PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910847

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910847

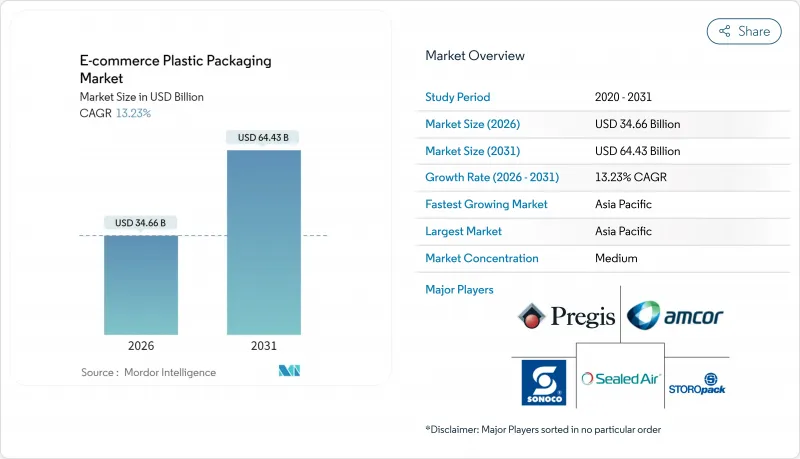

E-commerce Plastic Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

E-commerce plastic packaging market size in 2026 is estimated at USD 34.66 billion, growing from 2025 value of USD 30.60 billion with 2031 projections showing USD 64.43 billion, growing at 13.23% CAGR over 2026-2031.

Rapid online retail growth, rising consumer expectations for premium unboxing and mounting sustainability mandates shape the near-to-mid-term outlook. Lightweight flexible films, mono-material barrier constructions and design-rich substrates help brands cut freight costs, comply with recycling rules and enhance visual appeal. Manufacturers seize opportunities in smart labels, automated filling lines and temperature-controlled solutions that protect groceries and cosmetics shipped through dense urban fulfillment networks. Competitive intensity grows as integrated converters acquire niche specialists, patent novel resins and scale chemical recycling that safeguards supply security.

Global E-commerce Plastic Packaging Market Trends and Insights

Rising penetration of online retail

Uninterrupted growth in e-commerce drives demand for packaging that endures automated sortation, multi-modal transport and direct-to-consumer unboxing. Subscription beauty services in Japan highlight how premium designs and tamper-evident seals substitute for in-store experience. Higher parcel volumes push warehouses to adopt standard pack dimensions that maximize robotic throughput and storage density.

Growth in lightweight flexible formats

Metallocene polyethylene films cut thickness by 30% yet keep seals intact between -40 °C and 120 °C, reducing freight emissions and raw-material spend. Nano-additives bolster barrier strength, enabling thinner walls for electronics pouches. Converters replace rigid inserts with inflatable cushioning to slash dimensional weight and comply with mono-material recycling rules.

Regulatory bans and taxes on single-use plastics

California SB 54 demands 65% recycled content by 2032 while forthcoming EU rules insist on circular design. The compliance burden triggers costly line upgrades and portfolio rationalization, yet it spurs innovation in mono-material laminates that streamline post-consumer recovery. Brands delay launches until guidelines stabilize, though early adopters secure green-branding advantages.

Other drivers and restraints analyzed in the detailed report include:

- Proliferation of omnichannel fulfillment nodes

- Brand demand for printable design-rich plastics

- Volatility in virgin polymer prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polyethylene contributed 42.12% to the e-commerce plastic packaging market share in 2025, supported by favorable sealability and high throughput on automated form-fill-seal lines. Metallocene grades permit aggressive downgauging that curbs shipping mass without compromising puncture resistance. The e-commerce plastic packaging market size derived from polyethylene is projected to climb steadily on the back of mass accessible mailers and stretch sleeves. Polyethylene terephthalate, expanding at 14.42% CAGR, finds favor in temperature-sensitive grocery packs where superior oxygen and moisture barriers outweigh higher resin cost. Chemical recycling yields PET with 100% post-consumer content that retains food-contact clearance. Polypropylene secures demand in reusable totes and hingelid boxes, while bioplastics gain a foothold in premium cosmetics where compostability carries strong brand equity.

A second wave of polyethylene innovation centers on mono-material structures that eliminate metallized layers yet deliver equal aroma retention, smoothing passage through recycling streams. In PET films, nano-clay dispersions cut oxygen ingress by 15-20% and permit thinner laminates that reduce cube size during parcel transit. Such material advances reinforce the e-commerce plastic packaging market as a proving ground for high-performance sustainable polymers.

Pouches and bags controlled 37.95% of 2025 revenue thanks to versatility across apparel, home and personal care shipments. Yet protective packaging, including inflatable cushions and molded pulp liners, will record the fastest 14.55% CAGR through 2031 as fragile consumer electronics volumes swell. Origami-engineered paperboard pads from VTT create shock-absorbing hollows that rival plastic bubble wrap while trimming waste. Shrink and stretch films stay essential for pallet integrity within regional fulfillment centers, though gains trail segment leaders. Specialty thermal mailers carve niche growth as grocery e-tailers demand certified cold-chain compliance.

Protective solutions now integrate bio-based thermoplastic-impregnated nonwovens that break down in industrial composters yet shield products from drops and vibration. Such advances align with European plastic-tax regimes and corporate net-zero pledges, ensuring sustainable cushioning becomes a standard rather than a premium upsell.

The E-Commerce Plastic Packaging Market Report is Segmented by Material Type (Polyethylene, Polypropylene, and More), Product Type (Pouches and Bags, Mailers and Envelopes, and More), End-User Industry (Consumer Electronics and Media, Food and Beverage, and More), Packaging Function (Primary, Secondary, and More), and Geography (North America, South America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific leads growth with a 14.75% CAGR to 2031 as China's mature online retail ecosystem spreads sophisticated packaging standards across the region. Domestic converters mass-produce lightweight mailers tailored to high-speed sortation belts, keeping costs low and cycle times short. Japan's subscription culture drives demand for premium barrier laminates that preserve cosmetics in humid summers and sub-zero winters. South Korea's handheld commerce favors compact, brand-heavy packs that fit parcel lockers, while India's burgeoning volume tilts toward ultra-economical mono-layer bags that tolerate rough handling yet remain cost effective.

North America sustains large volumes through advanced warehouse robotics and a culture of premium unboxing, particularly in beauty and electronics. California's recycled-content mandate boosts early adoption of chemically recycled PET mailers. Canada benefits from new kraft paper capacity after Mondi's USD 5 million Hinton mill purchase, opening opportunities to blend fiber and polymer in hybrid e-commerce solutions. Mexico's near-shore plants supply poly mailers to U.S. retailers seeking shorter lead times.

Europe sets regulatory tone with stringent single-use rules, pushing converters toward mono-material and paper-based alternatives. German recyclers achieve high PET recovery rates that feed bottle-to-pouch loops. The United Kingdom shapes an independent framework after Brexit, yet still mirrors EU recyclate targets, keeping pressure on virgin resin use. Mondi's paper mailer launch shows how fiber substrates can meet durability thresholds for parcel journeys while satisfying plastic-reduction targets.

- Amcor plc

- Sealed Air Corporation

- Pregis LLC

- Sonoco Products Company

- Storopack Hans Reichenecker GmbH

- Huhtamaki Oyj

- CCL Industries Inc.

- ProAmpac LLC

- Clondalkin Group Holdings BV

- Smurfit WestRock

- Mondi plc

- International Paper Company

- Intertape Polymer Group Inc.

- Constantia Flexibles GmbH

- Klockner Pentaplast GmbH & Co. KG

- TransPak Corporation

- ProMach Inc.

- FlexiPack Group Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising penetration of online retail

- 4.2.2 Growth in lightweight flexible formats

- 4.2.3 Proliferation of omnichannel fulfilment nodes

- 4.2.4 Brand demand for printable, design-rich plastics

- 4.2.5 Surge in temperature-controlled grocery delivery

- 4.2.6 Rapid scaling of reusable packaging loops

- 4.3 Market Restraints

- 4.3.1 Regulatory bans and taxes on single-use plastics

- 4.3.2 Volatility in virgin polymer prices

- 4.3.3 E-commerce reverse-logistics damage rates

- 4.3.4 Brand-owner ESG pledges favouring fibre formats

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors on the Market

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Bargaining Power of Suppliers

- 4.8.2 Bargaining Power of Buyers/Consumers

- 4.8.3 Threat of New Entrants

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Polyethylene (PE)

- 5.1.2 Polypropylene

- 5.1.3 Polyethylene Terephthalate (PET)

- 5.1.4 Bioplastics

- 5.1.5 Other Material Types

- 5.2 By Product Type

- 5.2.1 Pouches and Bags

- 5.2.2 Mailers and Envelopes

- 5.2.3 Shrink and Stretch Films

- 5.2.4 Protective Packaging

- 5.2.5 Other Product Types

- 5.3 By End-user Industry

- 5.3.1 Consumer Electronics and Media

- 5.3.2 Food and Beverage

- 5.3.3 Personal Care and Cosmetics

- 5.3.4 Fashion and Apparel

- 5.3.5 Home Care and Furnishing

- 5.3.6 Other End-user Industries

- 5.4 By Packaging Function

- 5.4.1 Primary Packaging

- 5.4.2 Secondary Packaging

- 5.4.3 Void-Fill and Cushioning

- 5.4.4 Palletization/Stretch Wrap

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Chile

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Kenya

- 5.5.5.2.4 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Amcor plc

- 6.4.2 Sealed Air Corporation

- 6.4.3 Pregis LLC

- 6.4.4 Sonoco Products Company

- 6.4.5 Storopack Hans Reichenecker GmbH

- 6.4.6 Huhtamaki Oyj

- 6.4.7 CCL Industries Inc.

- 6.4.8 ProAmpac LLC

- 6.4.9 Clondalkin Group Holdings BV

- 6.4.10 Smurfit WestRock

- 6.4.11 Mondi plc

- 6.4.12 International Paper Company

- 6.4.13 Intertape Polymer Group Inc.

- 6.4.14 Constantia Flexibles GmbH

- 6.4.15 Klockner Pentaplast GmbH & Co. KG

- 6.4.16 TransPak Corporation

- 6.4.17 ProMach Inc.

- 6.4.18 FlexiPack Group Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment