PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1690912

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1690912

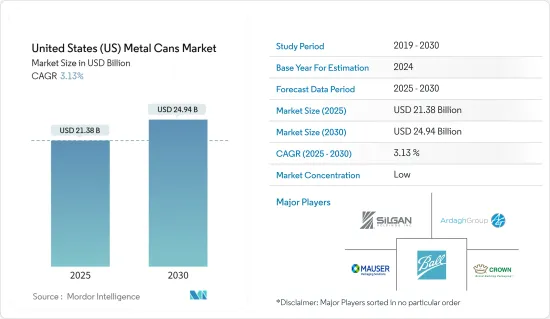

United States (US) Metal Cans - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The United States Metal Cans Market size is estimated at USD 21.38 billion in 2025, and is expected to reach USD 24.94 billion by 2030, at a CAGR of 3.13% during the forecast period (2025-2030).

Key Highlights

- The increasing popularity of metal cans can be attributed to various factors, including their sustainability, durability, and ease of use, as well as the increase in non-premise consumption and consumer preference for new formats (alcoholic and nonalcoholic), food and aerosol in which cans are the preferred packaging.

- Metal cans, especially aluminum, are the most recycled packaging units worldwide. They can be recycled at the end of their lifecycle without quality degradation, making them the preferred packaging material for brands across industries, ahead of other materials, such as plastic and paper. In the United States, 105,784 aluminum cans are recycled each minute, leading to an overall recycling rate of nearly 50%, the highest recycling rate for any beverage container.

- The demand for aluminum cans is expected to increase significantly by 2030, and North America, specifically the United States, is anticipated to contribute hugely to that demand growth. Several vertical and horizontal alignments are constantly taking place in the country owing to the immense demand for metal packaging. In May 2023, Manna Capital collaborated with Ball Corporation to expand the aluminum can sheet manufacturing and recycling facility in the United States.

- Metal cans are used for pet food packaging and have played a significant role in plastic-free pet food packaging. The increased demand for pet food in the United States is driving the increase in the production capacity of metal cans for pet food packaging. According to a Pet Sustainability Coalition (PSC) study published in July 2023, the pet food and treats industry generates an estimated 300 million pounds of plastic waste annually from the United States alone. This is a significant factor due to which some processors are moving away from plastic packaging and gravitating more toward metal cans for pet food.

- Metal cans packaging faces much competition from other packaging solutions. Alternatives such as plastic, paper, or glass packaging solutions are available. Plastic packaging continues to be the main competitor of metal packaging. The food and beverage industry, the primary user of metal cans, has started adopting recyclable plastic packaging solutions. Plastic cans are transparent, which helps brands to show their food's quality.

- Moreover, incremental enhancements in plastic packaging are posing a threat to the market. This can primarily be attributed to the popularity of plastics, such as polyethylene terephthalate (PET), as substitutes. PET plastics threaten to displace metal can packaging solutions in the food and beverage sector.

United States (US) Metal Cans Market Trends

Aluminum to Witness the Growth

- Aluminum cans offer long-term food quality preservation benefits and nearly 100% protection against light, oxygen, moisture, and other contaminants. The material is rust and corrosion-resistant, providing one of the most extended shelf lives considering any packaging. The rising application of aluminum cans in the food and beverage industry can be attributed to their protective properties, sustainability advantages, and convenience. This trend is expected to continue as both manufacturers and consumers recognize the benefits associated with aluminum packaging.

- Significant weight reductions are made possible by creating new alloys for aluminum aerosol cans, which are advanced in collaboration with slug manufacturers. This promotes even greater sustainability. The same applies to complete-layer transport packaging, which is utilized more frequently in the sector and benefits logistics and the environment.

- The aluminum aerosol can market share is driven by the increased usage of these cans in the personal care and automotive industries. Due to their practical packaging options, 100 to 250-ml aluminum aerosol cans are becoming more widely used. Other segments, including 251 ml to 500 ml, less than 100 ml, and others, are capturing better revenue in the global market.

- Aluminum cans have a higher recycling rate and more recycled content than competing package types. According to the Aluminum Association, it is one of the most recycled materials on the market. In April 2022, Ball Corporation partnered with Recycle Aerosol LLC to boost the recycling rates of aluminum aerosol cans in the United States. The collaboration would increase aerosol can recycling and establish a closed-loop system in which used cans are recycled into new aerosol cans.

- According to the Aluminum Association, the aluminum industry recycles more than 40 billion cans annually. The United States saves up to USD 800 million per year by recycling the amount of aluminum that goes into landfills presently.

- Recently, aluminum beverage cans have become the most recyclable beverage containers in the country. The beverage industry members of the Can Manufacturers Institute (CMI) are on a mission to raise US aluminum recycling rates to new levels. CMI published an in-depth primer and roadmap to explain how the CMI's ambitious 2020-2021 recycling rate targets were met. The new aluminum beverage recycling rate targets, announced by CMI members, aim to achieve 70% by 2030, 80% by 2040, and 90% recycling rates by 2050 in the United States.

Non-alcoholic Beverages to Witness Growth

- The beverage industry includes a variety of beverages, from carbonated soft drinks and juices to coffee and tea. It targets consumers with ever-changing tastes for refreshing and indulgent drinks. Health and wellness concerns are driving consumers to seek healthier beverages. This has increased the demand for functional drinks such as fortified water, sports drinks, vitamin and mineral-fortified beverages, and probiotics. Consumers are becoming increasingly aware of their sugar intake and its impact on their health and well-being. As a result, there is a growing need for sugar-free, natural, and organic drinks. The evolving landscape of the beverage industry has been a key driver for the growth of the non-alcoholic beverage cans market.

- New product launches in the non-alcoholic beverage sector have significantly contributed to the growth. For instance, in January 2023, PepsiCo launched Starry, a lemon and lime carbonated soft drink with a crisp and refreshing taste. The drink is available in Regular and Zero Sugar versions at United States retailers. Carbonated soft drinks are traditionally packaged in cans, and PepsiCo's introduction of Starry adds another product to the market that relies on cans for packaging. This can increase demand for standard and slimline beverage cans commonly used for carbonated beverages.

- According to the Beverage Industry Magazine, Red Bull was the United States' largest energy beverage brand in 2022, based on sales of about USD 6.85 billion. Energy drinks, including Red Bull, are typically packaged in cans due to their convenience, portability, and ability to preserve the product's freshness and carbonation. As Red Bull's sales grow, it directly contributes to an increased demand for beverage cans as the primary packaging choice for this product category.

- According to the Organic Trade Association, in 2022, the US consumption of organic beverages amounted to USD 2.5 billion and is forecasted to reach USD 2.8 billion by 2025. Organic drinks, which often include organic juices, teas, and other health-conscious options, are typically packaged in eco-friendly containers that align with organic and sustainable principles.

- Aluminum cans are a suitable choice for organic beverages because they are recyclable and align with the sustainability ethos of the organic movement. As consumption grows, the demand for cans as a packaging option for organic beverages may also increase.

United States (US) Metal Cans Market Overview

The US metal cans market is competitive in nature. Brand identity plays a significant role in the market due to the consumers' inclination toward a more well-identified brand. Market penetration is growing, with a strong presence of major players in established markets, and strategic partnerships are further intensifying the competition. The market also has significant players operating in the industry with higher shares. The barriers to exiting the market are high since metal can manufacturers require a significant divestment of quite specialized assets, which tends to intensify the competitive rivalry. Some of the key players operating in the region include Crown Holdings Inc., Ball Corporation, Silgan Holdings Inc., Mauser Packaging Solutions (BwayHolding Corporation), and Ardagh Metal Packaging SA (Ardagh Group SA).

- In September 2023, Novelis, a sustainable aluminum solutions provider, declared that it entered into an anchor customer agreement with Ball Corporation in North America. The agreement stipulates that Novelis will provide aluminum sheets to the Ball can manufacturing facilities in North America under the terms of the contract.

- In May 2023, Ardagh Metal Packaging and Crown Holdings, producers of aluminum beverage cans, announced their plans to invest in a new grant initiative as part of their ongoing support for initiatives to encourage the installation of further aluminum can capture equipment within material recovery facilities, which specialize in sorting single-stream recyclables.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 High Recyclability Rates of Metal Packaging

- 5.1.2 Convenience and Lower Price offered by Canned Food

- 5.2 Market Restraints

- 5.2.1 Presence of Alternate Packaging Solutions

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Aluminum

- 6.1.2 Steel

- 6.2 By Can Type

- 6.2.1 Food

- 6.2.1.1 Vegetables

- 6.2.1.2 Fruits

- 6.2.1.3 Pet Food

- 6.2.1.4 Soups

- 6.2.1.5 Coffee

- 6.2.1.6 Other Foods

- 6.2.2 Aerosols

- 6.2.2.1 Cosmetics and Personal Care

- 6.2.2.2 Household

- 6.2.2.3 Pharmaceutical/Veterinary

- 6.2.2.4 Paints and Varnishes

- 6.2.2.5 Automotive/Industrial

- 6.2.2.6 Other Aerosols

- 6.2.3 Beverages

- 6.2.3.1 Alcoholic Beverages

- 6.2.3.2 Non-alcoholic Beverages

- 6.2.1 Food

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Crown Holdings Inc.

- 7.1.2 Ball Corporation

- 7.1.3 Silgan Holdings Inc.

- 7.1.4 Mauser Packaging Solutions (Bway Holding Corporation)

- 7.1.5 Ardagh Metal Packaging S.A. (Ardagh Group SA)

- 7.1.6 DS Containers

- 7.1.7 CCL Container (CCL Industries Inc.)

- 7.1.8 Independent Can Company

- 7.1.9 Tecnocap Group

- 7.1.10 CAN-PACK Group (Giorgi Global Holdings Inc.)

- 7.1.11 Allstate Can Corporation

- 7.1.12 Envases Group (ABA Packaging Corporation)

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET