PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910911

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910911

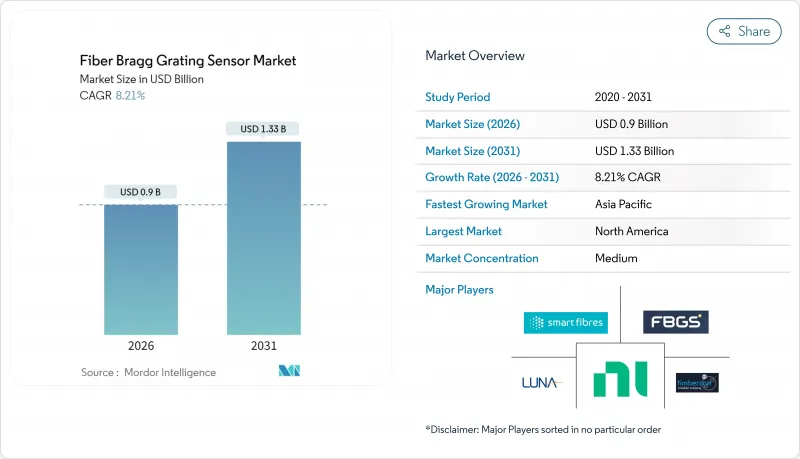

Fiber Bragg Grating Sensor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Fiber Bragg Grating Sensor market is expected to grow from USD 0.83 billion in 2025 to USD 0.9 billion in 2026 and is forecast to reach USD 1.33 billion by 2031 at 8.21% CAGR over 2026-2031.

The surging adoption of structural health monitoring, hydrogen pipelines, smart mining, and 5G backhaul infrastructure underpins this steady trajectory. Competitive differentiation centers on wavelength-dense sensor networks, multi-parameter measurement capabilities, and artificial intelligence-based signal processing. Rising infrastructure investments, safety-centric regulations, and the operational limits of traditional electrical gauges jointly favor optical sensing. Nevertheless, cross-sensitivity between temperature and strain, as well as higher upfront installation costs, continue to moderate near-term adoption in price-sensitive deployments.

Global Fiber Bragg Grating Sensor Market Trends and Insights

Growing Demand for Real-Time Structural Health Monitoring

Aging bridges, tunnels, and high-rise buildings are now monitored continuously with dense arrays of fiber Bragg gratings that reveal fatigue cracks and patterns of load redistribution before structural failure. The 2024 Francis Scott Key Bridge collapse accelerated federal mandates for continuous monitoring on high-traffic corridors in the United States. Distributed sensing along entire girders creates a complete strain profile, replacing scattered electrical gauges that overlook early-stage anomalies. Similar regulations in Europe tie public-funded infrastructure upgrades to the adoption of optical sensing, positioning the Fiber Bragg Grating Sensor market for long-term demand in civil assets.

Adoption in Hydrogen Pipeline Networks

Europe's Hydrogen Backbone initiative requires leak detection systems immune to hydrogen embrittlement, elevating fiber Bragg gratings as a safety standard. Dual-mode acoustic and strain detection enables operators to spot micro-leaks and mechanical deformation simultaneously, a capability that electrical systems cannot deliver in the corrosive hydrogen environment. Germany's H2-Netz specifications for new transmission lines create a replicable template that North American and Asia-Pacific projects are beginning to follow, widening the Fiber Bragg Grating Sensor market footprint in energy transport infrastructure.

Cross-Sensitivity to Temperature and Strain

Separating mechanical strain from thermal effects still necessitates costly dual-grating configurations or computational compensation that introduce 5-10% measurement uncertainty in aerospace and energy applications. Customers seeking +-1% accuracy often resort to redundant sensor schemes, which raises project budgets and hinders adoption in environments with wide thermal swings. This technical hurdle temporarily tempers the expansion of the Fiber Bragg Grating Sensor market until advanced compensation designs become price-competitive.

Other drivers and restraints analyzed in the detailed report include:

- Rising Investments in Smart Mining Operations

- Expansion of 5G Fiber Backhaul Infrastructure

- High Upfront Installation Cost versus Electrical Gauges

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Strain sensors contributed USD 0.31 billion to the Fiber Bragg Grating Sensor market in 2025, retaining a 37.78% revenue share, which underscores their ubiquity across bridges, aircraft wings, and concrete structures. Acoustic variants, while smaller in absolute terms, show a 9.12% CAGR as distributed acoustic sensing gains traction in perimeter security and leak detection. Strain devices will continue to anchor flagship infrastructure projects, but acoustic systems provide a high-growth complement.

Multi-parameter hybrids that co-locate strain and temperature gratings on a single fiber are shrinking compensation errors and lowering channel counts. Oilfield service providers are increasingly favoring combined sensors to reduce wellbore completion complexity, thereby broadening the reach of the Fiber Bragg Grating Sensor market across downhole conditions where electronic gauges fail.

The dominant C-Band segment generated nearly USD 0.37 billion in 2025, driven by telecom-grade component availability and proven interrogation hardware. Network-scale projects exhaust available C-Band channels, driving migration to the L-Band, which is posting the fastest 9.32% CAGR. The Fiber Bragg Grating Sensor market size for L-Band devices is forecast to expand significantly as mega-projects demand hundreds of sensing points on a single fiber.

Advanced interrogators now sweep across C- and L-Bands simultaneously, enabling mixed architectures that balance component cost with channel density. Research consortia are testing broader O-Band arrays for niche biomedical and underwater applications, although commercialization remains modest compared to mainstream wavelengths.

The Fiber Bragg Grating Sensor Market Report is Segmented by Type (Temperature Sensor, Strain Sensor, and More), Grating Wavelength Range (C-Band, L-Band, and More), End-User Industry (Telecommunication, Aerospace and Defense, and More), Application (Structural Health Monitoring, Temperature Monitoring, Vibration and Acoustic Monitoring, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

\North American revenue leadership stems from mandated structural monitoring after catastrophic bridge failures. Federal grants subsidize installation on aging steel arches, and the U.S. Navy's submarine hull integrity program extends military demand. Canada's extreme temperature swings make optical sensors a logical choice for remote transmission lines prone to ice loading. Mexico adopts fiber arrays in automotive factories to reduce unplanned downtime, adding a nascent industrial layer to the regional Fiber Bragg Grating Sensor market.

Asia-Pacific's dynamism is evident in China's multi-province high-speed rail rollout, with each viaduct equipped with thousands of gratings to detect rotational slip and joint displacement. Japan's stringent seismic codes drive real-time monitoring on new Shinkansen stations, while Korea integrates sensors into 5G trunk lines to localize fiber cuts within meters. India's smart-city program funds pilot traffic-monitoring grids using distributed acoustic sensing on roadway shoulders, thereby expanding the addressable demand.

Europe benefits from standardized regulations that align hydrogen, wind, and rail projects under frameworks like IEC 61757. Germany's H2-Ready pipeline criteria specify acoustic leak detection by default, and the United Kingdom's Crown Estate requires optical monitoring on fixed and floating wind assets. Southern Europe channels recovery funds into high-speed rail that crosses seismic zones, mandating optical arrays for tunnel liner strain measurement, buttressing the regional Fiber Bragg Grating Sensor market outlook.

- FBGS International NV

- Smart Fibres Ltd

- Micron Optics Inc - Luna Innovations

- Timbercon Inc

- National Instruments Corporation

- Hottinger Bruel and Kjaer HBM Inc

- Broptics Technology Inc

- ITF Technologies Inc

- Advanced Optics Solutions GmbH

- Technica Optical Components LLC

- Opsens Inc

- TeraXion Inc

- FISO Technologies Inc

- Optromix Inc

- Shenzhen Fibersail Technology Co Ltd

- Neoptix Inc

- Lightwave Logic Inc

- Smart Sensing Solutions GmbH

- Blue Road Research

- Cinogy Technologies GmbH

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for Real-Time Structural Health Monitoring

- 4.2.2 Adoption in Hydrogen Pipeline Networks

- 4.2.3 Rising Investments in Smart Mining Operations

- 4.2.4 Expansion of 5G Fiber Backhaul Infrastructure

- 4.2.5 Increasing Use in High-Voltage Direct Current (HVDC) Cables

- 4.2.6 Defense Focus on Condition-Based Aircraft Maintenance

- 4.3 Market Restraints

- 4.3.1 Cross-Sensitivity to Temperature and Strain

- 4.3.2 High Upfront Installation Cost versus Electrical Gauges

- 4.3.3 Limited Dynamic Range in Ultra-Fast Events

- 4.3.4 Scarcity of Skilled Fiber-Optic Technicians

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitute Products

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Type

- 5.1.1 Temperature Sensor

- 5.1.2 Strain Sensor

- 5.1.3 Pressure Sensor

- 5.1.4 Acoustic Sensor

- 5.1.5 Other Types

- 5.2 By Grating Wavelength Range

- 5.2.1 C-Band (1530-1565 nm)

- 5.2.2 L-Band (1565-1625 nm)

- 5.2.3 O-Band (1260-1360 nm)

- 5.2.4 Other Grating Wavelength Ranges

- 5.3 By End-User Industry

- 5.3.1 Telecommunication

- 5.3.2 Aerospace and Defense

- 5.3.3 Construction and Infrastructure

- 5.3.4 Energy and Power

- 5.3.5 Oil and Gas

- 5.3.6 Mining

- 5.3.7 Other End-User Industries

- 5.4 By Application

- 5.4.1 Structural Health Monitoring

- 5.4.2 Temperature Monitoring

- 5.4.3 Vibration and Acoustic Monitoring

- 5.4.4 Pressure Monitoring

- 5.4.5 Load and Weight Monitoring

- 5.4.6 Other Applications

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Russia

- 5.5.2.5 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 South Korea

- 5.5.3.5 Australia

- 5.5.3.6 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 Saudi Arabia

- 5.5.4.1.2 United Arab Emirates

- 5.5.4.1.3 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Egypt

- 5.5.4.2.3 Rest of Africa

- 5.5.4.1 Middle East

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 FBGS International NV

- 6.4.2 Smart Fibres Ltd

- 6.4.3 Micron Optics Inc - Luna Innovations

- 6.4.4 Timbercon Inc

- 6.4.5 National Instruments Corporation

- 6.4.6 Hottinger Bruel and Kjaer HBM Inc

- 6.4.7 Broptics Technology Inc

- 6.4.8 ITF Technologies Inc

- 6.4.9 Advanced Optics Solutions GmbH

- 6.4.10 Technica Optical Components LLC

- 6.4.11 Opsens Inc

- 6.4.12 TeraXion Inc

- 6.4.13 FISO Technologies Inc

- 6.4.14 Optromix Inc

- 6.4.15 Shenzhen Fibersail Technology Co Ltd

- 6.4.16 Neoptix Inc

- 6.4.17 Lightwave Logic Inc

- 6.4.18 Smart Sensing Solutions GmbH

- 6.4.19 Blue Road Research

- 6.4.20 Cinogy Technologies GmbH

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment