PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906254

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906254

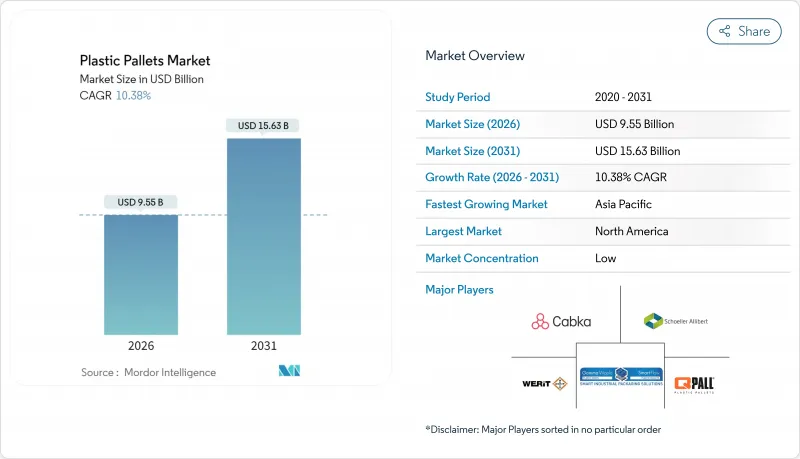

Plastic Pallets - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The plastic pallets market is expected to grow from USD 8.65 billion in 2025 to USD 9.55 billion in 2026 and is forecast to reach USD 15.63 billion by 2031 at 10.38% CAGR over 2026-2031.

Rising hygiene rules in pharmaceutical cold chains, ISPM-15 compliance costs for wood, and automation-ready warehouse designs are the central growth catalysts shaping the plastic pallets market. Demand also benefits from pooling systems that convert capital expenditure into an operating fee, making shared assets attractive to third-party logistics firms. Polyolefin resin recycling initiatives across the EU add further momentum by aligning pallets with circular-economy targets. Conversely, resin price swings tied to crude oil pose near-term margin pressure for manufacturers.

Global Plastic Pallets Market Trends and Insights

Adoption of Hygienic Plastic Pallets in Pharmaceutical Cold Chains

FDA rules classify pallets as transportation equipment, making cleanable, non-porous designs mandatory in pharma logistics. Plastic pallets resist moisture and maintain structure during temperature swings, lowering contamination risk compared with wood. European producers such as Schoeller Allibert now supply cleanroom-grade pallets tailored to sterile drug manufacturing. The rising cost of product recalls cements adoption, turning plastic units into standard infrastructure for regulated cold chains. As vaccine volumes stay elevated, North American demand remains strong, and similar hygienic standards are spreading across Europe.

Mandates for ISPM-15 Compliance Driving Shift from Wood to Plastic

ISPM-15 requires heat treatment or fumigation for wooden packaging, adding cost and delays to Asia's exports. Plastic pallets are exempt, giving them an immediate compliance advantage in China, Vietnam, and Thailand. Exporters avoid the USD 12-15 per-pallet treatment fee, improving margin on high-volume shipments. The American Lumber Standard Committee's rigorous audit schedule further dissuades wood use by raising administrative burde. As trade lanes tighten lead-time windows, plastic pallets offer certainty, speeding clearance in 182 ISPM-15-signatory nations.

High Upfront Capital Cost Barrier for SMEs in Emerging Southeast Asia

Plastic pallets cost three-to-five times more than wood, deterring cash-constrained SMEs that represent 98.7% of firms in the region. Subsidized loans exist but rarely cover working-capital upgrades of this scale. In Indonesia, where small processors dominate local plastics output, payback periods exceed typical planning horizons. Without cost-sharing pools, adoption remains limited to large exporters who can amortize investment over high rotation counts. Manufacturers now market lower-priced recycled-content pallets, yet financing gaps persist.

Other drivers and restraints analyzed in the detailed report include:

- Pooling Models Reducing Total Cost of Ownership for 3PLs

- Retail Automation Requiring Dimensionally Stable Pallets

- Limited Reverse Logistics Infrastructure for Bulk Return of Pallets

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

HDPE retained 66.03% plastic pallets market share in 2025 thanks to chemical resistance demanded by pharma and food handlers. The plastic pallets market now places premium value on recycled resin, pushing the recycled materials segment toward a 12.29% CAGR through 2031 as EU content mandates tighten. Virgin-resin volatility tied to crude prices makes recycled HDPE more financially attractive, smoothing input costs for manufacturers. Producers such as Q-Pall already manufacture pallets using 98% recycled feedstock, demonstrating technical feasibility at scale.Continued regulatory pressure will likely narrow the cost delta between recycled and virgin grades as demand spikes across Europe.

Recycled polymers also appeal to corporate ESG agendas, which increasingly require transport packaging to carry audited sustainability credentials. The plastic pallets market benefits because pallets can be ground and remolded repeatedly without degrading performance, fitting circular-economy loops that wooden pallets cannot replicate. Producers invest in wash-line capacity to guarantee contaminant removal, thereby meeting food-grade standards for recycled HDPE. North American buyers also test recycled-content offerings to hedge against resin price spikes, while Asian exporters adopt them to highlight low-carbon credentials in tender bids.

Nestable pallets accounted for 42.10% of global revenue in 2025 owing to their ability to cut empty-return freight by up to 80%. Yet the rackable segment will expand at an 11.62% CAGR because automated warehouses demand stable deflection limits that nestable designs seldom meet. Retailers installing AS/RS systems prefer rackable pallets that keep load sag below 6 mm under 1 ton static loads, safeguarding conveyor uptime. Producers answer with glass-fiber-reinforced HDPE to boost stiffness without adding weight.

Stackable pallets hold share in heavy manufacturing where columns two or three loads high demand rigid decks, but growth remains slower than rackable units. Display pallets, a niche sub-group, support promotional formats in big-box retail yet face limited churn due to specialized dimensions. The plastic pallets market continues to balance space-saving nestable designs for transport against rack-ready units for automated fulfillment, with many shippers dual-sourcing both formats to optimize supply chain nodes.

The Plastic Pallets Market Report is Segmented by Material Type (High-Density Polyethylene, and More), Pallet Type (Nestable, Rackable, Stackable, Display/Custom), End-User Industry (Food and Beverage, Chemical, and More), Load Capacity (Light-Duty, Medium-Duty, High-Duty), and Geography (North America, Europe, Asia-Pacific, Middle East and Africa, South America). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America commanded 29.20% of global revenue in 2025, supported by mature pooling networks and FDA hygiene regulations that encourage reusable, cleanable platforms. ORBIS's new Greenville, Texas plant shows continuing investment to meet local demand for automation-ready pallets. Retail DC automation further boosts adoption because plastic units maintain tighter dimensional tolerances than wood, reducing conveyor downtime.

Asia-Pacific is the fastest-growing territory, posting a 14.10% CAGR to 2031 as export-oriented firms switch to plastic to avoid ISPM-15 treatment fees. China's lithium battery boom spurs demand for anti-static pallets, while Thailand and Vietnam test cross-border designs launched by Loscam to ease regional flows. Yet financing gaps and limited return loops continue to slow adoption among Southeast Asian SMEs.

Europe benefits from stringent Packaging and Packaging Waste Regulation quotas, which require 40% reusability for transport packaging by 2030, furthering the shift to durable plastic pallets. Established pooling operators can exploit existing reverse-logistics density to hit those targets cost-effectively. Middle East & Africa and South America trail due to weaker retrieval networks, adding operational complexity and loss risk that undercut the life-cycle savings plastic offers over wood.

- Brambles Limited (CHEP)

- CABKA Group GmbH

- Orbis Corporation (Menasha)

- Schoeller Allibert Group BV

- Rehrig Pacific Company

- Tosca Services, LLC

- Loscam International Holdings

- Craemer Holding GmbH

- Gamma-Wopla NV / Smart-Flow NV

- Q-Pall BV

- Plasgad Plastic Products ACS Ltd.

- NAECO S.L.

- Polymer Solutions International Inc.

- RPP Containers

- IPS Plastics Pallets (IPS Group)

- Shandong Huaxiang Plastic Co., Ltd.

- Beijing Jingliang United Plastic Products Co., Ltd.

- TranPak Inc.

- Allied Plastics, Inc.

- Falkenhahn AG

- Buckhorn Inc.

- iGPS Logistics LLC

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Adoption of Hygienic Plastic Pallets in Pharmaceutical Cold Chains across North America and Europe

- 4.2.2 Mandates for ISPM-15 Compliance Driving Shift from Wood to Plastic in Asia Export Hubs

- 4.2.3 Pooling Models Reducing Total Cost of Ownership for 3PLs in Europe

- 4.2.4 Retail Automation (AS/RS and Conveyor Systems) Requiring Dimensionally Stable Pallets in the U.S.

- 4.2.5 Circular Economy Targets Pushing Demand for Recyclate-Based HDPE Pallets in the EU

- 4.2.6 Battery and Chemical Lithium Supply Chains Preferring Anti-Static Plastic Pallets in China

- 4.3 Market Restraints

- 4.3.1 High Upfront Capital Cost Barrier for SMEs in Emerging Southeast Asia

- 4.3.2 Limited Reverse Logistics Infrastructure for Bulk Return of Pallets in Africa and South America

- 4.3.3 Price Volatility of Virgin Polyolefin Resins Linked to Crude-Oil Swings

- 4.3.4 Perception of Lower Load Capacity Versus Hardwood Pallets Among Heavy-Duty Users in Construction

- 4.4 Supply-Chain Analysis

- 4.5 Technological Outlook

- 4.6 Sustainability and Recycling/Reusability of Plastic Pallets

- 4.7 Regulatory Framework and Standards

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Bargaining Power of Suppliers

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Threat of New Entrants

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 High-Density Polyethylene (HDPE)

- 5.1.2 Polypropylene (PP)

- 5.1.3 Recycled Materials

- 5.2 By Pallet Type

- 5.2.1 Nestable

- 5.2.2 Rackable

- 5.2.3 Stackable

- 5.2.4 Display / Custom

- 5.3 By End-User Industry

- 5.3.1 Food and Beverage

- 5.3.2 Chemical

- 5.3.3 Pharmaceutical and Healthcare

- 5.3.4 Retail and E-Commerce

- 5.3.5 Logistics and Warehousing

- 5.3.6 Automotive

- 5.3.7 Other End-User Industry

- 5.4 By Load Capacity

- 5.4.1 Light - Duty Pallets

- 5.4.2 Medium - Duty Pallets

- 5.4.3 High - Duty Pallets

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 India

- 5.5.3.3 Japan

- 5.5.3.4 South Korea

- 5.5.3.5 Australia and New Zealand

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 United Arab Emirates

- 5.5.4.1.2 Saudi Arabia

- 5.5.4.1.3 Turkey

- 5.5.4.1.4 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Nigeria

- 5.5.4.2.3 Egypt

- 5.5.4.2.4 Rest of Africa

- 5.5.4.1 Middle East

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Brambles Limited (CHEP)

- 6.4.2 CABKA Group GmbH

- 6.4.3 Orbis Corporation (Menasha)

- 6.4.4 Schoeller Allibert Group BV

- 6.4.5 Rehrig Pacific Company

- 6.4.6 Tosca Services, LLC

- 6.4.7 Loscam International Holdings

- 6.4.8 Craemer Holding GmbH

- 6.4.9 Gamma-Wopla NV / Smart-Flow NV

- 6.4.10 Q-Pall BV

- 6.4.11 Plasgad Plastic Products ACS Ltd.

- 6.4.12 NAECO S.L.

- 6.4.13 Polymer Solutions International Inc.

- 6.4.14 RPP Containers

- 6.4.15 IPS Plastics Pallets (IPS Group)

- 6.4.16 Shandong Huaxiang Plastic Co., Ltd.

- 6.4.17 Beijing Jingliang United Plastic Products Co., Ltd.

- 6.4.18 TranPak Inc.

- 6.4.19 Allied Plastics, Inc.

- 6.4.20 Falkenhahn AG

- 6.4.21 Buckhorn Inc.

- 6.4.22 iGPS Logistics LLC

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment