PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1936066

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1936066

Push-Pull Control Cables Market by Product type (Throttle, Gear Shift, Clutch, Parking Brake, Others), Industry (Automotive, Construction, Agriculture, Railway, Marine, Others), Cable Type, Application, Propulsion, and Region - Global forecast to 2032

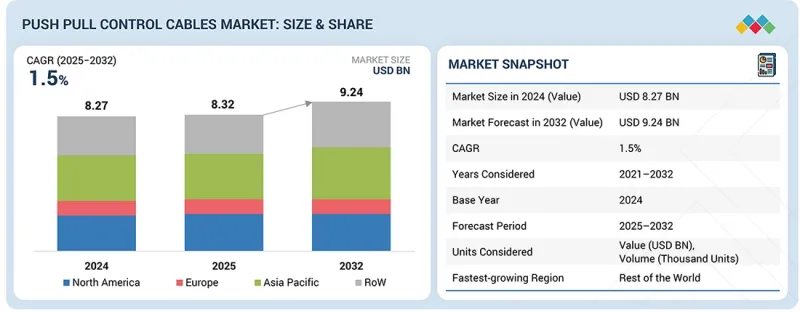

The push-pull control cables market is projected to grow from USD 8.32 billion in 2025 to reach USD 9.24 billion by 2032, at a CAGR of 1.5%.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Units Considered | Volume (Thousand Units) and Value (USD Million) |

| Segments | Product, Application, Cable Type, Vehicle Type, Industry |

| Regions covered | Asia Pacific, North America, Europe, and the Rest of the World (RoW) |

The growth of the market is driven by the increasing production of light, commercial, and electric vehicles, along with the rising demand for affordable and long-lasting actuation systems. Vehicle functions, such as throttle, clutch, brake, HVAC, and transmission, require reliable mechanical controls, which is also driving the global market for push-pull control cables.

Asia Pacific is projected to be the fastest-growing market for push-pull control cables, driven by their rising demand in China, South Korea, and Japan, where high vehicle production and expanding EV manufacturing require substantial push-pull control cables. Additionally, push-pull control cables are experiencing an increasing demand in the region due to their adoption in marine, railway, agricultural, and construction equipment, where they are required for precise, durable, and easily serviceable operation in demanding working conditions.

"By industry, the automotive segment is projected to account for the largest market during the forecast period."

The automotive segment is projected to be the largest market during the forecast period, due to the increasing use of push-pull control cables in passenger cars, light commercial vehicles, and heavy commercial vehicles. This growth can also be attributed to the rising adoption of mechanical cables in emerging markets for reliable and cost-effective actuation. Mechanical actuation cables are widely used in cruise control and adaptive cruise control (ACC) systems deployed in mid- to high-end passenger vehicles, for their cost efficiency, compact routing, and reliability. Additionally, the shift toward double-zone and multi-zone HVAC systems is generating incremental demand for HVAC control cables, enabling the precise actuation of blend doors and air distribution flaps. In electric vehicles, mechanical cables remain relevant across parking brake, HVAC, body, and thermal management applications. Moreover, core automotive applications continue to rely on mechanical actuation, alongside newer growth areas, such as cruise control and advanced HVAC systems. All these factors are driving the demand for push-pull control cables in the automotive segment.

"By product, the gear shift cable segment is estimated to be the second-largest segment in 2025."

The gear shift cables segment is estimated to be the second-largest segment in 2025, owing to their critical role in manual and AMT transmissions, particularly in emerging markets, such as Asian countries. Mechanical cables are cost-effective and preferred over electronic shifters because of their robustness, reliability, and ease of repair in high-vibration and harsh operating conditions. The push-pull designs enable precise force transmission, flexible routing, and minimal backlash, improving shift feel for drivers. Also, their lower lifecycle cost makes them especially attractive for low- to mid-segment vehicles where affordability and durability are critical.

Shift selector cables have limited but strategic penetration in electric cars. While most EVs use fully electronic shift-by-wire systems, some hybrid and mild-hybrid EVs retain manual or AMT-style gearboxes for cost efficiency and operational reliability. Moreover, these cables are generally more expensive than standard push-pull control cables due to their precision engineering, high-quality materials, complex routing, and stricter durability standards.

Within off-highway vehicles, construction and mining equipment is a significant market for gear shift cables, due to the rising production of excavators, loaders, dozers, and articulated dump trucks. These cables support transmission range selection and forward-neutral-reverse actuation, delivering reliable mechanical force transfer in dusty, high-shock, and high-temperature conditions. Additionally, mechanical cable-based systems remain the preferred choice due to their safety, predictable response, and low reliance on electronics in heavy-duty operations. Moreover, continued infrastructure spending, mining expansion, and more complex transmissions are expected to drive sustained demand for push-pull control cables.

"North America is projected to be the second-largest market during the forecast period."

North America is projected to be the second-largest market for push-pull control cables during the forecast period. The growth of this regional market is driven by growth in the automotive, construction, railway, marine, and agricultural industries. The growth is propelling the adoption of push-pull control cables in throttle, transmission, clutch, parking brake, and HVAC applications across ICE, hybrid, and cost-oriented EV vehicles. The growth of this regional market is also driven by sustained production of pick-up trucks, SUVs, and heavy commercial vehicles that continue to use cost-efficient, validated mechanical and hybrid actuation, alongside infrastructure-led construction activity, railway fleet upgrades, and steady demand for marine and agricultural equipment.

In North America, construction and off-highway systems are also generating a stable demand for high-load push-pull and pull-only cables used in excavators, loaders, and lifting machinery. Likewise, railway applications rely on mechanical cables for brake actuation, door control, and auxiliary systems that require low backlash and long service life. Similarly, marine and agricultural equipment require corrosion-resistant, long-stroke cables designed to operate in environments exposed to moisture, dust, and vibration. All these factors are driving growth in North America. Major players in the North America push-pull control cables market include Orscheln Products, Cablecraft, Grand Rapids Controls, Bergen Cable Technology, Conwire, and American Cable & Harness.

In-depth interviews were conducted with CEOs, marketing directors, other innovation and strategy directors, and executives from various key organizations operating in the push-pull control cables market.

- By Company Type: Push-pull Control Cable Manufacturers - 54%, OEMs - 38%, and Others - 8%

- By Designation: C-Level - 30%, Directors - 35%, and Other Designations - 35%

- By Region: Asia Pacific - 55%, Europe - 15%, North America - 20%, and Europe - 10%

Research Coverage

The study segments the push-pull control cables market based on Product (Throttle Cable, Gear Shift Cable, Clutch Cable, Parking Brake Cable, Hood Release Cable, Fuel Door Release Cable, Trunk Release Cable, Door Latch Cable, Spare Wheel Carrier Cable, Seat Recline Release Cable), Cable Type (Push Pull Cable, Pull-only Cable), Application (Engine Cable, Transmission Cable, Brake Cable, Auxiliary Cable), Vehicle Type (Passenger Car, Light Commercial Vehicle, Heavy Commercial Vehicle), Industry (Automotive, Marine, Construction, Agriculture, Railways, Others), and Region (Asia Pacific, North America, Europe, Rest of the World).

The study includes an in-depth competitive analysis of the significant mechanical control cable manufacturers, their company profiles, key observations related to product and business offerings, recent developments, and key market strategies.

Key Benefits of Buying the Report:

- The report will help market leaders/new entrants with information on the closest approximations of revenue numbers for the overall push-pull control cables market and its subsegments.

- This report will help stakeholders understand the competitive landscape and gain more insights to position their businesses better and plan suitable go-to-market strategies.

- The report will also help stakeholders understand the market pulse and provide information on key market drivers, restraints, challenges, and opportunities.

The report provides insight into the following pointers:

- Analysis of key drivers (Growth in construction and agriculture equipment with heavy-duty control cables, push toward compact packaging across marine, automotive, and industrial OEMs), restraints (Increasing autonomy across industries driving e-actuation systems), opportunities (Expansion in EV auxiliary functions, growth in marine craft manufacturing), and challenges (Durability and performance stability under severe conditions)

- Product Development/Innovation: Detailed insights into upcoming technologies and research & development activities in the push-pull control cables market

- Market Development: Comprehensive information about lucrative markets across varied regions

- Market Diversification: Exhaustive information about untapped geographies, recent developments, and investments in the push-pull control cables market

- Competitive Assessment: In-depth assessment of market share, growth strategies, and product offerings of leading players, such as HI-LEX Corporation (Japan), Suprajit (India), Orscheln Products (US), Kongsberg Automotive (Norway), and Carl Stahl Technocables GmbH (Germany), in the push-pull control cables market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKET SEGMENTATION & REGIONAL SCOPE

- 1.3.2 INCLUSIONS & EXCLUSIONS

- 1.4 YEARS CONSIDERED

- 1.5 CURRENCY CONSIDERED

- 1.6 UNIT CONSIDERED

- 1.7 STAKEHOLDERS

2 EXECUTIVE SUMMARY

- 2.1 KEY INSIGHTS & MARKET HIGHLIGHTS

- 2.2 KEY MARKET PARTICIPANTS: MAPPING OF STRATEGIC DEVELOPMENTS

- 2.3 DISRUPTIVE TRENDS IN PUSH-PULL CONTROL CABLES MARKET

- 2.4 HIGH-GROWTH SEGMENTS

- 2.5 REGIONAL SNAPSHOT: MARKET SIZE, GROWTH RATE, AND FORECAST

3 PREMIUM INSIGHTS

- 3.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN PUSH-PULL CONTROL CABLES MARKET

- 3.2 PUSH-PULL CONTROL CABLES MARKET, BY INDUSTRY

- 3.3 PUSH-PULL CONTROL CABLES MARKET, BY CABLE TYPE

- 3.4 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE

- 3.5 PUSH-PULL CONTROL CABLES MARKET , BY APPLICATION

- 3.6 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE

- 3.7 PUSH-PULL CONTROL CABLES MARKET, BY REGION

4 MARKET OVERVIEW

- 4.1 INTRODUCTION

- 4.2 MARKET DYNAMICS

- 4.2.1 DRIVERS

- 4.2.1.1 Growing adoption of construction and agricultural equipment

- 4.2.1.2 Push toward compact packaging across marine, automotive, and industrial OEMs

- 4.2.2 RESTRAINTS

- 4.2.2.1 Increasing autonomy across industries

- 4.2.3 OPPORTUNITY

- 4.2.3.1 Expansion in EV auxiliary functions

- 4.2.3.2 Growth in marine craft manufacturing

- 4.2.4 CHALLENGES

- 4.2.4.1 Durability and performance stability under severe operating conditions

- 4.2.1 DRIVERS

- 4.3 UNMET NEEDS AND WHITE SPACES

- 4.4 INTERCONNECTED MARKETS AND CROSS-SECTOR OPPORTUNITIES

- 4.5 STRATEGIC MOVES BY TIER 1, 2, 3 PLAYERS

5 INDUSTRY TRENDS

- 5.1 MACROECONOMIC INDICATORS

- 5.1.1 INTRODUCTION

- 5.1.2 GDP TRENDS AND FORECAST

- 5.1.2.1 Regional GDP dynamics

- 5.1.2.1.1 Developed markets (US, EU, and Japan)

- 5.1.2.1.2 Emerging markets (China, India, and Southeast Asia)

- 5.1.2.2 Investment environment

- 5.1.2.1 Regional GDP dynamics

- 5.1.3 TRENDS IN PUSH-PULL CONTROL CABLES MARKET

- 5.1.3.1 Powertrain transition and market dynamics

- 5.1.3.2 Growth in off-highway and industrial equipment

- 5.2 ECOSYSTEM ANALYSIS

- 5.2.1 RAW MATERIAL SUPPLIERS

- 5.2.2 MECHANICAL CONTROL CABLE MANUFACTURERS

- 5.2.3 TIER 1 SUPPLIERS

- 5.2.4 OEMS

- 5.3 PRICING ANALYSIS

- 5.3.1 AVERAGE SELLING PRICE OF MECHANICAL CONTROL CABLES, BY VEHICLE TYPE

- 5.3.2 AVERAGE SELLING PRICE OF MECHANICAL CONTROL CABLES, BY REGION

- 5.4 SUPPLY CHAIN ANALYSIS

- 5.5 CASE STUDY ANALYSIS

- 5.5.1 SUPRAJIT IMPLEMENTED DASSAULT SYSTEMES' 3DEXPERIENCE PLATFORM TO IMPROVE PRODUCT DEVELOPMENT EFFICIENCY AND CUSTOMIZATION

- 5.5.2 MECHANICAL CONTROL CABLE-BASED LATCH ACTUATION SYSTEM ENGINEERED TO ENSURE CONSISTENT DOOR LATCH RETENTION DURING CRASH

- 5.5.3 CHATTARPATI AUTOMOTIVE SYSTEMS PROVIDED HIGH-QUALITY GEAR LEVER CABLES DESIGNED FOR DURABILITY AND RELIABLE PERFORMANCE

- 5.6 KEY CONFERENCES & EVENTS

- 5.7 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.8 IMPACT OF US 2025 TARIFFS

- 5.8.1 INTRODUCTION

- 5.8.2 KEY TARIFF RATES

- 5.8.3 PRICE IMPACT ANALYSIS

- 5.8.4 IMPACT ON COUNTRY/REGION

- 5.8.4.1 US

- 5.8.4.2 Europe

- 5.8.4.3 Asia Pacific

- 5.8.5 IMPACT ON END-USE INDUSTRIES

- 5.8.5.1 Automotive

- 5.8.5.2 Off-highway (Construction & agriculture)

- 5.8.5.3 Marine

6 TECHNOLOGICAL ADVANCEMENTS, AI-DRIVEN IMPACT, PATENTS, INNOVATIONS, AND FUTURE APPLICATIONS

- 6.1 KEY TECHNOLOGIES

- 6.1.1 ADVANCED WIRE MATERIAL ENGINEERING AND SURFACE TREATMENT

- 6.1.2 LOW-FRICTION LINER AND LUBRICATION TECHNOLOGIES

- 6.1.3 AUTOMATED MANUFACTURING AND IN-LINE QUALITY CONTROL

- 6.2 COMPLEMENTARY TECHNOLOGIES

- 6.2.1 SENSOR-ENABLED MONITORING AND POSITION FEEDBACK

- 6.2.2 HYBRID MECHANICAL-ELECTRONIC ACTUATION SYSTEMS

- 6.3 ADJACENT TECHNOLOGIES

- 6.3.1 ELECTRONIC ACTUATION AND DRIVE-BY-WIRE SUBSYSTEMS

- 6.3.2 ELECTRIC MOTORS AND LINEAR ACTUATORS

- 6.4 IMPACT OF AI/GEN AI

- 6.4.1 TOP USE CASES AND MARKET POTENTIAL

- 6.4.2 INTERCONNECTED ECOSYSTEM AND IMPACT ON MARKET PLAYERS

- 6.4.3 CLIENTS' READINESS TO ADOPT GEN AI IN PUSH-PULL CONTROL CABLES MARKET

- 6.5 TRADE ANALYSIS

- 6.5.1 IMPORT DATA (HS CODE 848790)

- 6.5.2 EXPORT DATA (HS CODE 848790)

- 6.6 PATENT ANALYSIS

- 6.7 FUTURE APPLICATIONS

- 6.7.1 FAIL-SAFE AND REDUNDANT ACTUATION IN ELECTRIFIED VEHICLES

- 6.7.2 HYBRID MECHANICAL-ELECTRONIC CONTROL SYSTEMS

7 REGULATORY LANDSCAPE

- 7.1 REGULATORY FRAMEWORK

- 7.1.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 7.2 PUSH-PULL CONTROL CABLES MARKET: COUNTRY-WISE REGULATIONS

8 CUSTOMER LANDSCAPE AND BUYER BEHAVIOR

- 8.1 INTRODUCTION

- 8.2 DECISION-MAKING PROCESS

- 8.3 KEY STAKEHOLDERS & BUYING CRITERIA

- 8.3.1 KEY STAKEHOLDERS IN BUYING PROCESS, BY CABLE TYPE

- 8.3.2 BUYING CRITERIA

9 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE

- 9.1 INTRODUCTION

- 9.2 THROTTLE CABLE

- 9.2.1 FOCUS ON COST EFFICIENCY, MECHANICAL RELIABILITY, AND FUEL-SYSTEM COMPATIBILITY TO DRIVE MARKET

- 9.3 GEAR SHIFT CABLE

- 9.3.1 EMPHASIS ON MANUAL TRANSMISSION PENETRATION, PACKAGING FLEXIBILITY, AND SERVICE SIMPLICITY TO DRIVE MARKET

- 9.4 CLUTCH CABLE

- 9.4.1 DEMAND FOR CABLES WITH LOW MAINTENANCE COST TO DRIVE MARKET

- 9.5 PARKING BRAKE CABLE

- 9.5.1 WIDESPREAD ADOPTION OF CONTROL CABLES IN NON-ELECTRONIC BRAKE SYSTEMS TO DRIVE MARKET

- 9.6 HOOD RELEASE CABLE

- 9.6.1 NEED FOR SAFETY ACCESS REQUIREMENTS, ROUTINE SERVICE FREQUENCY, AND UNIVERSAL FITMENT TO BOOST MARKET

- 9.7 FUEL LID CABLE

- 9.7.1 FOCUS ON CENTRALIZING CABIN CONTROL AND ENSURING THEFT PREVENTION TO DRIVE MARKET

- 9.8 TRUNK RELEASE CABLE

- 9.8.1 EMPHASIS ON ENHANCING USER CONVENIENCE TO DRIVE DEMAND FOR TRUNK RELEASE CABLES

- 9.9 DOOR LATCH CABLE

- 9.9.1 STRINGENT OCCUPANT SAFETY REGULATIONS AND HIGH-CYCLE DURABILITY REQUIREMENTS TO DRIVE MARKET

- 9.10 SPARE WHEEL CARRIER CABLE

- 9.10.1 FOCUS ON SPACE OPTIMIZATION AND EASE OF ROADSIDE ACCESS TO DRIVE MARKET

- 9.11 SEAT RECLINER RELEASE CABLE

- 9.11.1 INCREASING DEMAND FOR ENHANCED VEHICLE CONTROL TO DRIVE MARKET

10 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION

- 10.1 INTRODUCTION

- 10.2 ENGINE

- 10.2.1 FOCUS ON ENHANCING RELIABILITY, DURABILITY, AND COST-EFFICIENCY OF VEHICLES TO DRIVE MARKET

- 10.3 TRANSMISSION

- 10.3.1 NEED FOR ENHANCING PRECISION, FLEXIBILITY, AND DURABILITY IN CARS TO SUPPORT GROWTH

- 10.4 BRAKE

- 10.4.1 EMPHASIS ON IMPROVING VEHICLE SAFETY, STRENGTH, AND RELIABILITY TO DRIVE MARKET

- 10.5 AUXILIARY

- 10.5.1 NEED FOR DURABILITY, CONVENIENCE, AND ROBUSTNESS IN VEHICLES TO DRIVE MARKET

11 PUSH-PULL CONTROL CABLES MARKET, BY INDUSTRY

- 11.1 INTRODUCTION

- 11.2 AUTOMOTIVE

- 11.2.1 RISING USE OF COMMERCIAL VEHICLES AND HIGH MECHANICAL ACTUATION TO SUPPORT GROWTH

- 11.3 CONSTRUCTION

- 11.3.1 RAPID INFRASTRUCTURE DEVELOPMENT, INDUSTRIALIZATION, AND DEMAND FOR HIGH CONSTRUCTION EQUIPMENT TO SUPPORT MARKET

- 11.3.2 EXCAVATORS

- 11.3.3 MINI EXCAVATORS

- 11.3.4 BACKHOE LOADERS

- 11.3.5 DOZERS

- 11.3.6 ROAD ROLLERS

- 11.3.7 COMPACTORS

- 11.3.8 DUMP TRUCKS

- 11.3.9 MOTOR GRADERS

- 11.4 AGRICULTURE

- 11.4.1 INCREASING USE OF MECHANICAL CABLES IN LIFTING IMPLEMENTS TO DRIVE MARKET

- 11.4.2 TRACTORS

- 11.4.2.1 < 30 hp

- 11.4.2.2 31-70 hp

- 11.4.2.3 71-130 hp

- 11.4.2.4 131-250 hp

- 11.4.2.5 > 250 hp

- 11.4.3 SPRAYERS

- 11.4.4 BALERS

- 11.4.5 HARVESTERS

- 11.5 MARINE

- 11.5.1 LARGE-SCALE PRODUCTION OF FISHING BOATS TO DRIVE MARKET

- 11.5.2 RECREATIONAL BOAT MARKET (INBOARD VS. OUTBOARD)

- 11.5.3 MARINE STEERING

- 11.6 RAILWAY

- 11.6.1 FOCUS ON RAILWAY NETWORK EXPANSION AND FLEET MODERNIZATION TO DRIVE MARKET

- 11.7 OTHERS

12 PUSH-PULL CONTROL CABLES MARKET, BY CABLE TYPE

- 12.1 INTRODUCTION

- 12.2 PUSH-PULL CABLE

- 12.2.1 NEED FOR ENHANCING PREDICTABLE MECHANICAL RESPONSE AND DURABILITY OF ICE VEHICLES TO DRIVE MARKET

- 12.3 PULL-ONLY CABLE

- 12.3.1 NEED FOR CABLES WITH UNIDIRECTIONAL SAFETY FUNCTIONS AND PACKAGING SIMPLICITY TO DRIVE MARKET

13 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE

- 13.1 INTRODUCTION

- 13.2 PASSENGER CAR

- 13.2.1 RISING DEMAND FOR MECHANICAL RELIABILITY AND SELECTIVE RETENTION OF CABLES IN ICE AND ELECTRIC VEHICLES TO DRIVE MARKET

- 13.2.2 ICE

- 13.2.3 EV

- 13.3 LIGHT COMMERCIAL VEHICLE

- 13.3.1 FOCUS ON ENHANCING MECHANICAL ROBUSTNESS AND EASE OF FIELD SERVICE IN LCVS TO DRIVE MARKET

- 13.4 HEAVY COMMERCIAL VEHICLE

- 13.4.1 HEAVY-DUTY OPERATION REQUIREMENTS TO ENCOURAGE USE OF MECHANICAL CONTROL CABLES

14 AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY REGION

- 14.1 INTRODUCTION

- 14.2 ASIA PACIFIC

- 14.2.1 CHINA

- 14.2.1.1 Need for localization of auxiliary cables to drive market

- 14.2.2 JAPAN

- 14.2.2.1 High durability requirements in auxiliary cables to drive market

- 14.2.3 INDIA

- 14.2.3.1 High penetration of manual transmission in passenger cars to drive market

- 14.2.4 SOUTH KOREA

- 14.2.4.1 Focus on mandatory fitment across vehicle classes to drive market

- 14.2.5 THAILAND

- 14.2.5.1 High fleet utilization in urban and industrial centers to support market

- 14.2.6 INDONESIA

- 14.2.6.1 Rapid adoption of control cables in locally assembled vehicles to drive market

- 14.2.7 REST OF ASIA PACIFIC

- 14.2.1 CHINA

- 14.3 EUROPE

- 14.3.1 GERMANY

- 14.3.1.1 High production volume of passenger cars to support market growth

- 14.3.2 FRANCE

- 14.3.2.1 Increased demand for small and mid-size ICE passenger cars to drive market

- 14.3.3 UK

- 14.3.3.1 High demand for body-related mechanical control cables in passenger cars to drive market

- 14.3.4 ITALY

- 14.3.4.1 Rising vehicle production and aging fleets to drive market

- 14.3.5 SPAIN

- 14.3.5.1 Increase in export of ICE vehicles to drive market

- 14.3.6 RUSSIA

- 14.3.6.1 Country's reliance on long-haul transportation to drive market

- 14.3.7 REST OF EUROPE

- 14.3.1 GERMANY

- 14.4 NORTH AMERICA

- 14.4.1 US

- 14.4.1.1 Residual ICE passenger car production to drive market

- 14.4.2 CANADA

- 14.4.2.1 Growth in demand for light commercial vehicles and longer vehicle lifecycles to drive market

- 14.4.3 MEXICO

- 14.4.3.1 Expansion of automotive manufacturing sector to drive market

- 14.4.1 US

- 14.5 REST OF THE WORLD

- 14.5.1 SOUTH AFRICA

- 14.5.1.1 Low EV penetration and local assembly of vehicles to drive market

- 14.5.2 SAUDI ARABIA

- 14.5.2.1 Continued use of mechanical control cables in ICE-based vehicles to drive market

- 14.5.3 EGYPT

- 14.5.3.1 Rapid growth in locally assembled and imported ICE vehicles to support growth

- 14.5.4 OTHERS

- 14.5.1 SOUTH AFRICA

15 COMPETITIVE LANDSCAPE

- 15.1 OVERVIEW

- 15.2 KEY PLAYER STRATEGIES/RIGHT TO WIN,

- 15.3 MARKET SHARE ANALYSIS, 2024

- 15.4 REVENUE ANALYSIS OF TOP LISTED/PUBLIC PLAYERS

- 15.5 COMPANY VALUATION AND FINANCIAL METRICS

- 15.5.1 COMPANY VALUATION

- 15.5.2 FINANCIAL METRICS

- 15.6 BRAND/PRODUCT COMPARISON

- 15.7 COMPANY EVALUATION MATRIX: KEY PLAYERS

- 15.7.1 STARS

- 15.7.2 EMERGING LEADERS

- 15.7.3 PERVASIVE PLAYERS

- 15.7.4 PARTICIPANTS

- 15.7.5 COMPANY FOOTPRINT

- 15.8 COMPANY EVALUATION MATRIX: REGIONAL PLAYERS, 2024

- 15.8.1 PROGRESSIVE COMPANIES

- 15.8.2 RESPONSIVE COMPANIES

- 15.8.3 DYNAMIC COMPANIES

- 15.8.4 STARTING BLOCKS

- 15.9 COMPETITIVE SCENARIO

- 15.9.1 PRODUCT LAUNCHES/DEVELOPMENTS

- 15.9.2 DEALS

- 15.9.3 EXPANSION

- 15.9.4 OTHER DEVELOPMENTS

16 COMPANY PROFILES

- 16.1 KEY PLAYERS

- 16.1.1 HI-LEX CORPORATION

- 16.1.1.1 Business overview

- 16.1.1.2 Products offered

- 16.1.1.3 Recent developments

- 16.1.1.3.1 Product launches/developments

- 16.1.1.3.2 Deals

- 16.1.1.3.3 Expansion

- 16.1.1.4 MnM view

- 16.1.1.4.1 Key strengths

- 16.1.1.4.2 Strategic choices

- 16.1.1.4.3 Weaknesses and competitive threats

- 16.1.2 SUPRAJIT

- 16.1.2.1 Business overview

- 16.1.2.2 Products offered

- 16.1.2.3 Recent developments

- 16.1.2.3.1 Product launches/developments

- 16.1.2.3.2 Deals

- 16.1.2.3.3 Expansion

- 16.1.2.3.4 Other developments

- 16.1.2.4 MnM view

- 16.1.2.4.1 Key strengths

- 16.1.2.4.2 Strategic choices

- 16.1.2.4.3 Weaknesses and competitive threats

- 16.1.3 ORSCHELN PRODUCTS

- 16.1.3.1 Business overview

- 16.1.3.2 Products offered

- 16.1.3.3 Recent developments

- 16.1.3.3.1 Deals

- 16.1.3.4 MnM view

- 16.1.3.4.1 Key strengths

- 16.1.3.4.2 Strategic choices

- 16.1.3.4.3 Weaknesses and competitive threats

- 16.1.4 KONGSBERG AUTOMOTIVE

- 16.1.4.1 Business overview

- 16.1.4.2 Products offered

- 16.1.4.3 Recent developments

- 16.1.4.3.1 Product launches/developments

- 16.1.4.3.2 Other developments

- 16.1.4.4 MnM view

- 16.1.4.4.1 Key strengths

- 16.1.4.4.2 Strategic choices

- 16.1.4.4.3 Weaknesses and competitive threats

- 16.1.5 CARL STAHL TECHNOCABLES GMBH

- 16.1.5.1 Business overview

- 16.1.5.2 Products offered

- 16.1.5.3 Recent developments

- 16.1.5.3.1 Product launches/developments

- 16.1.5.4 MnM view

- 16.1.5.4.1 Key strengths

- 16.1.5.4.2 Strategic choices

- 16.1.5.4.3 Weaknesses and competitive threats

- 16.1.6 CABLECRAFT MOTION CONTROLS

- 16.1.6.1 Business overview

- 16.1.6.2 Products offered

- 16.1.6.3 Recent developments

- 16.1.6.3.1 Product launches/developments

- 16.1.6.3.2 Deals

- 16.1.6.3.3 Other developments

- 16.1.7 DIPLOMA PLC

- 16.1.7.1 Business overview

- 16.1.7.2 Products offered

- 16.1.7.3 Recent developments

- 16.1.7.3.1 Deals

- 16.1.8 REMSONS INDUSTRIES LIMITED

- 16.1.8.1 Business overview

- 16.1.8.2 Products offered

- 16.1.8.3 Recent developments

- 16.1.8.3.1 Product launches/developments

- 16.1.8.3.2 Deals

- 16.1.9 SILA GROUP

- 16.1.9.1 Business overview

- 16.1.9.2 Products offered

- 16.1.10 LEGGETT & PLATT, INCORPORATED

- 16.1.10.1 Business overview

- 16.1.10.2 Products offered

- 16.1.11 DURA-SHILOH

- 16.1.11.1 Business overview

- 16.1.11.2 Products offered

- 16.1.1 HI-LEX CORPORATION

- 16.2 OTHER PLAYERS

- 16.2.1 STORK GROUP

- 16.2.2 SILCO AUTOMOTIVE SOLUTIONS LLP

- 16.2.3 KRAMAR CONTROLS GMBH

- 16.2.4 KUSTER HOLDING GMBH

- 16.2.5 VENHILL

- 16.2.6 FICOSA INTERNACIONAL SA

- 16.2.7 PIONEER AUTOMOTIVE INDUSTRIES

- 16.2.8 ELLIOTT MANUFACTURING

- 16.2.9 DRALLIM INDUSTRIES LIMITED

- 16.2.10 CALIFORNIA PUSH-PULL, INC.

- 16.2.11 GRAND RAPIDS CONTROLS, LLC

- 16.2.12 HINDLE CONTROLS

- 16.2.13 THAI STEEL CABLE PUBLIC COMPANY LIMITED

- 16.2.14 WR CONTROL GROUP AG

17 RESEARCH METHODOLOGY

- 17.1 RESEARCH DATA

- 17.1.1 SECONDARY DATA

- 17.1.1.1 List of secondary sources

- 17.1.1.2 Key data from secondary sources

- 17.1.2 PRIMARY DATA

- 17.1.2.1 Primary interviewees from demand and supply sides

- 17.1.2.2 Key primary insights

- 17.1.2.3 Breakdown of primary interviews

- 17.1.2.4 List of primary participants

- 17.1.1 SECONDARY DATA

- 17.2 MARKET SIZE ESTIMATION

- 17.2.1 BOTTOM-UP APPROACH

- 17.2.2 TOP-DOWN APPROACH

- 17.3 DATA TRIANGULATION

- 17.4 FACTOR ANALYSIS

- 17.5 RESEARCH ASSUMPTIONS AND RISK ASSESSMENT

- 17.6 RESEARCH LIMITATIONS

18 APPENDIX

- 18.1 INSIGHTS FROM INDUSTRY EXPERTS

- 18.2 DISCUSSION GUIDE

- 18.3 CUSTOMIZATION OPTIONS

- 18.4 RELATED REPORTS

- 18.5 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 18.6 AUTHOR DETAILS

List of Tables

- TABLE 1 MARKET DEFINITION, BY PRODUCT TYPE

- TABLE 2 MARKET DEFINITION, BY APPLICATION

- TABLE 3 MARKET DEFINITION, BY VEHICLE TYPE

- TABLE 4 MARKET DEFINITION, BY CABLE TYPE

- TABLE 5 MARKET DEFINITION, BY INDUSTRY

- TABLE 6 CURRENCY EXCHANGE RATES, 2020-2024

- TABLE 7 HEAVY-DUTY CONTROL CABLES USED IN AGRICULTURE AND CONSTRUCTION SECTORS

- TABLE 8 HEAVY-DUTY CONTROL CABLES USED IN COMMERCIAL AND UTILITY BOATS

- TABLE 9 COMPARISON BETWEEN HEAVY-DUTY CONTROL CABLES OFFERED BY TIER 1/2/3 SUPPLIERS

- TABLE 10 ROLE OF PLAYERS IN MARKET ECOSYSTEM

- TABLE 11 AVERAGE SELLING PRICE OF MECHANICAL CONTROL CABLES, BY VEHICLE TYPE, 2024 (USD)

- TABLE 12 AVERAGE SELLING PRICE, BY REGION, 2024 (USD)

- TABLE 13 KEY CONFERENCES & EVENTS, 2026-2027

- TABLE 14 RECIPROCAL TARIFF RATES ADJUSTED BY US

- TABLE 15 KEY PRODUCT-RELATED TARIFF EFFECTIVE FOR MECHANICAL CONTROL CABLES

- TABLE 16 EXPECTED CHANGE IN PRICES AND LIKELY IMPACT ON END-USE MARKET DUE TO TARIFF CHANGE

- TABLE 17 IMPORT DATA FOR HS CODE 848790-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 18 EXPORT DATA FOR HS CODE 848790-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- TABLE 19 KEY PATENTS, 2021-2025

- TABLE 20 NORTH AMERICA: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 21 EUROPE: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 22 ASIA PACIFIC: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 23 REST OF WORLD: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 24 PUSH-PULL CONTROL CABLES MARKET: COUNTRY-WISE REGULATIONS

- TABLE 25 DECISION-MAKING CRITERIA OF STAKEHOLDERS

- TABLE 26 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS, BY CABLE TYPE (%)

- TABLE 27 KEY BUYING CRITERIA FOR CABLE TYPES

- TABLE 28 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 29 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 30 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 31 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 32 THROTTLE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 33 THROTTLE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 34 THROTTLE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 35 THROTTLE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 36 GEAR SHIFT CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 37 GEAR SHIFT CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 38 GEAR SHIFT CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 39 GEAR SHIFT CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 40 CLUTCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 41 CLUTCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 42 CLUTCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 43 CLUTCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 44 PARKING BRAKE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 45 PARKING BRAKE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 46 PARKING BRAKE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 47 PARKING BRAKE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 48 HOOD RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 49 HOOD RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 50 HOOD RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 51 HOOD RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 52 FUEL LID CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 53 FUEL LID CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 54 FUEL LID CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 55 FUEL LID CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 56 TRUNK RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 57 TRUNK RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 58 TRUNK RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 59 TRUNK RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 60 DOOR LATCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 61 DOOR LATCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 62 DOOR LATCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 63 DOOR LATCH CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 64 SPARE WHEEL CARRIER CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 65 SPARE WHEEL CARRIER CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 66 SPARE WHEEL CARRIER CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 67 SPARE WHEEL CARRIER CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 68 SEAT RECLINER RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 69 SEAT RECLINER RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 70 SEAT RECLINER RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 71 SEAT RECLINER RELEASE CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 72 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION, 2021-2024 (THOUSAND UNITS)

- TABLE 73 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION, 2025-2032 (THOUSAND UNITS)

- TABLE 74 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION, 2021-2024 (USD MILLION)

- TABLE 75 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION, 2025-2032 (USD MILLION)

- TABLE 76 ENGINE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 77 ENGINE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 78 ENGINE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 79 ENGINE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 80 TRANSMISSION: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 81 TRANSMISSION: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 82 TRANSMISSION: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 83 TRANSMISSION: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 84 BRAKE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 85 BRAKE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 86 BRAKE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 87 BRAKE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 88 AUXILIARY: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 89 AUXILIARY: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 90 AUXILIARY: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 91 AUXILIARY: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 92 PUSH-PULL CONTROL CABLES MARKET, BY INDUSTRY, 2021-2024 (USD MILLION)

- TABLE 93 PUSH-PULL CONTROL CABLES MARKET, BY INDUSTRY, 2025-2032 (USD MILLION)

- TABLE 94 AUTOMOTIVE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 95 AUTOMOTIVE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 96 CONSTRUCTION: PUSH-PULL CONTROL CABLES MARKET, BY EQUIPMENT TYPE, 2021-2024 (USD MILLION)

- TABLE 97 CONSTRUCTION: PUSH-PULL CONTROL CABLES MARKET, BY EQUIPMENT TYPE, 2025-2032 (USD MILLION)

- TABLE 98 EXCAVATORS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 99 EXCAVATORS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 100 MINI EXCAVATORS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 101 MINI EXCAVATORS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 102 BACKHOE LOADERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 103 BACKHOE LOADERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 104 DOZERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 105 DOZERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 106 ROAD ROLLERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 107 ROAD ROLLERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 108 COMPACTORS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 109 COMPACTORS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 110 DUMP TRUCKS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 111 DUMP TRUCKS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 112 MOTOR GRADERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 113 MOTOR GRADERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 114 AGRICULTURE: PUSH-PULL CONTROL CABLES MARKET, BY EQUIPMENT TYPE, 2021-2024 (USD MILLION)

- TABLE 115 AGRICULTURE: PUSH-PULL CONTROL CABLES MARKET, BY EQUIPMENT TYPE, 2025-2032 (USD MILLION)

- TABLE 116 TRACTORS: PUSH-PULL CONTROL CABLES MARKET, BY ENGINE POWER OUTPUT, 2021-2024 (USD MILLION)

- TABLE 117 TRACTORS: PUSH-PULL CONTROL CABLES MARKET, BY ENGINE POWER OUTPUT, 2025-2032 (USD MILLION)

- TABLE 118 < 30 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 119 < 30 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 120 31-70 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 121 31-70 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 122 71-130 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 123 71-130 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 124 131-250 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 125 131-250 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 126 > 250 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 127 > 250 HP: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 128 SPRAYERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 129 SPRAYERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 130 BALERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 131 BALERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 132 HARVESTERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 133 HARVESTERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 134 MARINE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 135 MARINE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 136 RECREATIONAL BOAT MARKET, BY ENGINE LOCATION, 2021-2024 (USD MILLION)

- TABLE 137 RECREATIONAL BOAT MARKET, BY ENGINE LOCATION, 2025-2032 (USD MILLION)

- TABLE 138 MARINE STEERING: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 139 MARINE STEERING: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 140 RAILWAY: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 141 RAILWAY: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 142 OTHERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 143 OTHERS: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 144 PUSH-PULL CONTROL CABLES MARKET, BY CABLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 145 PUSH-PULL CONTROL CABLES MARKET, BY CABLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 146 PUSH-PULL CONTROL CABLES MARKET, BY CABLE TYPE, 2021-2024 (USD MILLION)

- TABLE 147 PUSH-PULL CONTROL CABLES MARKET, BY CABLE TYPE, 2025-2032 (USD MILLION)

- TABLE 148 PUSH-PULL CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 149 PUSH-PULL CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 150 PUSH-PULL CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 151 PUSH-PULL CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 152 PULL-ONLY CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 153 PULL-ONLY CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 154 PULL-ONLY CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 155 PULL-ONLY CABLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 156 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 157 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 158 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 159 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 160 PASSENGER CAR: PUSH-PULL CONTROL CABLES MARKET, BY PROPULSION, 2021-2024 (THOUSAND UNITS)

- TABLE 161 PASSENGER CAR: PUSH-PULL CONTROL CABLES MARKET, BY PROPULSION, 2025-2032 (THOUSAND UNITS)

- TABLE 162 PASSENGER CAR: PUSH-PULL CONTROL CABLES MARKET, BY PROPULSION, 2021-2024 (USD MILLION)

- TABLE 163 PASSENGER CAR: PUSH-PULL CONTROL CABLES MARKET, BY PROPULSION, 2025-2032 (USD MILLION)

- TABLE 164 ICE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 165 ICE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 166 ICE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 167 ICE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 168 EV: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 169 EV: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 170 EV: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 171 EV: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 172 LIGHT COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 173 LIGHT COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 174 LIGHT COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 175 LIGHT COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 176 HEAVY COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 177 HEAVY COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 178 HEAVY COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 179 HEAVY COMMERCIAL VEHICLE: PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 180 AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 181 AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 182 AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 183 AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 184 ASIA PACIFIC: MECHANICAL CONTROL CABLE PENETRATION IN PASSENGER CARS, BY PRODUCT TYPE

- TABLE 185 ASIA PACIFIC: MECHANICAL CONTROL CABLE PENETRATION IN LIGHT COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 186 ASIA PACIFIC: MECHANICAL CONTROL CABLE PENETRATION IN HEAVY COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 187 ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (THOUSAND UNITS)

- TABLE 188 ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (THOUSAND UNITS)

- TABLE 189 ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 190 ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 191 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 192 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 193 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 194 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 195 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 196 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 197 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 198 CHINA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 199 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 200 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 201 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 202 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 203 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 204 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 205 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 206 JAPAN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 207 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 208 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 209 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 210 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 211 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 212 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 213 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 214 INDIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 215 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 216 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 217 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 218 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 219 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 220 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 221 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 222 SOUTH KOREA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 223 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 224 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 225 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 226 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 227 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 228 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 229 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 230 THAILAND: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 231 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 232 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 233 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 234 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 235 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 236 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 237 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 238 INDONESIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 239 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 240 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 241 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 242 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 243 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 244 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 245 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 246 REST OF ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 247 EUROPE: MECHANICAL CONTROL CABLE PENETRATION IN PASSENGER CARS, BY PRODUCT TYPE

- TABLE 248 EUROPE: MECHANICAL CONTROL CABLE PENETRATION IN LIGHT COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 249 EUROPE: MECHANICAL CONTROL CABLE PENETRATION IN HEAVY COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 250 EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (THOUSAND UNITS)

- TABLE 251 EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (THOUSAND UNITS)

- TABLE 252 EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 253 EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 254 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 255 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 256 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 257 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 258 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 259 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 260 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 261 GERMANY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 262 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 263 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 264 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 265 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 266 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 267 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 268 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 269 FRANCE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 270 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 271 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 272 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 273 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 274 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 275 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 276 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 277 UK: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 278 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 279 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 280 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 281 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 282 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 283 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 284 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 285 ITALY: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 286 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 287 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 288 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 289 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 290 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 291 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 292 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 293 SPAIN: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 294 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 295 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 296 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 297 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 298 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 299 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 300 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 301 RUSSIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 302 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 303 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 304 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 305 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 306 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 307 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 308 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 309 REST OF EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 310 NORTH AMERICA: MECHANICAL CONTROL CABLE PENETRATION IN PASSENGER CARS, BY PRODUCT TYPE

- TABLE 311 NORTH AMERICA: MECHANICAL CONTROL CABLE PENETRATION IN LIGHT COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 312 NORTH AMERICA: MECHANICAL CONTROL CABLE PENETRATION IN HEAVY COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 313 NORTH AMERICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (THOUSAND UNITS)

- TABLE 314 NORTH AMERICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (THOUSAND UNITS)

- TABLE 315 NORTH AMERICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 316 NORTH AMERICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 317 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 318 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 319 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 320 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 321 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 322 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 323 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 324 US: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 325 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 326 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 327 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 328 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 329 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 330 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 331 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 332 CANADA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 333 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 334 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 335 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 336 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 337 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 338 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 339 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 340 MEXICO: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 341 REST OF THE WORLD: MECHANICAL CONTROL CABLE PENETRATION IN PASSENGER CARS, BY PRODUCT TYPE

- TABLE 342 REST OF THE WORLD: MECHANICAL CONTROL CABLE PENETRATION IN LIGHT COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 343 REST OF THE WORLD: MECHANICAL CONTROL CABLE PENETRATION IN HEAVY COMMERCIAL VEHICLES, BY PRODUCT TYPE

- TABLE 344 REST OF THE WORLD: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (THOUSAND UNITS)

- TABLE 345 REST OF THE WORLD: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (THOUSAND UNITS)

- TABLE 346 REST OF THE WORLD: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 347 REST OF THE WORLD: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 348 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 349 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 350 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 351 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 352 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 353 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 354 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 355 SOUTH AFRICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 356 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 357 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 358 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 359 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 360 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 361 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 362 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 363 SAUDI ARABIA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 364 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 365 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 366 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 367 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 368 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 369 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 370 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 371 EGYPT: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 372 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 373 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 374 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2021-2024 (USD MILLION)

- TABLE 375 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025-2032 (USD MILLION)

- TABLE 376 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 377 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 378 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 379 OTHERS: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 380 KEY PLAYER STRATEGIES/RIGHT TO WIN, JANUARY 2022-DECEMBER 2025

- TABLE 381 MARKET SHARE ANALYSIS, 2024

- TABLE 382 PUSH-PULL CONTROL CABLES MARKET: PRODUCT TYPE FOOTPRINT, 2024

- TABLE 383 PUSH-PULL CONTROL CABLES MARKET: INDUSTRY FOOTPRINT, 2024

- TABLE 384 PUSH-PULL CONTROL CABLES MARKET: REGION FOOTPRINT, 2024

- TABLE 385 COMPETITIVE BENCHMARKING: REGIONAL PLAYERS COMPANY FOOTPRINT, 2024

- TABLE 386 PUSH-PULL CONTROL CABLES MARKET: PRODUCT LAUNCHES/DEVELOPMENTS, JANUARY 2022-DECEMBER 2025

- TABLE 387 PUSH-PULL CONTROL CABLES MARKET: DEALS, JANUARY 2022-DECEMBER 2025

- TABLE 388 PUSH-PULL CONTROL CABLES MARKET: EXPANSION, JANUARY 2022-DECEMBER 2025

- TABLE 389 PUSH-PULL CONTROL CABLES MARKET: OTHER DEVELOPMENTS, JANUARY 2022-DECEMBER 2025

- TABLE 390 HI-LEX CORPORATION: COMPANY OVERVIEW

- TABLE 391 HI-LEX CORPORATION: PRODUCTS OFFERED

- TABLE 392 HI-LEX CORPORATION: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 393 HI-LEX CORPORATION: DEALS

- TABLE 394 HI-LEX CORPORATION: EXPANSION

- TABLE 395 SUPRAJIT: COMPANY OVERVIEW

- TABLE 396 SUPRAJIT: PRODUCTS OFFERED

- TABLE 397 SUPRAJIT: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 398 SUPRAJIT: DEALS

- TABLE 399 SUPRAJIT: EXPANSION

- TABLE 400 SUPRAJIT: OTHER DEVELOPMENTS

- TABLE 401 ORSCHELN PRODUCTS: COMPANY OVERVIEW

- TABLE 402 ORSCHELN PRODUCTS: PRODUCTS OFFERED

- TABLE 403 ORSCHELN PRODUCTS: DEALS

- TABLE 404 KONGSBERG AUTOMOTIVE: COMPANY OVERVIEW

- TABLE 405 KONGSBERG AUTOMOTIVE: PRODUCTS OFFERED

- TABLE 406 KONGSBERG AUTOMOTIVE: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 407 KONGSBERG AUTOMOTIVE: OTHER DEVELOPMENTS

- TABLE 408 CARL STAHL TECHNOCABLES GMBH: COMPANY OVERVIEW

- TABLE 409 CARL STAHL TECHNOCABLES GMBH: PRODUCTS OFFERED

- TABLE 410 CARL STAHL TECHNOCABLES GMBH: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 411 CABLECRAFT MOTION CONTROLS: COMPANY OVERVIEW

- TABLE 412 CABLECRAFT MOTION CONTROLS: PRODUCTS OFFERED

- TABLE 413 CABLECRAFT MOTION CONTROLS: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 414 CABLECRAFT MOTION CONTROLS: DEALS

- TABLE 415 CABLECRAFT MOTION CONTROLS: OTHER DEVELOPMENTS

- TABLE 416 DIPLOMA PLC: COMPANY OVERVIEW

- TABLE 417 DIPLOMA PLC: PRODUCTS OFFERED

- TABLE 418 DIPLOMA PLC: DEALS

- TABLE 419 REMSONS INDUSTRIES LIMITED: COMPANY OVERVIEW

- TABLE 420 REMSONS INDUSTRIES LIMITED: PRODUCTS OFFERED

- TABLE 421 REMSONS INDUSTRIES LIMITED: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 422 REMSONS INDUSTRIES LIMITED: DEALS

- TABLE 423 SILA GROUP: COMPANY OVERVIEW

- TABLE 424 SILA GROUP: PRODUCTS OFFERED

- TABLE 425 LEGGETT & PLATT, INCORPORATED: COMPANY OVERVIEW

- TABLE 426 LEGGETT & PLATT, INCORPORATED: PRODUCTS OFFERED

- TABLE 427 DURA-SHILOH: COMPANY OVERVIEW

- TABLE 428 DURA-SHILOH: PRODUCTS OFFERED

- TABLE 429 STORK GROUP: COMPANY OVERVIEW

- TABLE 430 SILCO AUTOMOTIVE SOLUTIONS LLP: COMPANY OVERVIEW

- TABLE 431 KRAMAR CONTROLS GMBH: COMPANY OVERVIEW

- TABLE 432 KUSTER HOLDING GMBH: COMPANY OVERVIEW

- TABLE 433 VENHILL: COMPANY OVERVIEW

- TABLE 434 FICOSA INTERNACIONAL SA: COMPANY OVERVIEW

- TABLE 435 PIONEER AUTOMOTIVE INDUSTRIES: COMPANY OVERVIEW

- TABLE 436 ELLIOTT MANUFACTURING: COMPANY OVERVIEW

- TABLE 437 DRALLIM INDUSTRIES LIMITED: COMPANY OVERVIEW

- TABLE 438 CALIFORNIA PUSH-PULL, INC.: COMPANY OVERVIEW

- TABLE 439 GRAND RAPIDS CONTROLS, LLC: COMPANY OVERVIEW

- TABLE 440 HINDLE CONTROLS: COMPANY OVERVIEW

- TABLE 441 THAI STEEL CABLE PUBLIC COMPANY LIMITED: COMPANY OVERVIEW

- TABLE 442 WR CONTROL GROUP AG: COMPANY OVERVIEW

List of Figures

- FIGURE 1 MARKET SCENARIO

- FIGURE 2 GLOBAL PUSH-PULL CONTROL CABLES MARKET, BY INDUSTRY, 2021-2032 (USD MILLION)

- FIGURE 3 MAJOR STRATEGIES ADOPTED BY KEY PLAYERS IN PUSH-PULL CONTROL CABLES MARKET, 2021-2025

- FIGURE 4 DISRUPTIVE TRENDS INFLUENCING GROWTH OF PUSH-PULL CONTROL CABLES MARKET

- FIGURE 5 HIGH-GROWTH SEGMENTS IN PUSH-PULL CONTROL CABLES MARKET, 2025

- FIGURE 6 ASIA PACIFIC TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 7 FAST-GROWING RAILWAY APPLICATIONS TO CREATE HIGH-VALUE OPPORTUNITY POCKETS

- FIGURE 8 RAILWAY TO BE FASTEST-GROWING SEGMENT DURING FORECAST PERIOD

- FIGURE 9 PULL-ONLY CABLE TO BE LARGER THAN PUSH-PULL CABLE SEGMENT DURING FORECAST PERIOD

- FIGURE 10 PARKING BRAKE CABLE SEGMENT TO ACCOUNT FOR LARGEST SHARE DURING FORECAST PERIOD

- FIGURE 11 BRAKE SEGMENT TO ACCOUNT FOR LARGEST SHARE DURING FORECAST PERIOD

- FIGURE 12 PASSENGER CAR SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 13 ASIA PACIFIC TO ACCOUNT FOR LARGEST SHARE DURING FORECAST PERIOD

- FIGURE 14 PUSH-PULL CONTROL CABLES MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 15 CONSTRUCTION EQUIPMENT AND TRACTOR SALES, 2021 VS. 2025 VS. 2032 (THOUSAND UNITS)

- FIGURE 16 ECOSYSTEM ANALYSIS

- FIGURE 17 SUPPLY CHAIN ANALYSIS

- FIGURE 18 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 19 IMPORT DATA FOR HS CODE 848790-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- FIGURE 20 EXPORT DATA FOR HS CODE 848790-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD MILLION)

- FIGURE 21 PATENTS APPLIED AND GRANTED, 2015-2025

- FIGURE 22 KEY BUYING CRITERIA FOR CABLE TYPES

- FIGURE 23 PUSH-PULL CONTROL CABLES MARKET, BY PRODUCT TYPE, 2025 VS. 2032 (USD MILLION)

- FIGURE 24 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION, 2025 VS. 2032 (USD MILLION)

- FIGURE 25 PUSH-PULL CONTROL CABLES MARKET, BY INDUSTRY, 2025 VS. 2032 (USD MILLION)

- FIGURE 26 PUSH-PULL CONTROL CABLES MARKET, BY APPLICATION, 2025 VS. 2032 (USD MILLION)

- FIGURE 27 PUSH-PULL CONTROL CABLES MARKET, BY VEHICLE TYPE, 2025 VS. 2032 (USD MILLION)

- FIGURE 28 AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET, BY REGION, 2025 VS. 2032 (USD MILLION)

- FIGURE 29 ASIA PACIFIC: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET SNAPSHOT

- FIGURE 30 EUROPE: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET SNAPSHOT

- FIGURE 31 NORTH AMERICA: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET SNAPSHOT

- FIGURE 32 REST OF THE WORLD: AUTOMOTIVE PUSH-PULL CONTROL CABLES MARKET SNAPSHOT

- FIGURE 33 MARKET SHARE ANALYSIS, 2024

- FIGURE 34 REVENUE ANALYSIS OF TOP LISTED/PUBLIC PLAYERS, 2021-2024 (USD BILLION)

- FIGURE 35 COMPANY VALUATION, 2025

- FIGURE 36 FINANCIAL METRICS, 2025

- FIGURE 37 BRAND/PRODUCT COMPARISON

- FIGURE 38 PUSH-PULL CONTROL CABLES MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 39 PUSH-PULL CONTROL CABLES MARKET: COMPANY FOOTPRINT, 2024

- FIGURE 40 PUSH-PULL CONTROL CABLES MARKET: COMPANY EVALUATION MATRIX (REGIONAL PLAYERS), 2025

- FIGURE 41 HI-LEX CORPORATION: COMPANY SNAPSHOT

- FIGURE 42 SUPRAJIT: COMPANY SNAPSHOT

- FIGURE 43 KONGSBERG AUTOMOTIVE: COMPANY SNAPSHOT

- FIGURE 44 DIPLOMA PLC: COMPANY SNAPSHOT

- FIGURE 45 REMSONS INDUSTRIES LIMITED: COMPANY SNAPSHOT

- FIGURE 46 LEGGETT & PLATT, INCORPORATED: COMPANY SNAPSHOT

- FIGURE 47 RESEARCH DESIGN

- FIGURE 48 RESEARCH DESIGN MODEL

- FIGURE 49 RESEARCH METHODOLOGY: HYPOTHESIS BUILDING

- FIGURE 50 BOTTOM-UP APPROACH

- FIGURE 51 TOP-DOWN APPROACH

- FIGURE 52 DATA TRIANGULATION

- FIGURE 53 FACTOR ANALYSIS FOR MARKET SIZING: DEMAND AND SUPPLY SIDES