PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1850195

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1850195

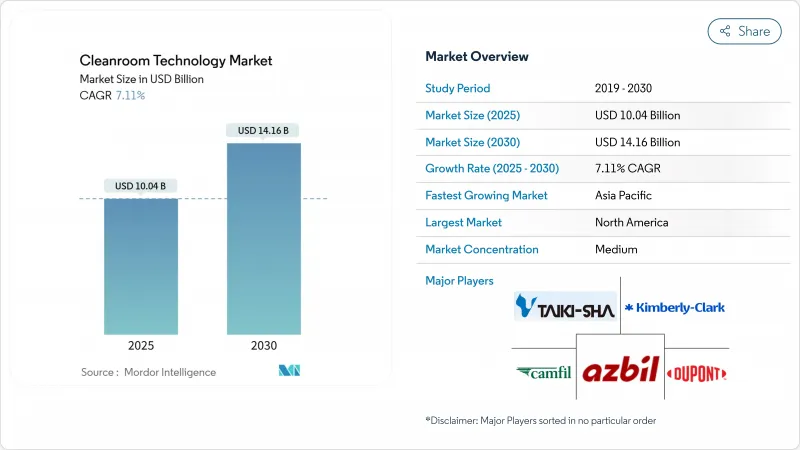

Cleanroom Technology - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The cleanroom technology market stood at USD 10.04 billion in 2025 and is forecast to reach USD 14.16 billion by 2030, registering a 7.11% CAGR through the period.

Sustained semiconductor capacity expansion, accelerated cell and gene therapy build-outs, and rising battery gigafactory investments underpin this steady advance. United States CHIPS Act grants, European Union medical-device regulations, and Asia-Pacific silicon-carbide wafer programs collectively widen the customer base and elevate specification levels. At the same time, filter-media redesign triggered by PFAS restrictions and a shortage of ISO-certified installers temper near-term growth in some regions. Suppliers that deliver modular, energy-efficient, and rapidly deployable systems continue to out-perform the overall cleanroom technology market.

Global Cleanroom Technology Market Trends and Insights

Cell and Gene Therapy Manufacturing Drives Modular Cleanroom Innovation

Multiple European facilities reached operational status in 2025, each requiring ISO 5-7 modular suites for living-medicine production. Novartis brought its fully automated viral-vector site in Slovenia online, part of a EUR 3.5 billion (USD 4.09 billion) national program, while Roche opened a EUR 90 million (USD 105.18 million) gene-therapy development center in Germany. Both projects emphasize flexible, pre-engineered layouts that shorten validation cycles and ease future scale-ups. National funding schemes accelerate order flow across the cleanroom technology market.

CHIPS Act-Funded Semiconductor Expansion Accelerates Infrastructure Demand

The USD 53 billion CHIPS and Science Act ignited an unprecedented wave of United States fab construction. Eighteen new plants broke ground in 2025, each demanding ISO 4 or tighter rooms with sub-0.1 µm control. TSMC's Arizona complex alone plans six fabs, illustrating how megaproject footprints translate directly into thousands of square metres of controlled environment. Domestic tooling suppliers and filter makers report multi-year backlogs, lifting the cleanroom technology market.

PFAS Regulations Drive Filter Media Cost Inflation

The U.S. EPA set 4 ppt drinking-water limits for PFOA and PFOS, prompting a phased withdrawal of fluorinated binder and sealant chemistries common in HEPA and ULPA media. Manufacturers now validate alternative polymers while absorbing re-tooling expenses that flow into component pricing. For buyers, quarterly filter quotes increased by double digits in early 2025, tightening operating budgets across the cleanroom technology market.

Other drivers and restraints analyzed in the detailed report include:

- Silicon Carbide Wafer Processing Demands Ultra-Precision Environments

- EU-MDR Compliance Creates Retrofit Demand Surge

- Skilled Labor Shortage Delays Critical Infrastructure Projects

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The equipment segment is projected to grow at 7.4% CAGR through 2030, outstripping the consumables category that nonetheless held a 55.2% slice of the cleanroom technology market in 2024. Energy-efficient fan-filter units and digitally monitored HVAC systems lead capital spending as fabs and therapy sites target lower operating costs and streamlined compliance reporting. Modular wall panels with factory-integrated cabling reduce onsite contamination risks while trimming installation time.

Desiccator cabinets engineered for battery-cell drying below 1% relative humidity, along with AI-enabled vacuum pumps that detect molecular contamination in real time, demonstrate how value migrates to intelligent hardware. Consumables still post steady volume gains as new square footage comes online, yet margin pressure from PFAS-related material changes shifts profit pools toward high-specification equipment providers.

Modular hardwall rooms controlled 56.9% of the cleanroom technology market in 2024, helped by proven structural integrity and simplified regulatory validation. Mobile or portable designs record an 8.1% CAGR as semiconductor, space, and contract-manufacturing users seek temporary capacity. These pre-engineered pods typically cut project schedules by 60% compared with stick-built spaces, an advantage when grant milestones or product launch dates loom.

Traditional stick-built suites remain relevant where complex utilities integration is essential. Rigid-wall rooms serve aerospace and defense programs requiring vibration dampening and electromagnetic shielding. Firms increasingly weigh lifecycle carbon footprints, and reusable modular frames align with corporate sustainability targets, reinforcing the shift in share within the cleanroom technology market.

The Cleanroom Technology Market Report is Segmented by Component (Equipment, and Consumables), Construction Type (Standard Stick-Built Cleanrooms, Modular Hardwall Cleanrooms, and More), Cleanroom Classification (ISO 14644) (ISO Class 1-3, ISO Class 4-5, and More), End-User (Pharmaceutical Manufacturing, Biotechnology R&D and Production, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America held 34% of 2024 revenue on the back of CHIPS Act megaprojects and an extensive biologics pipeline. The region continues to commission new ISO 4 and tighter suites through 2028, though installer shortages slow some timelines. Canada and Mexico contribute via automotive electronics and sterile injectables plants but remain secondary in scale.

Europe follows, propelled by EU-MDR retrofit activity and a surge in gene-therapy capacity across Germany, Slovenia, and the United Kingdom. Carbon-pricing under EU-ETS Phase IV incentivizes energy recovery systems and low-velocity airflow designs, pushing vendors to refine HVAC efficiency. Eastern European countries market cost-competitive labor for modular-room assembly, attracting investment in contract manufacturing.

Asia-Pacific displays the highest 7.6% CAGR, driven by China's USD 100 billion 300 mm fab pipeline, Taiwan's USD 75 billion advanced-node program, and South Korea's USD 81 billion capacity expansion. Wide-bandgap semiconductor programs, battery-cell gigafactories, and vaccine manufacturing hubs expand addressable demand. India's first leading-edge fab in Sanand entered validation in mid-2025, signalling broader regional adoption of high-specification suites. Other emerging markets in Southeast Asia leverage electronics assembly migration to bolster local cleanroom capacity.

- Azbil Corporation

- DuPont de Nemours Inc.

- Kimberly-Clark Corporation

- Camfil AB

- Taikisha Ltd.

- Ardmac Ltd.

- Terra Universal Inc.

- Clean Air Products Inc.

- Labconco Corporation

- Ansell Limited

- Illinois Tool Works Inc. (Texwipe)

- Berkshire Corporation

- ABN Cleanroom Technology NV

- Bouygues Energies and Services

- Skan AG

- Simplex Isolation Systems

- 3M Company

- Connect 2 Cleanrooms Ltd.

- Guardtech Cleanrooms Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid capacity expansion in EU cell and gene-therapy facilities demanding ISO 5-7 modular cleanrooms

- 4.2.2 CHIPS Act-funded United States fab construction adding Above 3 M sq ft of ISO 4 space (2025-28)

- 4.2.3 Surge in SiC wafer and advanced-packaging lines in Asia-Pacific requiring sub-0.1 µm control

- 4.2.4 EU-MDR transition forcing device SMEs to retrofit ISO 7 suites by 2027

- 4.2.5 Negative-pressure hospital wards post-COVID driving demand for healthcare cleanrooms

- 4.2.6 Li-ion gigafactories adopting ultra-dry modular cleanrooms (Less than 1 % RH)

- 4.3 Market Restraints

- 4.3.1 HEPA/ULPA media cost inflation from PFAS phase-out regulations

- 4.3.2 Shortage of ISO-certified installers in North America delaying projects Above 6 months

- 4.3.3 Energy-intensive HVAC facing carbon pricing under EU-ETS Phase IV

- 4.3.4 Semiconductor down-cycles triggering deferrals of ISO 1-3 projects

- 4.4 Industry Ecosystem Analysis

- 4.5 Regulatory Outlook (ISO Classification)

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Degree of Competition

- 4.8 Impact of Key Macroeconomic Trends on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Component

- 5.1.1 Equipment

- 5.1.1.1 Cleanroom Air Showers

- 5.1.1.2 HVAC Systems

- 5.1.1.3 Laminar Air-flow Cabinets

- 5.1.1.4 HEPA/ULPA Filters

- 5.1.1.5 Desiccator Cabinets

- 5.1.1.6 Fan-Filter Units

- 5.1.1.7 Modular Cleanroom Structures

- 5.1.2 Consumables

- 5.1.2.1 Apparel

- 5.1.2.2 Gloves

- 5.1.2.3 Wipes

- 5.1.2.4 Disinfectants and Cleaning Chemicals

- 5.1.2.5 Vacuum Systems

- 5.1.2.6 Adhesive Mats

- 5.1.1 Equipment

- 5.2 By Construction Type

- 5.2.1 Standard Stick-Built Cleanrooms

- 5.2.2 Modular Hardwall Cleanrooms

- 5.2.3 Modular Softwall Cleanrooms

- 5.2.4 Rigid-wall Cleanrooms

- 5.2.5 Mobile/Portable Cleanrooms

- 5.3 By Cleanroom Classification (ISO 14644)

- 5.3.1 ISO Class 1-3

- 5.3.2 ISO Class 4-5

- 5.3.3 ISO Class 6-7

- 5.3.4 ISO Class 8-9

- 5.4 By End-User

- 5.4.1 Pharmaceutical Manufacturing

- 5.4.2 Biotechnology R&D and Production

- 5.4.3 Medical Device Manufacturing

- 5.4.4 Hospitals and Healthcare Facilities

- 5.4.5 Semiconductor Fabrication

- 5.4.6 Micro-electronics and Optics

- 5.4.7 Food and Beverage Processing

- 5.4.8 Aerospace and Defense

- 5.4.9 Automotive and Battery Manufacturing

- 5.4.10 Other End-users

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Netherlands

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 South East Asia

- 5.5.3.6 Taiwan

- 5.5.3.7 Rest of Asia-Pacific

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Rest of South America

- 5.5.5 Middle East

- 5.5.5.1 Gulf Cooperation Council Countries

- 5.5.5.2 Turkey

- 5.5.5.3 Rest of Middle East

- 5.5.6 Africa

- 5.5.6.1 South Africa

- 5.5.6.2 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Azbil Corporation

- 6.4.2 DuPont de Nemours Inc.

- 6.4.3 Kimberly-Clark Corporation

- 6.4.4 Camfil AB

- 6.4.5 Taikisha Ltd.

- 6.4.6 Ardmac Ltd.

- 6.4.7 Terra Universal Inc.

- 6.4.8 Clean Air Products Inc.

- 6.4.9 Labconco Corporation

- 6.4.10 Ansell Limited

- 6.4.11 Illinois Tool Works Inc. (Texwipe)

- 6.4.12 Berkshire Corporation

- 6.4.13 ABN Cleanroom Technology NV

- 6.4.14 Bouygues Energies and Services

- 6.4.15 Skan AG

- 6.4.16 Simplex Isolation Systems

- 6.4.17 3M Company

- 6.4.18 Connect 2 Cleanrooms Ltd.

- 6.4.19 Guardtech Cleanrooms Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment