PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1846265

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1846265

Industrial Display - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

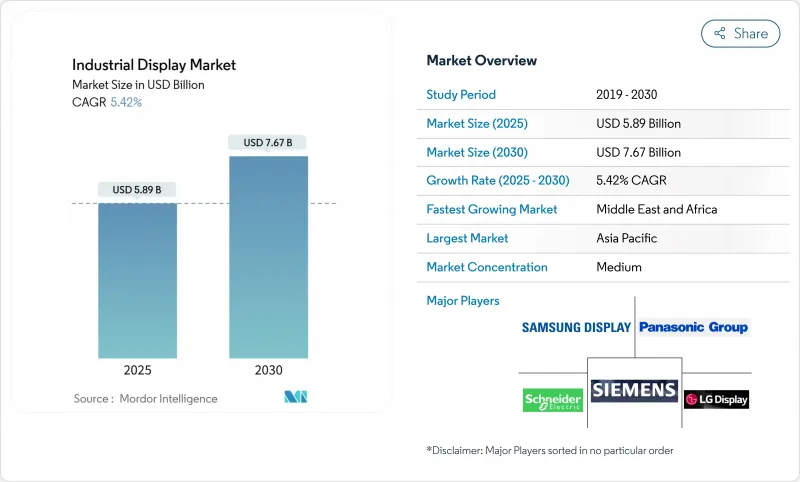

The industrial display market size stands at USD 5.89 billion in 2025 and is projected to reach USD 7.67 billion by 2030, reflecting a 5.42% CAGR over the forecast period.

Operators are moving from basic read-outs to multi-layered visualization hubs that connect plant-floor assets, edge gateways and cloud analytics platforms. Human-machine interface (HMI) consoles continue to dominate procurement, yet remote asset and pipeline visualization is scaling the fastest as energy firms centralize oversight of dispersed infrastructure. LCD panels preserve cost leadership, while OLED and AMOLED modules post the quickest growth as control rooms demand lower power draw and superior contrast for round-the-clock duty. Semiconductor shortages lengthen LCD controller lead times, pushing integrators to diversify technology roadmaps and pursue strategic component reserves. Regionally, Asia-Pacific leverages economies of scale in component fabrication, whereas the Middle East and Africa accelerates capital expenditure on explosion-proof visualization for oil and gas megaprojects.

Global Industrial Display Market Trends and Insights

Increasing Adoption of Industrial IoT in Discrete and Process Plants

Edge-ready HMIs now process millisecond latency data from Ethernet-based networks, enabling predictive maintenance dashboards that minimize unplanned shutdowns. Rockwell Automation identifies IIoT architecture as the principal digitization pathway for 2025, citing tighter coupling between controllers and visualization endpoints. HMS Networks confirms momentum, noting that Industrial Ethernet supplied 71% of new node installations in 2024, catalyzing demand for displays that support PROFINET, EtherNet/IP and EtherCAT stacks.

Demand Surge for Multi-featured HMI in Hazardous Chemical Facilities

The ISA-TR101.02-2019 technical report codifies usability and performance benchmarks that now influence every procurement brief. Suppliers such as VarTech Systems deliver C1D1 and C1D2 certified panels offering multi-touch, voice control and >1,000 nit brightness, aligning safety with functionality. These specifications support batch-to-batch integrity in chemicals and pharmaceuticals where micro-seconds matter for operator intervention.

High Cost of Implementation and Maintenance

Explosion-proof enclosures, conformal coatings, and specialized mounting kits elevate upfront system outlays. Comark Corporation projects that IECEx compliance can double equipment budgets for offshore platforms while extending engineering schedules by several quarters.

Other drivers and restraints analyzed in the detailed report include:

- Lean-Manufacturing Digital Signage (Andon) Roll-outs Across Automotive Lines

- Retrofit Wave of Aging North-American Factories for Electrification and Automation

- Prolonged LCD Controller Lead-Times Amid Chip Shortage

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Rugged housings rated to IP65-67 secured a 31.5% slice of the industrial display market in 2024, reflecting critical-duty requirements in drilling, mining and military platforms. Video walls are projected to compound at 5.9% annually, fueled by centralized control-room investment across petrochemical complexes. High-brightness open-frame modules integrate into kiosk enclosures, while panel-mount units remain the workhorse for machine-level HMIs. The industrial display market repeatedly favors vendors that combine shock resistance with modular I/O, ensuring rapid swap-out and minimal downtime. Marine-grade variants meet MIL-STD-167 vibration thresholds and salt-spray protocols, extending the industrial display market footprint to naval vessels and offshore rigs. Bar-type and stretch screens address multi-parameter dashboards in power plants, a niche translating to higher ASPs despite lower volumes.

Second-tier suppliers are blending ruggedization with narrow-bezel architectures, creating cross-over products that serve both field panels and command centers. Barco's enterprise cinema contract for 4,000 laser screens underscores manufacturing scalability that later translates into industrial video walls. Hybrid enclosures now embed redundant power supplies and edge gateways, aligning with IEC 60079-2025 safety clauses while enlarging the serviceable industrial display market.

HMI stations delivered 46.8% of 2024 revenue, but remote asset visualization will outpace at a 6.4% CAGR as pipeline and well-pad telemetry shifts to centralized NOCs. The industrial display market size for remote monitoring is forecast to expand steadily as satellite and LPWAN connectivity proliferate in deserts and offshore locations. Andon boards in lean plants and interactive kiosks for maintenance crews reinforce human-centric visual workflows that shorten fault-to-fix cycles. Control-room video walls constitute the premium class where bezel-less LCD or emerging Micro-LED arrays craft immersive situational awareness environments. Integration with AI-driven analytics platforms means operators now act on prescriptive prompts rendered directly on the screen, reducing operator fatigue and error incidence.

Distributed solar-powered screens demonstrated by OnePetro field trials prove viability in regions lacking grid access, widening the install base of the industrial display market in remote extraction zones. As cybersecurity rises in priority, displays are increasingly paired with hardware-root-of-trust modules to secure on-screen data flows, a requirement accentuated in cross-border pipeline operations.

The Industrial Display Market Report is Segmented by Type (Rugged Displays, Open Frame Monitors, and More), Application (Human-Machine Interface, Remote Asset and Pipeline Monitoring, and More), Technology (LCD, LED Backlit LCD, and More), Panel Size (Up To 14 Inch, 14 Inch - 21 Inch, and More), End-Use Industry (Manufacturing, Energy and Power, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific commanded 37% revenue in 2024, underpinned by China's factory automation drive and Japan's leadership in precision components. Samsung Display and LG Display operate global-scale OLED fabs, cementing the region's supply advantage across the industrial display market. Component governments back capex tax credits that accelerate panel plant expansions, ensuring steady panel availability even during semiconductor shortages.

The Middle East and Africa is poised for the fastest 6.3% CAGR to 2030. Multi-billion-dollar hydrocarbon projects across the Gulf rely on intrinsically safe screens certified under IEC 60079-2025, enlarging the industrial display market size for explosion-proof hardware. National oil companies pair centralized NOCs with regional micro-control rooms, demanding synchronized video walls that sustain high brightness amid desert temperatures.

North America witnesses a retrofit wave across mid-century factories seeking energy efficiencies and cybersecurity hardening. Proactive replacement of CRTs and resistive-touch panels with IP-based glass surfaces boosts the industrial display market as factories embrace digital performance boards. Europe advances Industry 4.0 blueprints with a focus on ergonomic HMI layouts compliant with EN ISO 9241-210 usability guidance, promoting operator well-being. South America's mining and hydroelectric sectors import hardy panels rated for high altitude and humidity, further diversifying geographic revenue.

- Samsung Display Co., Ltd.

- LG Display Co., Ltd.

- Panasonic Holdings Corp.

- Sharp Corp.

- Emerson Electric Co.

- Schneider Electric SE

- Siemens AG

- Rockwell Automation Inc.

- NEC Display Solutions, Ltd.

- Advantech Co., Ltd.

- Barco NV

- WinMate Inc.

- Planar Systems, Inc.

- AU Optronics Corp.

- Bosch Rexroth AG

- Mitsubishi Electric Corp.

- Honeywell International Inc.

- Kontron AG

- iBASE Technology Inc.

- Beijer Electronics Group AB

- Delta Electronics, Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Adoption of Industrial IoT in Discrete and Process Plants

- 4.2.2 Demand Surge for Multi-featured HMI in Hazardous Chemical Facilities

- 4.2.3 Lean-Manufacturing Digital Signage (Andon) Roll-outs Across Automotive Lines

- 4.2.4 Retrofit Wave of Aging North-American Factories for Electrification and Automation

- 4.2.5 Outdoor-Grade Sunlight-Readable Micro-OLED/Micro-LED Panels for Oilfield Operations

- 4.2.6 IECEx-2022 Mandate for Intrinsically Safe Offshore Display Hardware

- 4.3 Market Restraints

- 4.3.1 High Cost of Implementation and Maintenance

- 4.3.2 Prolonged LCD Controller Lead-Times Amid 2023-24 Chip Shortage

- 4.3.3 Legacy PLC Interface Fragmentation Limiting Display Interoperability

- 4.3.4 Accelerated Panel Burn-in in 24/7 Control-Room Duty Raising TCO

- 4.4 Indusrty Ecosystem Analysis

- 4.5 Regulatory and Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Type

- 5.1.1 Rugged Displays

- 5.1.2 Open Frame Monitors

- 5.1.3 Panel-Mount Monitors

- 5.1.4 Marine and Naval-Grade Displays

- 5.1.5 Industrial Video Walls

- 5.1.6 Bar-Type/Stretch Displays

- 5.2 By Application

- 5.2.1 Human-Machine Interface (HMI)

- 5.2.2 Remote Asset and Pipeline Monitoring

- 5.2.3 Interactive Kiosks and Operator Terminals

- 5.2.4 In-plant Digital Signage and Andon Boards

- 5.2.5 Control-Room Video Walls

- 5.3 By Technology

- 5.3.1 LCD

- 5.3.2 LED Backlit LCD

- 5.3.3 OLED/AMOLED

- 5.3.4 E-Paper and Reflective Displays

- 5.3.5 Micro-LED

- 5.4 By Panel Size

- 5.4.1 Up to 14 inch

- 5.4.2 14 inch - 21 inch

- 5.4.3 21 inch - 40 inch

- 5.4.4 40 inch and Above

- 5.5 By End-Use Industry

- 5.5.1 Manufacturing

- 5.5.2 Energy and Power

- 5.5.3 Oil and Gas

- 5.5.4 Mining and Metals

- 5.5.5 Chemical and Pharmaceutical

- 5.5.6 Transportation and Logistics

- 5.5.7 Others (Water and Wastewater, Defense)

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Nordics

- 5.6.2.5 Rest of Europe

- 5.6.3 South America

- 5.6.3.1 Brazil

- 5.6.3.2 Rest of South America

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South-East Asia

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 Gulf Cooperation Council Countries

- 5.6.5.1.2 Turkey

- 5.6.5.1.3 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves (M&A, JV, Agreements)

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Samsung Display Co., Ltd.

- 6.4.2 LG Display Co., Ltd.

- 6.4.3 Panasonic Holdings Corp.

- 6.4.4 Sharp Corp.

- 6.4.5 Emerson Electric Co.

- 6.4.6 Schneider Electric SE

- 6.4.7 Siemens AG

- 6.4.8 Rockwell Automation Inc.

- 6.4.9 NEC Display Solutions, Ltd.

- 6.4.10 Advantech Co., Ltd.

- 6.4.11 Barco NV

- 6.4.12 WinMate Inc.

- 6.4.13 Planar Systems, Inc.

- 6.4.14 AU Optronics Corp.

- 6.4.15 Bosch Rexroth AG

- 6.4.16 Mitsubishi Electric Corp.

- 6.4.17 Honeywell International Inc.

- 6.4.18 Kontron AG

- 6.4.19 iBASE Technology Inc.

- 6.4.20 Beijer Electronics Group AB

- 6.4.21 Delta Electronics, Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment