PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1836548

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1836548

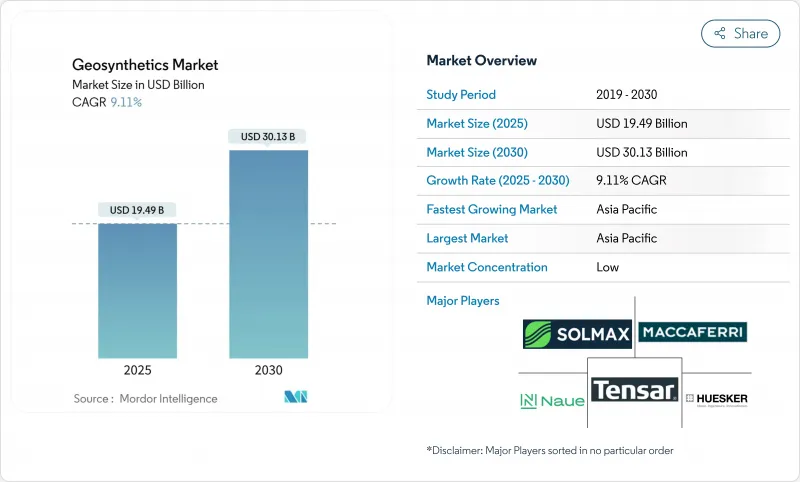

Geosynthetics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Geosynthetics Market size is estimated at USD 19.49 billion in 2025, and is expected to reach USD 30.13 billion by 2030, at a CAGR of 9.11% during the forecast period (2025-2030).

Growth rests on five converging forces. Infrastructure programmes in Asia Pacific, North America, and the Middle East are embedding geosynthetic solutions in roadbeds, retaining walls, and coastal defences because the materials cut aggregate demand and accelerate build schedules. Regulatory bodies in the United States, the European Union, and Japan are mandating stricter containment and filtration standards that favour geomembranes and geotextiles over conventional options. 1 Ongoing R&D in smart materials integrates sensors and recycled polymers to extend service life and enable real-time condition monitoring. Agriculture and mining are emerging end-users, drawn by the erosion-control and tailings-management benefits achieved with newer geogrids and dewatering tubes. Meanwhile, raw-material volatility and evolving European microplastic rules are tempering near-term profitability but also stimulating innovation toward biodegradable or recycled inputs.

Global Geosynthetics Market Trends and Insights

Growing Usage of Geotextiles in Construction Industry

Demand from road, bridge, and foundation projects is elevating the geosynthetics market as contractors replace thicker aggregate layers with geotextile reinforcement that preserves structural capacity while trimming up to 30% of material costs. The U.S. Federal Highway Administration now classifies most geosynthetics as construction materials under the Build America Buy America provisions, triggering mandatory domestic sourcing on federal-aid schemes from March 2025. Urban developers are also selecting geosynthetics for green roofs, where membranes and drainage composites cut stormwater runoff and drop cooling loads by up to 50%. Collectively, these changes underpin a 38% application share in 2024 and sustain long-term momentum for the segment.

Increase Usage of Geotextiles in Mining Activities

Operators of tailings storage facilities are installing composite liners, geogrids, and dewatering tubes to comply with the Global Industry Standards for Tailings Management, thereby reducing liquefaction risks and improving safety records. HUESKER has rolled out purpose-built reinforcement and filtration systems for mine haul roads and waste piles, demonstrating service life gains in Australian operations. As metals demand surges, industry uptake of geosynthetics helps mining account for a growing revenue slice and delivers a 0.3% uplift to the overall CAGR.

Volatile Polypropylene Pricing

Price swings in polypropylene and HDPE inflate production costs and compress margins across the geosynthetics market. Producers are trialling chemical recycling of used plastics to hedge raw-material risk and lower carbon footprints. Braskem's 139,000-ton capacity expansion in Brazil may ease supply tightness in Latin America by 2026.

Other drivers and restraints analyzed in the detailed report include:

- Stringent Regulatory Framework for Environmental Protection

- Increased Agricultural Applications

- Emerging Europe Micro-plastic Rules

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polypropylene, polyethylene and polyester together represented 94% of 2024 revenue and should mirror the overall 9.1% CAGR toward 2030, underscoring their cost-to-performance advantage. This synthetic cohort enjoys well-documented tensile strength, chemical resistance and supply availability, indicators that underpin its leadership in the geosynthetics market. High-density polyethylene geomembranes remain the preferred liner for hazardous-waste cells and heap leach pads under strict EPA protocols epa.gov.

Rising corporate sustainability commitments are propelling natural-fiber and biodegradable polymer research. Though the segment currently secures a single-digit share, EU regulatory pressure on microplastics is accelerating field trials of plant-based geogrids and PLA-blended nonwovens. Demonstrations with Typha domingensis fibre grids revealed break strengths that satisfy erosion-control design values while allowing full biodegradation within a cropping cycle. If validated at scale, these innovations could grow the eco-material slice of the geosynthetics market size at double-digit rates after 2028.

Geomembranes led 2024 turnover with a 35% share and are positioned to register a 10.27% CAGR to 2030, outperforming other product categories in the geosynthetics market. Early adoption in landfill caps has expanded to PFAS containment basins, anaerobic lagoons, and floating-cover reservoir projects that demand near-zero permeability.

Geotextiles remain a large-volume workhorse for filtration and reinforcement. Yet growth is slower as regulatory scrutiny on fibre loss intensifies, spurring material substitutions. Geocomposites and liners that pair drainage cores with geotextiles or membranes are picking up velocity because they combine multiple functions in a thinner profile, appealing to contractors chasing lower excavation volumes and reduced greenhouse-gas footprints. These dynamics imply a gradual redistribution of geosynthetics market share toward multifunctional engineered systems through the forecast window.

The Geosynthetics Market Report Segments the Industry by Material (Polypropylene, Polyethylene, and Polyester, and Others), Type (Geotextile, Geomembrane, Geocomposite, and More), Function (Separation, Drainage, Reinforcement, and More), Application (Construction, Transportation, Environmental, and Other Applications) and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia Pacific held 45% of 2024 revenue and will expand at a 9.99% CAGR as public-sector megaprojects converge with private industrial parks. China's Belt and Road corridors drive bulk orders for geomembranes in high-speed rail embankments and desert expressways. India's Smart Cities Mission catalyses municipal landfill upgrades and canal-lining contracts that embed geotextiles in concrete revetments. Japan and South Korea channel R&D into earthquake-resistant retaining walls that combine geosynthetic reinforcement with lightweight fills, reinforcing demand resilience.

North America continues to consolidate end-user uptake, led by the United States' infrastructure modernisation package. DOT mandates for domestic sourcing of construction materials elevate adoption throughout federal highways, Army Corps flood-control projects and airport runway extensions. Canada's tailings-dam upgrades in the oil-sand sector and Mexico's inter-oceanic corridor represent additional growth nodes.

Europe's stringent circular-economy policies sustain existing penetration yet temper short-term volume gains while producers adapt to microplastic caps. Germany, France and the United Kingdom favour premium geomembranes and geocomposites that meet end-of-life recyclability criteria. Innovators trial biodegradable liners in Scandinavian infrastructure, signalling future shifts in geosynthetics market share toward eco-certified products.

South America and the Middle East & Africa contribute smaller but increasingly strategic volumes. Brazil's Mineracao expansion spurs geosynthetic containment in bauxite residue disposal, whereas Saudi Arabia's NEOM and Red Sea tourism projects specify geogrids for coastal stabilisation. Multilateral financing for water-harvesting dams and desert road networks underpins a steady demand trajectory across these emerging territories.

- ACE Geosynthetics

- Agru America Inc.

- Belton Industries

- Berry Global Inc.

- Bonar Plastics

- Carthage Mills

- Contech Engineered Solutions LLC

- Dow

- Freudenberg Group

- Geo-Synthetics Systems LLC (GSI)

- Hanes Geo Components

- Huesker International

- KayTech

- Minerals Technologies Inc.

- Naue GmbH & Co. KG

- Officine Maccaferri SpA

- Presto Products Company

- SKAPS Industries

- Solmax

- Strata Systems Inc.

- Taian Modern Plastic Co., Ltd

- TENAX SPA

- Tensar, A Division of CMC

- Tessilbrenta S.p.A.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Usage of Geotextiles in Construction Industry

- 4.2.2 Increase Usage of Geotextiles in Mining Activities

- 4.2.3 Stringent Regulatory Framework for Environmental Protection

- 4.2.4 Increased Agricultural Applications

- 4.2.5 Technological Advancements in Material Engineering

- 4.3 Market Restraints

- 4.3.1 Volatile Polypropylene Pricing

- 4.3.2 Emerging Europe Micro-plastic Rules Potentially Restricting Conventional Geotextiles

- 4.3.3 Product Standardization Issues

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Material

- 5.1.1 Polypropylene, Polyethylene, and Polyester

- 5.1.2 Others

- 5.2 By Type

- 5.2.1 Geotextile

- 5.2.2 Geomembrane

- 5.2.3 Geocomposite

- 5.2.4 Geosynthetic Liner and Others

- 5.3 By Function

- 5.3.1 Separation

- 5.3.2 Drainage

- 5.3.3 Reinforcement

- 5.3.4 Filtration

- 5.3.5 Moisture Barrier

- 5.4 By Application

- 5.4.1 Construction

- 5.4.2 Transportation

- 5.4.3 Environmental

- 5.4.4 Other Applications

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 ACE Geosynthetics

- 6.4.2 Agru America Inc.

- 6.4.3 Belton Industries

- 6.4.4 Berry Global Inc.

- 6.4.5 Bonar Plastics

- 6.4.6 Carthage Mills

- 6.4.7 Contech Engineered Solutions LLC

- 6.4.8 Dow

- 6.4.9 Freudenberg Group

- 6.4.10 Geo-Synthetics Systems LLC (GSI)

- 6.4.11 Hanes Geo Components

- 6.4.12 Huesker International

- 6.4.13 KayTech

- 6.4.14 Minerals Technologies Inc.

- 6.4.15 Naue GmbH & Co. KG

- 6.4.16 Officine Maccaferri SpA

- 6.4.17 Presto Products Company

- 6.4.18 SKAPS Industries

- 6.4.19 Solmax

- 6.4.20 Strata Systems Inc.

- 6.4.21 Taian Modern Plastic Co., Ltd

- 6.4.22 TENAX SPA

- 6.4.23 Tensar, A Division of CMC

- 6.4.24 Tessilbrenta S.p.A.

7 Market Opportunities and Future Outlook

- 7.1 White-Space and Unmet-Need Assessment

- 7.2 Expected Increase in Usage Green Roof and Green Wall Construction