PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844722

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1844722

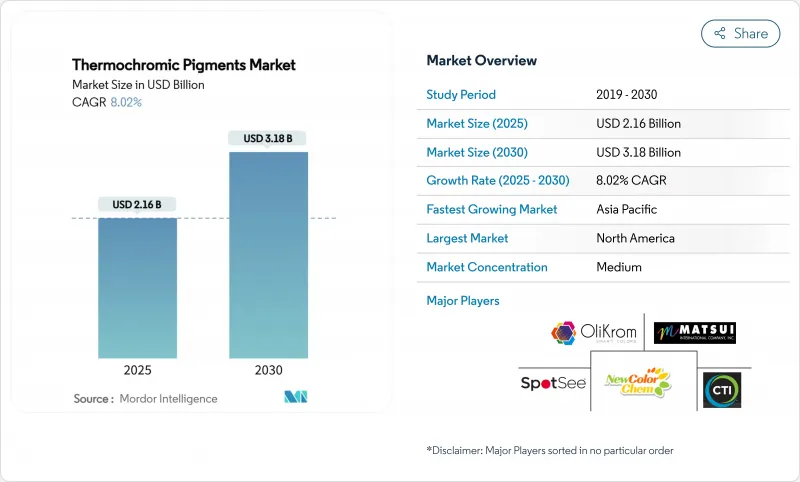

Thermochromic Pigments - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Thermochromic Pigments Market size is estimated at USD 2.16 billion in 2025, and is expected to reach USD 3.18 billion by 2030, at a CAGR of 8.02% during the forecast period (2025-2030).

This expansion is propelled by the widening use of temperature-responsive materials in smart packaging, textiles, and security printing, while progress in microencapsulation keeps pigments stable in demanding environments. Increasing pharmaceutical demand for cold-chain indicators, the pivot toward energy-efficient building coatings, and automotive applications that blend aesthetics with thermal management add further momentum. Large regional end-users continue to integrate smart pigments into compliance seals and food packaging, reducing spoilage and enhancing consumer safety. Cost-down efforts in synthesis, combined with regulatory moves favoring visible temperature indicators, sharpen the market's growth outlook.

Global Thermochromic Pigments Market Trends and Insights

Growing Demand for Smart Packaging

Smart packaging continues to amplify demand as food and pharmaceutical suppliers adopt visible, temperature-sensitive indicators that confirm product integrity across logistics networks. Cold-chain breaks for vaccines, biologics, and ready-to-eat meals trigger irreversible color changes, offering quick, on-site verification for handlers and end users. Studies highlight that unprotected thermochromic polymer blends degrade in acidic conditions, prompting multilayer barriers and durable microcapsules that resist leaching. Regulatory agencies now insist on compliant seals for critical medications, raising baseline volumes of irreversible pigment labels in both mature and developing markets. Multinational pharma firms sourcing North American production spur early adoption, while smaller regional producers in Asia and Africa rely on visual indicators to offset inconsistent refrigeration infrastructure. The cost premium narrows as scale economies in microencapsulation improve, reinforcing the thermochromic pigments market trajectory.

Rising Demand from Smart Textile Industry

Smart textiles represent a high-growth frontier, with yarns embedding thermochromic capsules that shift hue in response to body heat, ambient temperature, or electrical input. Wet-spinning lines deposit capsules uniformly, producing fibers that cycle between colors thousands of times without fatigue. Solar-responsive fabrics reach 52.6 °C in direct sun, changing from orange to green to signal ultraviolet intensity. Integration with conductive threads enables on-demand color control via low-voltage circuits, opening avenues in sportswear, medical monitoring, and adaptive camouflage. Continuous pilot-scale production in China and South Korea lowers unit cost, while fashion houses in Europe trial limited-edition garments that merge aesthetic novelty with functional feedback. These developments underpin the long-term uplift embedded in the thermochromic pigments market.

High Cost with Respect to Conventional Pigments

Thermochromic grades often cost three to five times more than standard pigments, pressuring margins in volume-driven segments such as architectural coatings and commodity textiles. Microencapsulation demands tight process control and specialized reactors, elevating CAPEX for producers. Adoption hinges on proven return-on-investment through spoilage reduction or regulatory compliance for packagers and printers working on razor-thin budgets. Producers counter this restraint by scaling production, localizing supply chains, and adopting less expensive wall materials for microcapsules. These steps gradually close the price gap, especially as global volumes rise inside the thermochromic pigments market.

Other drivers and restraints analyzed in the detailed report include:

- Growth of Security Inks for Anti-Counterfeit Printing

- Expansion of Decorative Paints and Coatings

- Narrow Operational Temperature Range

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Irreversible variants dominate with 59.81% of the thermochromic pigments market share in 2024, reflecting their critical role in single-use pharmaceutical and food indicators. These products deliver permanent color shifts once specific thresholds are crossed, providing court-admissible evidence of temperature abuse. The segment's large installed base across vaccine vials and blood bags ensures recurring demand, sustaining the overall thermochromic pigments market size for this category.

Reversible formulations nonetheless command attention with the highest 8.91% CAGR outlook. Continuous color cycling suits smart textiles, reusable data-loggers, and industrial process monitors. Durability gains from epoxy-silica hybrid capsules now permit more than 10,000 switch cycles without fading.

The Thermochromic Pigments Report is Segmented by Type (Reversible and Irreversible), Application (Plastics and Polymers, Paints and Coatings, Fabrics, Inks, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America holds a 29.81% share of the thermochromic pigments market, anchored by stringent FDA mandates that demand visible temperature indicators for biologics, insulin, and specialty foods. Pharmaceutical majors cluster research and development, manufacturing, and distribution across the United States, driving early adoption and stable volumes. Canadian textile labs develop wearable sensors for elder care, and Mexican automotive plants trial thermochromic body panels to mitigate heat buildup.

Asia-Pacific posts an 8.76% CAGR from 2025-2030, the highest worldwide. Chinese fiber producers scale wet-spinning lines that integrate thermochromic capsules directly into polyester, lowering the cost per kilogram and widening access for mass-market apparel. Japan's materials institutes are perfecting near-infrared responsive pigments suited to autonomous-electronics thermal management, and South Korea's consumer-electronic giants are incorporating smart color films into foldable devices.

Europe remains a pivotal market, leveraging stringent building-energy codes and automotive safety regulations. German chemical firms devise catalyst-free synthesis routes that reduce solvent use, aiding environmental compliance. Fashion houses in France and Italy experiment with color-morphing couture that changes on runways under heat lamps. Though European growth is moderate compared with Asia-Pacific, regulatory certainty and green-technology funding schemes keep thermochromic pigments market penetration elevated.

- Chromatic Technologies Inc.

- Global New Material International

- Hali Pigment Co. Ltd

- iSuoChem

- KingChroma Technology

- L'Arca SRL

- Matsui International Company Inc.

- Merck KGA

- NEW PRISMATIC ENTERPRISE CO., LTD.

- NewColorChem

- OliKrom SA

- QCR Solutions Corp.

- SFXC

- SMAROL Industrial Co. Ltd

- SpotSee

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for Smart Packaging

- 4.2.2 Rising Demand from Smart Textile Industry

- 4.2.3 Growth of Security Inks for Anti-Counterfeit Printing

- 4.2.4 Expansion of Decorative Paints and Coatings

- 4.2.5 Increasing Adoption in Net-Zero Smart-Window Glazing

- 4.3 Market Restraints

- 4.3.1 High Cost with Respect to Conventional Pigments

- 4.3.2 Narrow Operational Temperature Range

- 4.3.3 Durability and Light?Fastness Issues

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts )Value)

- 5.1 By Type

- 5.1.1 Reversible

- 5.1.2 Irreversible

- 5.2 By Application

- 5.2.1 Plastics and Polymers

- 5.2.2 Paints and Coatings

- 5.2.3 Fabrics

- 5.2.4 Inks

- 5.2.5 Other Applications (Smart Windows and Building Materials, etc.)

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 Japan

- 5.3.1.3 India

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 NORDIC Countries

- 5.3.3.8 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Chromatic Technologies Inc.

- 6.4.2 Global New Material International

- 6.4.3 Hali Pigment Co. Ltd

- 6.4.4 iSuoChem

- 6.4.5 KingChroma Technology

- 6.4.6 L'Arca SRL

- 6.4.7 Matsui International Company Inc.

- 6.4.8 Merck KGA

- 6.4.9 NEW PRISMATIC ENTERPRISE CO., LTD.

- 6.4.10 NewColorChem

- 6.4.11 OliKrom SA

- 6.4.12 QCR Solutions Corp.

- 6.4.13 SFXC

- 6.4.14 SMAROL Industrial Co. Ltd

- 6.4.15 SpotSee

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment