PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851769

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851769

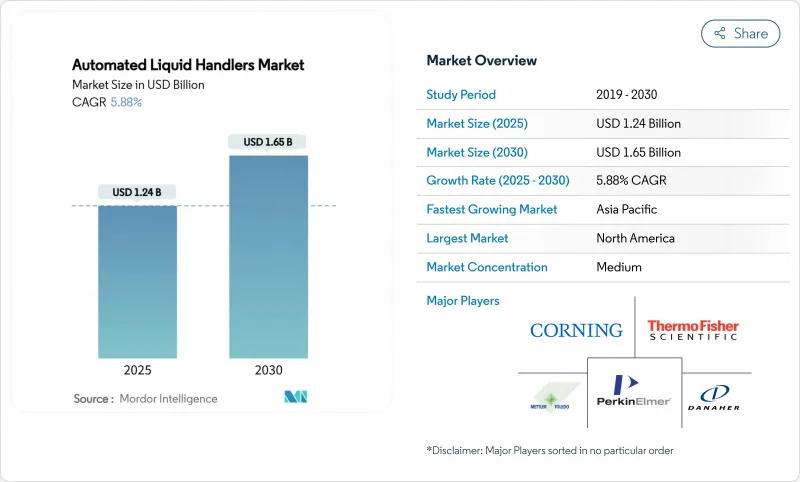

Automated Liquid Handlers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The automated liquid handlers market size is estimated at USD 1.24 billion in 2025 and is projected to reach USD 1.65 billion by 2030, expanding at a 5.88% CAGR.

The steady rise reflects the push for large-scale molecular diagnostics capacities, rapid uptake of AI-driven laboratory platforms, and the shift from manual pipetting to robotic precision. Hardware upgrades that shorten library-prep from hours to minutes in high-throughput genomic workflows add further momentum. Demand is also supported by mid-sized throughput systems that fit the daily sample volume of most clinical and research laboratories, giving the automated liquid handlers market a resilient baseline of recurring consumable sales. Emerging government funding in Asia-Pacific and steady replacement cycles in North America keep long-term visibility high.

Global Automated Liquid Handlers Market Trends and Insights

Integration with AI-Driven Drug-Discovery Platforms Accelerating Hit-to-Lead Timelines

Automated workstations that pair with machine-learning algorithms now run iterative design-execute-analyse loops without human intervention. Robots equipped with 19F NMR sensors can evaluate 21 reactions in parallel, enabling discovery teams to compress hit-to-lead cycles by 75%. Case studies at AstraZeneca and Weill Cornell show these closed-loop systems improving predictive accuracy for synergistic compounds while capturing granular assay metadata that feeds deep-learning models. The time savings and data richness directly translate into earlier patent filings and a better probability of clinical success, keeping the automated liquid handlers market firmly aligned with pharmaceutical digitalization.

Growing Throughput Requirements in High-Volume Genomic Screening (North America)

US reference labs that scaled up during the pandemic now process thousands of clinical genomes daily. Robotic pipetting solutions like the Biomek Echo One trim sample-prep from two hours to 10 minutes. The underlying economics reward laboratories able to push the cost per sequence below USD 100, which is only feasible when workflows are fully automated. As insurers broaden reimbursement for next-generation sequencing, high-capacity systems become default purchases, reinforcing North American leadership in the automated liquid handlers market.

High Initial CapEx for Flexible Deck Workstations in Emerging Markets

Import duties and multi-layer distribution inflate list prices by up to 116%, pushing a USD 350,000 system above USD 750,000 in parts of Africa. Grants rarely cover training or maintenance, leaving labs with unaffordable service contracts. The result is a widening capability gap that risks excluding emerging markets from global genomics consortia, dampening the automated liquid handlers market in these regions.

Other drivers and restraints analyzed in the detailed report include:

- Adoption of Miniaturized Assay Formats Reducing Reagent Costs

- Expansion of Personalized Medicine Driving High-Accuracy Liquid Handling

- Skill Gap in Programming and Maintenance of Robotic Systems

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Robotic workstations represent the largest slice of the automated liquid handlers market, holding 46% market share in 2024, because laboratories still prioritize mechanical precision for repeatable pipetting. Software and services, however, are forecast to grow at 7.7% CAGR as AI modules that schedule runs and predict tip usage deliver immediate cost savings. A growing installed base of robots ensures a recurring stream of consumables, and lubricant-infused tips reduce carry-over in viscous samples.

The product mix is shifting toward platform licences that unlock workflow libraries and cloud analytics. Vendors now bundle subscription dashboards that monitor uptime and flag anomalies, which further elevate software revenue. This pivot transforms competitive dynamics, encouraging ecosystem partnerships and making code libraries a core differentiator in the automated liquid handlers market.

Medium-throughput systems processing 100-1,000 samples per run accounted for 53.5% of the automated liquid handlers market size in 2024. They match typical batch volumes at clinical labs and mid-sized biotechs, offering balanced speed and price. High-throughput units that exceed 1,000 samples log the fastest 6.3% CAGR, thanks to large screening campaigns in drug discovery that surpass 100,000 assays a day.

Unit economics improve sharply once workflows cross 5,000 daily plates, prompting CROs to upgrade ahead of capacity bottlenecks. This trend anchors price premiums for robotic decks with multi-arm configurations and expanded tip racks. It also widens service opportunities in predictive maintenance, adding stability to revenue streams within the automated liquid handlers market.

The Automated Liquid Handlers Market Report is Segmented by Product Type (Robotic Liquid-Handling Workstations, and More), Throughput Capability (Low, Medium, and High), Platform Configuration (Stand-Alone Benchtop Systems, and Integrated Modular Platforms), Application (Drug Discovery, Genomics, and More), End User (CROs and CMOs, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America commanded 38.5% share of the automated liquid handlers market in 2024 on the back of permanent molecular diagnostic infrastructure and concentrated pharmaceutical clusters. US-based Thermo Fisher invested USD 2 billion in domestic manufacturing, ensuring short supply chains and compliance support. Canada adds strength in genomics research, while Mexico adopts automation for agrigenomics. The region benefits from venture capital that funds AI-driven lab-tech start-ups, though staffing shortages in robot programming still constrain scale.

Asia-Pacific is the fastest-growing region with a 6.9% CAGR through 2030, boosted by China's 1 trillion yuan robotics initiative and Korea's USD 128 million intelligent-robot program. Japan leverages decades of automation heritage, and Australia uses federal grants to build GMP-grade bioprocessing sites. Localized service centers cut downtime, overcoming historic reliance on imported technicians. Government procurement policies that favor domestic suppliers accelerate installed-base expansion, cementing Asia-Pacific as the primary incremental revenue source for the automated liquid handlers market.

Europe maintains a firm foothold in the automated liquid handlers market through stable pharma pipelines in Germany, the United Kingdom, and France. Regulatory alignment across the EU smooths cross-border tech transfer, while sustainability mandates drive preference for robots with validated CO2 footprints. Southern European labs deploy automation in food and environmental testing, enlarging the addressable demand. Skills gaps are mitigated by apprenticeship programs tied to equipment suppliers, enabling consistent uptime and moderating service costs.

- Thermo Fisher Scientific Inc.

- Danaher Corp. (Beckman Coulter Life Sciences)

- Tecan Group Ltd.

- Hamilton Company

- PerkinElmer Inc. (Revvity)

- Agilent Technologies Inc.

- Mettler-Toledo International Inc.

- Becton, Dickinson and Company

- Eppendorf AG

- Formulatrix Inc.

- Aurora Biomed Inc.

- Sartorius AG (Biohit)

- Synchron Lab Automation

- Hudson Robotics Inc.

- Analytik Jena AG (Endress + Hauser)

- Opentrons Labworks Inc.

- Biosero Inc. (BICO Group)

- Gilson Inc.

- Lab Services B.V.

- Andrew Alliance S.A. (Waters)

- Integra Biosciences AG

- Corning Incorporated

- SPT Labtech Ltd.

- Festo AG and Co. KG

- Starlab International GmbH

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Throughput Requirements in High-Volume Genomic Screening (North America)

- 4.2.2 Adoption of Miniaturized Assay Formats Reducing Reagent Costs

- 4.2.3 Integration with AI-Driven Drug-Discovery Platforms Accelerating Hit-to-Lead Timelines

- 4.2.4 Expansion of Personalized Medicine Driving High-Accuracy Liquid Handling (Europe and US)

- 4.2.5 Permanent Molecular-Diagnostic capacity Post-COVID-19 (Global Reference Labs)

- 4.2.6 Government Funding for Automated Bioprocessing (Asia-Pacific)

- 4.3 Market Restraints

- 4.3.1 High Initial CapEx for Flexible Deck Workstations in Emerging Markets

- 4.3.2 Skill Gap in Programming and Maintenance of Robotic Systems

- 4.3.3 Sample Cross-Contamination Risks in High-Viscosity Liquids

- 4.3.4 Legacy LIMS Integration Challenges in Big-Pharma Labs

- 4.4 Industry Ecosystem Analysis

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product Type

- 5.1.1 Robotic Liquid-Handling Workstations

- 5.1.2 Pipetting Systems

- 5.1.3 Reagent Dispensers

- 5.1.4 Consumables (Tips, Plates, Reagents)

- 5.1.5 Software and Services

- 5.2 By Throughput Capability

- 5.2.1 Low Throughput (Less than 100 samples/run)

- 5.2.2 Medium Throughput (100-1000 samples/run)

- 5.2.3 High Throughput (Above 1 000 samples/run)

- 5.3 By Platform Configuration

- 5.3.1 Stand-Alone Benchtop Systems

- 5.3.2 Integrated Modular Platforms

- 5.4 By Application

- 5.4.1 Drug Discovery and Lead Optimization

- 5.4.2 Genomics and Proteomics

- 5.4.3 Clinical Diagnostics

- 5.4.4 Cell Biology and Stem-Cell Research

- 5.4.5 Synthetic Biology and Bioprocess Development

- 5.4.6 Other Applications

- 5.5 By End User

- 5.5.1 Pharmaceutical and Biotechnology Companies

- 5.5.2 CROs and CMOs

- 5.5.3 Academic and Research Institutes

- 5.5.4 Clinical and Diagnostic Laboratories

- 5.5.5 Forensic and Environmental Testing Labs

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 Japan

- 5.6.3.3 South Korea

- 5.6.3.4 India

- 5.6.3.5 South East Asia

- 5.6.3.6 Rest of Asia-Pacific

- 5.6.4 South America

- 5.6.4.1 Brazil

- 5.6.4.2 Rest of South America

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 United Arab Emirates

- 5.6.5.1.2 Saudi Arabia

- 5.6.5.1.3 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)}

- 6.4.1 Thermo Fisher Scientific Inc.

- 6.4.2 Danaher Corp. (Beckman Coulter Life Sciences)

- 6.4.3 Tecan Group Ltd.

- 6.4.4 Hamilton Company

- 6.4.5 PerkinElmer Inc. (Revvity)

- 6.4.6 Agilent Technologies Inc.

- 6.4.7 Mettler-Toledo International Inc.

- 6.4.8 Becton, Dickinson and Company

- 6.4.9 Eppendorf AG

- 6.4.10 Formulatrix Inc.

- 6.4.11 Aurora Biomed Inc.

- 6.4.12 Sartorius AG (Biohit)

- 6.4.13 Synchron Lab Automation

- 6.4.14 Hudson Robotics Inc.

- 6.4.15 Analytik Jena AG (Endress + Hauser)

- 6.4.16 Opentrons Labworks Inc.

- 6.4.17 Biosero Inc. (BICO Group)

- 6.4.18 Gilson Inc.

- 6.4.19 Lab Services B.V.

- 6.4.20 Andrew Alliance S.A. (Waters)

- 6.4.21 Integra Biosciences AG

- 6.4.22 Corning Incorporated

- 6.4.23 SPT Labtech Ltd.

- 6.4.24 Festo AG and Co. KG

- 6.4.25 Starlab International GmbH

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment