PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1846206

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1846206

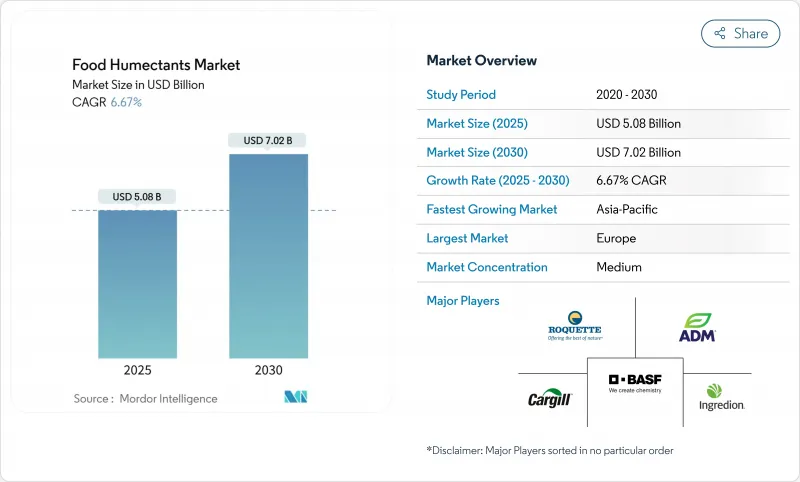

Food Humectants - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The food humectants market size is expected to reach USD 5.08 billion in 2025, the food humectants market is on track to surge to an estimated USD 7.02 billion by 2030, boasting a consistent CAGR of 6.67%.

Regulatory bodies, notably the FDA and EFSA, are ramping up their scrutiny, pushing the industry towards heightened standards in functionality, safety, and sustainability. In response to this regulatory impetus, the industry is channeling investments into cutting-edge technologies. These advancements not only bolster moisture retention and prolong product shelf life but also align with the clean-label claims that consumers are increasingly prioritizing. To navigate these shifting demands, formulators are turning to innovative solutions. These include bio-based propylene glycol, precision-fermented glycerine, and blends of sugar alcohols. Such choices not only adhere to regulatory benchmarks but also champion environmental sustainability. The competitive arena is witnessing a transformation. Multinational giants are honing their supply chains for enhanced efficiency. Simultaneously, niche suppliers are carving out a larger market share by rolling out natural, multifunctional ingredients that resonate with consumer desires.

Global Food Humectants Market Trends and Insights

Rising demand for moisture-retaining ingredients in bakery and confectionary

The bakery and confectionery sector's transition toward extended shelf-life products is driving significant advancements in humectant selection and regulatory compliance. The FDA's classification of glycerin as Generally Recognized as Safe (GRAS) under 21 CFR 582.1320, when used in accordance with good manufacturing practices, provides manufacturers with a reliable regulatory framework. This clarity fosters innovation in moisture-retention solutions, which are critical for maintaining product quality and enhancing consumer satisfaction in bakery applications. Additionally, the Food and Agriculture Organization's Codex GSFA standards for glycerol (E422) establish internationally recognized guidelines, facilitating seamless global trade of bakery products containing humectants. To address evolving moisture management challenges across product lifecycles-from production to retail distribution-manufacturers are increasingly adopting advanced formulations that combine multiple humectants. These formulations are tailored to optimize moisture retention while ensuring product stability.

Demand from frozen and refrigerated food categories

Innovations in humectant technology and formulation strategies are being driven by the unique moisture management challenges posed by frozen food applications. In February 2025, a pilot plant jointly launched by Dow and Evonik, converting hydrogen peroxide to propylene glycol, marked a significant leap in sustainable humectant production. This method slashes water consumption by over 95% when stacked against conventional techniques. Such advancements cater to the frozen food sector's pressing demands: effective moisture retention and a commitment to environmental sustainability. Formulators are honing in on curbing ice crystal formation during freeze-thaw cycles. To uphold product integrity, they're turning to essential stabilizer combinations, notably starches and hydrocolloids. The surge in plant-based frozen alternatives adds layers of complexity. These alternatives exhibit moisture migration patterns that starkly contrast with their traditional animal-based counterparts, necessitating tailored humectant systems.

Regulatory restrictions om usage levels in food applications

Major markets are tightening their regulatory frameworks, posing compliance challenges that limit humectant usage and complicate formulations. In February 2025, China rolled out its GB 2760-2024 standards, imposing stricter limits on food additives. These revisions not only set new usage requirements for humectants but also banned certain compounds in specific food categories. Reflecting heightened safety concerns, the FDA is consulting on contamination limits for ethylene glycol and diethylene glycol in food additives, a move that could influence humectant sourcing and processing. Meanwhile, European regulations on mineral oil hydrocarbons in food add another layer of compliance challenges. The EU's guidelines targeting MOAH in foodstuffs have implications for both packaging and processing materials. Such regulatory pressures are inflating compliance costs and extending product development timelines. This is especially burdensome for smaller manufacturers who often lack extensive regulatory expertise.

Other drivers and restraints analyzed in the detailed report include:

- Use in low-sugar and sugar-free products

- Technology innovations in clean-label humectants

- Limited awarness in developing countries

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

In 2024, sugar alcohols capture a 44.23% market share, bolstered by global regulatory endorsements and proven safety records. The FDA's designation of sorbitol as GRAS under 21 CFR Part 184 paves the way for its widespread use in food applications. Such regulatory backing empowers manufacturers to harness sugar alcohols across various applications, all while adhering to stringent food safety standards. The segment's stronghold is further solidified by the FAO's Codex GSFA standards, which set global benchmarks for sugar alcohols in food, promoting international trade and consistency. Beyond their roles as sweeteners, sugar alcohols serve as humectants, meeting manufacturers' demands for versatile ingredients that streamline formulations without compromising quality or compliance.

Glycols are set to be the fastest-growing segment, boasting an 8.04% CAGR through 2030, thanks to their enhanced performance in niche applications and a surge in regulatory endorsements. The FDA's oversight of propylene glycol mono- and diesters under 21 CFR 172.856 underscores the agency's acknowledgment of glycol-based humectants in targeted food uses. This regulatory nod fuels innovations in glycol formulations, tackling moisture management in frozen and processed foods. The segment is also reaping rewards from strides in sustainable production, notably the rise of bio-based propylene glycol via eco-friendly processing techniques. These advancements not only lessen environmental footprints but also uphold performance standards. Modern glycol formulations are now equipped with controlled-release features, ensuring moisture retention throughout a product's shelf life, effectively countering quality dips in less-than-ideal storage conditions.

The Food Humectants Market Report is Segmented by Type (Sugar Alcohol, Glycerol, Glycol, Lactate, and Others), by Application (Bakery & Confectionery, Functional & Nutritional Foods, Beverages, Dairy and Frozen Desserts, and More), by Source (Natural, and Synthetic), and by Geography (North America, Europe, Asia-Pacific, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

In 2024, Europe holds a leading 32.88% market share, driven by its advanced food processing industries and stringent quality standards that promote humectant usage across a wide range of applications. The region's regulatory framework, particularly the implementation of Commission Regulation (EU) 2023/915, which sets maximum contaminant levels, creates a dual landscape of challenges and opportunities for humectant suppliers. Germany, the United Kingdom, and France dominate regional consumption, supported by their sophisticated bakery industries and increasing demand for clean-label ingredients. Europe's strong focus on sustainability aligns with the growing preference for natural humectants, while its well-established supply chains ensure consistent product availability and quality.

Asia-Pacific is positioned as the fastest-growing region, with a projected CAGR of 7.74% through 2030. This growth is fueled by rapid industrialization in food processing and changing dietary habits that favor convenience foods. Meanwhile, India and Southeast Asia drive volume growth through rising consumption of processed foods, while Australia and South Korea contribute with their adoption of advanced food technologies. The region's diverse regulatory environment necessitates tailored strategies, prompting companies to establish local partnerships and production facilities to address specific market demands effectively.

North America maintains a strong market presence, supported by its leadership in innovation and a well-established food processing infrastructure that enables advanced humectant applications. The region benefits from the FDA's comprehensive regulatory framework, including the GRAS designation for key humectants under 21 CFR Part 184, which facilitates streamlined product development and market entry. Mexico's expanding food processing industry and Canada's focus on natural ingredients further contribute to the region's growth dynamics. In contrast, South America and the Middle East & Africa represent emerging opportunities. In South America, Brazil and Argentina lead the expansion, driven by their growing food processing capabilities. Simultaneously, the Middle East's emphasis on food security and Africa's rapidly urbanizing population are increasing the demand for shelf-stable products, underscoring the critical role of effective moisture management systems in these regions.

- Archer Daniels Midland Company

- Cargill Incorporated

- BASF SE

- Dow Inc.

- Ingredion Incorporated

- Finasucre SA (Galactic s.a.)

- Roquette Freres SA

- Corbion N.V

- K.C.P Sugar and Industries Corporation Ltd

- Tate & Lyle PLC

- Jungbunzlauer Holding AG (Jungbunzlauer Suisse AG)

- Lallemand Group (Isaltis Inc.)

- Celanese Corporation

- International Flavors & Fragrances Inc.

- Henry Lamotte Oils GmbH

- Mitsubishi Corporation Life Sciences Limited

- Mitsui Group (B Food Science Co., Ltd.)

- Gulshan Polyols Ltd

- ACURO Organics Ltd

- Foodchem International Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising demand for moisture-retaining ingredients in bakery and confectionary

- 4.2.2 Demand from frozen and refrigerated food categories

- 4.2.3 Use in low-sugar and sugar-free products

- 4.2.4 Technology innovations in clean-label humectants

- 4.2.5 Growing adoption in plant-based dairy alternatives

- 4.2.6 Development of multi-functional humectants

- 4.3 Market Restraints

- 4.3.1 Regulatory restrictions om usage levels in food applications

- 4.3.2 Limited awarness in developing countries

- 4.3.3 Growing demand for preservative-free and natural products

- 4.3.4 Adultration risks in unregulated markets

- 4.4 Supply Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Type

- 5.1.1 Sugar Alcohol

- 5.1.2 Glycerol

- 5.1.3 Glycol

- 5.1.4 Lactate

- 5.1.5 Others

- 5.2 By Source

- 5.2.1 Natural

- 5.2.2 Synthetic

- 5.3 By Application

- 5.3.1 Bakery and Confectionery

- 5.3.2 Functional and Nutritional Foods

- 5.3.3 Beverage

- 5.3.4 Dairy and Frozen Desserts

- 5.3.5 Savory and Snacks

- 5.3.6 Others

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.1.4 Rest of North America

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 Italy

- 5.4.2.4 France

- 5.4.2.5 Spain

- 5.4.2.6 Netherlands

- 5.4.2.7 Poland

- 5.4.2.8 Belgium

- 5.4.2.9 Sweden

- 5.4.2.10 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 China

- 5.4.3.2 India

- 5.4.3.3 Japan

- 5.4.3.4 Australia

- 5.4.3.5 Indonesia

- 5.4.3.6 South Korea

- 5.4.3.7 Thailand

- 5.4.3.8 Singapore

- 5.4.3.9 Rest of Asia-Pacific

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Colombia

- 5.4.4.4 Chile

- 5.4.4.5 Peru

- 5.4.4.6 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 South Africa

- 5.4.5.2 Saudi Arabia

- 5.4.5.3 United Arab Emirates

- 5.4.5.4 Nigeria

- 5.4.5.5 Egypt

- 5.4.5.6 Morocco

- 5.4.5.7 Turkey

- 5.4.5.8 Rest of Middle East and Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Ranking Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials (if available), Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Archer Daniels Midland Company

- 6.4.2 Cargill Incorporated

- 6.4.3 BASF SE

- 6.4.4 Dow Inc.

- 6.4.5 Ingredion Incorporated

- 6.4.6 Finasucre SA (Galactic s.a.)

- 6.4.7 Roquette Freres SA

- 6.4.8 Corbion N.V

- 6.4.9 K.C.P Sugar and Industries Corporation Ltd

- 6.4.10 Tate & Lyle PLC

- 6.4.11 Jungbunzlauer Holding AG (Jungbunzlauer Suisse AG)

- 6.4.12 Lallemand Group (Isaltis Inc.)

- 6.4.13 Celanese Corporation

- 6.4.14 International Flavors & Fragrances Inc.

- 6.4.15 Henry Lamotte Oils GmbH

- 6.4.16 Mitsubishi Corporation Life Sciences Limited

- 6.4.17 Mitsui Group (B Food Science Co., Ltd.)

- 6.4.18 Gulshan Polyols Ltd

- 6.4.19 ACURO Organics Ltd

- 6.4.20 Foodchem International Corporation

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK