PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851911

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851911

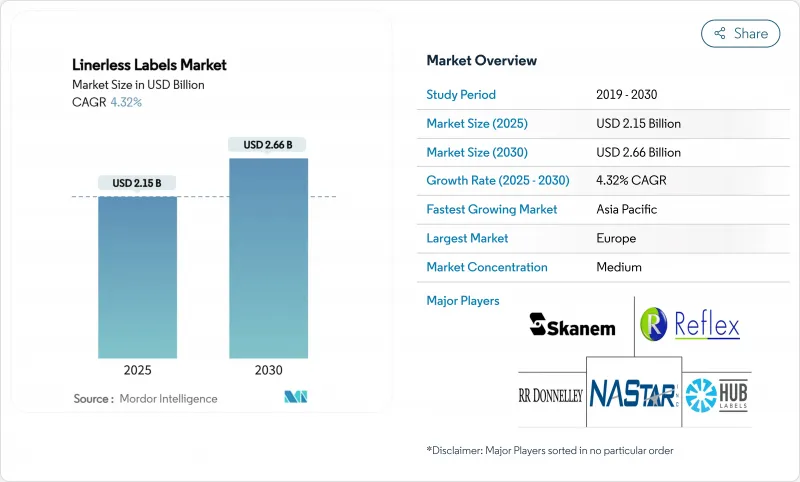

Linerless Labels - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The linerless labels market size is valued at USD 2.15 billion in 2025 and is forecast to reach USD 2.66 billion by 2030, advancing at a 4.32% CAGR.

Growth is anchored in stricter global packaging regulations, particularly the European Union's Packaging and Packaging Waste Regulation, which requires all packaging to be recyclable by 2030 and targets a 15% cut in per-capita packaging waste by 2040. Flexography continues to hold a 40.32% share, yet digital systems led by inkjet and thermal technologies are expanding at a 7.43% CAGR as e-commerce drives demand for variable-length, on-demand printing. Film facestocks account for 48.23% share, while specialty and recycled substrates post the strongest 8.11% CAGR amid corporate circular-economy goals. Water-based acrylic adhesives remain dominant at 42.32% share; UV-curable chemistries grow the fastest at 7.84% CAGR, solving cold-chain performance gaps. Europe leads with 34.62% share; however, Asia-Pacific rises at an 8.53% CAGR on the back of manufacturing scale-up and e-commerce expansion.

Global Linerless Labels Market Trends and Insights

Surge in Sustainable Food and Beverage Packaging Demand

Food brands are embedding linerless labels to meet both regulatory compliance and consumer expectations for lower-impact packaging. Avery Dennison reported 15% organic sales growth in its Intelligent Labels division during 2024, attributing much of the increase to food applications that cut material use by 30% and carbon footprint by 49% versus linered products. Fresh produce suppliers increasingly specify linerless solutions to slash landfill waste and enhance traceability, while automated packaging lines leverage dynamic label sizing to trim material usage by up to 40%. Combined, these factors accelerate market uptake across chilled, frozen and ambient product categories. The effect compounds as large processors set supplier mandates that cascade through regional value chains. Investments in recyclable facestocks and food-grade UV-curable adhesives further propel adoption in prepared-meal sectors.

E-commerce Logistics Boom Requiring Variable-Length Shipping Labels

Soaring parcel volumes force fulfillment centers to optimize label inventory and waste. Toshiba's DL1024 industrial printer merges shipping labels and packing slips into one variable-length format, lowering printing costs by 40% and eliminating liner waste. The United States Postal Service's revised parcel-labeling guide emphasizes streamlined designs that speed automated scanning, indirectly supporting linerless migration. High-volume facilities report 50% more labels per roll, translating into fewer roll changes and faster throughput. In micro-fulfillment hubs, space savings from liner elimination unlock additional picking capacity. Retailers' stricter sustainability scorecards are pushing suppliers toward linerless systems to avoid penalties linked to excess packaging.

Retrofit Costs for Legacy Labeling Lines

Switching to linerless often demands capital upgrades of USD 50,000 - 200,000 per line, a hurdle for smaller converters that extends payback periods to roughly two years. FoxJet's all-electric labelers now offer modular retrofit kits that remove compressed-air requirements, lowering operating costs and easing installation. Still, personnel training and revised maintenance routines add indirect expense. Many producers adopt hybrid workflows: linerless on new SKUs while legacy gear handles long-running products. Equipment vendors that bundle finance packages or subscription models can accelerate conversion by alleviating upfront cash pressure.

Other drivers and restraints analyzed in the detailed report include:

- Regulatory Waste-Reduction Mandates in Europe and North America

- QSR Kitchen Automation Uptake of On-Demand Linerless Printing

- Raw-Material Price Volatility Affecting Adhesives and Release Coatings

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Flexography maintained a 40.32% slice of the linerless labels market in 2024, but the digital segment is expanding at a 7.43% CAGR. The linerless labels market size for digital presses serving short and mid runs is set to widen quickly as e-commerce brands demand variable data and real-time customization. Hybrid presses that merge flexo priming with inkjet finishing lower waste and speed changeovers, an advantage for converters chasing small batch jobs. Thermal direct systems flourish in logistics because labels must survive material-handling abrasion yet remain cost-effective. Digital workflows also reduce water and solvent use, aligning with sustainability scorecards. Investments in inline finishing and cloud-connected color management lift output consistency, helping digital formats compete head-on with conventional flexo for medium runs.

Compatibility with RFID inlay insertion further elevates digital's role, enabling one-pass production of smart labels. Converters leveraging web-to-label portals capture new revenue from small sellers needing personalized designs without minimum-order hurdles. As substrate manufacturers release primer-free films, ink adhesion improves and reduces consumable costs. In summary, the printing-technology mix is shifting rapidly, with flexo staying relevant for commoditized SKUs while digital becomes the default for fast-moving, data-rich applications across the linerless labels market.

Film-based facestocks-largely PP and PET-retain a 48.23% grip on the linerless labels market share thanks to moisture resistance and shelf appeal. Yet specialty and recycled alternatives outpace at an 8.11% CAGR, propelled by buyers' circular-economy pledges and regulatory recycled-content quotas. The linerless labels market size for recycled-content films covering food and personal-care packages is forecast to climb steadily through 2030. UPM Raflatac's Carbon Action portfolio uses ISCC-certified feedstocks to cut cradle-to-gate emissions and appeal to brands chasing Scope-3 reductions.

Paper facestocks defend niches where compostability or tactile branding trumps durability. Hybrid structures pairing thin PP overcell with recycled-kraft bases optimize strength while shrinking virgin-plastic content. Wash-off films that delaminate in alkaline baths permit closed-loop PET recycling, crucial for beverage suppliers seeking bottle-to-bottle systems. Suppliers broaden color and finish ranges to rival conventional laminated labels, removing one more barrier to specialty adoption. Continuous investment in biax-stretch lines and depolymerization recycling plants indicates that feed-stock availability will scale to meet rising demand.

The Linerless Labels Market Report is Segmented by Printing Technology (Digital, Flexography, Gravure, Offset and Letterpress), Facestock Material (Paper, Film, Specialty and Recycled Substrates), Adhesive Type (Water-Based Acrylic, Hot-Melt, UV-Curable, Solvent-Based), End-User Industry (Food, Beverage, Healthcare and Pharmaceuticals, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Europe commanded 34.62% of 2024 revenue on the strength of early regulatory adoption, dense retail networks and established converter bases. Regional majors such as UPM Raflatac and HERMA pioneer wash-off and recycled-content formats, creating spill-over demand among private-label brands. Government procurement criteria specifying recyclable packaging further cement Europe's lead. North America follows, buoyed by e-commerce acceleration and statewide extended-producer-responsibility bills that internalize disposal costs for packaging suppliers. Converters here invest in high-speed UV lines to serve chilled-food and parcel hubs, while CCL Industries expands capacity via strategic acquisitions.

Asia-Pacific registers the fastest 8.53% CAGR, driven by China's manufacturing scale and India's rapid e-commerce penetration. The linerless labels market share in the region is poised to climb as local converters add digital presses and overseas brands demand harmonized sustainable packaging. Japan's Lintec Corporation invests in capacity upgrades and R&D for cold-resistant adhesives, reinforcing regional technology leadership. Emerging markets such as Vietnam and Indonesia adopt linerless to meet export certification standards set by Western retailers. South America sees selective growth as Brazil's beverage giants trial wash-off films in PET bottle recycling projects. In the Middle East & Africa, uptake centers on United Arab Emirates and South Africa where multinational FMCG plants deploy global specifications.

Collectively, regulatory harmonization, cross-border e-commerce and capacity investments suggest sustained regional demand rotation. As capital flows into Asia-Pacific capacity, raw-material supply chains adapt, further lowering unit costs and accelerating substitution away from linered stock. Europe remains the regulatory bellwether; its policy innovations are increasingly mirrored worldwide, embedding linerless capability as a baseline requirement for export-oriented manufacturers.

- Avery Dennison Corporation

- CCL Industries (Inc. & Innovia Films)

- 3M Company

- Beontag

- UPM Raflatac

- Coveris

- Hub Labels Inc.

- Reflex Labels Ltd

- Skanem AS

- NAStar Inc.

- Optimum Group

- SATO Europe GmbH

- ProPrint Group

- Lexit Group AS

- R.R. Donnelley & Sons Co.

- Gipako UAB

- Lintec Corporation

- HERMA GmbH

- Zebra Technologies

- Multi-Color Corporation

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in sustainable food and beverage packaging demand

- 4.2.2 E-commerce logistics boom requiring variable-length shipping labels

- 4.2.3 Regulatory waste-reduction mandates in Europe and North America

- 4.2.4 QSR kitchen automation uptake of on-demand linerless printing

- 4.2.5 RFID-enabled connected packaging and micro-fulfillment adoption

- 4.3 Market Restraints

- 4.3.1 Retrofit costs for legacy labeling lines

- 4.3.2 Raw-material price volatility (adhesives and release coating)

- 4.3.3 Adhesive build-up issues in cold-chain environments

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Printing Technology

- 5.1.1 Digital (Inkjet and Thermal)

- 5.1.2 Flexography

- 5.1.3 Gravure

- 5.1.4 Offset and Letterpress

- 5.2 By Facestock Material

- 5.2.1 Paper

- 5.2.2 Film (PP, PET, PE)

- 5.2.3 Specialty and Recycled Substrates

- 5.3 By Adhesive Type

- 5.3.1 Water-based Acrylic

- 5.3.2 Hot-Melt

- 5.3.3 UV-Curable

- 5.3.4 Solvent-based

- 5.4 By End-user Industry

- 5.4.1 Food

- 5.4.2 Beverage

- 5.4.3 Healthcare and Pharmaceuticals

- 5.4.4 Cosmetics and Personal Care

- 5.4.5 Household Chemicals

- 5.4.6 Logistics and E-commerce

- 5.4.7 Other End-User Industry

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Avery Dennison Corporation

- 6.4.2 CCL Industries (Inc. & Innovia Films)

- 6.4.3 3M Company

- 6.4.4 Beontag

- 6.4.5 UPM Raflatac

- 6.4.6 Coveris

- 6.4.7 Hub Labels Inc.

- 6.4.8 Reflex Labels Ltd

- 6.4.9 Skanem AS

- 6.4.10 NAStar Inc.

- 6.4.11 Optimum Group

- 6.4.12 SATO Europe GmbH

- 6.4.13 ProPrint Group

- 6.4.14 Lexit Group AS

- 6.4.15 R.R. Donnelley & Sons Co.

- 6.4.16 Gipako UAB

- 6.4.17 Lintec Corporation

- 6.4.18 HERMA GmbH

- 6.4.19 Zebra Technologies

- 6.4.20 Multi-Color Corporation

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment