PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851811

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851811

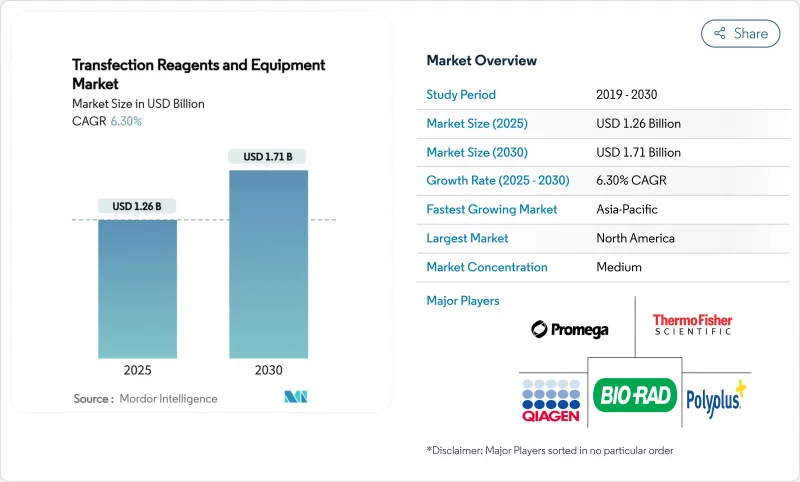

Transfection Reagents And Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The transfection reagents and equipment market size reached USD 1.26 billion in 2025 and is forecast to advance to USD 1.71 billion by 2030, reflecting a 6.30% CAGR.

This steady expansion is propelled by regulatory momentum in cell and gene therapies, sustained R&D spending by pharmaceutical manufacturers, and rapid method-level innovation that improves scalability for commercial production. Consolidation among suppliers, the emergence of AI-guided reagent design, and heightened outsourcing to contract development and manufacturing organizations (CDMOs) are reinforcing competitive barriers while widening end-user options. Asia-Pacific's double-digit growth, Europe's regulatory harmonization around advanced therapies, and North America's established manufacturing base collectively intensify global demand for GMP-grade transfection solutions. Equipment revenues are rising faster than reagents as laboratories replace manual protocols with high-throughput electroporation, microfluidic, and nanoparticle platforms optimized for consistency, traceability, and automated parameter control. Together, these factors confirm a durable expansion cycle for the transfection reagents and equipment market through 2030.

Global Transfection Reagents And Equipment Market Trends and Insights

Technological Advancements in Non-Viral Transfection Chemistries

Multiple research groups are engineering ionizable cationic lipids with biodegradable cores that remove cholesterol and phospholipids while maintaining high transfection efficiency, lowering toxicity and enabling organ-targeted delivery. Polyplus supplemented this progress with FectoVIR-AAV, a reagent calibrated for industrial AAV production that boosts viral titers in GMP environments. The expansion of polymer-based and hybrid nanotube carriers furthers non-viral uptake, mitigating batch variability and reducing viral safety concerns. Manufacturers now embed predictive algorithms that adjust reagent ratios in real time, assuring consistent performance across different cell lines and reducing development timelines. As non-viral efficiencies approach viral benchmarks, the technology becomes integral to large-scale therapeutic manufacturing, driving consumption of high-performance reagents.

Growing R&D Spend by Pharma & Biotech Firms

Despite broader cost pressures, leading life-science companies preserve or raise gene-therapy budgets to secure premium assets that command higher pricing in specialty indications. Roche deployed EUR 90 million in a German gene-therapy center, while AstraZeneca invested USD 300 million in a U.S. cell-therapy plant, both requiring high-capacity transfection lines. These projects expand demand for platform reagents that adhere to data-rich quality-by-design protocols. Generative AI further accelerates screening cycles, mandating automated equipment that can execute tens of thousands of optimized transfections each week. This capex shift cascades down the supply chain, widening the installed base of high-throughput devices and recurring reagent sales.

High Cost of Advanced Reagents & Instruments

GMP-compliant reagents ship at premium price points, and clinical-grade electroporation devices can exceed USD 300,000, deterring start-ups and academic labs. Equipment leasing and reagent subscription models are emerging to soften upfront burdens, yet many emerging-market firms still defer procurement or rely on lower-spec alternatives that hinder scalability. Facility divestitures-such as UniQure's sale of a production plant-highlight the operational cost strain on mid-tier innovators. Suppliers with global service footprints and financing programs gain a competitive edge by democratizing access to premium platforms.

Other drivers and restraints analyzed in the detailed report include:

- Surge in Synthetic Gene & mRNA Demand

- Expansion of Cell & Gene-Therapy Clinical Pipelines

- Limited Cell-Type Specificity / Cytotoxicity Issues

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Reagents represented 74.01% of the transfection reagents and equipment market in 2024, reflecting steady demand from repeat consumables required for each experiment or production batch. This dominance translated into more than USD 930 million in reagent revenues within the transfection reagents and equipment market size, while equipment contributed the balance. Lipid-based chemistries remain the largest subset due to established safety profiles; polymer and hybrid lipid-polymer systems gain share in applications that benefit from reduced immunogenicity. The reagents category also benefits from shorter innovation cycles, with suppliers introducing formulations engineered for mRNA, CRISPR guides, or AAV production every 12-18 months.

Equipment revenues, though smaller in absolute terms, are increasing at 12.85% CAGR as manufacturers replace manual or low-throughput methods. Electroporation platforms account for the largest share of equipment sales; recent models include cartridge-based disposables that minimize cross-contamination risk. Microinjection systems remain essential for embryonic stem-cell applications despite labor-intensive workflows, whereas microfluidic devices offer automated throughput for early-stage screens. AI-enabled electroporation chambers that adjust field strength and pulse duration in real time address long-standing variability challenges. As CDMOs and large biologics producers expand capacity, equipment backlogs support robust forward demand.

Viral approaches held 43.12% market share in 2024 within the transfection reagents and equipment market. Sponsors rely on AAV and lentiviral delivery for their high integration efficiency, critical in ex vivo therapies such as CAR-T. The regulatory familiarity of viral systems and the availability of readymade vector platforms reduce development risk. However, concerns around immunogenicity and insertional mutagenesis motivate exploration of alternative techniques.

Physical methods are realizing 14.71% CAGR propelled by potent electroporation and sonoporation technologies that reach efficiencies above 90% without viral proteins. These systems support closed-system manufacturing, aligning with GMP expectations by minimizing contamination risk. Sonoporation further extends applicability to hard-to-transfect tissues via ultrasound-mediated membrane permeabilization, a feature attractive in in vivo gene therapies. Although biochemical methods like calcium-phosphate precipitation persist in basic research, their market share is gradually declining as next-generation modalities scale throughput and reduce cytotoxicity.

The Transfection Reagents and Equipment Market Report is Segmented by Product (Reagents, Equipment), Method (Biochemical Methods, Physical Methods, and Viral Methods), Application (Protein Production, and More), Cell Type (Mammalian Cells, and More), End User (Pharmaceutical & Biotechnology Companies, and More), and Geography (North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America held 38.12% market share in 2024, underpinned by FDA leadership and robust venture funding. The region hosts large-scale facilities like AstraZeneca's new USD 300 million cell-therapy site, reinforcing domestic demand for production-scale reagents and electroporation equipment. Integer capacity constraints and rising operating expenses nevertheless motivate select companies to explore CDMO partnerships in lower-cost jurisdictions.

Asia-Pacific records the highest regional CAGR at 10.31%, energized by China's 228 drug approvals in 2024 and regulatory reforms that target full convergence with ICH guidelines by 2027. Domestic suppliers scale up GMP-grade vector and reagent production, while multinational CDMOs expand footprint to serve both local and export pipelines. Japan and South Korea are codifying dedicated advanced-therapy frameworks, streamlining clinical entry for allogeneic products. Southeast Asian governments are offering tax incentives and greenfield bioparks, positioning the sub-region as a future transfection manufacturing hub.

Europe benefits from harmonized ATMP guidelines and proactive EMA approvals such as the CRISPR-based CASGEVY therapy, sustaining demand for end-to-end transfection solutions. Roche's EUR 90 million gene-therapy center exemplifies how global incumbents anchor production within the EU, leveraging workforce expertise and streamlined release testing. Environmental compliance initiatives spur innovation in biodegradable lipid formulations, while supply-chain traceability regulations encourage digitalization of equipment platforms.

- Thermo Fisher Scientific

- Lonza Group Ltd.

- Merck

- Bio-Rad Laboratories

- QIAGEN

- MaxCyte

- Mirus Bio

- Polyplus-transfection

- Promega

- Agilent Technologies

- Takara Bio

- Bio-Techne (R&D Systems)

- OriGene Technologies

- Integrated DNA Technologies (IDT)

- SignaGen Laboratories

- Altogen Biosystems

- Biontex Laboratories GmbH

- Celetrix LLC

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Technological Advancements In Non-Viral Transfection Chemistries

- 4.2.2 Growing R&D Spend By Pharma & Biotech Firms

- 4.2.3 Surge In Synthetic Gene & Mrna Demand

- 4.2.4 Expansion Of Cell & Gene-Therapy Clinical Pipelines

- 4.2.5 AI-Driven Reagent-Formulation Optimization

- 4.2.6 Microfluidic High-Throughput Transfection Platforms

- 4.3 Market Restraints

- 4.3.1 High Cost Of Advanced Reagents & Instruments

- 4.3.2 Limited Cell-Type Specificity / Cytotoxicity Issues

- 4.3.3 GMP-Grade Plasmid Supply Bottlenecks

- 4.3.4 Scale-Up Challenges For Commercial Manufacturing

- 4.4 Technological Outlook

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size & Growth Forecasts (Value, USD)

- 5.1 By Product

- 5.1.1 Reagents

- 5.1.1.1 Lipid-based

- 5.1.1.2 Polymer-based

- 5.1.1.3 Protein-based

- 5.1.2 Equipment

- 5.1.2.1 Electroporation Systems

- 5.1.2.2 Microinjection Systems

- 5.1.2.3 Nanoparticle-mediated Systems

- 5.1.1 Reagents

- 5.2 By Method

- 5.2.1 Biochemical Methods

- 5.2.1.1 Lipofection

- 5.2.1.2 Calcium-Phosphate

- 5.2.2 Physical Methods

- 5.2.2.1 Electroporation

- 5.2.2.2 Microinjection

- 5.2.2.3 Sonoporation

- 5.2.3 Viral Methods

- 5.2.3.1 Retroviral

- 5.2.3.2 Lentiviral

- 5.2.3.3 AAV

- 5.2.1 Biochemical Methods

- 5.3 By Application

- 5.3.1 Protein Production

- 5.3.2 Gene & mRNA Expression Studies

- 5.3.3 Cell & Gene Therapy Manufacturing

- 5.3.4 Cancer Research

- 5.3.5 Drug Discovery & Screening

- 5.4 By Cell Type

- 5.4.1 Mammalian Cells

- 5.4.2 Bacterial Cells

- 5.4.3 Yeast & Fungi

- 5.4.4 Insect Cells

- 5.4.5 Plant Cells

- 5.5 By End User

- 5.5.1 Pharmaceutical & Biotechnology Companies

- 5.5.2 Academic & Research Institutes

- 5.5.3 CROs & CMOs

- 5.6 Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 Japan

- 5.6.3.3 India

- 5.6.3.4 South Korea

- 5.6.3.5 Australia

- 5.6.3.6 Rest of Asia-Pacific

- 5.6.4 Middle East and Africa

- 5.6.4.1 GCC

- 5.6.4.2 South Africa

- 5.6.4.3 Rest of Middle East and Africa

- 5.6.5 South America

- 5.6.5.1 Brazil

- 5.6.5.2 Argentina

- 5.6.5.3 Rest of South America

- 5.6.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Market Share Analysis

- 6.3 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.3.1 Thermo Fisher Scientific Inc.

- 6.3.2 Lonza Group Ltd.

- 6.3.3 Merck KGaA (Millipore Sigma)

- 6.3.4 Bio-Rad Laboratories Inc.

- 6.3.5 Qiagen N.V.

- 6.3.6 MaxCyte Inc.

- 6.3.7 Mirus Bio LLC

- 6.3.8 Polyplus-transfection SA

- 6.3.9 Promega Corporation

- 6.3.10 Agilent Technologies Inc.

- 6.3.11 Takara Bio Inc.

- 6.3.12 Bio-Techne (R&D Systems)

- 6.3.13 OriGene Technologies Inc.

- 6.3.14 Integrated DNA Technologies (IDT)

- 6.3.15 SignaGen Laboratories

- 6.3.16 Altogen Biosystems

- 6.3.17 Biontex Laboratories GmbH

- 6.3.18 Celetrix LLC

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment