PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1936068

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1936068

Electronic Potting Compound Market for EV charger, By Charger Type (AC, DC), Setup Type (Wall Mount, Stationary), Material Type (Polyurethane, Silicone, Epoxy), Curing Technology, Application, EV Component, and Region - Global Forecast to 2032

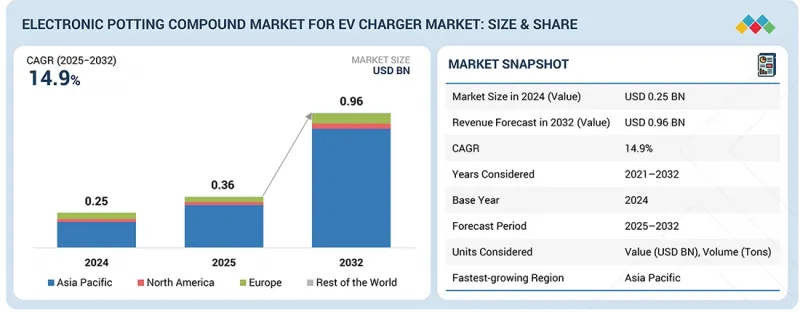

The electronic potting compound market for EV charger is projected to reach USD 0.96 billion by 2032 from USD 0.36 billion in 2025 at a CAGR of 14.9%. AC chargers are increasingly adopting compact, integrated power and control boards, driving demand for low-viscosity potting compounds that ensure complete coverage without affecting heat dissipation.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2032 |

| Units Considered | Value (USD Million), Volume (Tons) |

| Segments | By Charger Type, Setup Type, Material Type, Curing Technology, EV Component, Application |

| Regions covered | Asia Pacific, Europe, North America, Rest of the World |

In DC chargers, the transition toward ultra-fast charging is intensifying the need for high-thermal-conductivity and high-partial-discharge-resistant potting materials. DC charger designs are also moving toward liquid-cooled and sealed power modules, increasing potting thickness and material consumption. Across both charger types, compatibility with automated dispensing and fast thermal curing is becoming a key material requirement. Additionally, materials with long-term resistance to moisture ingress and electrical tracking are gaining importance as outdoor charger deployments expand.

"DC charger is projected to lead the electronic potting compound market for EV charger during the forecast period."

DC chargers are expected to lead the electronic potting compound market for EV chargers during the forecast period due to their significantly higher power density and operating stress compared with AC or onboard chargers. Public DC charging sites and fleet depots operate in harsher environments exposed to moisture, vibration, and continuous duty cycles, which increase demand for robust encapsulation to ensure electrical insulation, environmental protection, and vibration damping. Large-scale infrastructure rollouts by OEMs and charge network operators are prioritizing high-power DC installations along highways, at commercial sites, and within fleet depots, concentrating unit volumes in charger platforms that require heavy and consistent potting usage. Material suppliers such as Parker Hannifin Corp are responding with low viscosity, fast flow thermally conductive potting compounds that can fill narrow gaps and efficiently transfer heat to housings and heat sinks in high power DC modules, while direct injection and pourable systems with faster curing and in-line quality control are gaining traction to support high throughput manufacturing. In parallel, ongoing government backed programs such as the US NEVI (National Electric Vehicle Infrastructure) initiative and China's continued expansion of ultra fast public charging corridors are accelerating the deployment of high power DC chargers. For instance, in August 2025, the California Energy Commission launched a USD 55 million Fast Charge California Program to subsidize public fast charger installations, including high-power DC stations at businesses and public sites. These investments increase demand for thermally robust and electrically reliable potting compounds, as each new high-power DC installation requires substantial encapsulation material to ensure long-term operational stability and regulatory compliance.

"The epoxy material is projected to register the highest growth in the electronic potting compound market for EV charger during the forecast period."

The epoxy segment is projected to register the highest growth in the electronic potting compound market for EV charger during the forecast period. Epoxy resins play a critical role in EV charger potting applications due to their high mechanical strength and structural rigidity, which provide durable protection for sensitive electronic and power components exposed to thermal cycling, vibration, and mechanical shock. They offer excellent electrical insulation and chemical resistance, making them well-suited for high voltage AC/DC conversion and safety-critical functions in both onboard and offboard charging systems. Epoxy potting compounds also deliver strong moisture and contaminant barrier performance, extending the operational life of EV charger electronics across diverse environmental conditions. Their formulation flexibility allows the incorporation of thermally conductive fillers, enabling improved heat dissipation in high-power modules and dense power electronics. In addition, the mature global manufacturing base and well-established supplier ecosystem for epoxy systems support scalability and cost efficiency in EV charger production. There is also growing emphasis on environmentally compliant epoxy formulations with lower VOC emissions and alignment with evolving regulations such as REACH, without sacrificing insulation or durability. For instance, in November 2025, Wevo Chemie introduced flame-retardant, thermally conductive epoxy potting resins designed to meet strict safety standards, such as EN 45545-2 and UL 94 V-0. These materials offer strong resistance to partial discharge and improved flow characteristics, making them suitable for high-voltage and high-performance applications, including advanced EV charger encapsulation.

"Europe is projected to hold a significant share in the electronic potting compound market for EV charger during the forecast period."

Europe is rapidly expanding its EV charging infrastructure with public charger installations exceeding 1.2 million units by the end of 2025 and continued strong growth in fast and ultra-fast charging, driving higher volumes of charger electronics that require potting and encapsulation. Strong regulatory and policy support, most notably the EU's Alternative Fuels Infrastructure Regulation and broader emission reduction targets, mandate widespread deployment of high-power chargers across member states, increasing demand for durable and compliant potting materials. European charger OEMs and charging service providers such as Wallbox are investing heavily in smart, high-density, and ultra-fast charging hubs that integrate complex power and control electronics, benefiting from potting for insulation, thermal management, and environmental protection. The region's strong emphasis on interoperability and safety standards, including CCS implementations with ISO 15118 features, further raises performance and reliability requirements for electronic protection materials, encouraging the use of advanced potting compounds in charger designs. The rapidly increasing share of DC and ultra-fast chargers in public networks is also elevating the need for thermally conductive and mechanically robust potting compounds to manage heat and ensure long-term reliability. At the same time, harmonized interfaces, communication protocols, and safety frameworks across the EU simplify charger platforms and promote consistency in potting material specifications. The region is also home to leading potting compound manufacturers, including Henkel, Electrolube, Demak Group, and ELANTAS.

In-depth interviews were conducted with CEOs, marketing directors, other innovation and technology directors, and executives from various key organizations operating in this market.

- By Company Type: OEM - 20 %, Tier 1 - 70%, and Tier 2 - 10%

- By Designation: C-level - 40%, Directors - 35%, and Others - 25%

- By Region: Asia Pacific - 35%, North America - 35%, Europe - 25%, and Rest of the World - 5%

The electronic potting compound market for EV charger is dominated by major players, including Henkel Corporation (Germany), Dow (US), Parker Hannifin Corp (US), ELANTAS (Germany), and Momentive (US). These companies are expanding their portfolios to strengthen their position in the electronic potting compound market for EV charger.

Research Coverage:

The report covers the electronic potting compound market for EV charger in terms of setup type (wall mount, stationary), charger type (AC charger, DC charger), application (power electronics, HV components, busbars, and sensor relays, PCB and control modules, connector cable IP zones, charging gun, others), material type (polyurethane, epoxy, silicone), curing technology (room temperature cured, thermal cured, UV cured), EV component (electric motor stator, EV battery cells, EV battery cooling system, on-board charger, in-vehicle charging connector, in-vehicle power converter, others), and region. It covers the competitive landscape and company profiles of the significant players in the electronic potting compound market for EV charger.

The study also includes an in-depth competitive analysis of the key market players, their company profiles, key observations related to product and business offerings, recent developments, and key market strategies.

Key Benefits of Buying the Report:

- The report will help market leaders/new entrants with information on the closest approximations of revenue numbers for the electronic potting compound market for EV charger and their subsegments.

- This report will help stakeholders understand the competitive landscape and gain more insights to position their businesses better and plan suitable go-to-market strategies.

- The report also helps stakeholders understand the market pulse and provides information on key market drivers, restraints, challenges, and opportunities.

- The report will help market leaders/new entrants with information on various trends in the electronic potting compound market for EV charger based on setup type, charger type, application, material type, curing technology, EV component, and region.

The report provides insight into the following points:

- Analysis of key drivers (rising power density in charger electronics driving demand for high-thermal-conductivity potting materials, tightening electrical safety, insulation, and high-voltage testing standards, expansion of high-power DC fast charging drives advanced thermal cycling and stress-resistant potting requirements), restraints (regulatory tightening on flame-retardant chemistries and additive bans, restrictions on SVHCs under REACH and tightening RoHS scrutiny), opportunities (commercialization of high-thermal-conductivity silicone potting for WBG-enabled power modules, turnkey integration of automated dispensing and advanced potting materials for high-volume EV charger production), and challenges (SiC/GaN high-stress behavior creating new reliability failure modes for existing potting systems, circularity and end-of-life issues limiting high-performance polymer choices)

- Product Development/Innovation: Detailed insights into upcoming technologies, research & development activities, and product launches in the electronic potting compound market for EV charger

- Market Development: Comprehensive information about lucrative markets across varied regions

- Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in the electronic potting compound market for EV charger

- Competitive Assessment: In-depth assessment of market share, growth strategies, and product offerings of leading players, such as Henkel Corporation (Germany), Dow (US), Parker Hannifin Corp (US), ELANTAS (Germany), and Momentive (US), in the electronic potting compound market for EV charger

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 MARKET SCOPE AND SEGMENTATION

- 1.3.1 MARKETS COVERED AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS & EXCLUSIONS

- 1.4 YEARS CONSIDERED

- 1.5 CURRENCY CONSIDERED

- 1.6 UNITS CONSIDERED

- 1.7 STAKEHOLDERS

2 EXECUTIVE SUMMARY

- 2.1 KEY INSIGHTS & MARKET HIGHLIGHTS

- 2.2 KEY MARKET PARTICIPANTS: MAPPING OF STRATEGIC DEVELOPMENTS

- 2.3 DISRUPTIVE TRENDS SHAPING ELECTRONIC POTTING COMPOUND MARKET FOR ELECTRIC VEHICLE (EV) CHARGER

- 2.4 HIGH-GROWTH SEGMENTS

- 2.5 SNAPSHOT: GLOBAL MARKET SIZE, GROWTH RATE, AND FORECAST

3 PREMIUM INSIGHTS

- 3.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER

- 3.2 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION

- 3.3 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY SETUP TYPE

- 3.4 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE

- 3.5 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY MATERIAL TYPE

- 3.6 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CURING TECHNOLOGY

- 3.7 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY EV COMPONENT

4 MARKET OVERVIEW

- 4.1 INTRODUCTION

- 4.2 MARKET DYNAMICS

- 4.2.1 DRIVERS

- 4.2.1.1 Rising power density driving demand for high-thermal-conductivity potting materials

- 4.2.1.1.1 Ev charger types and utilization trends, 2026-2032

- 4.2.1.2 Tightening electrical safety, insulation, and high-voltage testing standards

- 4.2.1.3 Expansion of high-power DC fast charging increasing need for stress-resistant and thermal-cycling-stable potting materials

- 4.2.1.1 Rising power density driving demand for high-thermal-conductivity potting materials

- 4.2.2 RESTRAINTS

- 4.2.2.1 Regulatory pressure on flame-retardant chemistries and additive bans

- 4.2.2.2 Restrictions on substances of very high concern (SVHC)

- 4.2.3 OPPORTUNITIES

- 4.2.3.1 Commercialization of high-thermal-conductivity silicone potting for WBG-enabled power modules

- 4.2.3.2 Turnkey integration of automated dispensing and advanced potting materials for high-volume electric vehicle charger production

- 4.2.4 CHALLENGES

- 4.2.4.1 High-stress behavior of silicon carbide (SiC)/gallium nitride (GaN) creating new reliability failure modes for existing potting systems

- 4.2.4.2 Circularity and end-of-life issues limiting high-performance polymer choices

- 4.2.1 DRIVERS

- 4.3 UNMET NEEDS AND WHITE SPACES

- 4.3.1 UNMET NEEDS IN ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER

- 4.3.2 WHITE SPACE OPPORTUNITIES

- 4.4 INTERCONNECTED MARKETS AND CROSS-SECTOR OPPORTUNITIES

- 4.4.1 INTERCONNECTED MARKETS

- 4.4.2 CROSS-SECTOR OPPORTUNITIES

- 4.5 STRATEGIC MOVES BY TIER 1/2/3 PLAYERS

- 4.5.1 STRATEGIC MOVES BY TIER 1/2/3 PLAYERS

5 INDUSTRY TRENDS

- 5.1 MACROECONOMIC INDICATORS

- 5.1.1 INTRODUCTION

- 5.1.2 GDP TRENDS AND FORECAST

- 5.1.3 TRENDS IN GLOBAL ELECTRIC VEHICLE CHARGING STATION MARKET

- 5.1.4 TRENDS IN GLOBAL ELECTRIC VEHICLE INDUSTRY

- 5.2 TRENDS & DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.3 PRICING ANALYSIS

- 5.3.1 INDICATIVE PRICING ANALYSIS, BY CHARGER TYPE, 2024-2026 (USD/TON)

- 5.3.2 AVERAGE SELLING PRICE TREND FOR CHARGER TYPES, BY REGION, 2024-2026

- 5.3.2.1 Average selling price trend for AC chargers, by region, 2024-2026

- 5.3.2.2 Average selling price trend for DC chargers, by region, 2024-2026

- 5.4 ECOSYSTEM ANALYSIS

- 5.5 SUPPLY CHAIN ANALYSIS

- 5.6 CASE STUDY ANALYSIS

- 5.6.1 IMPROVING THERMAL PERFORMANCE AND RELIABILITY OF ELECTRIC VEHICLE ON-BOARD CHARGERS USING LOW-VISCOSITY POLYURETHANE POTTING COMPOUNDS

- 5.6.2 ENHANCING DURABILITY AND RELIABILITY OF ELECTRIC VEHICLE CHARGING CONNECTORS USING ADVANCED POTTING COMPOUNDS

- 5.6.3 MITIGATING THERMAL RUNAWAY IN CYLINDRICAL BATTERY SYSTEMS USING ADVANCED POLYURETHANE POTTING COMPOUNDS

- 5.7 INVESTMENT AND FUNDING SCENARIO

- 5.8 TRADE ANALYSIS

- 5.8.1 IMPORT SCENARIO (HS CODE 3910)

- 5.8.2 EXPORT SCENARIO (HS CODE 3910)

- 5.8.3 IMPORT SCENARIO (HS CODE 390730)

- 5.8.4 EXPORT SCENARIO (HS CODE 390730)

- 5.9 KEY CONFERENCES AND EVENTS, 2026

- 5.10 INSIGHTS INTO MATERIAL CONSUMPTION PER EV CHARGER

- 5.10.1 POTTING COMPOUND CONSUMPTION PER CHARGER ARCHITECTURE

- 5.11 FUTURE ROADMAP FOR POTTING COMPOUND MATERIALS IN EV CHARGING STATIONS

- 5.11.1 MATERIALS ENABLING HIGHER POWER DENSITY AND ULTRA-FAST CHARGING

- 5.11.2 THERMAL AND ELECTRICAL PERFORMANCE UPGRADES FOR CONTINUOUS OPERATION

- 5.11.3 MANUFACTURING-OPTIMIZED POTTING FOR SCALABLE CHARGER DEPLOYMENT

- 5.11.4 SUSTAINABILITY, REWORKABILITY, AND END-OF-LIFE COMPLIANCE

- 5.12 INSIGHTS INTO PUBLIC ELECTRIC VEHICLE CHARGER SETUP FOR MAJOR MARKETS

- 5.12.1 AC CHARGER

- 5.12.2 DC CHARGER

6 TECHNOLOGICAL ADVANCEMENTS, AI-DRIVEN IMPACT, PATENTS, INNOVATIONS, AND FUTURE APPLICATIONS

- 6.1 PATENT ANALYSIS

- 6.2 IMPACT OF GENERATIVE AI ON ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER

- 6.2.1 TOP USE CASES AND MARKET POTENTIAL

- 6.2.1.1 High-performance power electronics

- 6.2.1.2 Connector and harness reliability

- 6.2.1.3 Custom compound design

- 6.2.2 BEST PRACTICES FOLLOWED BY MANUFACTURERS/OEMS

- 6.2.2.1 Generative design in formulation

- 6.2.2.2 AI-driven manufacturing and quality

- 6.2.3 CASE STUDIES RELATED TO AI IMPLEMENTATION

- 6.2.3.1 Accelerating potting compound innovation using AI-driven R&D platforms

- 6.2.3.2 Generative AI for advanced polymer and materials design

- 6.2.3.3 Customized potting compounds for EV power electronics

- 6.2.4 INTERCONNECTED ADJACENT ECOSYSTEM AND IMPACT OF MARKET PLAYERS

- 6.2.4.1 Supply chain and services

- 6.2.4.2 Adjacent technologies

- 6.2.5 CLIENTS' READINESS TO ADOPT AI-INTEGRATED PROCESS IN ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER

- 6.2.1 TOP USE CASES AND MARKET POTENTIAL

- 6.3 KEY EMERGING TECHNOLOGIES

- 6.3.1 ADVANCED THERMALLY CONDUCTIVE SILICONE TECHNOLOGIES FOR EV CHARGER POWER ELECTRONICS

- 6.3.2 WIDE BANDGAP (WBG) POWER SEMICONDUCTORS

- 6.3.3 LOW-VISCOSITY, VOID-FREE POTTING CHEMISTRIES

- 6.3.4 FAST-CURE AND SNAP-CURE POTTING FORMULATIONS

- 6.4 COMPLEMENTARY TECHNOLOGIES

- 6.4.1 AUTOMATED DISPENSING AND METERING SYSTEMS

- 6.4.2 AL-ENABLED PROCESS MONITORING AND CONTROL

- 6.5 ADJACENT TECHNOLOGIES

- 6.5.1 CONFORMAL COATINGS AND SELECTIVE ENCAPSULATION

- 6.5.2 ADVANCED ADHESIVES AND STRUCTURAL BONDING MATERIALS

- 6.5.3 RECYCLABLE AND DEBONDABLE POLYMER SYSTEMS

- 6.6 TECHNOLOGY/PRODUCT ROADMAP

- 6.6.1 SHORT-TERM (2025-2027) | FOUNDATION & EARLY COMMERCIALIZATION

- 6.6.2 MID-TERM (2028-2030) | EXPANSION & STANDARDIZATION

- 6.6.3 LONG-TERM (2031-2035+) | MASS COMMERCIALIZATION & DISRUPTION

7 REGULATORY LANDSCAPE AND SUSTAINABILITY INITIATIVES

- 7.1 REGIONAL REGULATIONS AND COMPLIANCE

- 7.2 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 7.2.1 INDUSTRY STANDARDS

- 7.3 SUSTAINABILITY INITIATIVES

- 7.3.1 CARBON IMPACT AND ECO-APPLICATIONS

- 7.3.1.1 Bio-based resins

- 7.3.1.2 Low-VOC, solventless formulations

- 7.3.1.3 Removable (debondable) potting

- 7.3.2 SUSTAINABILITY IMPACT AND REGULATORY POLICY INITIATIVES

- 7.3.3 CERTIFICATIONS, LABELING, AND ECO-STANDARDS

- 7.3.1 CARBON IMPACT AND ECO-APPLICATIONS

8 CUSTOMER LANDSCAPE & BUYER BEHAVIOR

- 8.1 DECISION-MAKING PROCESS

- 8.2 BUYER STAKEHOLDERS AND BUYING EVALUATION CRITERIA

- 8.2.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 8.2.2 BUYING CRITERIA

- 8.3 ADOPTION BARRIERS & INTERNAL CHALLENGES

9 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE

- 9.1 INTRODUCTION

- 9.2 AC CHARGER

- 9.2.1 INCREASING POWER DENSITY IN COMPACT AC CHARGER DESIGNS TO FUEL GROWTH

- 9.3 DC CHARGER

- 9.3.1 GOVERNMENT-BACKED EXPANSION OF ULTRA-FAST DC CHARGING NETWORKS TO FUEL GROWTH

- 9.4 KEY PRIMARY INSIGHTS

10 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY SETUP TYPE

- 10.1 INTRODUCTION

- 10.2 WALL MOUNT (PRIVATE)

- 10.2.1 EXPANSION OF RESIDENTIAL LEVEL 2 CHARGING INFRASTRUCTURE TO FUEL GROWTH

- 10.3 STATIONARY (PUBLIC)

- 10.3.1 SCALING DEPLOYMENT OF ULTRA-FAST PUBLIC CHARGING HUBS TO FUEL GROWTH

- 10.4 KEY PRIMARY INSIGHTS

11 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY MATERIAL TYPE

- 11.1 INTRODUCTION

- 11.2 POLYURETHANE

- 11.2.1 ADVANCEMENTS IN TWO-COMPONENT POLYURETHANE SYSTEMS FOR EV CHARGER ENCAPSULATION TO FUEL GROWTH

- 11.3 SILICONE

- 11.3.1 SHIFT TOWARD HIGH THERMALLY CONDUCTIVE SILICONE MATERIALS IN ULTRA-FAST CHARGING PLATFORMS TO DRIVE MARKET

- 11.4 EPOXY

- 11.4.1 EXPANSION OF LOW-VOC, REGULATION-COMPLIANT EPOXY FORMULATIONS IN ELECTRIC VEHICLE CHARGING APPLICATIONS TO FUEL GROWTH

- 11.5 KEY PRIMARY INSIGHTS

12 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CURING TECHNOLOGY

- 12.1 INTRODUCTION

- 12.2 ROOM TEMPERATURE CURED

- 12.2.1 EXPANSION OF TWO-COMPONENT ROOM-TEMPERATURE-CURED SYSTEMS IN AC AND DC CHARGERS TO FUEL GROWTH

- 12.3 THERMAL CURED

- 12.3.1 HIGHER POWER RATINGS AND SIC INTEGRATION ACCELERATING USE OF THERMALLY CURED POTTING COMPOUNDS

- 12.4 UV CURED

- 12.4.1 EXPANSION OF HYBRID UV CURING SYSTEMS IN COMPACT AND SMART CHARGER DESIGNS TO FUEL GROWTH

- 12.5 KEY PRIMARY INSIGHTS

13 ELECTRONIC POTTING COMPOUND MARKET, BY EV COMPONENT

- 13.1 INTRODUCTION

- 13.2 ELECTRIC MOTOR STATOR

- 13.2.1 SHIFT TOWARD HIGH-DENSITY DRIVE UNITS STRENGTHENING NEED FOR RELIABLE STATOR ENCAPSULATION

- 13.3 EV BATTERY CELL

- 13.3.1 INCREASING FOCUS ON THERMAL RUNAWAY MITIGATION IN ELECTRIC VEHICLE BATTERIES TO DRIVE MARKET

- 13.4 EV BATTERY COOLING SYSTEM

- 13.4.1 RISING ADOPTION OF CELL-TO-PACK AND CELL-TO-CHASSIS ARCHITECTURES TO BOOST ENCAPSULATION DEMAND

- 13.5 ON-BOARD CHARGER

- 13.5.1 GROWING INTEGRATION OF MULTI-FUNCTIONAL OBC AND DC-DC UNITS TO DRIVE DEMAND

- 13.6 IN-VEHICLE CHARGING CONNECTOR

- 13.6.1 RISING ADOPTION OF HIGH-CURRENT, COMPACT EV CHARGING CONNECTORS TO FUEL GROWTH

- 13.7 IN-VEHICLE POWER CONVERTER

- 13.7.1 RISING INTEGRATION OF MULTIPLE POWER-ELECTRONICS FUNCTIONS TO FUEL GROWTH

- 13.8 OTHERS

- 13.9 KEY PRIMARY INSIGHTS

14 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY APPLICATION

- 14.1 INTRODUCTION

- 14.2 POWER ELECTRONICS

- 14.3 HV COMPONENTS, BUSBARS, AND SENSOR RELAYS

- 14.4 PCB AND CONTROL MODULES

- 14.5 CONNECTOR CABLE IP ZONES

- 14.6 CHARGING GUNS

- 14.7 OTHERS

15 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION

- 15.1 INTRODUCTION

- 15.2 ASIA PACIFIC

- 15.2.1 CHINA

- 15.2.1.1 Presence of well-established domestic manufacturing ecosystem for chargers, power electronics, and materials to drive market

- 15.2.2 INDIA

- 15.2.2.1 Growing localization of EV charger manufacturing under "Make in India" initiative to fuel growth

- 15.2.3 JAPAN

- 15.2.3.1 Increasing installation of high-output EV chargers under Japan's 2030 targets to drive market

- 15.2.4 SOUTH KOREA

- 15.2.4.1 Government-backed deployment of ultra-fast charging networks to fuel growth

- 15.2.5 THAILAND

- 15.2.5.1 Rapid deployment of high-power DC fast chargers to drive market

- 15.2.6 INDONESIA

- 15.2.6.1 Rapid deployment of public EV charging stations and local manufacturing to drive market

- 15.2.7 SINGAPORE

- 15.2.7.1 Deployment of compact, high-density public EV charging systems to drive market

- 15.2.1 CHINA

- 15.3 EUROPE

- 15.3.1 AUSTRIA

- 15.3.1.1 Strategic investment in high-power EV charging under eMove Austria to fuel growth

- 15.3.2 DENMARK

- 15.3.2.1 Acceleration of residential and public EV charger installations under regulatory reforms to drive market

- 15.3.3 FRANCE

- 15.3.3.1 Fleet-focused charging rollouts and OEM-led infrastructure expansion to drive market

- 15.3.4 GERMANY

- 15.3.4.1 Expansion of multi-family residential and corridor charging infrastructure to drive market

- 15.3.5 NETHERLANDS

- 15.3.5.1 High per-capita EV charger installations to drive market

- 15.3.6 NORWAY

- 15.3.6.1 Expansion of highway DC fast-charging corridors to drive market

- 15.3.7 SPAIN

- 15.3.7.1 Government-backed expansion of corridor and rural EV charging networks to fuel growth

- 15.3.8 SWEDEN

- 15.3.8.1 Megawatt charging corridor development to drive high-power charger installations

- 15.3.9 SWITZERLAND

- 15.3.9.1 Subsidized deployment of high-power fleet charging systems to drive market

- 15.3.10 UK

- 15.3.10.1 Government-backed expansion of motorway super hubs and depot charging to fuel growth

- 15.3.1 AUSTRIA

- 15.4 NORTH AMERICA

- 15.4.1 US

- 15.4.1.1 Strategic OEM partnerships and high-voltage charger rollouts to drive market

- 15.4.2 CANADA

- 15.4.2.1 Government-backed rollout of EV chargers to drive market

- 15.4.3 MEXICO

- 15.4.3.1 Strategic rollout of retail and commercial charging sites to fuel growth

- 15.4.1 US

- 15.5 REST OF THE WORLD

- 15.5.1 BRAZIL

- 15.5.1.1 Policy-backed residential charging access expansion in multi-unit buildings to fuel growth

- 15.5.2 UAE

- 15.5.2.1 Scaling fleet-focused and destination DC fast charging networks to drive market

- 15.5.1 BRAZIL

16 COMPETITIVE LANDSCAPE

- 16.1 OVERVIEW

- 16.2 KEY PLAYERS' STRATEGIES/RIGHT TO WIN

- 16.3 MARKET SHARE ANALYSIS OF EV CHARGER POTTING COMPOUND MANUFACTURERS, 2025

- 16.4 REVENUE ANALYSIS OF TOP LISTED/PUBLIC PLAYERS, 2020-2024

- 16.5 COMPANY VALUATION AND FINANCIAL METRICS, 2026

- 16.5.1 COMPANY VALUATION

- 16.5.2 FINANCIAL METRICS

- 16.6 BRAND/ PRODUCT COMPARISON

- 16.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2026

- 16.7.1 STARS

- 16.7.2 EMERGING LEADERS

- 16.7.3 PERVASIVE PLAYERS

- 16.7.4 PARTICIPANTS

- 16.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2026

- 16.7.5.1 Company footprint

- 16.7.5.2 Region footprint

- 16.7.5.3 Charger type footprint

- 16.7.5.4 Material type footprint

- 16.7.5.5 Setup type footprint

- 16.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2026

- 16.8.1 PROGRESSIVE COMPANIES

- 16.8.2 RESPONSIVE COMPANIES

- 16.8.3 DYNAMIC COMPANIES

- 16.8.4 STARTING BLOCKS

- 16.8.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2026

- 16.8.5.1 List of startups/SMEs

- 16.8.5.2 Competitive benchmarking of startups/SMEs

- 16.9 COMPETITIVE SCENARIO

- 16.9.1 PRODUCT LAUNCHES

- 16.9.2 DEALS

- 16.9.3 EXPANSIONS

- 16.9.4 OTHER DEVELOPMENTS

17 COMPANY PROFILES

- 17.1 KEY PLAYERS

- 17.1.1 HENKEL CORPORATION

- 17.1.1.1 Business overview

- 17.1.1.2 Products offered

- 17.1.1.3 Recent developments

- 17.1.1.3.1 Product launches

- 17.1.1.4 MnM view

- 17.1.1.4.1 Key strengths

- 17.1.1.4.2 Strategic choices

- 17.1.1.4.3 Weaknesses and competitive threats

- 17.1.2 PARKER HANNIFIN CORP

- 17.1.2.1 Business overview

- 17.1.2.2 Product offered

- 17.1.2.3 Recent developments

- 17.1.2.3.1 Other developments

- 17.1.2.4 MnM view

- 17.1.2.4.1 Key strengths

- 17.1.2.4.2 Strategic choices

- 17.1.2.4.3 Weaknesses and competitive threats

- 17.1.3 ELANTAS

- 17.1.3.1 Business overview

- 17.1.3.2 Products offered

- 17.1.3.3 MnM view

- 17.1.3.3.1 Key strengths

- 17.1.3.3.2 Strategic choices

- 17.1.3.3.3 Weaknesses and competitive threats

- 17.1.4 DOW

- 17.1.4.1 Business overview

- 17.1.4.2 Products offered

- 17.1.4.3 Recent developments

- 17.1.4.3.1 Product launches

- 17.1.4.3.2 Other developments

- 17.1.4.4 MnM view

- 17.1.4.4.1 Key strengths

- 17.1.4.4.2 Strategic choices

- 17.1.4.4.3 Weaknesses and competitive threats

- 17.1.5 MOMENTIVE

- 17.1.5.1 Business overview

- 17.1.5.2 Products offered

- 17.1.5.3 MnM view

- 17.1.5.3.1 Key strengths

- 17.1.5.3.2 Strategic choices

- 17.1.5.3.3 Weaknesses and competitive threats

- 17.1.6 ELECTROLUBE

- 17.1.6.1 Business overview

- 17.1.6.2 Products offered

- 17.1.6.3 Recent developments

- 17.1.6.3.1 Other developments

- 17.1.7 DEMAK GROUP

- 17.1.7.1 Business overview

- 17.1.7.2 Products offered

- 17.1.8 WEVO-CHEMIE GMBH

- 17.1.8.1 Business overview

- 17.1.8.2 Products offered

- 17.1.8.3 Recent developments

- 17.1.8.3.1 Product launches

- 17.1.9 EPOXIES, ETC.

- 17.1.9.1 Business overview

- 17.1.9.2 Products offered

- 17.1.10 RAMPF

- 17.1.10.1 Business overview

- 17.1.10.2 Products offered

- 17.1.10.3 Recent developments

- 17.1.10.3.1 Expansions

- 17.1.10.3.2 Other developments

- 17.1.11 KISLING

- 17.1.11.1 Business overview

- 17.1.11.2 Products offered

- 17.1.11.3 Recent developments

- 17.1.11.3.1 Deals

- 17.1.12 SIKA AUTOMOTIVE

- 17.1.12.1 Business overview

- 17.1.12.2 Products offered

- 17.1.1 HENKEL CORPORATION

- 17.2 OTHER PLAYERS

- 17.2.1 MASTER BOND

- 17.2.2 PERMABOND

- 17.2.3 DOPAG

- 17.2.4 FINEFINISH

- 17.2.5 MG CHEMICALS

- 17.2.6 3M

- 17.2.7 VEEYOR POLYMERS

- 17.2.8 NAGASE & CO., LTD.

- 17.2.9 WACKER CHEMIE AG

- 17.2.10 PROSTECH

- 17.2.11 MB ENTERPRISES

- 17.2.12 ELKEM ASA

- 17.2.13 ITW PERFORMANCE POLYMERS

18 RESEARCH METHODOLOGY

- 18.1 RESEARCH DATA

- 18.1.1 SECONDARY DATA

- 18.1.1.1 List of key secondary sources

- 18.1.1.2 Key data from secondary sources

- 18.1.2 PRIMARY DATA

- 18.1.2.1 Primary interview participants

- 18.1.2.2 Key industry insights and breakdown of primary interviews

- 18.1.2.3 List of primary interview participants

- 18.1.1 SECONDARY DATA

- 18.2 MARKET SIZE ESTIMATION

- 18.2.1 BOTTOM-UP APPROACH

- 18.2.2 TOP-DOWN APPROACH

- 18.3 DATA TRIANGULATION

- 18.4 FACTOR ANALYSIS

- 18.4.1 DEMAND- AND SUPPLY-SIDE FACTOR ANALYSIS

- 18.5 RESEARCH ASSUMPTIONS

- 18.6 RESEARCH LIMITATIONS

- 18.7 RISK ASSESSMENT

19 APPENDIX

- 19.1 DISCUSSION GUIDE

- 19.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 19.3 CUSTOMIZATION OPTIONS

- 19.3.1 BREAKDOWN OF ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY SETUP TYPE, AT COUNTRY LEVEL (FOR COUNTRIES COVERED IN REPORT)

- 19.3.2 COMPANY INFORMATION:

- 19.3.2.1 Profiling of additional market players (up to 5)

- 19.4 RELATED REPORTS

- 19.5 AUTHOR DETAILS

List of Tables

- TABLE 1 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DEFINITION OF CHARGER TYPES

- TABLE 2 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DEFINITION OF SETUP TYPES

- TABLE 3 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DEFINITION OF MATERIAL TYPES

- TABLE 4 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DEFINITION OF CURING TECHNOLOGIES

- TABLE 5 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DEFINITION OF EV COMPONENTS

- TABLE 6 USD EXCHANGE RATES, 2021-2025

- TABLE 7 EV CHARGER TYPES AND UTILIZATION TRENDS, 2026-2032

- TABLE 8 ELECTRIC VEHICLE CHARGING INCENTIVES, BY COUNTRY

- TABLE 9 IMPACT OF MARKET DYNAMICS ON ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER

- TABLE 10 GDP PERCENTAGE CHANGE, BY KEY COUNTRY, 2021-2030

- TABLE 11 INDICATIVE PRICING ANALYSIS, BY CHARGER TYPE, 2024-2026 (USD/TON)

- TABLE 12 AVERAGE SELLING PRICE TREND FOR AC CHARGERS, BY REGION, 2024-2026 (USD/TON)

- TABLE 13 AVERAGE SELLING PRICE TREND FOR DC CHARGERS, BY REGION, 2024-2026 (USD/TON)

- TABLE 14 ELECTRONIC COMPOUND MARKET FOR EV CHARGER: ROLE OF COMPANIES IN MARKET ECOSYSTEM

- TABLE 15 IMPORT DATA FOR HS CODE 3910, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 16 EXPORT DATA FOR HS CODE 3910, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 17 IMPORT DATA FOR HS CODE 390730, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 18 EXPORT DATA FOR HS CODE 390730, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 19 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: KEY CONFERENCES AND EVENTS, 2026

- TABLE 20 POTTING COMPOUND CONSUMPTION PER CHARGER ARCHITECTURE (IN GRAMS)

- TABLE 21 AC CHARGER SETUP, BY KEY COUNTRIES, 2025

- TABLE 22 DC CHARGER SETUP, BY KEY COUNTRIES, 2025

- TABLE 23 PATENT ANALYSIS, 2025

- TABLE 24 POTTING MATERIAL COMPARISON

- TABLE 25 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 26 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 27 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 28 GLOBAL INDUSTRY STANDARDS, BY COUNTRY/REGION

- TABLE 29 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS OF POTTING COMPOUND IN EV CHARGERS, BY CHARGER TYPE (%)

- TABLE 30 KEY BUYING CRITERIA FOR POTTING COMPOUND IN EV CHARGERS, BY CHARGER TYPE

- TABLE 31 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 32 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 33 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 34 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 35 AC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 36 AC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 37 AC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (USD MILLION)

- TABLE 38 AC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (USD MILLION)

- TABLE 39 DC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 40 DC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 41 DC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (USD MILLION)

- TABLE 42 DC CHARGER: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (USD MILLION)

- TABLE 43 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY SETUP TYPE, 2021-2024 (TONS)

- TABLE 44 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY SETUP TYPE, 2025-2032 (TONS)

- TABLE 45 WALL MOUNT (PRIVATE): ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 46 WALL MOUNT (PRIVATE): ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 47 STATIONARY (PUBLIC): ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 48 STATIONARY (PUBLIC): ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 49 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY MATERIAL TYPE, 2021-2024 (TONS)

- TABLE 50 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY MATERIAL TYPE, 2025-2032 (TONS)

- TABLE 51 POLYURETHANE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 52 POLYURETHANE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 53 SILICONE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 54 SILICONE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 55 EPOXY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 56 EPOXY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 57 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CURING TECHNOLOGY, 2021-2024 (TONS)

- TABLE 58 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CURING TECHNOLOGY, 2025-2032 (TONS)

- TABLE 59 ROOM TEMPERATURE CURED: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 60 ROOM TEMPERATURE CURED: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 61 THERMAL CURED: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 62 THERMAL CURED: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 63 UV CURED: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 64 UV CURED: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 65 ELECTRONIC POTTING COMPOUND MARKET, BY EV COMPONENT, 2021-2024 (TONS)

- TABLE 66 ELECTRONIC POTTING COMPOUND MARKET, BY EV COMPONENT, 2025-2032 (TONS)

- TABLE 67 ELECTRIC MOTOR STATOR: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 68 ELECTRIC MOTOR STATOR: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 69 EV BATTERY CELL: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 70 EV BATTERY CELL: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 71 EV BATTERY COOLING SYSTEM: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 72 EV BATTERY COOLING SYSTEM: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 73 ON-BOARD CHARGER: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 74 ON-BOARD CHARGER: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 75 IN-VEHICLE CHARGING CONNECTOR: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 76 IN-VEHICLE CHARGING CONNECTOR: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 77 IN-VEHICLE POWER CONVERTER: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 78 IN-VEHICLE POWER CONVERTER: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 79 OTHERS: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2021-2024 (KILOS)

- TABLE 80 OTHERS: ELECTRONIC POTTING COMPOUND MARKET, BY REGION, 2025-2032 (KILOS)

- TABLE 81 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (TONS)

- TABLE 82 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (TONS)

- TABLE 83 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2021-2024 (USD MILLION)

- TABLE 84 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025-2032 (USD MILLION)

- TABLE 85 ASIA PACIFIC: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (TONS)

- TABLE 86 ASIA PACIFIC: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (TONS)

- TABLE 87 ASIA PACIFIC: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 88 ASIA PACIFIC: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 89 CHINA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 90 CHINA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 91 CHINA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 92 CHINA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 93 INDIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 94 INDIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 95 INDIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 96 INDIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 97 JAPAN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 98 JAPAN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 99 JAPAN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 100 JAPAN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 101 SOUTH KOREA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 102 SOUTH KOREA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 103 SOUTH KOREA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 104 SOUTH KOREA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 105 THAILAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 106 THAILAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 107 THAILAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 108 THAILAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 109 INDONESIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 110 INDONESIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 111 INDONESIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 112 INDONESIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 113 SINGAPORE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 114 SINGAPORE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 115 SINGAPORE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 116 SINGAPORE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 117 EUROPE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (TONS)

- TABLE 118 EUROPE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (TONS)

- TABLE 119 EUROPE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 120 EUROPE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 121 AUSTRIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 122 AUSTRIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 123 AUSTRIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 124 AUSTRIA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 125 DENMARK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 126 DENMARK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 127 DENMARK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 128 DENMARK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 129 FRANCE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 130 FRANCE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 131 FRANCE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 132 FRANCE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 133 GERMANY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 134 GERMANY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 135 GERMANY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 136 GERMANY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 137 NETHERLANDS: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 138 NETHERLANDS: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 139 NETHERLANDS: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 140 NETHERLANDS: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 141 NORWAY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 142 NORWAY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 143 NORWAY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 144 NORWAY: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 145 SPAIN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 146 SPAIN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 147 SPAIN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 148 SPAIN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 149 SWEDEN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 150 SWEDEN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 151 SWEDEN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 152 SWEDEN: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 153 SWITZERLAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 154 SWITZERLAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 155 SWITZERLAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 156 SWITZERLAND: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 157 UK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 158 UK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 159 UK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 160 UK: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 161 NORTH AMERICA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (TONS)

- TABLE 162 NORTH AMERICA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (TONS)

- TABLE 163 NORTH AMERICA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 164 NORTH AMERICA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 165 US: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 166 US: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 167 US: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 168 US: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 169 CANADA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 170 CANADA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 171 CANADA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 172 CANADA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 173 MEXICO: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 174 MEXICO: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 175 MEXICO: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 176 MEXICO: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 177 REST OF THE WORLD: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (TONS)

- TABLE 178 REST OF THE WORLD: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (TONS)

- TABLE 179 REST OF THE WORLD: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 180 REST OF THE WORLD: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 181 BRAZIL: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 182 BRAZIL: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 183 BRAZIL: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 184 BRAZIL: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 185 UAE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (TONS)

- TABLE 186 UAE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (TONS)

- TABLE 187 UAE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2021-2024 (USD MILLION)

- TABLE 188 UAE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025-2032 (USD MILLION)

- TABLE 189 KEY PLAYER STRATEGIES/RIGHT TO WIN, 2021-2026

- TABLE 190 MARKET SHARE ANALYSIS OF TOP 5 PLAYERS, 2025

- TABLE 191 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: REGION FOOTPRINT, 2026

- TABLE 192 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: CHARGER TYPE FOOTPRINT, 2026

- TABLE 193 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: MATERIAL TYPE FOOTPRINT, 2026

- TABLE 194 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: SETUP TYPE FOOTPRINT, 2026

- TABLE 195 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: LIST OF KEY STARTUPS/SMES

- TABLE 196 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: COMPETITIVE BENCHMARKING OF KEY STARTUPS/SMES

- TABLE 197 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: PRODUCT LAUNCHES, JANUARY 2021-FEBRUARY 2026

- TABLE 198 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DEALS, JANUARY 2021-FEBRUARY 2026

- TABLE 199 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: EXPANSIONS, JANUARY 2021-FEBRUARY 2026

- TABLE 200 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: OTHER DEVELOPMENTS, JANUARY 2021- FEBRUARY 2026

- TABLE 201 HENKEL CORPORATION: COMPANY OVERVIEW

- TABLE 202 HENKEL CORPORATION: PRODUCTS OFFERED

- TABLE 203 HENKEL CORPORATION: POTTING PRODUCT PORTFOLIO

- TABLE 204 HENKEL CORPORATION: PRODUCT LAUNCHES

- TABLE 205 PARKER HANNIFIN CORP: COMPANY OVERVIEW

- TABLE 206 PARKER HANNIFIN CORP: PRODUCTS OFFERED

- TABLE 207 PARKER HANNIFIN CORP: POTTING & ENCAPSULANTS PORTFOLIO

- TABLE 208 PARKER HANNIFIN CORP: OTHER DEVELOPMENTS

- TABLE 209 ELANTAS: COMPANY OVERVIEW

- TABLE 210 ELANTAS: PRODUCTS OFFERED

- TABLE 211 DOW: COMPANY OVERVIEW

- TABLE 212 DOW: PRODUCTS OFFERED

- TABLE 213 DOW: PRODUCT LAUNCHES

- TABLE 214 DOW: OTHER DEVELOPMENTS

- TABLE 215 MOMENTIVE: COMPANY OVERVIEW

- TABLE 216 MOMENTIVE: PRODUCTS OFFERED

- TABLE 217 ELECTROLUBE: COMPANY OVERVIEW

- TABLE 218 ELECTROLUBE: PRODUCTS OFFERED

- TABLE 219 ELECTROLUBE: OTHER DEVELOPMENTS

- TABLE 220 DEMAK GROUP: COMPANY OVERVIEW

- TABLE 221 DEMAK GROUP: PRODUCTS OFFERED

- TABLE 222 WEVO-CHEMIE GMBH: COMPANY OVERVIEW

- TABLE 223 WEVO-CHEMIE GMBH: PRODUCTS OFFERED

- TABLE 224 WEVO-CHEMIE GMBH: SOLUTIONS FOR EV CHARGING

- TABLE 225 WEVO-CHEMIE GMBH: PRODUCT LAUNCHES

- TABLE 226 EPOXIES, ETC.: COMPANY OVERVIEW

- TABLE 227 EPOXIES, ETC.: PRODUCTS OFFERED

- TABLE 228 RAMPF: COMPANY OVERVIEW

- TABLE 229 RAMPF: PRODUCTS OFFERED

- TABLE 230 RAMPF: EXPANSIONS

- TABLE 231 RAMPF: OTHER DEVELOPMENTS

- TABLE 232 KISLING: COMPANY OVERVIEW

- TABLE 233 KISLING: PRODUCTS OFFERED

- TABLE 234 KISLING: DEALS

- TABLE 235 SIKA AUTOMOTIVE: COMPANY OVERVIEW

- TABLE 236 SIKA AUTOMOTIVE: PRODUCTS OFFERED

List of Figures

- FIGURE 1 MARKET SCENARIO

- FIGURE 2 GLOBAL ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, 2021-2032

- FIGURE 3 MAJOR STRATEGIES ADOPTED BY KEY PLAYERS IN ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, 2021-2025

- FIGURE 4 DISRUPTIONS INFLUENCING GROWTH OF ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER

- FIGURE 5 HIGH-GROWTH SEGMENTS IN ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, 2025-2032

- FIGURE 6 ASIA PACIFIC TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 7 GROWTH IN HIGH-POWER EV CHARGER INSTALLATIONS REQUIRING INSULATION AND THERMAL PROTECTION TO DRIVE MARKET

- FIGURE 8 ASIA PACIFIC ACCOUNTED FOR LARGEST MARKET SHARE IN 2025

- FIGURE 9 STATIONARY TO BE FASTER-GROWING SEGMENT THAN WALL MOUNT DURING FORECAST PERIOD

- FIGURE 10 DC CHARGER SEGMENT TO LEAD MARKET IN 2032

- FIGURE 11 EPOXY SEGMENT TO BE FASTEST-GROWING SEGMENT DURING FORECAST PERIOD

- FIGURE 12 THERMAL CURED SEGMENT TO ACCOUNT FOR LARGEST MARKET SHARE IN 2032

- FIGURE 13 EV BATTERY CELL SEGMENT TO ACCOUNT FOR LARGEST MARKET SHARE IN 2032

- FIGURE 14 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 15 TRENDS & DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 16 INDICATIVE PRICING ANALYSIS, BY CHARGER TYPE, 2024-2026 (USD/TON)

- FIGURE 17 AVERAGE SELLING PRICE TREND FOR AC CHARGERS, BY REGION, 2024-2026 (USD/TON)

- FIGURE 18 AVERAGE SELLING PRICE TREND FOR DC CHARGERS, BY REGION, 2024-2026 (USD/TON)

- FIGURE 19 ELECTRONIC COMPOUND MARKET FOR EV CHARGER ECOSYSTEM

- FIGURE 20 SUPPLY CHAIN ANALYSIS

- FIGURE 21 INVESTMENT AND FUNDING SCENARIO, 2022-2025

- FIGURE 22 IMPORT DATA FOR HS CODE 3910, BY COUNTRY, 2021-2024 (USD MILLION)

- FIGURE 23 EXPORT DATA FOR HS CODE 3910, BY COUNTRY, 2021-2024 (USD MILLION)

- FIGURE 24 IMPORT DATA FOR HS CODE 390730, BY COUNTRY, 2021-2024 (USD MILLION)

- FIGURE 25 EXPORT DATA FOR HS CODE 390730, BY COUNTRY, 2021-2024 (USD MILLION)

- FIGURE 26 PATENT ANALYSIS, 2016-2025

- FIGURE 27 LEGAL STATUS OF PATENTS, 2016-2025

- FIGURE 28 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS OF POTTING COMPOUND IN EV CHARGER, BY CHARGER TYPE

- FIGURE 29 KEY BUYING CRITERIA FOR POTTING COMPOUND IN EV CHARGER, BY CHARGER TYPE

- FIGURE 30 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CHARGER TYPE, 2025 VS. 2032 (USD MILLION)

- FIGURE 31 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY SETUP TYPE, 2025 VS. 2032 (TONS)

- FIGURE 32 EV POTTING COMPOUND MATERIAL, BY TEMPERATURE RESISTANCE

- FIGURE 33 EV POTTING COMPOUND MATERIAL, BY FLEXIBILITY AND MECHANICAL STRENGTH

- FIGURE 34 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY MATERIAL TYPE, 2025 VS. 2032 (TONS)

- FIGURE 35 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY CURING TECHNOLOGY, 2025 VS. 2032 (TONS)

- FIGURE 36 ELECTRONIC POTTING COMPOUND MARKET, BY EV COMPONENT, 2025 VS. 2032 (TONS)

- FIGURE 37 EV MOTOR POTTING COMPOUND, THERMALLY CONDUCTIVE

- FIGURE 38 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY REGION, 2025 VS. 2032 (USD MILLION)

- FIGURE 39 ASIA PACIFIC: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER SNAPSHOT

- FIGURE 40 EUROPE: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025 VS. 2032 (USD MILLION)

- FIGURE 41 NORTH AMERICA: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER SNAPSHOT

- FIGURE 42 REST OF THE WORLD: ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER, BY COUNTRY, 2025 VS. 2032 (USD MILLION)

- FIGURE 43 MARKET SHARE ANALYSIS OF TOP EV CHARGER POTTING COMPOUND MANUFACTURERS, 2025

- FIGURE 44 REVENUE ANALYSIS OF TOP LISTED MARKET PLAYERS, 2020-2024

- FIGURE 45 COMPANY VALUATION OF TOP LISTED PLAYERS, 2026 (USD BILLION)

- FIGURE 46 FINANCIAL METRICS OF TOP-LISTED PLAYERS, 2026

- FIGURE 47 BRAND COMPARISON OF TOP 5 PLAYERS

- FIGURE 48 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2026

- FIGURE 49 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: COMPANY FOOTPRINT, 2026

- FIGURE 50 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: STARTUP/SME EVALUATION MATRIX, 2026

- FIGURE 51 HENKEL CORPORATION: COMPANY SNAPSHOT

- FIGURE 52 HENKEL CORPORATION: APPLICATION OF POTTING IN CHARGING CONNECTORS

- FIGURE 53 PARKER HANNIFIN CORP: COMPANY SNAPSHOT

- FIGURE 54 ELANTAS: COMPANY SNAPSHOT

- FIGURE 55 DOW: COMPANY SNAPSHOT

- FIGURE 56 RESEARCH DESIGN

- FIGURE 57 RESEARCH PROCESS FLOW

- FIGURE 58 KEY INSIGHTS FROM INDUSTRY EXPERTS

- FIGURE 59 BREAKDOWN OF PRIMARY INTERVIEWS

- FIGURE 60 RESEARCH METHODOLOGY: HYPOTHESIS BUILDING

- FIGURE 61 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: BOTTOM-UP APPROACH

- FIGURE 62 ELECTRONIC POTTING COMPOUND MARKET FOR EV CHARGER: TOP-DOWN APPROACH

- FIGURE 63 DATA TRIANGULATION

- FIGURE 64 MARKET GROWTH PROJECTIONS FROM DEMAND-SIDE DRIVERS AND OPPORTUNITIES