PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844537

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844537

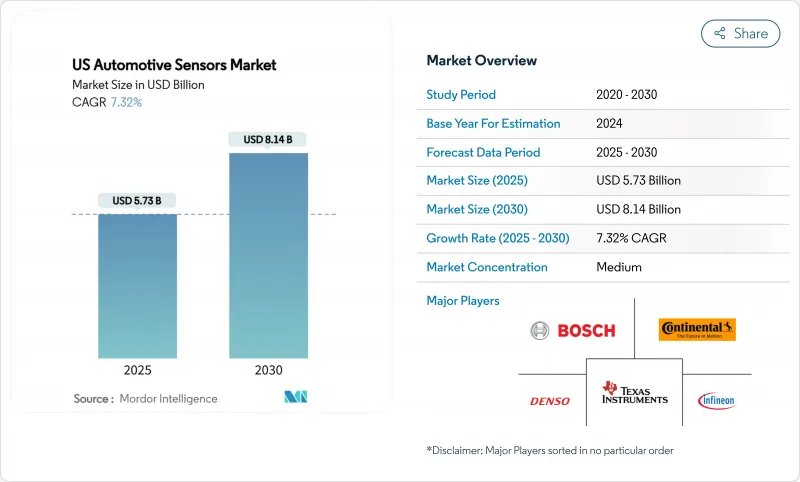

US Automotive Sensors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The US Automotive Sensors Market size is estimated at USD 5.73 billion in 2025, and is expected to reach USD 8.14 billion by 2030, at a CAGR of 7.32% during the forecast period (2025-2030).

Automakers are embedding more sensors per vehicle to comply with tire-pressure, stability-control, and automated-braking mandates. At the same time, fleet operators adopt sensor-rich telematics to control insurance costs and emissions. Radar, lidar, and MEMS-based devices continue to achieve cost and performance breakthroughs, giving legacy suppliers and start-ups new avenues for differentiation in the United States automotive sensors market.

US Automotive Sensors Market Trends and Insights

CHIPS Act Incentivises On-Shore MEMS Fabs

New federal grants worth USD 39 billion are steering wafer-fab projects to Arizona, Texas and upstate New York, ensuring a local pipeline of MEMS pressure, inertial and magnetic sensors that underpin engine, battery and chassis controls. Rogue Valley Microdevices has already secured USD 6.7 million for a Florida plant that will nearly triple its automotive MEMS capacity, illustrating how smaller foundries can scale under the program. The added capacity reduces lead-times, cuts shipping risk and supports just-in-time delivery for Detroit and coastal assembly plants. Universities gain research grants that seed next-gen micromachining processes, further anchoring innovation inside the United States automotive sensors market. Combined, these actions lift resilience and pull future production back from overseas fabs.

EV Adoption Pushes Sensor Content per Vehicle

Electric models integrate two to three times more semiconductors than ICE cars, pushing sensor value toward a greater share by 2030. Battery-management systems alone require multiple temperature, current and voltage nodes to prevent thermal runaway. Position and magnetic sensors monitor e-motor speed, while high-voltage isolation devices maintain safety. Government tax credits and coast-to-coast charging grants accelerate delivery volumes, so suppliers are scaling SiC-based pressure and temperature dies to meet harsher under-hood environments. As a result, the United States automotive sensors market is benefiting from higher average selling prices even when overall vehicle production remains flat.

Silicon-Supply Water-Stress Constraints

Next-generation fabs in Arizona may each draw significant liters of water daily, straining aquifers already under drought pressure. Community opposition or permitting delays could cap local wafer output, tightening the flow of automotive pressure and inertial dies. To mitigate risk, manufacturers are installing closed-loop recycling that recovers more than 70% of process water, yet capital outlays lengthen payback. Prolonged shortages could temper growth for the United States automotive sensors market if additional sites are not approved.

Other drivers and restraints analyzed in the detailed report include:

- Connected-Insurance Telematics Retrofits

- Software-Defined Vehicle Architectures

- Cost & Price-Erosion Squeeze Tier-1 Margins

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Pressure devices delivered 29.35% of 2024 revenue, anchoring applications such as fuel injection, brake boost and mandated tire-pressure monitoring. The United States automotive sensors market size for pressure units is set to expand steadily in line with fuel-efficiency and emissions targets. Radar modules, although smaller today, will grow at a 8.23% CAGR through 2030 thanks to falling 77 GHz chipset prices and NCAP pressure to add blind-spot, front-collision and cross-traffic alerts. Tier-1s now bundle four-corner 4D radar into mainstream SUVs, signalling that sensor fusion is shifting from premium to volume segments.

Second-generation millimetre-wave architectures integrate digital beam-forming and AI-enhanced object classification on a single CMOS die. This reduces bill-of-materials and simplifies thermal design, helping radar to erode camera-only ADAS share. Suppliers that combine radar with inertial reference units promise high-accuracy odometry even when GPS is blocked, creating new value pools within the United States automotive sensors industry.

Powertrain systems accounted for 36.56% of 2024 spend, covering air-flow, knock, coolant-temperature and battery pack sensors. Compliance with Tier 3 emissions rules keeps powertrain allocations high. At the same time, ADAS and autonomous functions will expand at an 8.71% CAGR to 2030, raising their portion of the United States automotive sensors market size considerably. Ultrasonic, camera, radar and lidar combinations enable Level-2+ functions, while NHTSA's new automatic emergency-braking mandate locks in baseline volumes.

To meet redundancy targets, OEMs specify dual independent sensing paths for lateral and longitudinal control. This pushes total semiconductor count per vehicle past thousand mark by 2029, cementing ADAS as the fastest-growing budget line for sensors. Continuous over-the-air feature upgrades further stretch lifecycle revenue because dormant compute headroom can be monetised years after vehicle sale.

The United States Automotive Sensors Market Report is Segmented by Sensor Type (Temperature Sensors and More), Application (Powertrain and More), Vehicle Type (Motorcycles and More), Sales Channel (OEM and More), Propulsion (Internal Combustion Vehicles and More), and Sensor Technology (MEMS and More). The Market Forecasts are Provided in Terms of Value (USD) and Volume (Units).

List of Companies Covered in this Report:

- Robert Bosch GmbH

- DENSO Corporation

- Continental AG

- HELLA GmbH & Co. KGaA

- Valeo SA

- Texas Instruments Inc.

- Infineon Technologies AG

- NXP Semiconductors NV

- Analog Devices Inc.

- Hitachi Astemo Americas Inc.

- Sensata Technologies

- TE Connectivity

- Aptiv PLC

- STMicroelectronics NV

- onsemi

- BorgWarner Inc.

- Renesas Electronics Corp.

- Honeywell International Inc.

- Allegro MicroSystems LLC

- Microchip Technology Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 CHIPS Act Incentivizes On-Shore MEMS Fabs

- 4.2.2 EV Adoption Pushes Sensor Content per Vehicle

- 4.2.3 Federal TPMS, ESC & NCAP Upgrades

- 4.2.4 Connected-Insurance Telematics Retrofits

- 4.2.5 Software-Defined Vehicle Architectures

- 4.2.6 Fleet Decarbonisation Targets (Corporate)

- 4.3 Market Restraints

- 4.3.1 Silicon-Supply Water-Stress Constraints

- 4.3.2 Cost & Price-Erosion Squeeze Tier-1 Margins

- 4.3.3 Harsh-Duty Reliability & Calibration Issues

- 4.3.4 Sensor-Level Cyber-Security Liabilities

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Sustainability & Energy-Footprint Analysis

- 4.8 Porter's Five Forces

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers/Consumers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitute Products

- 4.8.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value (USD) and Volume (Units))

- 5.1 By Sensor Type

- 5.1.1 Temperature Sensors

- 5.1.2 Pressure Sensors

- 5.1.3 Speed / Velocity Sensors

- 5.1.4 Level / Position Sensors

- 5.1.5 Magnetic Sensors

- 5.1.6 Gas / Chemical Sensors

- 5.1.7 Inertial Sensors (Accel/Gyro)

- 5.1.8 LiDAR Sensors

- 5.1.9 Radar Sensors

- 5.1.10 Ultrasonic Sensors

- 5.1.11 Image / Camera Sensors

- 5.1.12 Current Sensors

- 5.2 By Application

- 5.2.1 Powertrain

- 5.2.2 Body Electronics & Comfort

- 5.2.3 Vehicle Security & Safety

- 5.2.4 ADAS & Autonomous Systems

- 5.2.5 Telematics & Connectivity

- 5.2.6 Battery-Management (EV)

- 5.3 By Vehicle Type

- 5.3.1 Motorcycles

- 5.3.2 Passenger Cars

- 5.3.3 Light Commercial Vehicles

- 5.3.4 Heavy Commercial Vehicles

- 5.4 By Sales Channel

- 5.4.1 OEM

- 5.4.2 Aftermarket

- 5.5 By Propulsion

- 5.5.1 Internal-Combustion Vehicles

- 5.5.2 Hybrid Electric Vehicles

- 5.5.3 Battery Electric Vehicles

- 5.5.4 Fuel-Cell Electric Vehicles

- 5.6 By Sensor Technology

- 5.6.1 MEMS

- 5.6.2 Non-MEMS / Macro Sensors

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share for Key Companies, Products and Services, SWOT Analysis, and Recent Developments)

- 6.4.1 Robert Bosch GmbH

- 6.4.2 DENSO Corporation

- 6.4.3 Continental AG

- 6.4.4 HELLA GmbH & Co. KGaA

- 6.4.5 Valeo SA

- 6.4.6 Texas Instruments Inc.

- 6.4.7 Infineon Technologies AG

- 6.4.8 NXP Semiconductors NV

- 6.4.9 Analog Devices Inc.

- 6.4.10 Hitachi Astemo Americas Inc.

- 6.4.11 Sensata Technologies

- 6.4.12 TE Connectivity

- 6.4.13 Aptiv PLC

- 6.4.14 STMicroelectronics NV

- 6.4.15 onsemi

- 6.4.16 BorgWarner Inc.

- 6.4.17 Renesas Electronics Corp.

- 6.4.18 Honeywell International Inc.

- 6.4.19 Allegro MicroSystems LLC

- 6.4.20 Microchip Technology Inc.

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-Need Assessment