PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1907326

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1907326

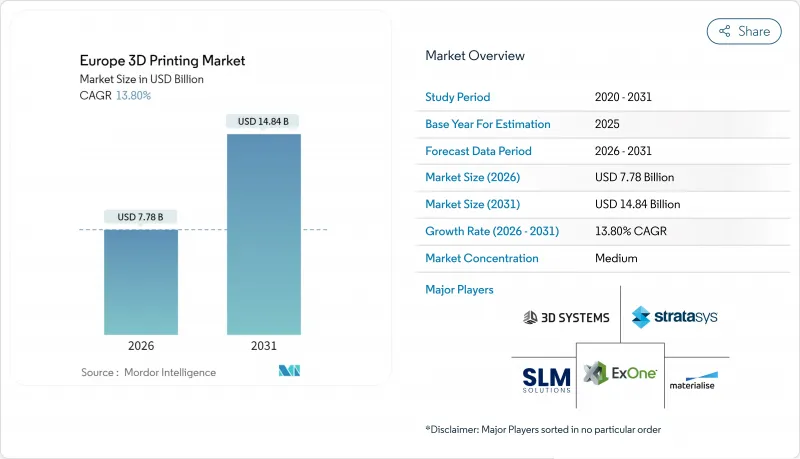

Europe 3D Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Europe 3D printing market is expected to grow from USD 6.84 billion in 2025 to USD 7.78 billion in 2026 and is forecast to reach USD 14.84 billion by 2031 at 13.8% CAGR over 2026-2031.

This expansion occurs as manufacturers across the region accelerate distributed-production strategies to cut lead times, hedge against supply-chain shocks and meet carbon-border adjustment requirements that reward localized output. Fast innovation cycles, falling metal-printer costs and the integration of artificial-intelligence process control underpin a widening set of production-grade use cases across automotive, healthcare and maritime industries. Hardware sales still dominate revenue, yet service-oriented "manufacturing as a service" models are scaling quickly, reflecting user preference for flexible capacity without large capital outlays. Country-level momentum is uneven: Germany leverages patent depth and automation expertise to safeguard its leadership position, while the Netherlands deploys world-class logistics and maritime clusters to register the highest growth pace. Competitive intensity rises as incumbents integrate vertically, newer entrants push novel materials and the European Union harmonizes technical standards to ease cross-border operations.

Europe 3D Printing Market Trends and Insights

Government Initiatives and Funding for Industry 4.0 and AM

European governments deploy sizeable capital to speed additive-manufacturing adoption. France's EUR 54 billion "France 2030" program earmarks funds for advanced manufacturing platforms. Horizon Europe further backs "manufacturing as a service" pilots that network equipment across borders into cloud-managed production lines. In Germany, additive-manufacturing firms invest 30.6% of turnover in research, amplified by national and EU grants, cementing leadership in metal systems. The shared funding model drives technology transfer from laboratories to shop floors and builds a cadre of suppliers aligned to common technical standards. As a result, the Europe 3D printing market secures economies of scale that lower entry barriers for mid-sized enterprises.

Automotive OEM Demand for Lightweight Prototyping and Tooling

Automotive manufacturers now pursue additive-manufacturing beyond early prototyping. The EU-funded Multi-FUN project reveals multi-material builds that embed wiring and sensors into lightweight structures. German suppliers print low-volume production tooling to manage model-specific parts without storing costly inventory. By exploiting single-build assemblies that cut welds and bolts, companies save weight and shorten production cycles, sustaining momentum for the Europe 3D printing market in core automotive corridors.

High Capital Investment and Maintenance Costs

Industrial-grade printers carry six-figure price tags, and users must add powder-handling, post-processing, and quality-assurance gear. Small and medium-sized enterprises often defer purchases even as hardware prices decline. Compliance with the EU Medical Device Regulation imposes rigorous documentation and post-market surveillance, inflating overhead for healthcare adopters. Fragmented certification regimes for rail, aerospace, and energy sectors multiply testing budgets, narrowing the addressable base of the Europe 3D printing market until rental or service models offset risk.

Other drivers and restraints analyzed in the detailed report include:

- Healthcare Adoption for Patient-Specific Devices

- Declining Cost of Metal Printers and Materials

- Shortage of Design-for-AM Talent

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Service providers captured a growing slice of revenue as enterprises prioritize flexibility. Although hardware still anchored 67.62% of the Europe 3D printing market in 2025, service-oriented models are scaling at 15.97% CAGR as firms outsource design optimization, build preparation and post-processing. Contract manufacturers such as K3D and FKM deploy multi-printer farms, giving customers just-in-time parts without locking capital into machines. This transition lowers the cost of experimentation and spreads risk across diverse client pipelines.

In parallel, hardware vendors bundle software, maintenance, and training subscriptions, blurring lines between equipment sales and recurring services. Cloud dashboards aggregate fleet-wide data, enabling predictive maintenance and consumable replenishment. These integrated offers reinforce adoption, propelling the Europe 3D printing market toward outcome-based procurement norms.

FDM maintained the largest share in 2025 at 29.12% thanks to mature materials, low operating costs, and broad user familiarity. Yet DLP is registering an impressive 14.42% CAGR, propelled by sub-50-micron feature capability that suits dental aligners, hearing aids, and tissue-scaffold research. Advances in plant-based photopolymers reinforce sustainability credentials while widening the bio-compatibility palette. SLA and SLS cater to aerospace and automotive requirements for heat-resistant components, whereas electron-beam melting remains the go-to for titanium lattice structures in orthopedic implants.

Technology differentiation now hinges on automation and closed-loop control. AI-driven voxel-level correction trims support mass and eases depowdering, elevating utilization rates across the Europe 3D printing market. Multi-laser coordination in powder-bed systems balances productivity and surface finish, giving manufacturers confidence to qualify parts for serial production.

The Europe 3D Printing Market Report is Segmented by Component (Hardware and Services), Technology (Stereolithography, Fused Deposition Modeling, and More), Material (Polymers, Metals and Alloys, and More), End-User Industry (Automotive, Aerospace and Defense, Healthcare, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Stratasys Ltd.

- 3D Systems Corporation

- EOS GmbH

- General Electric Company (GE Additive)

- Hoganas AB (Digital Metal(R))

- Sisma S.p.A.

- ExOne Company

- SLM Solutions Group AG

- HP Inc.

- Ultimaker B.V.

- Materialise N.V.

- voxeljet AG

- Renishaw plc

- Prodways Group SA

- Arcam AB

- Carbon, Inc.

- Markforged Holding Corp.

- XJet Ltd.

- Photocentric Ltd.

- Desktop Metal, Inc.

- BEAMIT S.p.A.

- DWS Systems S.r.l.

- Farsoon Technologies Europe GmbH

- B9Creations, LLC

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Government initiatives and funding for Industry 4.0 and AM

- 4.2.2 Automotive OEM demand for lightweight prototyping and tooling

- 4.2.3 Healthcare adoption for patient-specific devices

- 4.2.4 Declining cost of metal printers and materials

- 4.2.5 EU carbon-border adjustment boosting localized production

- 4.2.6 On-demand spare-parts needs in rail and maritime sectors

- 4.3 Market Restraints

- 4.3.1 High capital investment and maintenance costs

- 4.3.2 Shortage of design-for-AM talent

- 4.3.3 Fragmented EU certification and standards landscape

- 4.3.4 Metal-powder supply volatility and recycling hurdles

- 4.4 Regulatory Landscape

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Suppliers

- 4.6.3 Bargaining Power of Buyers

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Component

- 5.1.1 Hardware

- 5.1.2 Services

- 5.2 By Technology

- 5.2.1 Stereolithography (SLA)

- 5.2.2 Fused Deposition Modeling (FDM)

- 5.2.3 Selective Laser Sintering (SLS)

- 5.2.4 Electron Beam Melting (EBM)

- 5.2.5 Digital Light Processing (DLP)

- 5.2.6 Other Technologies

- 5.3 By Material

- 5.3.1 Polymers

- 5.3.2 Metals and Alloys

- 5.3.3 Ceramics

- 5.3.4 Composites and Others

- 5.4 By End-user Industry

- 5.4.1 Automotive

- 5.4.2 Aerospace and Defense

- 5.4.3 Healthcare

- 5.4.4 Construction and Architecture

- 5.4.5 Energy and Utilities

- 5.4.6 Food and Beverage

- 5.4.7 Other Industries

- 5.5 By Country

- 5.5.1 Germany

- 5.5.2 United Kingdom

- 5.5.3 France

- 5.5.4 Italy

- 5.5.5 Spain

- 5.5.6 Netherlands

- 5.5.7 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Stratasys Ltd.

- 6.4.2 3D Systems Corporation

- 6.4.3 EOS GmbH

- 6.4.4 General Electric Company (GE Additive)

- 6.4.5 Hoganas AB (Digital Metal(R))

- 6.4.6 Sisma S.p.A.

- 6.4.7 ExOne Company

- 6.4.8 SLM Solutions Group AG

- 6.4.9 HP Inc.

- 6.4.10 Ultimaker B.V.

- 6.4.11 Materialise N.V.

- 6.4.12 voxeljet AG

- 6.4.13 Renishaw plc

- 6.4.14 Prodways Group SA

- 6.4.15 Arcam AB

- 6.4.16 Carbon, Inc.

- 6.4.17 Markforged Holding Corp.

- 6.4.18 XJet Ltd.

- 6.4.19 Photocentric Ltd.

- 6.4.20 Desktop Metal, Inc.

- 6.4.21 BEAMIT S.p.A.

- 6.4.22 DWS Systems S.r.l.

- 6.4.23 Farsoon Technologies Europe GmbH

- 6.4.24 B9Creations, LLC

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment