PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851234

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851234

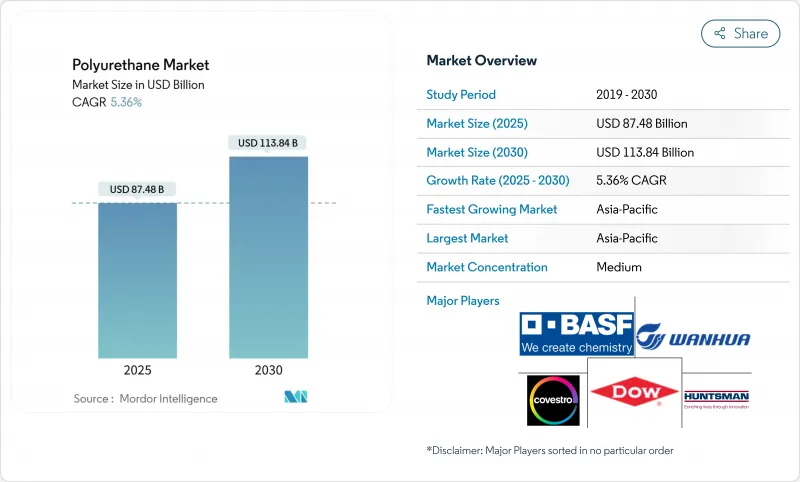

Polyurethane - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The polyurethane market size is estimated at USD 87.48 billion in 2025 and is projected to reach USD 113.84 billion by 2030, expanding at a 5.36% CAGR during 2025-2030.

This solid growth is anchored in the material's broad adoption across construction, automotive, furniture, and electronics, each valuing polyurethane's insulation, lightweighting, and durability advantages. Asia-Pacific's 46% revenue lead-supported by large-scale capacity additions in China and robust petrochemical investments in India-continues to tilt global supply toward the region. The building sector sustains baseline volume through stricter energy codes, while automotive producers accelerate demand for advanced polyurethane composites to lower vehicle weight and boost fuel efficiency. Innovation momentum is reinforced by investments in bio-based polyols, closed-loop recycling technologies, and low-VOC coatings that reduce lifecycle emissions and regulatory exposure. Even amid MDI/TDI price swings and upcoming trade investigations, the polyurethane market benefits from entrenched value-chain integration and a growing roster of sustainability-driven applications.

Global Polyurethane Market Trends and Insights

Lightweight Materials in Automotive

Automakers are swapping metal components for fiber-reinforced polyurethane to trim curb weight, meet fuel-economy mandates, and curb tailpipe CO2. Dow's molded PU seats slash the embodied footprint by 50% per seat while preserving comfort, proving the readiness of circular-grade foams for mass production. Acoustically optimized headliners and interior trim from Covestro cut noise and volatile organic compound (VOC) release, raising cabin-air quality with minimal redesign effort. Tier-1 suppliers integrating these composites report assembly-line compatibility without new capital outlays, reinforcing adoption prospects through 2030.

Building & Construction Growth

Global energy codes now specify higher R-values and tighter air-sealing, which play directly to rigid polyurethane's thermal and vapor control strengths. Asia-Pacific's construction boom, coupled with North American retrofit incentives, keeps architects reliant on thin-but-high-performing spray and boardstock insulation. Manufacturers respond by widening capacity and launching CO2-modified rigid foams that substitute 20% of fossil polyol, lowering cradle-to-gate emissions without shifting processing parameters. The policy-led momentum supports steady demand expansion across new-build and retrofit markets.

MDI/TDI Feedstock Volatility

MDI's 41.20% raw-material share ties polyurethane producers to benzene and crude-oil swings. Scheduled turnarounds, such as Wanhua's Ningbo outage, and antidumping actions on Chinese MDI entering the United States in 2025 inject price spikes and allocation cuts. Processors hedge with longer contracts, yet margin compression persists, delaying downstream investment in expansion lines until supply stabilizes.

Other drivers and restraints analyzed in the detailed report include:

- Bedding & Furniture Demand

- Energy-Efficiency Requirements

- Regulatory Restrictions on Additives

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Flexible foam captured 32% of polyurethane market share in 2024, maintaining a comfort-driven edge across bedding, furniture, and automotive seating. The polyurethane market size for flexible foam is projected to rise at 6.07% CAGR through 2030, aided by viscoelastic upgrades that improve pressure redistribution and by "bed-in-a-box" fulfillment models that hinge on compressed, quick-recovery foams. Producers enhance resilience and airflow, enabling thinner mattress builds that match premium ergonomic expectations. Recyclers refine acidolysis processes that reclaim polyol streams at 82% yield, moving the segment closer to circular supply loops.

Rigid foam takes second position, favored in construction insulation for its high R-value per inch and ability to deliver air-sealing in a single pass. Adoption accelerates in retrofit projects where wall cavities constrain thickness, reinforcing sustained volume demand in temperate as well as extreme-climate markets. CASE sub-segments (coatings, adhesives, sealants, elastomers) extend polyurethane's utility to vibration damping, industrial flooring, and corrosion-resistant linings. Thermoplastic polyurethane (TPU) wins share in footwear and electronics enclosures, buoyed by Lubrizol's biomass-balanced ESTANE RNW grade that cuts manufacturing carbon by up to 59%.

The Polyurethane Market Report Segments the Industry by Type (Rigid Foam, Flexible Foam, and More), Raw Material (Methylene Diphenyl Di-Isocyanate (MDI), Toluene Di-Isocyanate (TDI), Polyether Polyols, and More), End-User Industry (Furniture, Building and Construction, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific generated 46% of polyurethane market revenue in 2024, with China acting as both production nucleus and consumption powerhouse. Local leaders such as Wanhua aggressively scale MDI and polyol capacity, while India's USD 87 billion petrochemical pipeline amplifies regional feedstock security and derivative growth. Public and private construction booms, paired with rapid motorization, ensure the region retains the highest 6.01% CAGR through 2030.

North America follows with a mature yet innovative market. The United States leans on high R-value insulation for residential retrofits and pursues circular-grade automotive seating foams to meet corporate environmental targets. Policy moves-such as the 2025 antidumping investigation on Chinese MDI-reshape sourcing strategies and encourage domestic capacity investments. Canada's net-zero building agenda further anchors steady regional demand.

Europe's polyurethane market is shaped by stringent chemical regulations. The looming PFAS restriction compels wide-ranging formulation revisions, favoring suppliers with advanced additive R&D and rapid regulatory compliance processes. At the same time, green public-procurement criteria reward low-VOC and low-carbon products, nudging manufacturers toward biomass-balanced and CO2-modified grades.

South America, the Middle East, and Africa represent smaller slices of the polyurethane market yet grow from infrastructure, furniture, and packaging demand. Brazil promotes domestic petrochemicals expansion to reduce import dependence, while Saudi Arabia leverages feedstock advantage to explore polyurethane exports. Technology and best-practice diffusion from larger markets help emerging regions fast-track compliance with international sustainability benchmarks.

- BASF SE

- Carpenter Co.

- Covestro AG

- DIC Corporation

- Dow

- Huntsman International LLC

- INOAC Corporation

- LANXESS

- Mitsui Chemicals Inc.

- Momentive

- PPG Industries, Inc.

- Rogers Corporation

- Saint-Gobain

- Sekisui Chemical Co., Ltd.

- Sheela Foam Ltd.

- The Lubrizol Corporation

- Tosoh Corporation

- Wanhua

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Demand for Lightweight and High-performance Composites from the Automotive Industry

- 4.2.2 Increasing Demand from the Building and Construction Industry

- 4.2.3 Increasing Demand from the Bedding, Carpet, and Cushioning Industries

- 4.2.4 Growing Demand for Energy-Efficient Materials

- 4.2.5 Shift Towards Low-VOC (Volatile Organic Compounds) and Waterborne Polyurethanes

- 4.3 Market Restraints

- 4.3.1 Volatility in MDI/TDI Feedstock Linked to Meta-Xylene and Crude Oil Price Swings

- 4.3.2 EU REACH and China RoHS Limits on PFAS-Based PU Additives

- 4.3.3 Environmental Concerns

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products and Services

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value and Volume)

- 5.1 By Type

- 5.1.1 Rigid Foam

- 5.1.2 Flexible Foam

- 5.1.3 CASE (Coatings, Adhesives, Sealants and Elastomers)

- 5.1.4 Thermoplastic Polyurethane (TPU)

- 5.1.5 Other Types

- 5.2 By Raw Material

- 5.2.1 Methylene Diphenyl Di-isocyanate (MDI)

- 5.2.2 Toluene Di-isocyanate (TDI)

- 5.2.3 Polyether Polyols

- 5.2.4 Polyester Polyols

- 5.2.5 Others (Bio-based Polyols)

- 5.3 By End-user Industry

- 5.3.1 Furniture

- 5.3.2 Building and Construction

- 5.3.3 Electronics and Appliances

- 5.3.4 Automotive

- 5.3.5 Footwear

- 5.3.6 Packaging

- 5.3.7 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Nordics

- 5.4.3.7 Russia

- 5.4.3.8 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 United Arab Emirates

- 5.4.5.3 South Africa

- 5.4.5.4 Nigeria

- 5.4.5.5 Rest of Middle East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/ Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 BASF SE

- 6.4.2 Carpenter Co.

- 6.4.3 Covestro AG

- 6.4.4 DIC Corporation

- 6.4.5 Dow

- 6.4.6 Huntsman International LLC

- 6.4.7 INOAC Corporation

- 6.4.8 LANXESS

- 6.4.9 Mitsui Chemicals Inc.

- 6.4.10 Momentive

- 6.4.11 PPG Industries, Inc.

- 6.4.12 Rogers Corporation

- 6.4.13 Saint-Gobain

- 6.4.14 Sekisui Chemical Co., Ltd.

- 6.4.15 Sheela Foam Ltd.

- 6.4.16 The Lubrizol Corporation

- 6.4.17 Tosoh Corporation

- 6.4.18 Wanhua

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Increasing Demand for Bio-based Polyurethane