PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851424

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851424

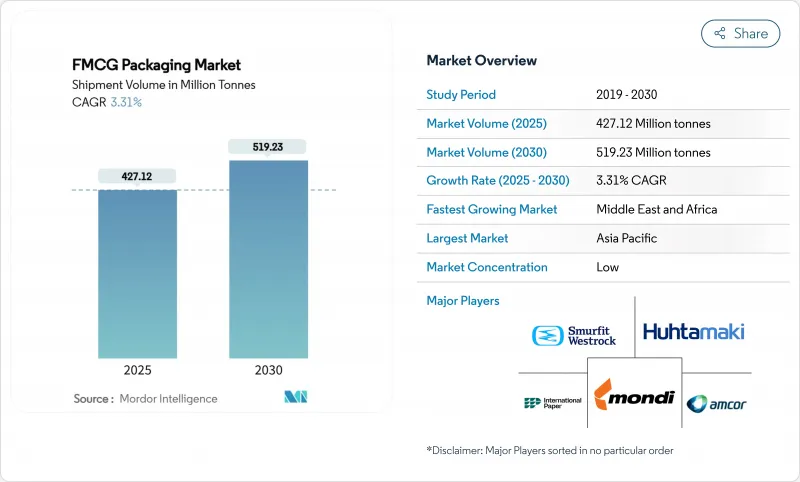

FMCG Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The FMCG packaging market reached 427.12 million tonnes in 2025 and is forecast to climb to 519.23 million tonnes by 2030, advancing at a 3.31% CAGR.

Growth rests on steady household demand for packaged essentials, expanding e-commerce volumes, and policy measures that reward recyclable and refillable solutions. Large converters are redesigning formats to trim material use and freight costs while protecting goods that travel through longer, more complex supply chains. Bio-based substrates and chemical-recycled resins are moving from pilot to commercial scale, yet plastics remain indispensable in high-barrier and lightweight roles. Regional demand is led by Asia-Pacific thanks to rapid urbanization and small-household purchasing, while Middle East and Africa (MEA) offers the quickest tonnage expansion as modern retail spreads.

Global FMCG Packaging Market Trends and Insights

Rapid Growth of E-commerce Requiring Protective, Lightweight Packs

Online retail now frames design briefs around parcel durability, dimensional weight limits, and friction-free returns. Brand owners specify cushioned mailers, air-column pouches, and fit-to-size cartons that slash void space and freight spend. Packaging plants add digital print lines so each shipper can carry scannable codes that confirm authenticity or trigger replenishment services. Smart indicators that reveal impact or temperature misuse are becoming standard on premium categories, a trend reinforced by parcel insurers who offer lower premiums for traceable packs. These needs keep flexible films and corrugated board in high demand and encourage resin suppliers to accelerate drop-in recycled grades that retain mechanical properties.

Urban Single-Serve Consumption Boom in Asia Boosting Convenience Formats

Rising numbers of single-person households and congested commutes in China, India, and Southeast Asia spur uptake of portion-controlled pouches, cups, and sachets. Manufacturers are automating high-speed fill-seal lines to reach price points competitive with bulk packs while trimming food waste from partially used larger units. Retailers dedicate premium shelf space to resealable snack packs and ready-to-eat meals sized for one, pushing converters to enhance barrier layers that keep contents fresh until the last serving. Growth spills into home-care and personal-care items, where refill pods and travel-friendly minis fit hectic urban lifestyles. Demand for laminates that couple easy-tear openings with drop-resistance underpins a notable slice of incremental Asian capacity additions.

Resin Price Volatility Creating Planning Uncertainty

Fluctuating crude-oil and naphtha benchmarks upset quarterly contract negotiations, prompting converters to hedge feedstock or accelerate substitution toward recycled and bio-based grades. Smaller firms lacking scale struggle to absorb spikes, which compress margins and slow capital investment. Sudden shortages of specialty additives, often linked to geopolitical events, force ad-hoc reformulations that risk downtime and customer penalties. In response, multinationals diversify sourcing and lock in multi-year supply pacts, while financial teams roll out cost-pass-through clauses keyed to industry indices. Such turbulence favors producers with integrated resin assets and strong working-capital positions.

Other drivers and restraints analyzed in the detailed report include:

- RTD Beverage Surge Driving High-Barrier Pouch Adoption

- Premiumisation in Personal-Care Triggering Smart and Decorative Packs

- Single-Use-Plastic Bans Dampening Conventional Flexibles

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastics maintained a 62.45% share of the FMCG packaging market in 2024, reflecting unmatched strength-to-weight ratios and broad processability. Bio-based and compostable grades, though still niche, are expanding at 6.85% CAGR as converters commercialize PLA and PHA blends with enhanced oxygen and moisture barriers. Rigid metals find favor in premium beverage lines for infinite recyclability, and paperboard gains share where dry food or personal-care formats permit fiber-based walls. The FMCG packaging market continues to favor polyethylene and polypropylene in flexible laminates thanks to cost efficiency, but chemical recycling, now scaling in North America and Europe, promises high-quality post-consumer resins that moderate virgin demand. Innovations in reactive coating lines let paper cups hold acidic juices without plastic liners, opening another pathway for plastics displacement.

Plastics suppliers counter sustainability pressures by launching certified-circular PE and PP grades derived from pyrolysis oil, giving brand owners a drop-in route to lower emissions while retaining incumbent converting lines. The FMCG packaging market size for bio-based resins is projected to surpass 8 million tonnes by 2030 as governmental green-procurement rules take hold. Meanwhile, aluminum's light-weight advantage in aerosol cans and pet-food trays aligns with refill stations that prefer robust formats surviving multiple cycles. Glass stays relevant where taste neutrality is prized, yet weight and breakage limit its volume share. Overall, material choice now hinges on balancing functional performance, regulatory compliance, and total carbon impact rather than unit price alone.

With a 54.65% share in 2024, flexible formats dominate the FMCG packaging market and are tracking a 6.35% CAGR to 2030. Brand owners value lower material-to-product ratios, high graphics potential, and pack-out efficiency that allows more units per pallet. The shift to e-commerce adds demand for mail-friendly pillow packs and multi-layer sachets that endure automated sortation without extra void fill. Continuous-motion horizontal form-fill-seal (HFFS) lines supply snack and confectionery categories at speeds exceeding 1,500 packs per minute, highlighting the operational gains that recursive format optimisation delivers.

Rigid options still command niches where structure and reclosability are critical. PET bottles retain leadership in carbonated soft drinks, while glass jars project premium cues in gourmet sauces. Hybrid "rigid-in-flexible" pouch designs with molded caps combine both worlds, slicing weight by up to 70% versus equivalently sized glass containers. The FMCG packaging market size for rigid formats is forecast to post low-single-digit growth, reflecting saturation in mature categories but fresh opportunities in refillable personal-care dispensers. Equipment builders now offer modular filler blocs that handle fitment pouches, jars, and bottles on one line, letting converters hedge against demand swings across formats.

The FMCG Packaging Market Report is Segmented by Material Type (Paper and Paperboard, Plastics, Metal, Glass, Bio-Based and Compostable Materials), Packaging Type (Flexible Packaging, Rigid Packaging), End-Use Industry (Food, Beverages, Personal Care and Cosmetics, and More), Distribution Channel (Direct Sales, Indirect Sales), and Geography. The Market Forecasts are Provided in Terms of Volume (Tonnes).

Geography Analysis

Asia-Pacific generated 45.63% of 2024 shipments, positioning the region as the anchor of the FMCG packaging market. China and India supply mammoth domestic demand and serve export flows, leveraging clusters of integrated resin crackers, film extruders, and converting plants. Urban micro-kitchens and on-the-go eating habits fuel single-serve pouch uptake, while national plastic-reduction mandates accelerate trials of paper-based flexibles. Rising disposable incomes enable trading-up to premium personal-care formats, deepening per-capita packaging intensity. Government-backed cold-chain corridors in India and Southeast Asia unleash further need for insulated shippers and tamper-evident seals.

North America follows with a stable share rooted in broad e-commerce penetration and advanced corrugated capacity. The Smurfit-WestRock merger, valued at USD 20 billion, exemplifies the push for scale to dilute fixed costs and fund circular-economy R&D. Investments such as Green Bay Packaging's USD 1 billion kraft linerboard mill in Arkansas strengthen domestic supply security and expand lightweight liner offerings. United States state regulations on recycled content in beverage containers catalyze PET reclaim projects, pushing local converters to lock in rPET feedstock. Canada and Mexico gain from near-shoring that relocates consumer-goods filling lines closer to core demand.

Europe's mature market taps innovation to meet its stringent recyclability targets under the Packaging and Packaging Waste Regulation. Germany and France upgrade MRFs and chemical-recycling pilots to satisfy minimum recycled-content thresholds, while brand owners redesign individual packs to pass "sort-ability" tests. Premium confectionery chooses fiber-based wrapping with bio-barriers, and UK supermarkets roll out refill trials that test shopper uptake of returnable pouches. These initiatives stabilize overall tonnage but shift value toward higher-spec materials and linked digital services.

Middle East and Africa register the fastest 6.58% CAGR, albeit from a lower base, as organized retail expands and population growth drives packaged staples. Gulf states invest in state-of-the-art flexible plants that supply both domestic fast-food chains and export orders. South Africa and Kenya attract mobile filling units for milk and juice cartons that extend shelf life in areas lacking refrigeration. Foreign direct investment from European and Asian groups introduces multilayer extrusion technology, lifting local capabilities.

South America offers steady upside as economic reforms in Brazil and Colombia revive consumer spending. Regional fiber availability supports cost-competitive corrugated, and sugar-cane-based bio-PE capacity in Brazil gives global brands a renewable-content narrative. Tariff structures still influence plant-location decisions, nudging converters to adopt multinational footprints that straddle Mercosur and Pacific Alliance blocs.

- Amcor plc

- Ball Corporation

- Mondi Group

- International Paper Co.

- Sealed Air Corporation

- Constantia Flexibles

- Smurfit Westrock Plc

- Crown Holdings Inc.

- Coveris Holdings S.A.

- Graphic Packaging International LLC

- Tetra Pak International

- Stora Enso Oyj

- Sonoco Products Co.

- Huhtamaki Oyj

- Toyo Seikan Group HD

- Nampak Ltd

- Mpact Pty Ltd

- Albea S.A.

- Owens-Illinois (O-I)

- Verallia SA

- Napco National

- 3P Gulf Group

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid Growth of E-commerce Requiring Protective, Lightweight Packs

- 4.2.2 Urban Single-Serve Consumption Boom in Asia Boosting Convenience Formats

- 4.2.3 RTD Beverage Surge Driving High-Barrier Pouch Adoption

- 4.2.4 Premiumisation in Personal-Care Triggering Smart and Decorative Packs

- 4.2.5 Cold-Chain Expansion in Emerging Markets Raising Multilayer Film Usage

- 4.3 Market Restraints

- 4.3.1 Resin Price Volatility Creating Planning Uncertainty

- 4.3.2 Recycling-Infrastructure Deficit in Developing Nations

- 4.3.3 Single-Use-Plastic Bans Dampening Conventional Flexibles

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VOLUME)

- 5.1 By Material Type

- 5.1.1 Paper and Paperboard

- 5.1.2 Plastics

- 5.1.2.1 Polyethylene (LDPE/HDPE)

- 5.1.2.2 Polypropylene (PP)

- 5.1.2.3 Polyethylene Terephthalate (PET)

- 5.1.2.4 Other Plastics (PVC, PS,etc)

- 5.1.3 Metal

- 5.1.4 Glass

- 5.1.5 Bio-based and Compostable Materials

- 5.2 By Packaging Type

- 5.2.1 Flexible Packaging

- 5.2.1.1 Pouches and Bags

- 5.2.1.2 Films and Wraps

- 5.2.1.3 Other Flexible Packaging

- 5.2.2 Rigid Packaging

- 5.2.2.1 Bottles and Jars

- 5.2.2.2 Cans

- 5.2.2.3 Trays and Containers

- 5.2.2.4 Other Rigid Packaging

- 5.2.1 Flexible Packaging

- 5.3 By End-use Industry

- 5.3.1 Food

- 5.3.2 Beverages

- 5.3.3 Personal Care and Cosmetics

- 5.3.4 Household Care Products

- 5.3.5 Pharmaceuticals and Healthcare

- 5.3.6 Other End-use Industry

- 5.4 By Distribution Channel

- 5.4.1 Direct Sales

- 5.4.2 Indirect Sales

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 Ball Corporation

- 6.4.3 Mondi Group

- 6.4.4 International Paper Co.

- 6.4.5 Sealed Air Corporation

- 6.4.6 Constantia Flexibles

- 6.4.7 Smurfit Westrock Plc

- 6.4.8 Crown Holdings Inc.

- 6.4.9 Coveris Holdings S.A.

- 6.4.10 Graphic Packaging International LLC

- 6.4.11 Tetra Pak International

- 6.4.12 Stora Enso Oyj

- 6.4.13 Sonoco Products Co.

- 6.4.14 Huhtamaki Oyj

- 6.4.15 Toyo Seikan Group HD

- 6.4.16 Nampak Ltd

- 6.4.17 Mpact Pty Ltd

- 6.4.18 Albea S.A.

- 6.4.19 Owens-Illinois (O-I)

- 6.4.20 Verallia SA

- 6.4.21 Napco National

- 6.4.22 3P Gulf Group

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment