PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1934732

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1934732

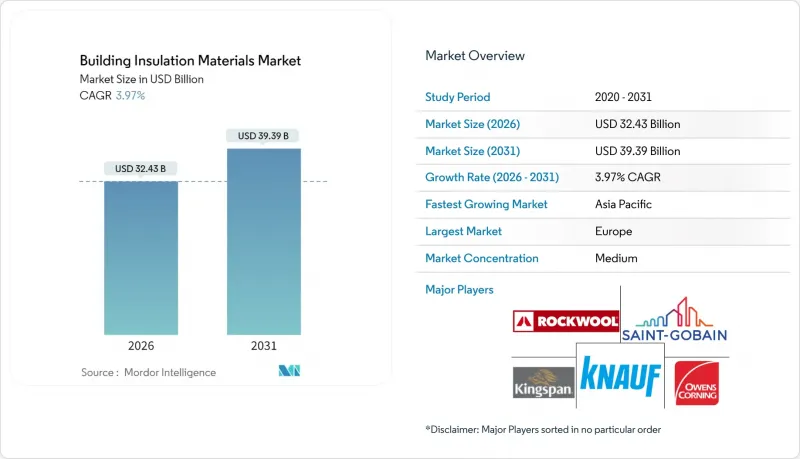

Building Insulation Materials - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Building Insulation Materials Market is expected to grow from USD 31.19 billion in 2025 to USD 32.43 billion in 2026 and is forecast to reach USD 39.39 billion by 2031 at 3.97% CAGR over 2026-2031.

Heightened regulatory stringency in Europe and North America, rapid urbanization in Asia-Pacific, and growing homeowner awareness of utility savings are together expanding the addressable base for advanced thermal and acoustic solutions. Material innovation intensifies as manufacturers race to deliver higher R-values in slimmer profiles, lower embodied carbon, and superior fire performance-often within a single product family. Competitive strategies revolve around acquisitions that broaden geographic reach and product scope, illustrated by Owens Corning's USD 3.9 billion purchase of Masonite International that added complementary building envelope products while promising USD 125 million in cost synergies.

Global Building Insulation Materials Market Trends and Insights

Growing demand for energy-efficient buildings

New codes, such as the 2024 International Energy Conservation Code, require R49 attic insulation in US Climate Zones 2-3 and R60 in Zones 4-8, tightening thermal envelope thresholds that push specifiers toward higher-performance products. Across the Atlantic, the revised Energy Performance of Buildings Directive sets a binding 16% reduction in energy use by 2030, reinforcing momentum for upgrades in European housing stock. As commercial owners strive to meet ANSI/ASHRAE/IES 90.1-2022, which yields 9.8% site energy savings versus the 2019 edition, demand is shifting toward materials that deliver equivalent R-values in thinner assemblies to preserve rentable area. Manufacturers are responding with hybrid solutions that pair low-conductivity cores with reflective facers to maximize thermal performance per millimeter.

Increasing green retrofitting incentives in North America

The US Energy Efficient Home Improvement Credit reimburses up to 30% of qualifying insulation expenses, effectively narrowing payback periods for homeowners. Complementary standards for affordable housing are driving significant annual household savings, encouraging adoption among lower-income brackets. These programs coincide with municipal climate plans that mandate energy retrofits for buildings above defined floor-area thresholds, creating a pipeline of projects that sustain material demand through the decade. Manufacturers with blown-in and spray foam systems tailored to retrofit cavities are positioned to capture this incremental volume.

High materials and installation cost

Many price-sensitive markets still perceive advanced systems such as aerogel blankets as cost-prohibitive despite superior thermal resistance, because specialized handling elevates total installed cost. Capital constraints in large-scale social housing programs further dampen momentum for premium products, forcing specifiers to revert to mid-range fiberglass or polystyrene even when lifecycle savings justify higher outlays. Until manufacturing scale lowers unit price or incentives bridge the gap, premium materials will remain confined to niche projects where performance drives specification.

Other drivers and restraints analyzed in the detailed report include:

- Increasing government support for eco-friendly and sustainable materials

- Growing preference for low-VOC bio-based foams

- Availability of affordable alternatives

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Fiberglass held 34.62% of the building insulation materials market in 2025, anchored by long-established supply chains and competitive pricing. Its glass-fiber core delivers reliable thermal resistance and non-combustibility, making it a staple across climate zones. Polystyrene is the fastest climber at 4.16% CAGR thanks to capacity expansions such as BASF's upgrade in Ludwigshafen that improves bead consistency and thermal performance. Mineral wool retains traction where fire rating and sound attenuation are paramount, while cellulose growth rides sustainability credentials and regional programs that value recycled content. PUR and PIR foams address premium applications requiring high R-value per inch, yet their share is checked by cost and flammability perceptions. Aerogels remain niche but could disrupt as costs fall due to process improvements that shorten supercritical drying cycles.

Cost, embodied-carbon targets and tightening fire regulations now shape specification more than R-value alone. This shift is creating space for hybrid panels that laminate different cores to combine strengths such as moisture tolerance and structural rigidity. Manufacturers are investing in binder chemistries that lower formaldehyde and phenol emissions, anticipating stricter indoor-air-quality standards. As a result, the building insulation materials market sees parallel tracks: mature commodities stabilize on volume, while high-performance classes grow faster albeit from a smaller base.

Roof assemblies captured 29.12% of 2025 revenue because heat-flux concentration through the top of the envelope makes them the first target for energy upgrades. Installation is comparatively straightforward, and subsidies for solar-ready roofs often bundle thermal packages, which sustains volume. The building insulation materials market size for acoustic partition and HVAC ducts is forecast to expand at a 4.85% CAGR to 2031 as health authorities recognize noise pollution as a public health issue. Wall cavities and external insulation finish systems follow closely because renovation programs prioritize facade upgrades that boost both aesthetics and thermal performance. Floor and basement solutions grow in colder climates where slab-edge losses weaken overall envelope performance.

Integrated design is gaining ground: architects specify systems that address thermal, acoustic and moisture objectives simultaneously to simplify detailing and shorten construction schedules. This holistic mindset drives demand for multi-functional boards that eliminate puncture-prone vapor barriers or incorporate acoustic mats. Consequently, product messaging increasingly highlights system compatibility rather than stand-alone thermal metrics, reinforcing a consultative selling approach among leading suppliers.

The Building Insulation Materials Market Report is Segmented by Material Type (Fiberglass, Mineral Wool, Cellulose, and More), Application (Roof, Wall, Floor and Basement, and More), End-User (Residential and Non-Residential), Installation (New Construction and Renovation), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Europe maintained 37.88% share in 2025, driven by binding climate legislation that targets a 60% emission cut in buildings by 2030 and a zero-emission stock by 2050. National transposition of the directive accelerates demand for exterior insulation and finish systems, mineral wool, and high-performance rigid boards. Producers are scaling regional capacity, evidenced by Knauf's GBP 172 million rock mineral wool factory in the United Kingdom that will start operations in 2026.

Asia-Pacific is the fastest-growing region with a 4.88% CAGR to 2031 as China, India, and Southeast Asian markets align local codes with international best practice. Government stimulus for efficient appliances and green buildings reinforces underlying demographic demand from rapid urbanization. Capacity additions such as Rockwool's Tamil Nadu plant shorten lead times and localize pricing, which improves adoption in cost-sensitive segments.

North America combines a steady new-build pipeline with robust retrofit activity catalyzed by federal tax credits and utility rebates. Market interest is shifting to lower-VOC products, spurring material substitution in HVAC ducts and occupied spaces. Corporate ESG disclosure rules are advancing environmental transparency, favoring suppliers that can prove low embodied carbon through verified EPDs.

- Armacell

- Aspen Aerogels Inc.

- Atlas Roofing Corporation

- BASF SE

- Beijing New Building Materials Public Limited Company

- Cellofoam North America Inc.

- Covestro AG

- Dow

- DuPont

- GAF Materials LLC

- Holcim

- Huntsman International LLC

- Johns Manville

- Kingspan Group

- Knauf Group

- Owens Corning

- Recticel NV/SA

- ROCKWOOL A/S

- Saint-Gobain

- Synthos

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for Energy Efficient Buildings

- 4.2.2 Increasing Green Retrofitting Incentives in North America

- 4.2.3 Increasing Governemnt Support for the Usage of Eco-Friendly and Sustainable Materials

- 4.2.4 Growing Preference for Low-VOC Bio-based Foams

- 4.2.5 Rising Infrastructure and Industrialization in Asia-Pacific

- 4.3 Market Restraints

- 4.3.1 High Materials and Installation Cost

- 4.3.2 Availability of Affordable Alternatives

- 4.3.3 Regulatory Scrutiny on Global Warming Potential of Blowing Agents

- 4.4 Value Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Porter's Five Forces

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Material Type

- 5.1.1 Fiberglass

- 5.1.2 Mineral Wool

- 5.1.3 Cellulose

- 5.1.4 Polyurethane/Polyisocyanurate Foams (PUR/PIR)

- 5.1.5 Polystyrene

- 5.1.6 Other Materials (Cork, Aerogel and Vacuum Insulation Panels, Spray Foams, Hemp, Calcium-Silicate, etc.)

- 5.2 By Application

- 5.2.1 Roof

- 5.2.2 Wall (External and Cavity)

- 5.2.3 Floor and Basement

- 5.2.4 Ceiling and Attic

- 5.2.5 Acoustic Partition and HVAC Duct

- 5.3 By End-User

- 5.3.1 Residential

- 5.3.2 Non-Residential

- 5.3.2.1 Commercial

- 5.3.2.2 Infrastructure

- 5.3.2.3 Other Non-Residential Industries (Education, Healthcare, Civic and Religious,etc.)

- 5.4 By Installation

- 5.4.1 New Construction

- 5.4.2 Renovation

- 5.5 By Geography

- 5.5.1 Asia-Pacific

- 5.5.1.1 China

- 5.5.1.2 India

- 5.5.1.3 Japan

- 5.5.1.4 South Korea

- 5.5.1.5 ASEAN Countries

- 5.5.1.6 Rest of Asia-Pacific

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Nordics Countries

- 5.5.3.7 Rest of Europe

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Rest of South America

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles {(includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Armacell

- 6.4.2 Aspen Aerogels Inc.

- 6.4.3 Atlas Roofing Corporation

- 6.4.4 BASF SE

- 6.4.5 Beijing New Building Materials Public Limited Company

- 6.4.6 Cellofoam North America Inc.

- 6.4.7 Covestro AG

- 6.4.8 Dow

- 6.4.9 DuPont

- 6.4.10 GAF Materials LLC

- 6.4.11 Holcim

- 6.4.12 Huntsman International LLC

- 6.4.13 Johns Manville

- 6.4.14 Kingspan Group

- 6.4.15 Knauf Group

- 6.4.16 Owens Corning

- 6.4.17 Recticel NV/SA

- 6.4.18 ROCKWOOL A/S

- 6.4.19 Saint-Gobain

- 6.4.20 Synthos

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment

- 7.2 Technological Advancements in Green Insulation Materials