PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1905997

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1905997

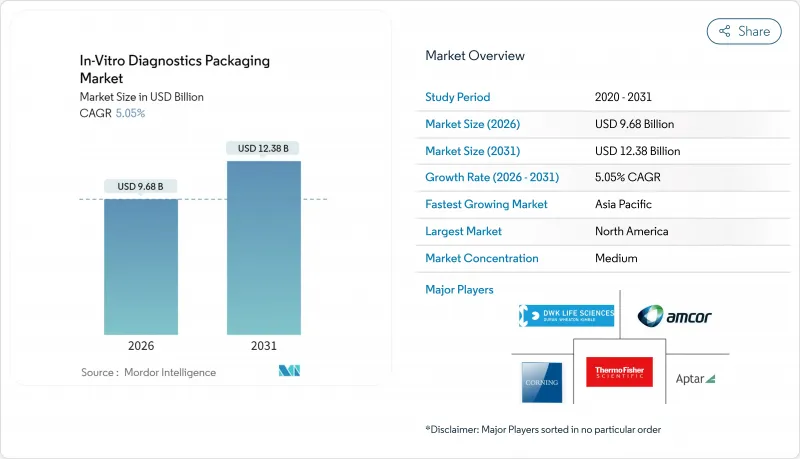

In-Vitro Diagnostics Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The in-vitro diagnostics packaging market size in 2026 is estimated at USD 9.68 billion, growing from 2025 value of USD 9.21 billion with 2031 projections showing USD 12.38 billion, growing at 5.05% CAGR over 2026-2031.

This momentum reflects growing adoption of automation-ready tubes, pre-validated primary containers, and cold-chain shippers that safeguard increasingly complex molecular assays. Demand for low-extractable polymers and tamper-evident components is broadening supplier portfolios, while environmental stewardship and polymer-sourcing volatility inject fresh challenges into margin management. Competitive intensity remains moderate yet is rising, as vertically integrated players combine proprietary anticoagulants, pre-bar-coded labeling, and just-in-time services to secure laboratory contracts. Meanwhile, glass-polymer hybrids and ultra-low extraction copolymers are carving high-value niches within high-throughput molecular workflows. In parallel, regional reimbursement reforms that favor at-home testing and decentralized sample collection are expanding end-user diversity, driving the development of packaging formats optimized for user friendliness and ambient stability.

Global In-Vitro Diagnostics Packaging Market Trends and Insights

Proliferation of At-Home Point-of-Care Tests

Expanded reimbursement codes issued by the Centers for Medicare and Medicaid Services in 2024 now cover continuous glucose monitors and coagulation strips, spurring demand for single-use devices with integrated sample stabilizers that sidestep cold-chain constraints. The Food and Drug Administration's finalized guidance on home-use labeling requires pictogram instructions and child-resistant closures, prompting redesign of containers and investment in multilingual digital presses.

Pharmacy chains across the United States and Europe have begun stocking rapid tests in vending kiosks, further taxing packaging to withstand the effects of humidity shifts and repeated handling. Together, payer support, regulatory clarity, and retail distribution are sustaining double-digit growth in at-home test packaging.

Automation Surge in High-Throughput Molecular Labs

Laboratories adopting Siemens Healthineers' Atellica automation platform reduce turnaround times by approximately 30%, yet must source tubes with strict dimensional tolerances and machine-readable labels that withstand robotic handling. Next-generation sequencing workflows favor low-bind polypropylene plates that minimize DNA loss, steering suppliers toward surface-modified polymers. ISO 15189 accreditation enhances traceability requirements, prompting labs to invest in pre-validated consumables that exclude lower-specification generics. As a result, automation-ready formats are consolidating spend with established vendors.

Environmental Concerns Around Single-Use Plastics

Although the EU Single-Use Plastics Directive exempts medical devices, health systems voluntarily target waste reduction, with the UK National Health Service pledging a 25% cut by 2028. ISO 18604 issued in 2024 obliges manufacturers to disclose recycled content and design for recyclability, extending development cycles and compliance costs. Pilot take-back schemes, such as Becton Dickinson's German recycling program, illustrate interest yet highlight biohazard decontamination and cost hurdles. Recycled-grade polypropylene premiums and revalidation demands further temper adoption.

Other drivers and restraints analyzed in the detailed report include:

- Shift Toward Pre-Bar-Coded Primary Containers

- Biobank Expansion Fueling Cryogenic Vial Demand

- Supply Chain Volatility for Medical-Grade Polymers

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polypropylene captured 40.84% of 2025 revenue, reinforcing its status as the workhorse substrate for serum-separator tubes, urine containers, and general reagent vessels. Cyclic olefin copolymer is forecast to grow 6.12% annually through 2031, underpinned by its ultra-low extractables profile and optical clarity that favor microfluidic cartridges and single-use bioreactors. Topas Advanced Polymers registered a 40% surge in COC shipments to IVD firms, citing demand for pre-filled reagent cassettes that minimize breakage during automated handling. Polyethylene terephthalate remains the go-to material for reagent and buffer bottles, thanks to its superior moisture-barrier properties, while borosilicate glass holds niche applications requiring extreme chemical inertness.

COC momentum will likely accelerate as molecular diagnostics platforms integrate sample preparation, amplification, and detection into compact, disposable cartridges. Stevanato Group's EZ-Fill format exemplifies this trend, pairing COC bodies with integrated needles and barcodes at line speeds exceeding 300 units per minute. Polypropylene suppliers are countering with clarity-enhanced copolymers; however, requalification costs and higher resin prices slow uptake. Over the forecast horizon, performance needs, regulatory compliance, and total cost of ownership will determine the pace at which COC displaces incumbent materials in the in-vitro diagnostics packaging market.

Tubes commanded 38.25% of product-type revenue in 2025, driven by the adoption of vacuum blood collection and the expansion of point-of-care testing that relies on micro-collection devices. Closures are expected to register the fastest advance at a 6.49% CAGR, driven by new FDA and EU safety mandates that require tamper-evident and child-resistant features. Becton Dickinson's Hemogard closure claimed more than 60% of the company's blood-collection revenue in 2024, underscoring how incremental safety can capture premium pricing. Vials and bottles supply critical roles in lyophilized reagent storage and bulk-reagent delivery, while integrated sampling devices bridge patient convenience and lab automation.

Revised ISO 8317 torque and child-resistance protocols require suppliers to engineer push-and-turn or squeeze-and-turn caps, which increase molding complexity and unit cost. West Pharmaceutical Services' color-change flip-off seal targets forensic and doping control use cases where the chain of custody matters. Tubes designed for molecular workflows are increasingly incorporating stabilizer reagents that require higher seal integrity to prevent evaporation. The convergence of safety, regulatory, and functional needs is elevating closures from commodity to value-added components across the in vitro diagnostics packaging market.

The In-Vitro Diagnostics Packaging Market Report is Segmented by Material Type (Polypropylene, Polyethylene Terephthalate, Borosilicate Glass, and More), Product Type (Bottles, Vials, Tubes, and More), Packaging Format (Primary Packaging, Secondary Packaging, and Tertiary Packaging), End User (Hospitals, Diagnostic Laboratories, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America maintained a 39.50% revenue share in 2025 as high testing rates, entrenched automation, and stringent regulatory frameworks entrenched incumbent suppliers. Market players continue to expand domestic tube capacity to hedge against geopolitical risk and meet state-level legislation that favors local sourcing. Canada's public procurement now stipulates UDI traceability for IVD consumables, mirroring U.S. FDA alignment and reinforcing demand for serialized containers. The region's emphasis on at-home diagnostics and chronic disease monitoring accelerates orders for single-use kits that combine tamper-evident closures with ambient stability.

The Asia-Pacific region shows the fastest trajectory, projected to grow at 7.68% through 2031. China's policy requiring county hospitals to deploy molecular capabilities by 2027 will generate a high volume of tubes, reagent cartridges, and cold-chain shippers. Becton Dickinson's USD 150 million Suzhou expansion exemplifies supplier moves to capture this demand. India's National Health Mission allocation of INR 50 billion (USD 600 million) for lab upgrades likewise stimulates the adoption of automation-ready containers. Regional growth is amplified by local manufacturers receiving NMPA approvals, which intensifies competition while shortening supply chains for high-volume plastics.

Europe demonstrates stable growth under the Medical Device and In Vitro Diagnostic Regulations that took full force in 2024, demanding UDI-encoded bar codes and post-market surveillance that elevate compliance cost. Schott AG's EUR 100 million (USD 109 million) glass tubing plant in China enables European-based assay vendors to source compliant vials closer to Asian filling sites. The United Kingdom's post-Brexit divergence adds dual conformity assessments, extending time-to-market for suppliers but also fostering domestic innovation. South America's modernization programs and the African Union's pooled procurement platform promise incremental growth but face currency volatility and fragmented cold-chain infrastructure. Suppliers planning global expansion now calibrate go-to-market tactics to local regulatory and logistics maturity rather than adopting uniform strategies across the in-vitro diagnostics packaging market.

- Amcor plc

- AptarGroup Inc.

- Corning Incorporated

- Greiner AG

- Thermo Fisher Scientific Inc.

- COMAR LLC

- WS Packaging Group Inc.

- DWK Life Sciences GmbH

- Gerresheimer AG

- Schott AG

- SiO2 Materials Science LLC

- SGD Pharma SAS

- Nipro Corp.

- Becton Dickinson and Company

- Terumo Corp.

- West Pharmaceutical Services Inc.

- Catalent Inc.

- Origin Pharma Packaging Ltd.

- Owen Mumford Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for Tubes

- 4.2.2 Proliferation of At-Home Point-of-Care Tests

- 4.2.3 Automation Surge in High-Throughput Molecular Labs

- 4.2.4 Shift Toward Pre-Bar-Coded Primary Containers

- 4.2.5 Increasing Adoption of Vacuum Blood Collection Systems

- 4.2.6 Biobank Expansion Fueling Cryogenic Vial Demand

- 4.3 Market Restraints

- 4.3.1 Environmental Concerns Around Single-Use Plastics

- 4.3.2 Supply Chain Volatility for Medical-Grade Polymers

- 4.3.3 Stringent EU MDR and IVDR Labeling Mandates

- 4.3.4 Cost Pressures from Centralized Procurement in Public Health Systems

- 4.4 Impact of Macroeconomic Factors on the Market

- 4.5 Industry Value Chain Analysis

- 4.6 Regulatory Landscape

- 4.7 Technological Outlook

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitute Products

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Polypropylene (PP)

- 5.1.2 Polyethylene Terephthalate (PET)

- 5.1.3 Borosilicate Glass

- 5.1.4 Cyclic Olefin Copolymer (COC)

- 5.1.5 Other Material Types

- 5.2 By Product Type

- 5.2.1 Bottles

- 5.2.2 Vials

- 5.2.3 Tubes

- 5.2.4 Closures

- 5.2.5 Other Product Types

- 5.3 By Packaging Format

- 5.3.1 Primary Packaging

- 5.3.2 Secondary Packaging

- 5.3.3 Tertiary Packaging

- 5.4 By End User

- 5.4.1 Hospitals

- 5.4.2 Diagnostic Laboratories

- 5.4.3 Academic and Research Institutes

- 5.4.4 Home Healthcare Providers

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Chile

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 United Kingdom

- 5.5.3.2 Germany

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia and New Zealand

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 United Arab Emirates

- 5.5.5.1.2 Saudi Arabia

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Kenya

- 5.5.5.2.3 Nigeria

- 5.5.5.2.4 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 AptarGroup Inc.

- 6.4.3 Corning Incorporated

- 6.4.4 Greiner AG

- 6.4.5 Thermo Fisher Scientific Inc.

- 6.4.6 COMAR LLC

- 6.4.7 WS Packaging Group Inc.

- 6.4.8 DWK Life Sciences GmbH

- 6.4.9 Gerresheimer AG

- 6.4.10 Schott AG

- 6.4.11 SiO2 Materials Science LLC

- 6.4.12 SGD Pharma SAS

- 6.4.13 Nipro Corp.

- 6.4.14 Becton Dickinson and Company

- 6.4.15 Terumo Corp.

- 6.4.16 West Pharmaceutical Services Inc.

- 6.4.17 Catalent Inc.

- 6.4.18 Origin Pharma Packaging Ltd.

- 6.4.19 Owen Mumford Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment