PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910899

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910899

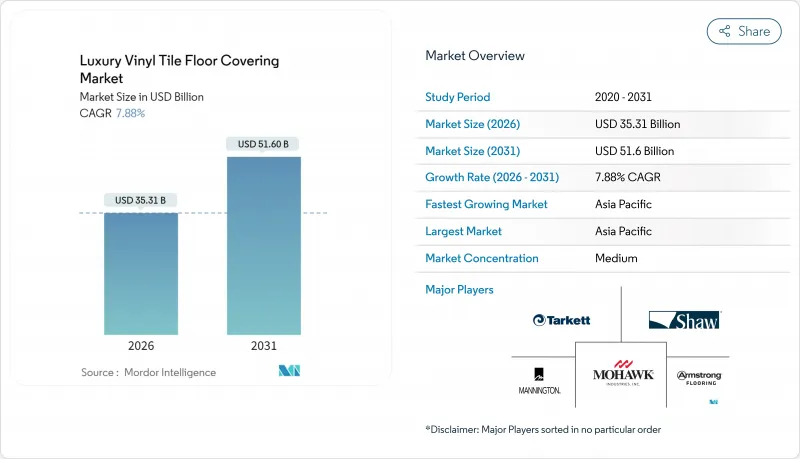

Luxury Vinyl Tile Floor Covering - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The luxury vinyl tile floor covering market is expected to grow from USD 32.73 billion in 2025 to USD 35.31 billion in 2026 and is forecast to reach USD 51.6 billion by 2031 at 7.88% CAGR over 2026-2031.

A combination of affordability, authentic aesthetics, and waterproof durability enables the category to compete directly with hardwood and ceramic across remodel and new-build projects. Accelerating domestic production, faster click-lock installation methods, and omnichannel retail models are widening access, while digital printing elevates realism to the point that even design professionals specify vinyl planks in premium developments. Healthcare networks, hotels, and hybrid offices now regard the product as a hygiene-forward, low-maintenance surface that fulfils both safety and branding requirements. Homeowners, conversely, prize the weekend install capability, scratch resistance, and seamless room-to-room coordination that the luxury vinyl tile floor covering market uniquely offers compared with other resilient solutions.

Global Luxury Vinyl Tile Floor Covering Market Trends and Insights

Cost-effective hardwood alternative

Luxury vinyl tile planks replicate the appearance of white oak, walnut, and reclaimed barn wood, offering a cost-efficient alternative to solid wood. These planks eliminate challenges such as seasonal cupping and the need for sanding cycles. Advanced emboss-in-register printing synchronizes grain patterns with tactile ridges, creating a hand-scraped feel that designers frequently mistake for hardwood during specification walk-throughs. Multifamily developers redirect savings toward upgraded lighting and smart-home packages, improving asset valuation without exceeding budget ceilings. Home-improvement chains now stock extra-long 72-inch planks and extra-wide 10-inch formats, extending sight lines in open-concept layouts. The luxury vinyl tile floor covering market gains incremental volume whenever interest rates squeeze consumer financing capacity, as value-engineered floors become the practical route to upscale aesthetics.

Rigid-core waterproof renovations

Stone Plastic Composite (SPC) and Wood Plastic Composite (WPC) cores resist subfloor moisture, allowing installation in basements, bathrooms, and pool-house kitchens that historically defaulted to ceramic tile. Coretec's 18 X 18 inch SPC tiles with integrated grout bevels shorten labour time by close to one-third and deliver ceramic realism without wet saws. Insurance carriers in flood-prone states recommend rigid-core floors in renovation payouts, reinforcing demand. Field data show a 35% reduction in callbacks tied to moisture-related failures versus laminate, raising installer confidence. Rising multigenerational housing, where basement conversions are common, further accelerates the penetration of rigid-core products in the luxury vinyl tile floor covering market.

PVC feedstock price volatility

Polyvinyl chloride resin prices spiked by two cents per pound in August 2023 despite sluggish construction starts, slicing margins at converters without hedges. Small manufacturers lack tank-farm capacity to stockpile low-priced cargoes, leaving them exposed to spot swings. Forward-buy contracts now require higher take-or-pay penalties, straining working capital. Public-sector bids often restrict price-escalation clauses, slowing award cycles. Resulting cost uncertainty tempers short-term order quantities in the luxury vinyl tile floor covering market until input prices stabilize.

Other drivers and restraints analyzed in the detailed report include:

- Omnichannel & e-commerce expansion

- Domestic LVT capacity build-outs (tariff & CO2 hedge)

- Trade-tariff uncertainty on Asian supply

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

In 2025, rigid core products accounted for 63.92% of the total revenue in the luxury vinyl tile floor covering market, underscoring their significant market share and growing demand. The projected CAGR of 13.71% highlights the increasing reliance on the advanced performance characteristics of SPC and WPC materials. SPC's exceptional static-load tolerance and WPC's superior Impact Insulation Class (IIC) ratings are critical factors driving their widespread adoption across various end-user applications. These materials are particularly valued in environments requiring durability and noise reduction, such as healthcare facilities, retail spaces, and multi-family residential buildings. Their ability to withstand heavy loads, such as hospital gurneys and grocery pallets, while simultaneously reducing noise transmission to lower floors, positions them as a preferred choice for both commercial and residential applications.

As inventory mix evolves, flexible LVT retains a role in budget apartment turns where sub-floors are uneven and rent moratoria squeeze CapEx. Suppliers enhance these entry products with hardened UV coatings and fiberglass meshes to mitigate telegraphing. Hybrid plank designs marry a pliable top film to a rigid backbone, offering installers a margin-friendly mid-tier option. Design departments exploit digital printing to issue micro-collections, such as terrazzo chip or lime-washed oak, that refresh assortments seasonally without tooling changes, sustaining engagement for the luxury vinyl tile floor covering market.

Glue-down accounted for 47.64% of the total revenue in the luxury vinyl tile floor covering market, underscoring its significant market share. Interlocking profiles overtook glue-down in share growth, recording a 10.62% CAGR. The do-it-yourself (DIY) segment highlights the operational advantages of odor-free installations, which allow immediate usability of newly installed flooring. This feature aligns with consumer demand for convenience and time efficiency, particularly in residential applications. Small-business contractors also benefit from reduced insurance risks associated with solvent-based adhesive fumes, which contribute to safer and more compliant work environments. To address shifting consumer preferences and modern design aesthetics, several brands have introduced extra-wide 10-inch planks. These planks are designed with precision-milled profiles to ensure strong locking mechanisms, enhancing durability and structural performance.

Glue-down tiles maintain a significant presence in high-traffic commercial environments, such as supermarkets, airports, and medical corridors, due to their ability to meet stringent rolling-load requirements and fire-code edge-sealing standards. Innovations in pressure-sensitive adhesive technology have further optimized glue-down installations by accelerating set times, thereby reducing labour costs and narrowing the efficiency gap with floating systems. Self-adhesive tiles have also gained popularity in specialized applications, including trade-show booths and seasonal retail kiosks, offering enhanced flexibility and adaptability within the luxury vinyl tile market. Additionally, some manufacturers of SPC flooring have implemented hybrid solutions by incorporating partial adhesive strips beneath end joints. This approach combines the benefits of fully floating and semi-permanent systems, providing end-users with the option for future lift-and-replace functionality while maintaining installation stability and performance.

The Luxury Vinyl Tile Floor Covering Market is Segmented by Product Type (Rigid Core, Flexible), End User (Residential, Commercial), Installation Type (Self-Adhesive Vinyl Tiles, Glue-Down LVT, Interlocking Vinyl Tiles, Others), Distribution Channel (B2C / Retail Consumers, B2B / Contractors / Builders) and Geography (North America, South America and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific generated 42.29% of 2025 revenue and is forecast to maintain double-digit expansion at 12.49% CAGR through 2031. Urban migration adds hundreds of millions of square feet of multifamily floor area each year, and buyers prefer hard surfaces for perceived cleanliness and modern aesthetic. Manufacturing shifts from coastal China to inland provinces and neighbouring Vietnam and Cambodia, reducing landed cost in the United States while keeping proximity to local demand intact. Government housing schemes in India now include rigid-core planks in their standard specification, accelerating baseline consumption in the luxury vinyl tile floor covering market.

North America ranks second in value. Domestic lines in Georgia, Tennessee, and Ontario supply colour-on-demand programs, enabling regional house flippers to match local trim colours within a month. Buy-American restrictions embedded in federal infrastructure funding steer institutional buyers toward U.S.-made tiles, lifting plant utilization rates. The cold-weather durability of SPC appeals to Canadian cottage owners who face seasonal freeze-thaw cycles, ensuring additional volume.

Europe is the proving ground for sustainability claims. LEED, BREEAM, and French VOC regulations reward Environmental Product Declarations and post-consumer content. Brands offering third party-verified take-back receive preferential scoring on public tenders. Economic headwinds in Germany dim new-build forecasts, but renovation incentives for energy-efficient makeovers keep flooring spend resilient. South America and the Gulf Cooperation Council are smaller today, yet hotel pipelines for the 2026 FIFA World Cup and Expo 2030 push specification teams toward quick-install, low-maintenance solutions, positioning the luxury vinyl tile floor covering market for above-average regional growth.

- Armstrong Flooring

- Tarkett Group

- Mohawk Industries

- Shaw Industries

- Mannington Mills

- Gerflor

- Interface Inc.

- Forbo Flooring Systems

- Karndean Designflooring

- Amtico International

- Polyflor

- Beaulieu International Group

- CFL Flooring

- AHF Products

- Floor & Decor Holdings

- HMTX Industries

- Republic Floor

- MSI Surfaces

- Raskin Industries

- FloorFolio Industries

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Cost-effective hardwood alternative

- 4.2.2 Surge in rigid-core waterproof renovations

- 4.2.3 Omnichannel & e-commerce expansion

- 4.2.4 Commercial retrofit boom (healthcare, hospitality, offices)

- 4.2.5 Domestic LVT capacity build-outs (tariff & CO2 hedge)

- 4.2.6 Bio-based / PVC-free LVT adoption

- 4.3 Market Restraints

- 4.3.1 PVC feed-stock price volatility

- 4.3.2 Trade-tariff uncertainty on Asian supply

- 4.3.3 SPC field-failure & warranty claims

- 4.3.4 Weak recycling ecosystem - ESG backlash

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Bargaining Power of Buyers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 Market Size & Growth Forecasts

- 5.1 By Product Type

- 5.1.1 Flexible

- 5.1.2 Rigid Core

- 5.1.2.1 Stone Plastic Composite (SPC)

- 5.1.2.2 Wood Plastic Composite (WPC)

- 5.2 By Installation Type

- 5.2.1 Self-Adhesive Vinyl Tiles

- 5.2.2 Glue-Down LVT

- 5.2.3 Interlocking Vinyl Tiles

- 5.2.4 Others

- 5.3 By End User

- 5.3.1 Residential

- 5.3.2 Commercial

- 5.4 By Distribution Channel

- 5.4.1 B2C / Retail Consumers

- 5.4.2 B2B / Contractors / Builders

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 Canada

- 5.5.1.2 United States

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Peru

- 5.5.2.3 Chile

- 5.5.2.4 Argentina

- 5.5.2.5 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 United Kingdom

- 5.5.3.2 Germany

- 5.5.3.3 France

- 5.5.3.4 Spain

- 5.5.3.5 Italy

- 5.5.3.6 BENELUX

- 5.5.3.7 NORDICS

- 5.5.3.8 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 India

- 5.5.4.2 China

- 5.5.4.3 Japan

- 5.5.4.4 Australia

- 5.5.4.5 South Korea

- 5.5.4.6 South East Asia

- 5.5.4.7 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 United Arab Emirates

- 5.5.5.2 Saudi Arabia

- 5.5.5.3 South Africa

- 5.5.5.4 Nigeria

- 5.5.5.5 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Armstrong Flooring

- 6.4.2 Tarkett Group

- 6.4.3 Mohawk Industries

- 6.4.4 Shaw Industries

- 6.4.5 Mannington Mills

- 6.4.6 Gerflor

- 6.4.7 Interface Inc.

- 6.4.8 Forbo Flooring Systems

- 6.4.9 Karndean Designflooring

- 6.4.10 Amtico International

- 6.4.11 Polyflor

- 6.4.12 Beaulieu International Group

- 6.4.13 CFL Flooring

- 6.4.14 AHF Products

- 6.4.15 Floor & Decor Holdings

- 6.4.16 HMTX Industries

- 6.4.17 Republic Floor

- 6.4.18 MSI Surfaces

- 6.4.19 Raskin Industries

- 6.4.20 FloorFolio Industries

7 Market Opportunities & Future Outlook

- 7.1 Launch click-lock PVC-free hybrid LVT targeting LEED & EU Green Deal projects

- 7.2 AI-driven room-visualizer platforms to raise online conversion for mid-tier retailers