PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906983

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906983

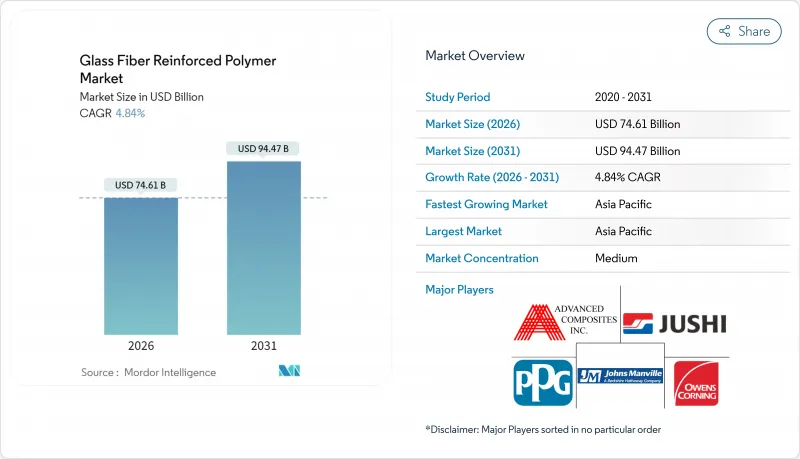

Glass Fiber Reinforced Polymer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Glass Fiber Reinforced Polymer market is expected to grow from USD 71.17 billion in 2025 to USD 74.61 billion in 2026 and is forecast to reach USD 94.47 billion by 2031 at 4.84% CAGR over 2026-2031.

Demand is rising as OEMs in transportation, renewable energy, aerospace, and construction replace heavier metals with corrosion-free composites to lower weight, boost durability, and meet stricter sustainability targets. Rapid urbanization, especially in Asia-Pacific, is stimulating infrastructure investments that specify glass fiber reinforced polymer solutions for rebar, bridge decks, and pipeline liners. Material innovation is widening the performance envelope: bio-based epoxy chemistries are entering series production, while quadaxial stitched reinforcements and hybrid carbon-glass fabrics are enabling new structural applications. Competition is intense but fragmented; multinationals are pruning low-margin lines and partnering with recyclers, whereas regional producers expand capacity close to customers to hedge logistics risk and currency volatility. End-of-life hurdles remain; nevertheless, breakthroughs in pyrolysis and silicon-carbide up-cycling are improving the circularity narrative and easing regulatory pressure in Europe and North America.

Global Glass Fiber Reinforced Polymer Market Trends and Insights

Growing Demand from the Automotive Sector

Electric-mobility programs are accelerating composite uptake because every kilogram saved extends driving range and shrinks battery size. Glass fiber reinforced thermoplastics now replace stamped steel in battery enclosures, trimming mass by 40% while improving fire resistance and thermal insulation. OEMs deploy hybrid carbon-glass transmission housings that cut 30% weight yet keep stiffness for precise gear alignment. Glass fiber reinforced polymer market participants also exploit lower tooling costs to localize niche parts such as tension leaf springs that remove up to 50 kg from commercial vehicles, thereby permitting higher payloads.

Increasing Usage of Glass Fiber Reinforced Polymers in Wind Turbines

The wind sector is the fastest-growing end-user because taller towers and longer blades mandate lighter yet stronger materials. Turbine OEMs integrate carbon-glass hybrid spars and root inserts to keep tip deflection within limits, thereby enabling 15-MW platforms. Lithuanian researchers have validated pyrolysis routes that reclaim fibers and toxic styrene from end-of-life blades, reducing disposal impacts by up to 51% versus landfill. These advances improve the life-cycle credentials that national tenders increasingly require.

High Manufacturing Cost

Specialized fiber sizing, tight process controls, and energy-intensive melting raise costs versus commodity metals. Price declines during 2024 squeezed margins; Owens Corning's Composites sales fell 11% to USD 523 million in Q1 2024, prompting a strategic review of its glass reinforcements unit. Capital-intensive furnaces and limited economies of scale in emerging regions keep unit costs elevated, delaying adoption in cost-driven segments.

Other drivers and restraints analyzed in the detailed report include:

- Increasing Adoption of Glass Fiber Reinforced Polymers in the Aerospace Industry

- Expansion of Construction and Infrastructure Sector

- Limited Recycling Capabilities

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polyester resins dominated 2025 demand with a 61.47% share of the glass fiber reinforced polymer market size, thanks to low price and broad compatibility with compression and spray-up processes. Epoxy, though smaller, will register the highest 4.99% CAGR to 2031 because its superior adhesion, fatigue resistance, and low-void processing meet stringent aerospace, wind, and automotive specifications. Vinyl ester fills the mid-performance niche, combining better chemical resistance than polyester with lower cost than epoxy, and thus appeals to marine and chemical containment projects. Recent bio-based epoxies containing 23% renewable glycol cut manufacturing emissions by 21% without sacrificing mechanical strength, supporting ESG scorecards and procurement guidelines. Nanofiller-modified epoxies that double as solid polymer electrolytes open structural battery and supercapacitor use cases. The glass fiber reinforced polymer market expects continued cost pressure on conventional polyester as downstream customers seek lower embedded carbon alternatives.

Vinyl ester producers are enhancing cure kinetics to suit high-speed resin transfer lines, while polyurethane chemistries gain adoption in impact-absorption panels where toughness outweighs stiffness. Niche thermoplastics such as PEEK remain essential in oil-and-gas downhole tools requiring 240 °C service temperatures. Oversupply concerns are limited because large polyester plants in China run captive furnace networks, allowing quick output throttling during demand swings. Epoxy suppliers hedge raw-material volatility through forward contracts on bisphenol-A and epichlorohydrin, stabilizing pricing to aerospace primes. Innovations in continuous processing, such as snap-cure epoxies that reach demold in 60 seconds, will compress cycle time and support volume ramp-ups in the glass fiber reinforced polymer market.

Compression molding, including Sheet Molding Compound and Glass Mat Thermoplastic, accounted for 30.56% of 2025 revenue due to high repeatability and favorable economics at medium volumes. Injection molding will post a 4.89% CAGR through 2031 as high-flow, long-fiber thermoplastic compounds allow thin-wall complex parts without secondary finishing. Vacuum-assisted resin transfer molding has evolved; adding pressure during cure boosts fiber volume to 62% and lifts tensile strength to 760 MPa while trimming thickness by 4%. Manual lay-up persists for architectural panels and yacht hulls where design freedom overrules takt time.

Continuous pultrusion lines now integrate inline sanding and priming, reducing downstream labor for window frames and power-grid crossarms. Hybrid production cells that switch between thermoset and thermoplastic matrices extend asset utilization and enable multimaterial modules in the glass fiber reinforced polymer market. Robotic handling lowers scrap, and closed-loop digital twins detect resin-rich zones in real time, preventing delamination hot spots. Cost parity with aluminum extrusion is within reach for high-volume automotive sill beams once cycle times fall below 55 seconds, a benchmark that major Tier-1 suppliers target by 2027. In emerging economies, localized compression presses fill regional demand, aided by concessional financing that supports technology transfer.

The Glass Fiber Reinforced Polymer Market Report Segments the Industry by Resin Type (Polyester, Vinyl Ester, Epoxy, and More), Process (Manual Process, Compression Molding, and More), Fiber Form (Rovings, Chopped Strands Mats, and More), End-User Industry (Energy, Automotive, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific dominated with 48.35% revenue in 2025 and is projected to grow at a 4.93% CAGR through 2031. China accelerates capacity with mega-plants such as BASF's USD 10.8 billion Zhanjiang Verbund, which will operate on 100% renewable electricity and supply automotive and electronics composites. India's rail and road modernization campaigns stimulate local demand; BASF has announced additional polyamide and PBT expansions to serve downstream converters. ASEAN countries leverage near-shoring as supply-chain diversification pushes glass fiber reinforced polymer market participants to locate closer to end users.

In North America, the United States leads turbine blade, aerospace, and infrastructure uptake. Jushi Group is finalizing a greenfield furnace in the country, promising regional supply security and import duty avoidance. Federal Buy-America clauses increasingly favor domestic sourcing, benefitting incumbent producers and new entrants. Canada focuses on lightweight buses and battery enclosures to meet zero-emission vehicle mandates. Europe enforces circular-economy legislation that spurs investment in recyclable resins and blade-to-blade glass reclamation. Carbon Rivers' multi-stage pyrolysis recovers fiber for reuse in insulation and sheet molding compounds, attracting grants and brand-owner partnerships. Germany supports hydrogen pipeline retrofits that require corrosion-resistant liners, while offshore wind build-out in the North Sea sustains high-modulus roving demand. South America and Middle East & Africa remain niche but are gaining momentum as Brazil upgrades ports and Saudi Arabia funds mega-projects in transport and renewable energy, opening new arenas for the glass fiber reinforced polymer market.

- Advanced Composites Inc.

- BASF SE

- BGF Industries

- Binani Industries Ltd.

- Celanese Corporation

- China Beihai Fiberglass Co. Ltd

- China Jushi Co. Ltd

- Chongqing Polycomp International Corp. (CPIC)

- Gurit Services AG, Zurich

- Jiuding New Material Co., Ltd

- Johns Manville

- Nippon Electric Glass Co.,Ltd.

- Owens Corning

- PPG Industries Inc.

- Reliance Industries Limited

- SAERTEX GmbH & Co. KG

- Scott Bader Company Ltd.

- The Composite Group

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand from the Automotive Sector

- 4.2.2 Increasing Usage of Glass Fiber Reinforced Polymers in Wind Turbines

- 4.2.3 Increasing Adoption of Glass Fiber Reinforced Polymers in the Aerospace Industry

- 4.2.4 Expandion of Construction and Infrastructure Sector

- 4.2.5 Growing Emphasis on Energy Efficent and Low-Weight Materials in Construction Industry

- 4.3 Market Restraints

- 4.3.1 High Manufacturing Cost

- 4.3.2 Limited Recycling Capabilities

- 4.3.3 Availability of Alternative Materials

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Resin Type

- 5.1.1 Polyester

- 5.1.2 Vinyl Ester

- 5.1.3 Epoxy

- 5.1.4 Polyurethane

- 5.1.5 Other Resin Types (PEEK Resin, Phenolic Resin, etc.)

- 5.2 By Process

- 5.2.1 Manual Process

- 5.2.2 Compression Molding

- 5.2.2.1 Sheet Molding Compound Process

- 5.2.2.2 Glass Mat Thermoplastic Process

- 5.2.3 Continuous Process

- 5.2.4 Injection Molding

- 5.3 By Fiber Form

- 5.3.1 Rovings

- 5.3.2 Chopped Strands Mats

- 5.3.3 Continuous Filament Mats

- 5.3.4 Woven Rovings/Fabrics

- 5.4 By End User Industry

- 5.4.1 Energy

- 5.4.2 Automotive

- 5.4.3 Marine

- 5.4.4 Construction and Infrastructure

- 5.4.5 Electrical and Electronics

- 5.4.6 Aerospace and Defence

- 5.4.7 Other End User Industries (Healthcare, Consumer Goods)

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle-East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Advanced Composites Inc.

- 6.4.2 BASF SE

- 6.4.3 BGF Industries

- 6.4.4 Binani Industries Ltd.

- 6.4.5 Celanese Corporation

- 6.4.6 China Beihai Fiberglass Co. Ltd

- 6.4.7 China Jushi Co. Ltd

- 6.4.8 Chongqing Polycomp International Corp. (CPIC)

- 6.4.9 Gurit Services AG, Zurich

- 6.4.10 Jiuding New Material Co., Ltd

- 6.4.11 Johns Manville

- 6.4.12 Nippon Electric Glass Co.,Ltd.

- 6.4.13 Owens Corning

- 6.4.14 PPG Industries Inc.

- 6.4.15 Reliance Industries Limited

- 6.4.16 SAERTEX GmbH & Co. KG

- 6.4.17 Scott Bader Company Ltd.

- 6.4.18 The Composite Group

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Increasing Applications in Marine Industry