURE PLASTIC MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 32 EV/EBITDA OF KEY MANUFACTURERS IN FURNITURE PLASTIC MARKET

- FIGURE 33 YEAR-TO-DATE (YTD) PRICE TOTAL RETURN AND 5-YEAR STOCK BETA OF KEY MANUFACTURERS IN FURNITURE PLASTIC MARKET

- FIGURE 34 ENTERPRISE VALUATION OF KEY PLAYERS IN FURNITURE PLASTIC MARKET (2025)

- FIGURE 35 KETER GROUP: COMPANY SNAPSHOT

- FIGURE 36 NILKAMAL: COMPANY SNAPSHOT

- FIGURE 37 THE SUPREME INDUSTRIES LIMITED: COMPANY SNAPSHOT

- FIGURE 38 TRAMONTINA: COMPANY SNAPSHOT

- FIGURE 39 CELLO: COMPANY SNAPSHOT

- FIGURE 40 INTER IKEA SYSTEMS B.V.: COMPANY SNAPSHOT

- FIGURE 41 MILLERKNOLL, INC.: COMPANY SNAPSHOT

- FIGURE 42 HARWAL GROUP OF COMPANIES: COMPANY SNAPSHOT

- FIGURE 43 FURNITURE PLASTIC MARKET: RESEARCH DESIGN

- FIGURE 44 KEY DATA FROM SECONDARY SOURCES IN FURNITURE PLASTIC MARKET

- FIGURE 45 KEY DATA FROM PRIMARY SOURCES IN FURNITURE PLASTIC MARKET

- FIGURE 46 KEY INSIGHTS FROM PRIMARY EXPERTS IN FURNITURE PLASTIC MARKET

- FIGURE 47 BREAKDOWN OF PRIMARY INTERVIEWS, BY COMPANY TYPE, DESIGNATION, AND REGION

- FIGURE 48 FURNITURE PLASTIC MARKET: BOTTOM-UP APPROACH

- FIGURE 49 FURNITURE PLASTIC MARKET: TOP-DOWN APPROACH

- FIGURE 50 FURNITURE PLASTIC MARKET: DATA TRIANGULATION

- FIGURE 51 FURNITURE PLASTIC MARKET: STUDY ASSUMPTIONS

- FIGURE 52 FURNITURE PLASTIC MARKET: RESEARCH LIMITATIONS