PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851614

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851614

Abrasives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

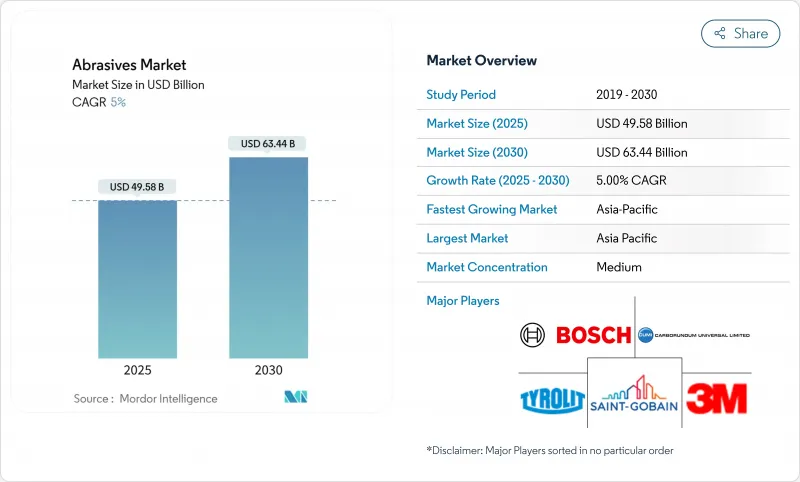

The Abrasives Market size is estimated at USD 49.58 billion in 2025, and is expected to reach USD 63.44 billion by 2030, at a CAGR of 5% during the forecast period (2025-2030).

Sales momentum reflects rising demand for high-performance materials that can hold tight tolerances on advanced CNC equipment, especially in electric vehicle (EV) and aerospace component machining. Synthetic grades continue to capture orders because they deliver reliable hardness and thermal stability, while bonded formats remain the workhorse for high-temperature grinding. Rapid industrialization in Asia, the pivot toward precision electronics, and the emergence of post-processing needs for additive manufacturing all reinforce the growth runway for the abrasives market. Competitive rivalry is intensifying: large incumbents are refining product portfolios around eco-friendly chemistries as regulators tighten particulate and volatile-organic-compound (VOC) standards, and niche producers are carving share in specialty niches such as diamond-based super-abrasives.

Global Abrasives Market Trends and Insights

Increasing use in aerospace and automotive industries

Demand for advanced aircraft alloys and lightweight EV drivetrains is pushing producers to specify cubic boron nitride (CBN) and diamond wheels that maintain form at high speeds. Tier-one suppliers are optimizing E-Axle, rotor shaft, and battery-housing machining lines with vitrified CBN and ceramic media that cut cycle time and extend dresser intervals. Norton Abrasives reports measurable reductions in scrap rates when diamond tools are paired with automated load-sensing systems, illustrating why OEMs are standardizing on premium grades for repeatability. As robotics proliferate on assembly lines, the abrasives market gains from consistent surface-finish requirements that manual grinding cannot meet.

Growing metal manufacturing and fabrication industries

Steel service centers, pressure-vessel shops, and contract fabricators have upgraded grinding stations with ceramic-grain belts that increase stock removal by up to 40% while lowering power draw. Lower downtime for belt changes translates into higher overall equipment effectiveness (OEE), a metric increasingly monitored under lean programs. Specialized top-coats such as VSM TOP SIZE mitigate heat discoloration on stainless workpieces, enabling higher feed pressures without thermal distortion. These productivity gains support rapid order throughput, making high-end ceramic grades essential in cost-sensitive mass-production settings.

High production and equipment cost

Synthetic diamond and CBN crystals are grown under pressures and temperatures that exceed geological conditions, pushing capital intensity for reactor vessels well above conventional fused-alumina lines. Single-head CNC grinders configured for diamond wheels require precision spindles and closed-loop coolant systems, raising acquisition costs. While these tools deliver longer life and lower per-part expense, small and midsize job shops in price-sensitive economies still defer upgrades. Vendors are experimenting with leasing models and consumable-credit programs, but adoption remains gated by financing constraints.

Other drivers and restraints analyzed in the detailed report include:

- Growing manufacturing activities in emerging economies

- Additive-manufacturing post-processing requiring super-abrasives

- Stringent regulations on usage of abrasives

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Synthetic grades commanded 67% share of the abrasives market in 2024, underlining user preference for consistent crystal morphology that translates into predictable wear patterns during production runs. Aluminum oxide remains the volume leader; however, silicon carbide addresses non-ferrous machining, while CBN is preferred for hardened steels. Novel nano-polycrystalline diamonds under development by Sumitomo Electric promise superior fracture toughness, positioning the abrasives market to tackle nickel-based super-alloys at lower wheel wear rates. Natural garnet retains a foothold in waterjet and blasting tasks where recyclable bulk media and low free-silica content improve site safety, making it attractive for infrastructure refurbishment projects.

The shift toward synthetic offerings aligns with automated feed systems that demand tight grit distributions, a parameter easier to achieve through engineered production routes. With Asia ramping fused-alumina capacity, supply security is improving, although power-tariff volatility can swing output costs. Manufacturers pursuing eco-labels are investing in renewable-powered arc furnaces and closed-loop water quench circuits to retain share in regulated regions. As a result, the abrasives market continues to upgrade quality benchmarks even in high-volume segments.

Bonded wheels generated 48% of 2024 revenue, reflecting their role in cutting, sharpening, and surface-conditioning jobs across automotive, aerospace, and general engineering workshops. Resinoid and vitrified matrices provide thermal stability during deep-cut operations, enabling consistent tolerances on crankshafts and turbine blades where metallurgical integrity is critical. Advances in sol-gel alumina and engineered pore structures improve chip evacuation, permitting higher metal removal rates without risk of burn.

Coated abrasives, while lighter in tonnage, enjoy widespread use in finishing and deburring. Backings ranging from flexible film to fiber discs optimize performance across curved surfaces and hard-to-reach areas. Super-abrasives hold a niche position today, but their double-digit growth underpins the future direction of the abrasives market. Additive manufacturing shops specify diamond pads and CBN mandrels for thin-wall titanium parts where conventional wheels load quickly. Suppliers such as Imerys offer tailor-made fused alumina and sol-gel grains that extend dresser intervals, reinforcing bonded wheels' dominance while bridging performance gaps with super-abrasives.

The Abrasives Market Report is Segmented by Material (Natural Abrasives and Synthetic Abrasives), Type (Bonded Abrasives, Coated Abrasives, and Super Abrasives), Abrasives Grain/Raw Material (Aluminum Oxide, Silicon Carbide, and More), End-User Industry (Metal Manufacturing and Fabrication, Automotive and Aerospace, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific accounted for 56% of global purchases in 2024, reflecting China's large machining base and India's accelerated infrastructure build-out. Government incentives for domestic EV battery manufacturing and electronics assembly further stimulate local demand. Japan and South Korea leverage advanced diamond semiconductor research to create new downstream uses for super-abrasives, such as slicing large-area diamond wafers. These factors collectively sustain Asia's leadership position and encourage multinationals to localize mixing and pressing operations.

North America retains strong momentum in aerospace, medical, and additive-manufacturing segments. Regulatory scrutiny on VOCs and particulate emissions propels shifts toward garnet blasting media and water-based coolants, generating product-mix upgrades.

Europe emphasizes sustainability and circular-economy principles, with suppliers like Saint-Gobain implementing recycled-bond systems to curtail carbon intensity. Adoption of super-abrasives is accelerating in Germany's precision engineering clusters, while southern Europe focuses on construction-related blasting and cutting disc consumption. South America, the Middle East, and Africa remain smaller in volume yet register healthy growth as industrialization deepens; Brazil's shipbuilding yards and Gulf petrochemical projects illustrate expanding end-user diversity. Local converting partnerships help global brands penetrate these regions, strengthening global coverage of the abrasives market.

- 3M

- Abrasive Technology

- ARC Abrasives Inc.

- Asahi Diamond Industrial Co. Ltd.

- CUMI

- Deerfos

- Fujimi Incorporated

- Imerys

- Mirka Ltd.

- NORITAKE CO., LIMITED

- Robert Bosch GmbH

- Saint-Gobain

- SAK ABRASIVES LIMITED

- Sia Abrasives Industries AG

- Tyrolit - Schleifmittelwerke Swarovski AG & Co KG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Use in the Aerospace and Automotive Industries

- 4.2.2 Growing Metal Manufacturing and Fabrication Industries

- 4.2.3 Growing Manufacturing Activities in Emerging Economies

- 4.2.4 Additive-Manufacturing Post-processing Requiring Super-abrasives

- 4.2.5 Increased Adoption of Precision and CNC Machinery

- 4.3 Market Restraints

- 4.3.1 High production and Equipment Cost

- 4.3.2 Stringent Regulations on Usage of Abrasives

- 4.3.3 Substitution by Alternative Materials or Methods

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Material

- 5.1.1 Natural Abrasives

- 5.1.2 Synthetic Abrasives

- 5.2 By Type

- 5.2.1 Bonded Abrasives

- 5.2.2 Coated Abrasives

- 5.2.3 Super Abrasives

- 5.3 By Abrasive Grain/Raw Material

- 5.3.1 Aluminum Oxide

- 5.3.2 Silicon Carbide

- 5.3.3 Ceramic and Zirconia Alumina

- 5.3.4 Others (Including Garnet)

- 5.4 By End-user Industry

- 5.4.1 Metal Manufacturing and Fabrication

- 5.4.2 Automotive and Aerospace

- 5.4.3 Electronics and Semiconductors

- 5.4.4 Construction and Infrastructure

- 5.4.5 Medical Devices

- 5.4.6 Oil and Gas

- 5.4.7 Others (Industrial Machinery and Agriculture Equipment)

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 Malaysia

- 5.5.1.6 Thailand

- 5.5.1.7 Indonesia

- 5.5.1.8 Vietnam

- 5.5.1.9 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Nordic Countries

- 5.5.3.7 Turkey

- 5.5.3.8 Russia

- 5.5.3.9 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Colombia

- 5.5.4.4 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 Qatar

- 5.5.5.3 United Arab Emirates

- 5.5.5.4 Nigeria

- 5.5.5.5 Egypt

- 5.5.5.6 South Africa

- 5.5.5.7 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 3M

- 6.4.2 Abrasive Technology

- 6.4.3 ARC Abrasives Inc.

- 6.4.4 Asahi Diamond Industrial Co. Ltd.

- 6.4.5 CUMI

- 6.4.6 Deerfos

- 6.4.7 Fujimi Incorporated

- 6.4.8 Imerys

- 6.4.9 Mirka Ltd.

- 6.4.10 NORITAKE CO., LIMITED

- 6.4.11 Robert Bosch GmbH

- 6.4.12 Saint-Gobain

- 6.4.13 SAK ABRASIVES LIMITED

- 6.4.14 Sia Abrasives Industries AG

- 6.4.15 Tyrolit - Schleifmittelwerke Swarovski AG & Co KG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Growing Use of Automation and Robotics