PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844549

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844549

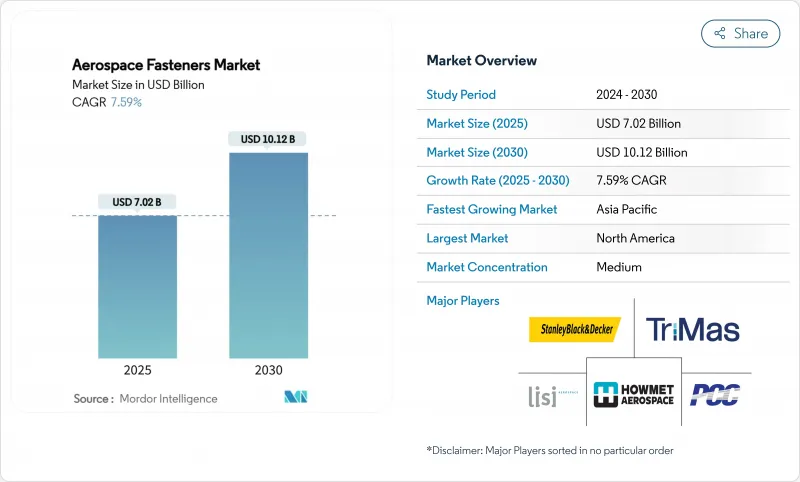

Aerospace Fasteners - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The aerospace fasteners market size is valued at USD 7.02 billion in 2025. It is forecast to reach USD 10.12 billion by 2030, advancing at a 7.59% CAGR as commercial and defense aircraft programs return to growth.

Heightened production rates for single-aisle jets, demand for next-generation military aircraft, and the rise of electric vertical-takeoff-and-landing (eVTOL) fleets are the primary engines that will keep assembly lines active and lift aftermarket volumes. Aircraft OEMs are moving to higher-strength, lighter alloys and automated robotic fastening to meet record backlogs. At the same time, urban-air-mobility platforms expand the application base for small, high-cycle components. Titanium price volatility and supply-chain shocks such as the February 2025 Precision Castparts plant fire underscore the need for diversified sourcing and greater inventory buffers. At the same time, environmental rules phasing out cadmium plating accelerate the adoption of zinc-nickel and other compliant coatings in the aerospace fasteners market.

Global Aerospace Fasteners Market Trends and Insights

Accelerated growth in commercial aircraft production and deliveries

Record backlogs exceeding 8,600 aircraft at Airbus and 6,100 at Boeing translate directly into rising orders for certified bolts, screws, rivets, and specialty panel fasteners. Single-aisle jets, which each require nearly 1 million fasteners, are the focal point of the ramp-up, stretching supplier capacity and allowing premium pricing for high-volume lines. LISI AEROSPACE reported EUR 838.9 million (USD 986.70 million) in 2024 revenue, a 17% jump linked to single-aisle build rates and 26.5% growth in European fastener operations. Embraer's outlook for 10,500 new sub-150-seat jets augments long-term demand beyond traditional narrowbody programs. Automated assembly cells built around laser-guided robots boost throughput and consistency across the aerospace fasteners market.

Fleet-modernisation and lightweighting push

Airlines targeting 15-20% fuel-burn cuts increasingly specify advanced alloys and integrated fastening solutions that reduce aircraft empty weight. Titanium grades such as Ti-6Al-2Sn-2Zr-2Mo-2Cr provide up to 30% weight savings over steel counterparts while meeting stringent fatigue limits. Composite-compatible polymer fasteners, which avoid galvanic corrosion when joining CFRP skins to metallic frames, post the fastest adoption and are forecast to rise 10.65% annually through 2030. The B787 and A350 airframes show that strategic fastener lightweighting can shave 2-3% of overall structural mass. The drive also extends to specialty panel devices that merge captive nuts, seals, and quick-release features, trimming part counts on high-volume doors and interior modules.

Fluctuating raw-material prices impacting cost stability

Aerospace-grade titanium moved 10.91% higher between early 2024 and late 2025, reaching USD 15-30 per pound, compared with USD 6-10 for commercial grades. The Russia-Ukraine conflict and tightening export controls spur OEMs to lock in volume through multiyear contracts or vertically integrate recycling streams. Aluminum and nickel costs rose on energy-related curbs at European smelters, raising pressure on fastener suppliers to hedge inputs or pass costs to customers.

Other drivers and restraints analyzed in the detailed report include:

- Increased procurement of next-generation military aircraft

- Expansion of global MRO infrastructure and aftermarket demand

- Disruptions in OEM production lines affecting fastener demand cycles

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Bolts and screws retained the largest 35.71% share in 2024 as primary structures and engines rely on their tensile strength. Specialty panel fasteners, though smaller in absolute volume, are the clear growth engine at 9.32% CAGR to 2030. This niche's aerospace fasteners market size is projected to expand as integrated, flush-mount designs reduce assembly steps on doors, fairings, and interiors. TriMas Aerospace won a global contract covering Airbus A320, A350, and A220 programs, centred on robot-friendly fastener geometries that lower takt time. Adhesive-bonded studs from Click Bond illustrate how eliminating drilling can cut installation time by 60% while avoiding delamination on composite panels. Fast-advance riveting systems valued at USD 185.9 million by 2034 add to automation momentum.

In parallel, demand for nuts, collars, pins, and inserts remains steady as OEMs standardize self-locking and self-sealing variants that meet high-bypass engines' and rotorcraft's vibration and leakage limits. Blind rivets serve one-sided-access sections of wings and fuselages, benefiting from new alloys offering 10% higher shear strength at equal mass. Together, these trends sustain the aerospace fasteners market even as total part count per airframe falls.

Titanium alloys led with a 32.87% share in 2024, a position they will likely maintain given superior weight-to-strength and corrosion resistance. Yet composite-compatible polymer fasteners register the highest 10.65% CAGR as carbon-fiber skins proliferate. Aluminum alloys remain vital for legacy aluminum fuselages, while high-temperature nickel super-alloys secure engine and exhaust placements.

The aerospace fasteners market share tied to titanium may widen as recycling technology matures; IperionX and Vegas Fastener are partnering to supply recycled titanium hardware for the US Army, signalling growing acceptance of circular-material flows. Meanwhile, EJOT's FLOWpoint DELTA PT screws drive direct fastening into CFRP without pilot holes, avoiding conductive galvanic couples. Such innovations allow OEMs to eliminate metallic inserts and save weight on flight-critical joints.

The Aerospace Fasteners Market Report is Segmented by Product Type (Bolts and Screws, Nuts and Collars, Rivets and Blind Fasteners, Pins and Inserts, and Specialty/Panel Fasteners), Material (Aluminum Alloy, Titanium Alloy, and More), Application (Commercial Aircraft, and More), End-User (Commercial and Military), and Geography (North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America led the aerospace fasteners market with 35.76% share in 2024, anchored by Boeing's production centers, extensive defense budgets, and the world's largest network of MRO facilities. Howmet Aerospace posted record Q1 2025 revenue and a 28.8% EBITDA margin, reflecting robust domestic demand. The Precision Castparts plant fire exposed supply-chain fragility, prompting policy moves to expand domestic titanium output and diversify regional fastener capacity. Government initiatives now support recycling and new mine feasibility studies to minimize import reliance.

Asia-Pacific is the clear growth engine at 9.25% CAGR to 2030. India exemplifies momentum: Boeing alone sources over USD 1.25 billion annually from local suppliers, while policy incentives under the Production-Linked scheme aim to lift aerospace value addition locally. China's COMAC C919, carrying more than 1,000 orders, will lift regional fastener volumes as annual production climbs toward 200 jets by 2029. China's 60% share of global titanium production provides material leverage, though aerospace-grade quality gaps still require imports for critical parts.

Europe maintains a mature yet pivotal position backed by Airbus ramps and strong aftermarket activity. The European Court of Justice annulled earlier chromium VI authorizations, accelerating the industry toward trivalent alternatives and placing compliance pressure on coating lines. LISI AEROSPACE recorded double-digit growth across eight straight quarters, highlighting recovery at key French and German plants. Brexit continues to reshape logistics, with several suppliers establishing dual inventory hubs to serve EU and UK customers without customs delays.

South America benefits from Embraer programs and the rise of regional MRO centers, though currency volatility moderates near-term investment. While smaller today, the Middle East and Africa see long-range fleets and local overhaul clusters emerging in the Gulf states, gradually expanding the aerospace fasteners market footprint.

- Stanley Black & Decker, Inc.

- Arconic Corporation

- Howmet Aerospace Inc.

- LISI Aerospace (LISI Group)

- Precision Castparts Corp. (Berkshire Hathaway Inc.)

- TriMas Corporation

- Boeing Distribution Services Inc. (The Boeing Company)

- Bufab International AB

- National Aerospace Fasteners Corporation

- FSL Aerospace Ltd.

- SFS Group AG

- Avantus Aerospace, Inc.

- Alinabal LLC

- B&B Specialties, Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Accelerated growth in commercial aircraft production and deliveries

- 4.2.2 Fleet-modernisation and lightweighting push

- 4.2.3 Increased procurement of next-generation military aircraft

- 4.2.4 Expansion of global MRO infrastructure and aftermarket demand

- 4.2.5 Adoption of automated robotic fastening in complex assembly lines

- 4.2.6 Rising fastener demand from emerging urban air mobility (eVTOL) platforms

- 4.3 Market Restraints

- 4.3.1 Fluctuating raw material prices impacting cost stability

- 4.3.2 Disruptions in OEM production lines affecting fastener demand cycles

- 4.3.3 Increasing adoption of adhesives and integrated composite assemblies reducing fastener usage

- 4.3.4 Environmental regulations limiting the use of cadmium-plated steel fasteners

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product Type

- 5.1.1 Bolts and Screws

- 5.1.2 Nuts and Collars

- 5.1.3 Rivets and Blind Fasteners

- 5.1.4 Pins and Inserts

- 5.1.5 Specialty/Panel Fasteners

- 5.2 By Material

- 5.2.1 Aluminum Alloy

- 5.2.2 Titanium Alloy

- 5.2.3 Stainless and Alloy Steel

- 5.2.4 Super-Alloys

- 5.2.5 Composite-compatible Polymer Fasteners

- 5.3 By Application

- 5.3.1 Commercial Aviation

- 5.3.2 Military Aviation

- 5.3.3 General and Business Aviation

- 5.3.4 Helicopters

- 5.3.5 Spacecraft and Launch Vehicles

- 5.3.6 Unmanned Aerial Vehicles (UAVs)

- 5.4 By End-User

- 5.4.1 Commercial

- 5.4.2 Military

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Rest of Asia-Pacific

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Stanley Black & Decker, Inc.

- 6.4.2 Arconic Corporation

- 6.4.3 Howmet Aerospace Inc.

- 6.4.4 LISI Aerospace (LISI Group)

- 6.4.5 Precision Castparts Corp. (Berkshire Hathaway Inc.)

- 6.4.6 TriMas Corporation

- 6.4.7 Boeing Distribution Services Inc. (The Boeing Company)

- 6.4.8 Bufab International AB

- 6.4.9 National Aerospace Fasteners Corporation

- 6.4.10 FSL Aerospace Ltd.

- 6.4.11 SFS Group AG

- 6.4.12 Avantus Aerospace, Inc.

- 6.4.13 Alinabal LLC

- 6.4.14 B&B Specialties, Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment