PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844586

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844586

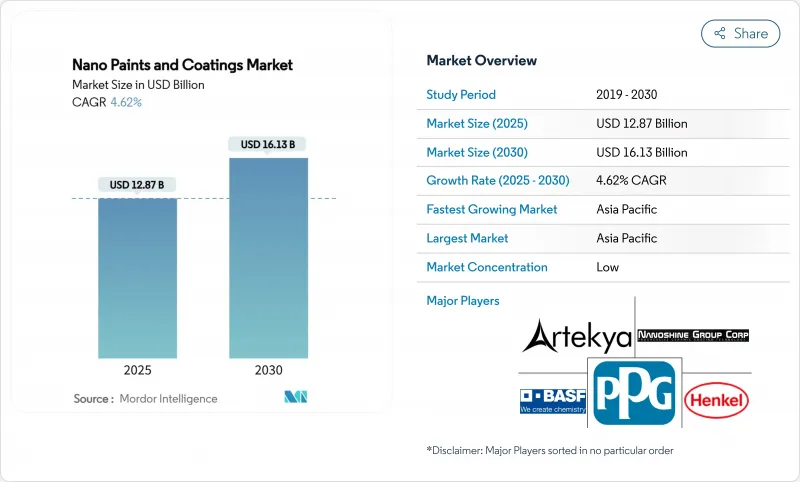

Nano Paints And Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Nano Paints & Coatings Market size is estimated at USD 12.87 billion in 2025, and is expected to reach USD 16.13 billion by 2030, at a CAGR of 4.62% during the forecast period (2025-2030).

Growing aerospace demand for corrosion-lightweight solutions, electric vehicle fire-safety requirements, and infrastructure durability needs keep the market on a steady upward course. A dominant 39.17% nano-TiO2 share combined with graphene's rapid 5.17% CAGR underlines the core role of advanced nanomaterials in sustaining competitive advantage. Regional momentum remains firmly with Asia-Pacific, which controls almost half of global revenues and commands the fastest regional growth. Supply advances in chemical vapor deposition (CVD) and a shift toward multifunctional formulations that merge corrosion protection, thermal management, and antimicrobial performance are shaping new business opportunities, while high production costs and evolving nano-toxicity rules restrain rapid scale-up.

Global Nano Paints And Coatings Market Trends and Insights

Aerospace and defense corrosion-light-weight push

Pentagon estimates that corrosion costs USD 23 billion each year across military equipment, intensifying the adoption of nano coatings that combine structural lightness with superior protection. Field data show nano-engineered layers lowering maintenance cycles on naval airframes, while icephobic properties enhance aircraft readiness in extreme climates. Programs under the U.S. Navy SBIR banner are moving from bench research to fleet trials, illustrating that rigorous certification barriers simultaneously limit new entrants and guarantee durable demand for validated suppliers. As defense procurement strategies favor platforms with reduced total ownership cost, single-application nano formulations that solve weight, durability, and environmental exposure challenges are increasingly specified.

Increase in demand for EV thermal-fire-safety coating

Rapid electrification pushes battery systems toward higher energy density and stricter safety standards. Specialized nano layers dissipate heat swiftly and form fire-retardant barriers, protecting cells and adjacent components. Resonac's thermal insulation product for EV packs highlights active commercial development. Carbon and graphene dispersions deliver thermal conductivity without sacrificing dielectric strength, matching OEM safety protocols. In parallel, passenger-comfort solutions such as Hyundai's nano cooling film that cuts cabin temperature by 10 °C demonstrate spill-over into ancillary applications. Regulatory frameworks that incorporate thermal runaway containment accelerate volume adoption, especially in Asia-Pacific, where battery production capacity is highest.

High production cost of nanomaterials

Specialized CVD reactors, low-yield batch processes, and stringent purity requirements keep unit costs elevated. Capital requirements delay adoption in price-sensitive uses such as consumer furniture, despite technical performance benefits. Venture capital continues to inject funds-Forge Nano's USD 40 million raise underscored private backing-but many scale-up programs remain in pilot phase, pointing to gradual cost attrition rather than abrupt drops. Producers pursue inline metrology, precursor recycling, and hybrid wet-chemistry steps to cut expenses, yet breakeven economics still hinge on premium applications.

Other drivers and restraints analyzed in the detailed report include:

- Growing requirement for high performance coatings

- Increasing demand from infrastructure sector

- Nano-toxicity regulatory uncertainty

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Nano-TiO2 kept its 39.17% hold on the nano paints & coatings market in 2024. Stable manufacturing, photocatalytic self-cleaning performance, and cost efficiency drive its acceptance on facades, automotive trims, and indoor anti-smog panels. Korean pilot lines producing ultra-large transparent screens using TiO2 nanoparticles at one-tenth the price of OLED glass underscore this material's scalability. Graphene, although capped at a modest base, posts a 5.17% CAGR through 2030 as demand from battery heat spreaders and electromagnetic shielding intensifies. Carbon nanotubes remain a niche choice for aerospace and high-end consumer electronics where structural stiffness, conductivity, and weight savings converge. Nano-SiO2 extends its presence in cement additions that lengthen infrastructure life, and nano-ZnO secures UV-blocking coatings for medical devices and smartphones. Future growth leans on hybrid recipes pairing multiple nanoparticles to secure synergistic properties.

The nano paints & coatings market size for titanium dioxide resin applications is projected to widen steadily, while graphene's share expands faster under supply chain releases and reactor capacity additions. Complementing that trajectory is a parallel push for green synthesis routes that use bio-derived precursors or solvent-free dispersion to cut carbon footprint.

The Nano Paints & Coatings Market Report is Segmented by Resin Type (Graphene, Carbon Nanotubes, Nano-TiO2, and More), Method (Electrospray and Electrospinning, Chemical Vapor Deposition, and More), End-User Industry (Aerospace and Defense, Automotive, Biomedical, and More), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific anchored 45.43% of global revenue in 2024, keeping the lead with a 4.91% CAGR outlook. China's electronics supply chains, Japan's materials science clusters, and South Korea's display fabs guarantee a stable baseline. Policy incentives, such as China's Made-in-China 2025 priorities and Japan's Moonshot R&D goals, accelerate nano production capability, shortening lead times. Local CVD reactor suppliers help diffuse technology beyond top-tier conglomerates, enabling mid-size coating shops to certify nano offerings.

North America's demand profile centers on aerospace, defense, and medical devices. U.S. Air Force sustainment commands and space launch primes view nano-layering as strategic maintenance cost reducers. Mexico's ascending EV assembly ecosystem imports nano thermal films and battery coating systems, integrating seamlessly with regional supply. Europe champions eco-design and worker safety, thus driving the adoption of nano-formulated water-borne coatings that satisfy REACH and green building labels. Germany's automotive Tier-1 suppliers and France's aerospace OEMs lock up multi-year framework agreements with nano-coating specialists.

South America injects momentum from infrastructure rehabilitation commitments in Brazil's transport corridors and Argentina's shale play servicing. Exposure to salt spray, high humidity, and UV intensity places a premium on high-performance coatings, and local paint majors partner with Japanese and German nanomaterial producers to localize blends. The Middle East's energy sector trials nano layers on downhole pumps and export pipelines to combat sour corrosion, while Africa's growth story lies in water networks, where internally applied nano sealants cut leak rates under high ambient heat.

- Aculon

- Artekya Teknoloji

- BASF

- Europlasma NV

- Graphene NanoChem

- GVD Corporation

- Henkel AG and Co. KGaA

- I-CanNano

- Nanofilm

- Nanoshine Group Corp

- Pearl Global Ltd.

- Pellucere

- PPG Industries, Inc.

- SIA Naco Technologies

- Starshield Technologies Pvt Ltd

- Tesla NanoCoatings Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Aerospace and defense corrosion-light-weight push

- 4.2.2 Increase in demand for EV thermal-fire-safety coating

- 4.2.3 Growing requirement for high performance coatings

- 4.2.4 Inceasing demand from infrastructure sector

- 4.2.5 Rise in utilization from electronics and consumer goods

- 4.3 Market Restraints

- 4.3.1 High production cost of nanomaterials

- 4.3.2 Nano-toxicity regulatory uncertainty

- 4.3.3 Graphene CVD reactor supply bottlenecks

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Consumers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Resin Type

- 5.1.1 Graphene

- 5.1.2 Carbon Nanotubes

- 5.1.3 Nano-TiO2 (Titanium Dioxide)

- 5.1.4 Nano-SiO2 (Silicon Dioxide)

- 5.1.5 Nano-ZnO

- 5.1.6 Nano Silver

- 5.2 By Method

- 5.2.1 Electrospray and Electrospinning

- 5.2.2 Chemical Vapor Deposition (CVD)

- 5.2.3 Physical Vapor Deposition (PVD)

- 5.2.4 Atomic Layer Deposition (ALD)

- 5.2.5 Aerosol Coating

- 5.2.6 Self-Assembly

- 5.2.7 Sol-Gel

- 5.3 By End-User Industry

- 5.3.1 Aerospace and Defense

- 5.3.2 Automotive

- 5.3.3 Electronics and Optics

- 5.3.4 Biomedical

- 5.3.5 Food and Packaging

- 5.3.6 Marine

- 5.3.7 Oil and Gas

- 5.3.8 Other End-user Industries (Energy and Power, Construction and Infrastructure, etc.)

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Aculon

- 6.4.2 Artekya Teknoloji

- 6.4.3 BASF

- 6.4.4 Europlasma NV

- 6.4.5 Graphene NanoChem

- 6.4.6 GVD Corporation

- 6.4.7 Henkel AG and Co. KGaA

- 6.4.8 I-CanNano

- 6.4.9 Nanofilm

- 6.4.10 Nanoshine Group Corp

- 6.4.11 Pearl Global Ltd.

- 6.4.12 Pellucere

- 6.4.13 PPG Industries, Inc.

- 6.4.14 SIA Naco Technologies

- 6.4.15 Starshield Technologies Pvt Ltd

- 6.4.16 Tesla NanoCoatings Inc.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment