PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1911827

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1911827

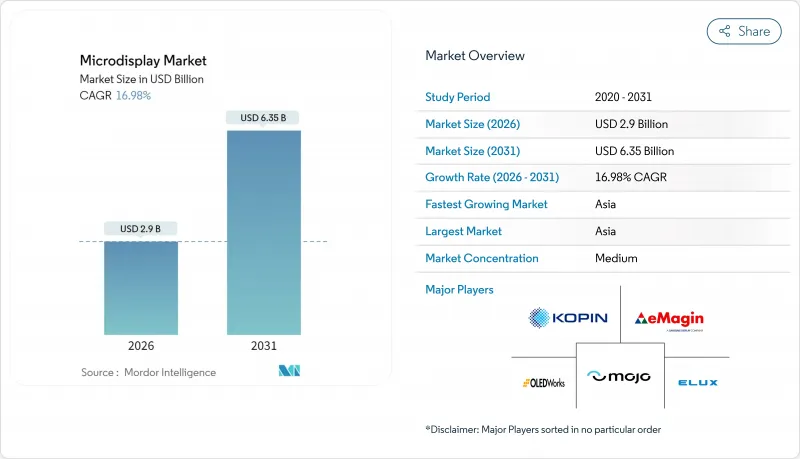

Microdisplay - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

Microdisplay market size in 2026 is estimated at USD 2.90 billion, growing from 2025 value of USD 2.48 billion with 2031 projections showing USD 6.35 billion, growing at 16.98% CAGR over 2026-2031.

Multiple innovation cycles are converging at once: MicroLED mass-transfer yields are finally stabilizing, AR/VR ecosystems are entering a scale-up phase, and Level 3-plus driver-assistance systems are pushing transparent head-up displays from prototype to production. Manufacturing breakthroughs, notably laser-induced forward transfer (LIFT) that reaches 99.7% placement accuracy for 5 µm MicroLED chips, have removed a cost barrier that long limited wider adoption. Competitive dynamics are heating up as consumer-electronics giants join forces with specialist suppliers, compressing the time from lab demonstration to consumer launch. Sustained defense spending and automotive safety mandates add resilient end-market demand that cushions cyclical swings. Supply constraints in sapphire substrates and silicon backplanes remain the main operational risk, yet ongoing capacity additions suggest these headwinds will ease after 2026.

Global Microdisplay Market Trends and Insights

Exploding Demand for Ultra-Compact Displays in AR/VR Wearables across Asia

Rising disposable incomes and an entrenched consumer-electronics supply chain have turned East Asia into the launchpad for next-generation smart glasses. Shanghai-based JBD has shipped more than 1 million MicroLED engines since 2021 and continues to post 50% annual unit growth, validating volume potential in the region. China's SidTek moved a USD 826.3 million twelve-inch OLED-on-silicon line into pilot run during 2024, ensuring local capacity matches the surge in demand. Regional integration shrinks both logistics costs and design-cycle time, letting OEMs iterate optics, waveguides, and driver ICs faster than competitors elsewhere. As component prices slide on the back of this manufacturing density, the microdisplay market gains a broader consumer addressable base. The virtuous loop of scale, cost, and adoption positions the region to remain the growth engine of the global microdisplay market.

Automotive OEM Shift to Transparent MicroLED HUDs for Level-3+ ADAS

Automakers are racing to merge driver information with real-world scenes in the windshield. MicroLED technology delivers the luminance reserve-20 to 50 times the efficiency of legacy projector-based HUDs-needed to stay readable in direct sunlight while conserving electrical power. Demonstrations such as AUO's "Virtual Sky Canopy" cockpit, unveiled at CES 2025, prove that curved, bezel-less visual surfaces are ready for series production. Transparent HUDs also mitigate distraction, a factor in one quarter of traffic accidents, by projecting alerts at eye level. The safety argument dovetails with regulatory pushes for Level 3 autonomy, particularly in Europe, making MicroLED HUDs a future default rather than an option. As fleet roll-outs begin in premium cars from 2026 onward, the pull-through effect on the wider microdisplay market will be significant.

Yield Losses in RGB MicroLED Mass-Transfer Processes

Despite USD 12 billion sunk into development and USD 2.4 billion in acquisitions, mass-transfer yield remains the cost pivot of full-color MicroLED displays. Even sub-micron placement errors translate into visible dead pixels, forcing costly rework. Coherent's LIFT process is a vital step forward, yet scaling single-panel accuracy to the multiple million chips needed for a headset still challenges inline inspection and repair workflows. Fab expansions by Osram in Malaysia and Ennostar in Taiwan have both slipped to 2026-2027 completion windows as engineers chase yield plateaus. The next two years will therefore set the adoption tempo for consumer-grade MicroLED.

Other drivers and restraints analyzed in the detailed report include:

- Defense Modernization Programs Specifying Low-SWaP Visor Displays

- Rise of Metaverse-Ready Smart Glasses from Big-Tech Partnerships

- Limited Through-Wafer Heat Dissipation in High-Brightness OLED-on-Si

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Traditional LCoS, LCD, and DLP modules controlled 48.62% of the microdisplay market in 2025. However, MicroLED devices are set to clock a 20.85% CAGR to 2031 as transfer yields rise and power efficiency outpaces rivals. Q-Pixel demonstrated 6,800 PPI MicroLED arrays, eclipsing Apple Vision Pro's 3,380 PPI benchmark and proving room for further visual fidelity. The microdisplay market size for MicroLEDs is therefore positioned to climb rapidly once cost curves cross those of OLED-on-Si. Europe, through Aledia's USD 200 million GaN-on-silicon line, provides an alternative source that diversifies the supply base beyond Asia. Quantum-dot-on-silicon concepts, showcased by Applied Materials prototypes that exceed 90% DCI-P3, offer a hybrid path for brands prioritizing color uniformity over absolute brightness.

OLED-on-Si sits between legacy and emergent solutions, benefitting from mature evaporation know-how while tackling luminance ceilings. Foxconn's partnership with Porotech, intended to spin up a MicroLED wafer line by late 2025, signals how contract manufacturers aim to bridge OLED and MicroLED camps simultaneously. That dual-track strategy highlights the increasingly diversified technology toolkit available to brands looking to balance cost, brightness, and lifetime in the microdisplay market.

The Microdisplay Market Report is Segmented by Technology (Traditional (LCoS, LCD, DLP), OLED-On-Si, Microleds, and More), Resolution (Up To 1024 X 768, 1024 X 768 To 1920 X 1080, and Above 1920 X 1080), Application (Consumer and Automotive (Augmented Reality/Virtual Reality Headsets, and More), Defense, and More), and Geography (North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific controlled 46.62% of revenue in 2025 and is on pace for a 17.42% CAGR through 2031, driven by aggressive fab construction in mainland China and robust substrate ecosystems in Taiwan. SidTek's twelve-inch OLED-on-Si ramp and JBD's cumulative million-plus MicroLED engine shipments exemplify regional volume leverage. The microdisplay market benefits from tight clustering of waveguide optics, driver IC, and finishing services, turning the region into a one-stop design-to-assembly hub. Government incentives, including city-level grants for display parks, further reduce capital payback times.

North America supplies critical system integration and dominates defense procurement. Kopin's U.S. Army contract validates domestic design know-how while actual wafer production often occurs offshore. Silicon Valley stakes in spatial-computing software ensure that use-case innovation remains anchored in the region. Canada and Mexico service the ecosystem through advanced optics polishing and final assembly, but scale remains modest relative to U.S. demand.

Europe's contribution centers on technology differentiation. Aledia's Grenoble line is Europe's flagship MicroLED project, promising 5,000 wafer starts per week when fully loaded. Fraunhofer IPMS pushes transparent OLED microdisplays for lightweight AR viewers, targeting industrial maintenance and surgical-assistance scenarios. Automotive tier-ones across Germany and Sweden also feed local demand for HUD modules that meet stringent safety standards. Although Europe cannot match Asia's volume, its R&D assets and premium automotive market keep it influential within the global microdisplay market.

- Sony Semiconductor Solutions Corporation

- JBD (Jade Bird Display)

- Kopin Corporation

- Seiko Epson Corporation

- eMagin Corporation

- LG Electronics

- Himax Technologies Inc.

- BOE Technology Group Co. Ltd.

- Citizen Finedevice Co. Ltd.

- Microoled SA

- VueReal Inc.

- OLiGHTEK Opto-electronic Co. Ltd.

- Syndiant Inc.

- Raontech Co. Ltd.

- Dresden Microdisplay GmbH

- AU Optronics (AUO)

- Universal Display Corp. (UDC)

- eLux Inc.

- Mojo Vision Inc.

- OLEDWorks

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Exploding Demand for Ultra-Compact Displays in AR/VR Wearables across Asia

- 4.2.2 Automotive OEM Shift to Transparent Micro-LED HUDs for Level-3+ ADAS

- 4.2.3 Defense Modernization Programs Specifying Low-SWaP Visor Displays (United States and NATO)

- 4.2.4 Rise of Metaverse-Ready Smart Glasses from Big-Tech Partnerships

- 4.2.5 Mini-Fab Outsourcing Enabling Cost-Effective OLED-on-Si for Consumer Cameras

- 4.2.6 Cinematic Drones and Micro-Projectors Driving High-Nits LCoS Adoption

- 4.3 Market Restraints

- 4.3.1 Yield Losses in RGB Micro-LED Mass-Transfer Processes

- 4.3.2 Limited Through-Wafer Heat Dissipation in High-Brightness OLED-on-Si

- 4.3.3 Supply-Chain Bottlenecks for High-Purity Sapphire and Silicon Backplanes

- 4.3.4 IP Litigation Risk among United States and Chinese Panel Makers

- 4.4 Industry Ecosystem Analysis

- 4.5 Technology Snapshot

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Threat of New Entrants

- 4.6.2 Bargaining Power of Buyers/Consumers

- 4.6.3 Bargaining Power of Suppliers

- 4.6.4 Threat of Substitute Products

- 4.6.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUES)

- 5.1 By Type of Technology

- 5.1.1 Traditional (LCoS, LCD, DLP)

- 5.1.2 OLED-on-Si

- 5.1.3 MicroLEDs

- 5.1.4 Quantum-Dot-on-Si

- 5.2 By Resolution

- 5.2.1 Up to 1024 x 768

- 5.2.2 1024 x 768 to 1920 x 1080

- 5.2.3 Above 1920 x 1080

- 5.3 By Application

- 5.3.1 Consumer and Automotive

- 5.3.1.1 Augmented Reality/Virtual Reality Headsets

- 5.3.1.2 Automotive HUDs

- 5.3.1.3 Traditional Applications (Projection/Camera, Others)

- 5.3.2 Defense

- 5.3.3 Others

- 5.3.1 Consumer and Automotive

- 5.4 By Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Mexico

- 5.4.2 Europe

- 5.4.2.1 Germany

- 5.4.2.2 United Kingdom

- 5.4.2.3 France

- 5.4.2.4 Nordics

- 5.4.2.5 Rest of Europe

- 5.4.3 South America

- 5.4.3.1 Brazil

- 5.4.3.2 Rest of South America

- 5.4.4 Asia-Pacific

- 5.4.4.1 China

- 5.4.4.2 Japan

- 5.4.4.3 India

- 5.4.4.4 South-East Asia

- 5.4.4.5 Rest of Asia-Pacific

- 5.4.5 Middle East and Africa

- 5.4.5.1 Middle East

- 5.4.5.1.1 Gulf Cooperation Council Countries

- 5.4.5.1.2 Turkey

- 5.4.5.1.3 Rest of Middle East

- 5.4.5.2 Africa

- 5.4.5.2.1 South Africa

- 5.4.5.2.2 Rest of Africa

- 5.4.5.1 Middle East

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Sony Semiconductor Solutions Corporation

- 6.4.2 JBD (Jade Bird Display)

- 6.4.3 Kopin Corporation

- 6.4.4 Seiko Epson Corporation

- 6.4.5 eMagin Corporation

- 6.4.6 LG Electronics

- 6.4.7 Himax Technologies Inc.

- 6.4.8 BOE Technology Group Co. Ltd.

- 6.4.9 Citizen Finedevice Co. Ltd.

- 6.4.10 Microoled SA

- 6.4.11 VueReal Inc.

- 6.4.12 OLiGHTEK Opto-electronic Co. Ltd.

- 6.4.13 Syndiant Inc.

- 6.4.14 Raontech Co. Ltd.

- 6.4.15 Dresden Microdisplay GmbH

- 6.4.16 AU Optronics (AUO)

- 6.4.17 Universal Display Corp. (UDC)

- 6.4.18 eLux Inc.

- 6.4.19 Mojo Vision Inc.

- 6.4.20 OLEDWorks

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment