PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910711

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910711

Industrial Drums - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

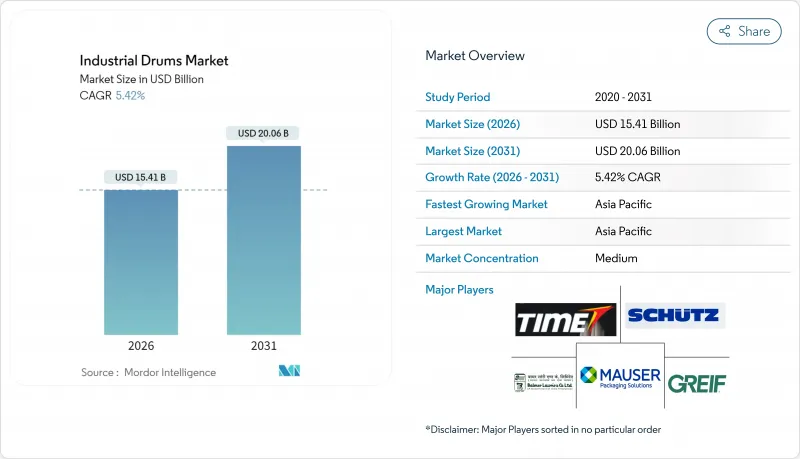

The industrial drums market is expected to grow from USD 14.62 billion in 2025 to USD 15.41 billion in 2026 and is forecast to reach USD 20.06 billion by 2031 at 5.42% CAGR over 2026-2031.

Steady chemical output, rising petrochemical investments, and widening food-grade export flows anchor demand. Regulatory momentum toward reusable packaging, demonstrated by Cummins' RFID-enabled returnable program, reinforces the shift away from single-use bulk bags. Composite drums win share as weight-sensitive shippers pursue corrosion-resistant options, while RFID adoption spreads across hazardous-materials fleets to improve traceability. Asia-Pacific drives volume on the back of China's cracker additions and India's 12% annual chemical growth target through 2030, whereas North America and Europe prioritize premium, compliance-led formats. Consolidation such as Berry Global's 2025 merger with Amcor adds scale advantages that squeeze smaller rivals.

Global Industrial Drums Market Trends and Insights

Growth in Chemical and Petrochemical Output

Robust specialty-chemical builds in China, cracker expansions in the Middle East, and mergers among Japanese majors collectively increase drum throughput requirements. The American Chemistry Council notes sustained resilience in U.S. chemical production despite logistics bottlenecks, while India is targeting 12% compound growth, which keeps drum demand firmly on an upward path. Larger integrated complexes process greater batch sizes, pushing shippers toward 100-plus gallon formats and composite linings that withstand aggressive intermediates. SysKem Chemie ships Class 8 caprylic acid exclusively in coated drums that meet United Nations test codes, illustrating the higher specification trend.

Expansion of Food-Grade Export Logistics

Diversification of ingredient sourcing has lengthened supply chains for sweeteners, plant proteins, and fruit concentrates. CDF Corporation launched USDA-compliant liners in February 2025, showing suppliers' response to stricter contamination thresholds. Harmonized documentation under the Codex Alimentarius enables multi-regional certification, supporting scale economies for manufacturers producing food-grade drums in bulk. Premium organic exporters have begun to pay price differentials for drums embedded with tamper-evident seals and QR-code lineage data, enhancing provenance claims in destination markets.

Raw-Material Price Volatility

Steel and resin swings squeeze margins as drum makers struggle to synchronize contracts with customer price lists. Ryerson's 2025 forecast flags potential anti-dumping duties on Asian hot-rolled coil, adding another layer of unpredictability. Balmer Lawrie is piloting 0.5 mm-wall drums that allow 80 units per TEU, four more than traditional gauges, to offset rising coil costs; at INR 23.39 billion (USD 280.8 million) 2024 sales, the savings are material.

Other drivers and restraints analyzed in the detailed report include:

- Strengthening Supply-Chain Resiliency Needs

- Regulatory Phase-Out of Single-Use Bulk Bags

- Cannibalization by IBCs and Flexitanks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Steel captured the lion's share at 46.68% because refinery and agrochemical players favor its mechanical strength and straightforward reconditioning loops. At the same time, composite drums are on a 7.21% trajectory as buyers weigh freight savings against initial premiums. Recent audits at Indian ports show that lightweight steel accounted for 37% of outbound haz-chem shipments, underscoring cost reductions from thinner gauges. The industrial drums market benefits from global scrap incentives that make low-alloy steel a closed-loop asset, whereas virgin HDPE resin tracks propylene prices more closely.

Plastic and fiber variants address niche solute compatibility or weight constraints. Although fiber units lack UN credentials for liquids, they now incorporate moisture-resistant liners that extend shelf life for dry food powders. Composite models combine polymer barriers with steel ribs, targeting formulators of moisture-sensitive adhesive ingredients. Their rise illustrates how the industrial drums market evolves through hybridization rather than a binary material switch.

Sixty-to-one-hundred-gallon drums align with forklift clearance and remain the workhorse at 35.21% share. However, fully automated chemical clusters prefer 110-gallon drums that support fewer lifts per ton processed. Through 2031, above-100-gallon formats hold the fastest 6.08% expansion rate. Camco Chemical's USD 3 million line allows dual fill heads for 30 and 110 gallon SKUs, underlining buyers' preference for multi-volume flexibility. The industrial drums market size for capacities beyond 100 gallons is projected to touch USD 4.55 billion by 2031, reflecting wider adoption of palletless robotic handling cells.

Smaller drums serve specialty flavors, pharma actives, and lab reagents where lot segregation trumps bulk economics. Yet their share erodes as tank-to-fill micro-blending units shrink on-site intermediate inventories. Overall, capacity choice mirrors a trade-off between ergonomic safety, freight utilization, and regulatory caps on allowable mass per package in airborne routes.

The Global Industrial Drums Market Report is Segmented by Material (Steel Drum, Plastic Drum, and More), Capacity (Up To 30 Gallons, 30-60 Gallons, and More), Closure Type (Tight-Head/Closed-Head, and Open-Head), End-User Industry (Chemicals and Fertilizers, Petroleum and Lubricants, and More), and Geography (North America, South America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific contributed 39.55% revenue in 2025, propelled by Chinese cracker projects and India's chemicals roadmap. Balmer Lawrie leveraged eight plants to secure national contracts for agrochemical exporters and logged INR 23.39 billion (USD 280.8 million) turnover. Regional governments offer land rebates for packaging clusters adjacent to refinery corridors, shortening delivery lead times and reducing dent damage.

North America benefits from shale-based feedstock and maintains stringent DOT oversight that drives demand for high-specification steel drums. Cummins' returnable system illustrates how U.S. OEMs internalize packaging for circularity gains. Europe emphasizes circular economy compliance under the Packaging and Packaging Waste Regulation and has seen pilot leasing pools triple since 2023, mostly for food and personal-care ingredients. South America and the Middle East and Africa remain smaller but high-growth nodes. Brazilian biodiesel exporters pivot to composite drums to mitigate soy-oil oxidation, whereas Gulf petrochemical hubs procure thick-gauge steel variants to withstand extreme ambient temperatures. Cross-regional freight arbitrage also stimulates backhaul drum reconditioning networks, reinforcing global linkages within the industrial drums market.

- Greif, Inc.

- Mauser Packaging Solutions Holding Company

- SCHUTZ GmbH & Co. KGaA

- Time Technoplast Ltd.

- Balmer Lawrie & Co. Ltd.

- Sicagen India Ltd.

- TPL Plastech Ltd.

- Peninsula Drums (Pty) Ltd.

- Eagle Manufacturing Company (Justrite Safety Group)

- U.S. Coexcell Inc.

- Industrial Container Services, Inc.

- Hoover Ferguson Group, Inc.

- Berry Global Group, Inc.

- Brambles Ltd.

- Myers Industries, Inc.

- Orlando Drum & Container Corp.

- Rahway Steel Drum Co., Inc.

- Re-Gen Drums Ltd.

- Palm Containers (Pty) Ltd.

- Schutz DSL (Asia) Pte Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growth in chemical and petrochemical output

- 4.2.2 Expansion of food-grade export logistics

- 4.2.3 Strengthening supply-chain resiliency needs

- 4.2.4 Regulatory phase-out of single-use bulk bags

- 4.2.5 Circular-economy leasing and re-conditioning models

- 4.2.6 RFID-enabled drum tracking for haz-mat compliance

- 4.3 Market Restraints

- 4.3.1 Raw-material price volatility

- 4.3.2 Environmental compliance cost for disposal

- 4.3.3 Cannibalization by IBCs and flexitanks

- 4.3.4 On-site micro-blending cutting drum demand

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Intensity of Competitive Rivalry

- 4.7.5 Threat of Substitutes

- 4.8 The Impact of Macroeconomic Factors on the Market

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material

- 5.1.1 Steel Drum

- 5.1.2 Plastic Drum

- 5.1.3 Fiber Drum

- 5.1.4 Composite/Hybrid Drum

- 5.2 By Capacity

- 5.2.1 Up to 30 Gallons

- 5.2.2 30 - 60 Gallons

- 5.2.3 60 - 100 Gallons

- 5.2.4 Above 100 Gallons

- 5.3 By Closure Type

- 5.3.1 Tight-Head / Closed-Head

- 5.3.2 Open-Head

- 5.4 By End-user Industry

- 5.4.1 Chemicals and Fertilizers

- 5.4.2 Petroleum and Lubricants

- 5.4.3 Food and Beverage

- 5.4.4 Pharmaceuticals

- 5.4.5 Paints, Coatings and Adhesives

- 5.4.6 Building and Construction

- 5.4.7 Other End-user Industries

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Chile

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Kenya

- 5.5.5.2.4 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Greif, Inc.

- 6.4.2 Mauser Packaging Solutions Holding Company

- 6.4.3 SCHUTZ GmbH & Co. KGaA

- 6.4.4 Time Technoplast Ltd.

- 6.4.5 Balmer Lawrie & Co. Ltd.

- 6.4.6 Sicagen India Ltd.

- 6.4.7 TPL Plastech Ltd.

- 6.4.8 Peninsula Drums (Pty) Ltd.

- 6.4.9 Eagle Manufacturing Company (Justrite Safety Group)

- 6.4.10 U.S. Coexcell Inc.

- 6.4.11 Industrial Container Services, Inc.

- 6.4.12 Hoover Ferguson Group, Inc.

- 6.4.13 Berry Global Group, Inc.

- 6.4.14 Brambles Ltd.

- 6.4.15 Myers Industries, Inc.

- 6.4.16 Orlando Drum & Container Corp.

- 6.4.17 Rahway Steel Drum Co., Inc.

- 6.4.18 Re-Gen Drums Ltd.

- 6.4.19 Palm Containers (Pty) Ltd.

- 6.4.20 Schutz DSL (Asia) Pte Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment