PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1852192

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1852192

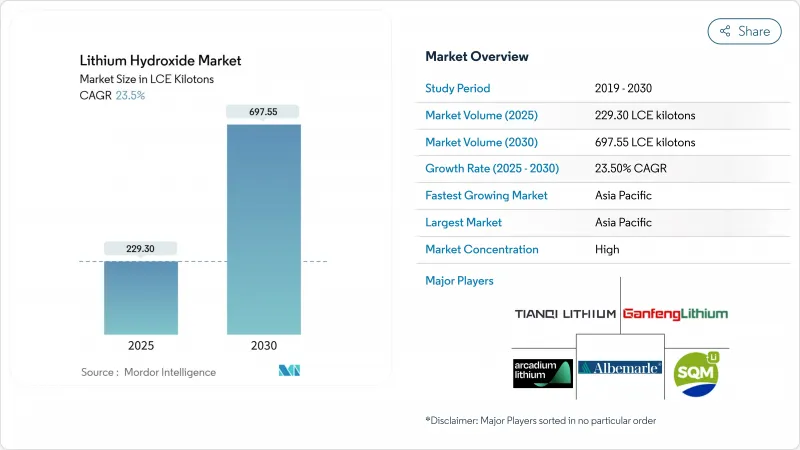

Lithium Hydroxide - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Lithium Hydroxide Market size is estimated at 229.30 LCE kilotons in 2025, and is expected to reach 697.55 LCE kilotons by 2030, at a CAGR of 23.5% during the forecast period (2025-2030).

Intensifying competition for battery-grade chemicals, fast-rising electric vehicle (EV) sales, and the rapid scale-up of direct lithium extraction (DLE) technologies are reshaping supply networks worldwide. Asia-Pacific commands the largest regional position with 40% of global consumption, delivering the fastest growth rate of 27.66% through 2030. Automakers locked in long-term procurement contracts in 2024 to secure high-purity feedstock, and several battery manufacturers accelerated vertical-integration strategies to hedge price swings. At the same time, stark feedstock price volatility-from USD 81,500/t to USD 22,500/t during 2023-continues to challenge project finance models.

Global Lithium Hydroxide Market Trends and Insights

Increasing Demand for Power Tools

Cordless power tools are replacing corded alternatives in construction and industrial maintenance because lithium-ion packs deliver longer run-time and a superior power-to-weight ratio. Manufacturers have launched cell formats optimized for high-discharge cycles, a profile that favors lithium hydroxide-rich nickel-cobalt-manganese cathodes. Uptake is strongest among professional contractors in North America and Europe, where tight labor markets place a premium on productivity gains. Continuous adoption of building-information-modeling workflows further accelerates cordless tool penetration because crews require untethered mobility on-site. Though smaller than EV demand, this niche yields above-average price realization for hydroxide producers supplying specialty cathode blends.

Commercialization of Direct Lithium Extraction (DLE) Unlocking Low-Cost Feedstock

Field-scale success at IBAT's Utah plant, utilizing modular adsorption columns, demonstrated 80-90% lithium recovery in hours versus the months needed for conventional pond evaporation. Project ATLiS in California secured a USD 1.36 billion conditional loan guarantee to deliver 20,000 t/y of lithium hydroxide from geothermal brine, affirming lender confidence in DLE scalability. Higher yields cut capital intensity per ton and enable operations in water-stressed regions because many ion-exchange and membrane variants consume less make-up water than pond systems. These economics bolster the long-run supply outlook for the lithium hydroxide market while reducing environmental footprints.

High Production Costs

Battery-grade lithium hydroxide plants demand sophisticated impurity control and costly crystallization circuits. Albemarle halted expansion of its Kemerton facility in Australia, slicing planned nameplate capacity in half and reducing onsite headcount by 40%. Multiyear payback periods, strict environmental licensing, and a limited pool of hydro-metallurgical talent maintain high entry barriers and slow new-build momentum, especially in regions with elevated energy tariffs.

Other drivers and restraints analyzed in the detailed report include:

- OEM-Backed Long-Term Contracts De-Risking New Capacity in Latin America

- Government Policies Supporting Battery Supply Chains

- Feedstock Price Volatility Hindering Project Financing

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Lithium-ion batteries generated 63% of 2024 demand and are forecast to expand at 26.77% CAGR through 2030. This segment alone accounts for the largest slice of the lithium hydroxide market size and delivers the highest incremental tonnage. Range-oriented chemistries such as nickel-cobalt-manganese (NCM) and nickel-cobalt-aluminum (NCA) require lithium hydroxide for synthesis rather than carbonate, anchoring structural demand. In contrast, lubricating greases, purified-air systems, and specialty synthesis remain steady but modest contributors. Growing recycling mandates in the European Union are expected to generate a secondary supply channel later in the forecast period, tempering but not displacing primary demand.

Energy storage deployments form the fastest-rising sub-application. Large-scale battery farms linked to renewable assets need long cycle-life chemistries. Projects such as California's multi-gigawatt-hour installations increasingly specify nickel-rich cathodes, reinforcing hydroxide consumption. As costs decline, smaller commercial and industrial behind-the-meter systems join the opportunity set, ensuring the lithium hydroxide market retains a diversified growth engine across stationary and mobile domains.

Battery-grade material held a commanding 70% share in 2024 and posts a forecast 25.55% CAGR, the highest within this segmentation. Stringent impurity controls on sodium, calcium, and heavy metals underpin price differentials over technical grade. Manufacturers such as Livent have invested in additional recrystallization and ion-exchange modules to achieve less than 100 ppm aggregate impurity limits. That investment raises capital intensity but also deepens competitive moats. Technical grade serves grease and ceramic markets where tolerance thresholds are looser, while industrial grade addresses water treatment and select synthesis routes.

The lithium hydroxide market share for battery-grade will keep rising as OEM specification sheets lengthen. Next-generation solid-state and high-silicon-anode designs rely on precise stoichiometry and ultra-low moisture content, factors that amplify quality premiums. Producers with vertically integrated brine or hard-rock feedstock plus in-house purification are best placed to capture this margin pool.

The Lithium Hydroxide Market Report is Segmented by Application (Lithium-Ion Batteries, Lubricating Grease, and More), End-Use Industry (Automotive, Consumer Electronics, and More), Grade (Battery Grade, Technical Grade, and Industrial Grade), Form (Monohydrate and Anhydrous), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa).

Geography Analysis

Asia-Pacific, with a 40% lithium hydroxide market share in 2024, benefits from unrivaled cell-manufacturing capacity and a dense cluster of downstream cathode, anode, and pack assemblers. Chinese policy directives now favor domestic sourcing, prompting active development of inland salt-lake brine as well as overseas equity stakes, while Japan and South Korea leverage long-standing material science expertise to stay competitive. India entered the fray with a National Manufacturing Mission and duty exemptions for critical minerals under the 2025-26 Union Budget, stimulating local hydroxide conversion proposals.

North America's expansion rests on large-scale funding packages. The DOE's USD 150 million grant to Albemarle supports a spodumene concentrator at Kings Mountain capable of feeding 1.6 million EVs annually. Hyundai Motor Group and SK On approved a USD 5 billion battery cell plant in Georgia, anchoring regional cathode demand for locally produced hydroxide. These initiatives aim to cut reliance on Asian supply chains and meet US Inflation Reduction Act sourcing thresholds.

South America remains the primary feedstock hub. Chile's National Lithium Strategy invites private participation while safeguarding state oversight, and new geological surveys lifted estimated reserves by 28%. Argentina attracted Rio Tinto's USD 2.5 billion mine investment and multiple OEM offtakes. Brazil saw EV sales jump 85% in 2024, led by BYD with 70% share, hinting at future domestic hydroxide conversion requirements.

Europe accelerates capacity with stringent CO2 regulations and comprehensive recycling mandates. Germany spearheads R&D on next-generation cathodes, while the EU Battery Regulation sets minimum lithium recovery quotas from 2025 onward. Several greenfield conversion plants in Finland, France, and Portugal are scheduled for commissioning by 2027, adding diversity to the lithium hydroxide market supply base. The bloc's push for strategic autonomy may reshape trade flows, especially if China enacts proposed technology export restrictions.

- Albemarle Corporation

- Arcadium Lithium

- Chengxin Lithium

- Ganfeng Lithium Group Co. Ltd.

- IGO Limited

- LevertonHELM Limited

- Nemaska Lithium (Investissement Quebec)

- Piedmont Lithium Inc.

- Shandong Ruifu Lithium Co., Ltd.

- Sinomine Resource Group

- SQM S.A.

- Tianqi Lithium Corporation

- Yahua Industrial Group Co.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Demand for Electric Vehicles

- 4.2.2 Increasing Demand for Power Tools

- 4.2.3 Commercialisation of Direct Lithium Extraction (DLE) Unlocking Low-Cost Hydroxide Feedstock

- 4.2.4 OEM-Backed Long-Term Contracts De-Risking New Hydroxide Capacity in Latin America

- 4.2.5 Government Policies Supporting Battery Supply Chains

- 4.3 Market Restraints

- 4.3.1 High Production Costs

- 4.3.2 Feedstock Price Volatility Hindering Project Financing

- 4.3.3 Rising concern About the Toxicity

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Volume and Value)

- 5.1 By Application

- 5.1.1 Lithium-ion Batteries

- 5.1.2 Lubricating Greases

- 5.1.3 Purification

- 5.1.4 Other Application (Polymer and Specialty Chemical Synthesis)

- 5.2 By End-use Industry

- 5.2.1 Automotive

- 5.2.2 Consumer Electronics

- 5.2.3 Energy Storage Systems

- 5.2.4 Others (Industrial and Off-Road Machinery)

- 5.3 By Grade

- 5.3.1 Battery Grade (Greater than or equal to 56.5% LiOH*H2O)

- 5.3.2 Technical Grade

- 5.3.3 Industrial Grade

- 5.4 By Form

- 5.4.1 Monohydrate

- 5.4.2 Anhydrous

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 Japan

- 5.5.1.3 South Korea

- 5.5.1.4 India

- 5.5.1.5 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Nordics

- 5.5.3.7 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Chile

- 5.5.4.4 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Albemarle Corporation

- 6.4.2 Arcadium Lithium

- 6.4.3 Chengxin Lithium

- 6.4.4 Ganfeng Lithium Group Co. Ltd.

- 6.4.5 IGO Limited

- 6.4.6 LevertonHELM Limited

- 6.4.7 Nemaska Lithium (Investissement Quebec)

- 6.4.8 Piedmont Lithium Inc.

- 6.4.9 Shandong Ruifu Lithium Co., Ltd.

- 6.4.10 Sinomine Resource Group

- 6.4.11 SQM S.A.

- 6.4.12 Tianqi Lithium Corporation

- 6.4.13 Yahua Industrial Group Co.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Rising Demand for Portable Electronic Devices