PUBLISHER: Roots Analysis | PRODUCT CODE: 1869569

PUBLISHER: Roots Analysis | PRODUCT CODE: 1869569

Dry Ramming Mass Market Till 2035: Distribution by Ramming Mass, Function, Areas of Application, Company Size, and Key Geographical Regions: Industry Trends and Global Forecasts

Dry Ramming Mass Market Overview

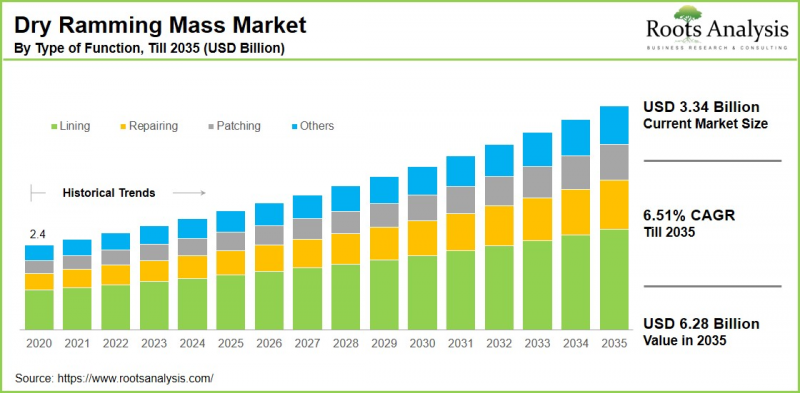

As per Roots Analysis, the global dry ramming mass market size is estimated to grow from USD 3.34 billion in the current year USD 6.28 billion by 2035, at a CAGR of 6.51% during the forecast period, till 2035.

The opportunity for dry ramming mass market has been distributed across the following segments:

Type of Ramming Mass

- Alumina Ramming Mass

- Chromite Based Ramming Mass

- Magnesia Based Ramming Mass

- Silica Based Ramming Mass

- Zirconia Based Ramming Mass

- Others

Type of Function

- Lining

- Patching

- Repairing

- Others

Areas of Application

- Blast Furnace

- Electric Arc Furnace

- Foundries

- Non-Steel

- Steel

- Others

Type of Enterprise

- Large Enterprises

- Small and Medium Enterprises

Geographical Regions

- North America

- US

- Canada

- Mexico

- Other North American countries

- Europe

- Austria

- Belgium

- Denmark

- France

- Germany

- Ireland

- Italy

- Netherlands

- Norway

- Russia

- Spain

- Sweden

- Switzerland

- UK

- Other European countries

- Asia

- China

- India

- Japan

- Singapore

- South Korea

- Other Asian countries

- Latin America

- Brazil

- Chile

- Colombia

- Venezuela

- Other Latin American countries

- Middle East and North Africa

- Egypt

- Iran

- Iraq

- Israel

- Kuwait

- Saudi Arabia

- UAE

- Other MENA countries

- Rest of the World

- Australia

- New Zealand

- Other countries

Dry Ramming Mass Market: Growth and Trends

Dry ramming mass is a type of refractory substance utilized in the building and maintenance of furnaces and other high-temperature processing apparatus. It consists of a dry, granular blend made up of refractory aggregates, powders, and bonding agents. The term "ramming" refers to the technique of installation, where the dry mixture is compacted (rammed) either manually or with machinery into the furnace lining or mold. Designed to endure extreme temperatures and challenging conditions, dry ramming mass provides thermal insulation while resisting chemical and mechanical deterioration.

The market for dry ramming mass is witnessing swift expansion due to several significant factors. One primary reason for this growth is the rising need for refractory materials across various industrial sectors. Refractory materials are crucial for lining furnaces, ladles, and other industrial containers that function at elevated temperatures. Another factor contributing to market growth is the increasing demand for energy-efficient refractory solutions. As industries work to cut down their energy usage and related expenses, they are increasingly choosing dry ramming mass, known for its excellent thermal conductivity and insulation capabilities. As a result, owing to the abovementioned factors, the dry ramming mass market is expected to grow significantly during the forecast period.

Dry Ramming Mass Market: Key Segments

Market Share by Type of Ramming Mass

Based on type of ramming mass, the global dry ramming mass market is segmented into alumina ramming mass, chromite based ramming mass, magnesia based ramming mass, silica based ramming mass, zirconia based ramming mass and others. According to our estimates, currently, the alumina ramming mass segment captures the majority of the market share, due to its outstanding characteristics and adaptability. Alumina-based products provide excellent refractoriness, resistance to thermal shock, and chemical stability, making them suitable for lining a variety of furnaces, including those used in steel production.

However, the silica-based ramming mass category is projected to experience significant growth during the forecast period. This can be attributed to its superior thermal conductivity, remarkable resistance to corrosion, and cost efficiency. It is commonly utilized in induction furnaces for producing steel and other high-temperature processes.

Market Share by Type of Function

Based on type of function, the global dry ramming mass market is segmented into lining, patching, repairing and others. According to our estimates, currently, the lining segment captures the majority of the market share. This can be attributed to the essential role that lining plays in the maintenance and optimization of furnace performance. Dry ramming mass is mainly utilized for lining furnaces across several industries, including steel, non-ferrous metals, and cement production.

However, the repairing segment is expected to grow at a higher CAGR during the forecast period. Due to regular wear and tear in industrial furnaces during operation, the need for continual maintenance and repair becomes essential for maintaining optimal furnace function. Dry ramming mass is widely used for repairing furnace linings, providing high-temperature resistance and durability. The growing focus on furnace maintenance and efficiency fuels the expansion of the repairing segment in the dry ramming mass market.

Market Share by Areas of Application

Based on areas of application, the global dry ramming mass market is segmented into blast furnace, electric arc furnace, foundries, non-steel and others. According to our estimates, currently, the foundries segment captures the majority of the market share, owing to the widespread utilization of dry ramming mass in foundry operations. Notably, it plays a vital role in lining induction furnaces and other equipment within the metal casting process.

However, the blast furnace segment is expected to grow at a higher CAGR during the forecast period. This increase is fueled by the fundamental role of blast furnaces in the manufacture of iron and steel, coupled with the rising demand for these metals in various sectors.

Market Share by Company Size

Based on company size, the global dry ramming mass market is segmented into large enterprises and small and medium enterprises. According to our estimates, currently, the large enterprises segment captures the majority of the market share.

However, the small & medium enterprises (SMEs) are expected to grow at a higher CAGR during the forecast period, driven by their agility, innovative approaches, niche-market focus, and adaptability to evolving customer needs and market dynamics.

Market Share by Geographical Regions

Based on geographical regions, the dry ramming mass market is segmented into North America, Europe, Asia, Latin America, Middle East and North Africa, and the rest of the world. According to our estimates, currently, Asia captures the majority share of the market. This can be attributed to the accelerated industrialization, especially in the steel and metal sectors. Expanding infrastructure projects, rapid urbanization, and rising manufacturing activity in countries such as China and India are further fueling demand.

Example Players in Dry Ramming Mass Market

- Arora Refractories

- ASK Chemicals

- Calderys

- Casco Specialty Products

- Compagnie de Saint-Gobain

- Dalmia Bharat Refractories

- Dense Refractories

- Foseco

- Galaxy Enterprise

- Gita Refractories

- Harbison Walker International

- Ibiden

- Imperial World Trade

- LMM

- Magnesita Refratarios

- Nippon Steel & Sumitomo Metal

- Nisso Seisakusho

- Norican Global

- Refcast

- Saint-Gobain

- Shenghe Refractories

- Showa Denko

- Shree B. S. Mining

- Shri Vinayak Industries

- Sino-Foundry Refractory (Jiangsu)

- Sumitomo Metal Industries

- Tama Refractory

- TMM India

- Vesuvius

- Vishva Vishal Refractory

- Wonjin Worldwide

- Zibo Long Keter New Materials

Dry Ramming Mass Market: Research Coverage

The report on the dry ramming mass market features insights on various sections, including:

- Market Sizing and Opportunity Analysis: An in-depth analysis of the dry ramming mass market, focusing on key market segments, including [A] type of ramming mass, [B] type of function, [C] areas of application, [D] company size, and [E] key geographical regions.

- Competitive Landscape: A comprehensive analysis of the companies engaged in the dry ramming mass market, based on several relevant parameters, such as [A] year of establishment, [B] company size, [C] location of headquarters and [D] ownership structure.

- Company Profiles: Elaborate profiles of prominent players engaged in the dry ramming mass market, providing details on [A] location of headquarters, [B] company size, [C] company mission, [D] company footprint, [E] management team, [F] contact details, [G] financial information, [H] operating business segments, [I] dry ramming mass portfolio, [J] moat analysis, [K] recent developments, and an informed future outlook.

- Megatrends: An evaluation of ongoing megatrends in the dry ramming mass industry.

- Patent Analysis: An insightful analysis of patents filed / granted in the dry ramming mass domain, based on relevant parameters, including [A] type of patent, [B] patent publication year, [C] patent age and [D] leading players.

- Recent Developments: An overview of the recent developments made in the dry ramming mass market, along with analysis based on relevant parameters, including [A] year of initiative, [B] type of initiative, [C] geographical distribution and [D] most active players.

- Porter's Five Forces Analysis: An analysis of five competitive forces prevailing in the dry ramming mass market, including threats of new entrants, bargaining power of buyers, bargaining power of suppliers, threats of substitute products and rivalry among existing competitors.

- SWOT Analysis: An insightful SWOT framework, highlighting the strengths, weaknesses, opportunities and threats in the domain. Additionally, it provides Harvey ball analysis, highlighting the relative impact of each SWOT parameter.

- Value Chain Analysis: A comprehensive analysis of the value chain, providing information on the different phases and stakeholders involved in the dry ramming mass market.

Key Questions Answered in this Report

- How many companies are currently engaged in dry ramming mass market?

- Which are the leading companies in this market?

- What factors are likely to influence the evolution of this market?

- What is the current and future market size?

- What is the CAGR of this market?

- How is the current and future market opportunity likely to be distributed across key market segments?

Reasons to Buy this Report

- The report provides a comprehensive market analysis, offering detailed revenue projections of the overall market and its specific sub-segments. This information is valuable to both established market leaders and emerging entrants.

- Stakeholders can leverage the report to gain a deeper understanding of the competitive dynamics within the market. By analyzing the competitive landscape, businesses can make informed decisions to optimize their market positioning and develop effective go-to-market strategies.

- The report offers stakeholders a comprehensive overview of the market, including key drivers, barriers, opportunities, and challenges. This information empowers stakeholders to stay abreast of market trends and make data-driven decisions to capitalize on growth prospects.

Additional Benefits

- Complimentary Excel Data Packs for all Analytical Modules in the Report

- 15% Free Content Customization

- Detailed Report Walkthrough Session with Research Team

- Free Updated report if the report is 6-12 months old or older

TABLE OF CONTENTS

SECTION I: REPORT OVERVIEW

1. PREFACE

- 1.1. Introduction

- 1.2. Market Share Insights

- 1.3. Key Market Insights

- 1.4. Report Coverage

- 1.5. Key Questions Answered

- 1.6. Chapter Outlines

2. RESEARCH METHODOLOGY

- 2.1. Chapter Overview

- 2.2. Research Assumptions

- 2.3. Database Building

- 2.3.1. Data Collection

- 2.3.2. Data Validation

- 2.3.3. Data Analysis

- 2.4. Project Methodology

- 2.4.1. Secondary Research

- 2.4.1.1. Annual Reports

- 2.4.1.2. Academic Research Papers

- 2.4.1.3. Company Websites

- 2.4.1.4. Investor Presentations

- 2.4.1.5. Regulatory Filings

- 2.4.1.6. White Papers

- 2.4.1.7. Industry Publications

- 2.4.1.8. Conferences and Seminars

- 2.4.1.9. Government Portals

- 2.4.1.10. Media and Press Releases

- 2.4.1.11. Newsletters

- 2.4.1.12. Industry Databases

- 2.4.1.13. Roots Proprietary Databases

- 2.4.1.14. Paid Databases and Sources

- 2.4.1.15. Social Media Portals

- 2.4.1.16. Other Secondary Sources

- 2.4.2. Primary Research

- 2.4.2.1. Introduction

- 2.4.2.2. Types

- 2.4.2.2.1. Qualitative

- 2.4.2.2.2. Quantitative

- 2.4.2.3. Advantages

- 2.4.2.4. Techniques

- 2.4.2.4.1. Interviews

- 2.4.2.4.2. Surveys

- 2.4.2.4.3. Focus Groups

- 2.4.2.4.4. Observational Research

- 2.4.2.4.5. Social Media Interactions

- 2.4.2.5. Stakeholders

- 2.4.2.5.1. Company Executives (CXOs)

- 2.4.2.5.2. Board of Directors

- 2.4.2.5.3. Company Presidents and Vice Presidents

- 2.4.2.5.4. Key Opinion Leaders

- 2.4.2.5.5. Research and Development Heads

- 2.4.2.5.6. Technical Experts

- 2.4.2.5.7. Subject Matter Experts

- 2.4.2.5.8. Scientists

- 2.4.2.5.9. Doctors and Other Healthcare Providers

- 2.4.2.6. Ethics and Integrity

- 2.4.2.6.1. Research Ethics

- 2.4.2.6.2. Data Integrity

- 2.4.3. Analytical Tools and Databases

- 2.4.1. Secondary Research

3. MARKET DYNAMICS

- 3.1. Forecast Methodology

- 3.1.1. Top-Down Approach

- 3.1.2. Bottom-Up Approach

- 3.1.3. Hybrid Approach

- 3.2. Market Assessment Framework

- 3.2.1. Total Addressable Market (TAM)

- 3.2.2. Serviceable Addressable Market (SAM)

- 3.2.3. Serviceable Obtainable Market (SOM)

- 3.2.4. Currently Acquired Market (CAM)

- 3.3. Forecasting Tools and Techniques

- 3.3.1. Qualitative Forecasting

- 3.3.2. Correlation

- 3.3.3. Regression

- 3.3.4. Time Series Analysis

- 3.3.5. Extrapolation

- 3.3.6. Convergence

- 3.3.7. Forecast Error Analysis

- 3.3.8. Data Visualization

- 3.3.9. Scenario Planning

- 3.3.10. Sensitivity Analysis

- 3.4. Key Considerations

- 3.4.1. Demographics

- 3.4.2. Market Access

- 3.4.3. Reimbursement Scenarios

- 3.4.4. Industry Consolidation

- 3.5. Robust Quality Control

- 3.6. Key Market Segmentations

- 3.7. Limitations

4. MACRO-ECONOMIC INDICATORS

- 4.1. Chapter Overview

- 4.2. Market Dynamics

- 4.2.1. Time Period

- 4.2.1.1. Historical Trends

- 4.2.1.2. Current and Forecasted Estimates

- 4.2.2. Currency Coverage

- 4.2.2.1. Overview of Major Currencies Affecting the Market

- 4.2.2.2. Impact of Currency Fluctuations on the Industry

- 4.2.3. Foreign Exchange Impact

- 4.2.3.1. Evaluation of Foreign Exchange Rates and Their Impact on Market

- 4.2.3.2. Strategies for Mitigating Foreign Exchange Risk

- 4.2.4. Recession

- 4.2.4.1. Historical Analysis of Past Recessions and Lessons Learnt

- 4.2.4.2. Assessment of Current Economic Conditions and Potential Impact on the Market

- 4.2.5. Inflation

- 4.2.5.1. Measurement and Analysis of Inflationary Pressures in the Economy

- 4.2.5.2. Potential Impact of Inflation on the Market Evolution

- 4.2.6. Interest Rates

- 4.2.6.1. Overview of Interest Rates and Their Impact on the Market

- 4.2.6.2. Strategies for Managing Interest Rate Risk

- 4.2.7. Commodity Flow Analysis

- 4.2.7.1. Type of Commodity

- 4.2.7.2. Origins and Destinations

- 4.2.7.3. Values and Weights

- 4.2.7.4. Modes of Transportation

- 4.2.8. Global Trade Dynamics

- 4.2.8.1. Import Scenario

- 4.2.8.2. Export Scenario

- 4.2.9. War Impact Analysis

- 4.2.9.1. Russian-Ukraine War

- 4.2.9.2. Israel-Hamas War

- 4.2.10. COVID Impact / Related Factors

- 4.2.10.1. Global Economic Impact

- 4.2.10.2. Industry-specific Impact

- 4.2.10.3. Government Response and Stimulus Measures

- 4.2.10.4. Future Outlook and Adaptation Strategies

- 4.2.11. Other Indicators

- 4.2.11.1. Fiscal Policy

- 4.2.11.2. Consumer Spending

- 4.2.11.3. Gross Domestic Product (GDP)

- 4.2.11.4. Employment

- 4.2.11.5. Taxes

- 4.2.11.6. R&D Innovation

- 4.2.11.7. Stock Market Performance

- 4.2.11.8. Supply Chain

- 4.2.11.9. Cross-Border Dynamics

- 4.2.1. Time Period

SECTION II: QUALITATIVE INSIGHTS

5. EXECUTIVE SUMMARY

6. INTRODUCTION

- 6.1. Chapter Overview

- 6.2. Overview of Dry Ramming Mass Market

- 6.2.1. Type of Ramming Mass

- 6.2.2. Type of Function

- 6.2.3. Areas of Application

- 6.3. Future Perspective

7. REGULATORY SCENARIO

SECTION III: MARKET OVERVIEW

8. COMPREHENSIVE DATABASE OF LEADING PLAYERS

9. COMPETITIVE LANDSCAPE

- 9.1. Chapter Overview

- 9.2. Dry Ramming Mass Market: Overall Market Landscape

- 9.2.1. Analysis by Year of Establishment

- 9.2.2. Analysis by Company Size

- 9.2.3. Analysis by Location of Headquarters

- 9.2.4. Analysis by Ownership Structure

10. WHITE SPACE ANALYSIS

11. COMPANY COMPETITIVENESS ANALYSIS

12. STARTUP ECOSYSTEM IN THE DRY RAMMING MASS MARKET

- 12.1. Dry Ramming Mass Market: Market Landscape of Startups

- 12.1.1. Analysis by Year of Establishment

- 12.1.2. Analysis by Company Size

- 12.1.3. Analysis by Company Size and Year of Establishment

- 12.1.4. Analysis by Location of Headquarters

- 12.1.5. Analysis by Company Size and Location of Headquarters

- 12.1.6. Analysis by Ownership Structure

- 12.2. Key Findings

SECTION IV: COMPANY PROFILES

13. COMPANY PROFILES

- 13.1. Chapter Overview

- 13.2. Arora Refractories*

- 13.2.1. Company Overview

- 13.2.2. Company Mission

- 13.2.3. Company Footprint

- 13.2.4. Management Team

- 13.2.5. Contact Details

- 13.2.6. Financial Performance

- 13.2.7. Operating Business Segments

- 13.2.8. Service / Product Portfolio (project specific)

- 13.2.9. MOAT Analysis

- 13.2.10. Recent Developments and Future Outlook

- 13.3. ASK Chemicals

- 13.4. Calderys

- 13.5. Casco Specialty Products

- 13.6. Compagnie de Saint-Gobain

- 13.7. Dalmia Bharat Refractories

- 13.8. Dense Refractories

- 13.9. Foseco

- 13.10. Galaxy Enterprise

- 13.11. Gita Refractories

- 13.12. Hubei Sinosteel Refractory

- 13.13. Ibiden

- 13.14. Imerys

- 13.15. Resco Products

- 13.16. Shri Vinayak Industries

- 13.17. Tama Refractory

- 13.18. TMM India

- 13.19. Vesuvius

SECTION V: MARKET TRENDS

14. MEGA TRENDS ANALYSIS

15. UNMET NEED ANALYSIS

16. PATENT ANALYSIS

17. RECENT DEVELOPMENTS

- 17.1. Chapter Overview

- 17.2. Recent Funding

- 17.3. Recent Partnerships

- 17.4. Other Recent Initiatives

SECTION VI: MARKET OPPORTUNITY ANALYSIS

18. GLOBAL DRY RAMMING MASS MARKET

- 18.1. Chapter Overview

- 18.2. Key Assumptions and Methodology

- 18.3. Trends Disruption Impacting Market

- 18.4. Demand Side Trends

- 18.5. Supply Side Trends

- 18.6. Global Dry Ramming Mass Market, Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 18.7. Multivariate Scenario Analysis

- 18.7.1. Conservative Scenario

- 18.7.2. Optimistic Scenario

- 18.8. Investment Feasibility Index

- 18.9. Key Market Segmentations

19. MARKET OPPORTUNITIES BASED ON TYPE OF RAMMING MASS

- 19.1. Chapter Overview

- 19.2. Key Assumptions and Methodology

- 19.3. Revenue Shift Analysis

- 19.4. Market Movement Analysis

- 19.5. Penetration-Growth (P-G) Matrix

- 19.6. Dry Ramming Mass Market for Alumina Ramming Mass: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 19.7. Dry Ramming Mass Market for Chromite Based Ramming Mass: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 19.8. Dry Ramming Mass Market for Magnesia Based Ramming Mass: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 19.9. Dry Ramming Mass Market for Silica Based Ramming Mass: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 19.10. Dry Ramming Mass Market for Zirconia Based Ramming Mass: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 19.11. Dry Ramming Mass Market for Others: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 19.12. Data Triangulation and Validation

- 19.12.1. Secondary Sources

- 19.12.2. Primary Sources

- 19.12.3. Statistical Modeling

20. MARKET OPPORTUNITIES BASED ON TYPE OF FUNCTION

- 20.1. Chapter Overview

- 20.2. Key Assumptions and Methodology

- 20.3. Revenue Shift Analysis

- 20.4. Market Movement Analysis

- 20.5. Penetration-Growth (P-G) Matrix

- 20.6. Dry Ramming Mass Market for Lining: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 20.7. Dry Ramming Mass Market for Patching: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 20.8. Dry Ramming Mass Market for Repairing: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 20.9. Dry Ramming Mass Market for Others: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 20.10. Data Triangulation and Validation

- 20.10.1. Secondary Sources

- 20.10.2. Primary Sources

- 20.10.3. Statistical Modeling

21. MARKET OPPORTUNITIES BASED ON AREAS OF APPLICATION

- 21.1. Chapter Overview

- 21.2. Key Assumptions and Methodology

- 21.3. Revenue Shift Analysis

- 21.4. Market Movement Analysis

- 21.5. Penetration-Growth (P-G) Matrix

- 21.6. Dry Ramming Mass Market for Blast Furnace: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 21.7. Dry Ramming Mass Market for Electric Arc Furnace: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 21.8. Dry Ramming Mass Market for Foundries: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 21.9. Dry Ramming Mass Market for Non-Steel: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 21.10. Dry Ramming Mass Market for Steel: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 21.11. Dry Ramming Mass Market for Others: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 21.12. Data Triangulation and Validation

- 21.12.1. Secondary Sources

- 21.12.2. Primary Sources

- 21.12.3. Statistical Modeling

22. MARKET OPPORTUNITIES BASED ON TYPE OF ENTERPRISE

- 22.1. Chapter Overview

- 22.2. Key Assumptions and Methodology

- 22.3. Revenue Shift Analysis

- 22.4. Market Movement Analysis

- 22.5. Penetration-Growth (P-G) Matrix

- 22.6. Dry Ramming Mass Market for Large Enterprise: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 22.7. Dry Ramming Mass Market for Small and Medium Enterprises: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 22.8. Data Triangulation and Validation

- 22.8.1. Secondary Sources

- 22.8.2. Primary Sources

- 22.8.3. Statistical Modeling

23. MARKET OPPORTUNITIES FOR DRY RAMMING MASS IN NORTH AMERICA

- 23.1. Chapter Overview

- 23.2. Key Assumptions and Methodology

- 23.3. Revenue Shift Analysis

- 23.4. Market Movement Analysis

- 23.5. Penetration-Growth (P-G) Matrix

- 23.6. Dry Ramming Mass Market in North America: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 23.6.1. Dry Ramming Mass Market in the US: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 23.6.2. Dry Ramming Mass Market in Canada: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 23.6.3. Dry Ramming Mass Market in Mexico: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 23.6.4. Dry Ramming Mass Market in Other North American Countries: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 23.7. Data Triangulation and Validation

24. MARKET OPPORTUNITIES FOR DRY RAMMING MASS IN EUROPE

- 24.1. Chapter Overview

- 24.2. Key Assumptions and Methodology

- 24.3. Revenue Shift Analysis

- 24.4. Market Movement Analysis

- 24.5. Penetration-Growth (P-G) Matrix

- 24.6. Dry Ramming Mass Market in Europe: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.1. Dry Ramming Mass Market in Austria: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.2. Dry Ramming Mass Market in Belgium: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.3. Dry Ramming Mass Market in Denmark: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.4. Dry Ramming Mass Market in France: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.5. Dry Ramming Mass Market in Germany: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.6. Dry Ramming Mass Market in Ireland: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.7. Dry Ramming Mass Market in Italy: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.8. Dry Ramming Mass Market in Netherlands: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.9. Dry Ramming Mass Market in Norway: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.10. Dry Ramming Mass Market in Russia: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.11. Dry Ramming Mass Market in Spain: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.12. Dry Ramming Mass Market in Sweden: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.13. Dry Ramming Mass Market in Switzerland: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.14. Dry Ramming Mass Market in the UK: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.6.15. Dry Ramming Mass Market in Other European Countries: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 24.7. Data Triangulation and Validation

25. MARKET OPPORTUNITIES FOR DRY RAMMING MASS IN ASIA

- 25.1. Chapter Overview

- 25.2. Key Assumptions and Methodology

- 25.3. Revenue Shift Analysis

- 25.4. Market Movement Analysis

- 25.5. Penetration-Growth (P-G) Matrix

- 25.6. Dry Ramming Mass Market in Asia: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.6.1. Dry Ramming Mass Market in China: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.6.2. Dry Ramming Mass Market in India: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.6.3. Dry Ramming Mass Market in Japan: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.6.4. Dry Ramming Mass Market in Singapore: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.6.5. Dry Ramming Mass Market in South Korea: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.6.6. Dry Ramming Mass Market in Other Asian Countries: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 25.7. Data Triangulation and Validation

26. MARKET OPPORTUNITIES FOR DRY RAMMING MASS IN MIDDLE EAST AND NORTH AFRICA (MENA)

- 26.1. Chapter Overview

- 26.2. Key Assumptions and Methodology

- 26.3. Revenue Shift Analysis

- 26.4. Market Movement Analysis

- 26.5. Penetration-Growth (P-G) Matrix

- 26.6. Dry Ramming Mass Market in Middle East and North Africa (MENA): Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.1. Dry Ramming Mass Market in Egypt: Historical Trends (Since 2020) and Forecasted Estimates (Till 205)

- 26.6.2. Dry Ramming Mass Market in Iran: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.3. Dry Ramming Mass Market in Iraq: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.4. Dry Ramming Mass Market in Israel: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.5. Dry Ramming Mass Market in Kuwait: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.6. Dry Ramming Mass Market in Saudi Arabia: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.7. Dry Ramming Mass Market in United Arab Emirates (UAE): Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.6.8. Dry Ramming Mass Market in Other MENA Countries: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 26.7. Data Triangulation and Validation

27. MARKET OPPORTUNITIES FOR DRY RAMMING MASS IN LATIN AMERICA

- 27.1. Chapter Overview

- 27.2. Key Assumptions and Methodology

- 27.3. Revenue Shift Analysis

- 27.4. Market Movement Analysis

- 27.5. Penetration-Growth (P-G) Matrix

- 27.6. Dry Ramming Mass Market in Latin America: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.6.1. Dry Ramming Mass Market in Argentina: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.6.2. Dry Ramming Mass Market in Brazil: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.6.3. Dry Ramming Mass Market in Chile: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.6.4. Dry Ramming Mass Market in Colombia Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.6.5. Dry Ramming Mass Market in Venezuela: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.6.6. Dry Ramming Mass Market in Other Latin American Countries: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 27.7. Data Triangulation and Validation

28. MARKET OPPORTUNITIES FOR DRY RAMMING MASS IN REST OF THE WORLD

- 28.1. Chapter Overview

- 28.2. Key Assumptions and Methodology

- 28.3. Revenue Shift Analysis

- 28.4. Market Movement Analysis

- 28.5. Penetration-Growth (P-G) Matrix

- 28.6. Dry Ramming Mass Market in Rest of the World: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 28.6.1. Dry Ramming Mass Market in Australia: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 28.6.2. Dry Ramming Mass Market in New Zealand: Historical Trends (Since 2020) and Forecasted Estimates (Till 2035)

- 28.6.3. Dry Ramming Mass Market in Other Countries

- 28.7. Data Triangulation and Validation

29. MARKET CONCENTRATION ANALYSIS: DISTRIBUTION BY LEADING PLAYERS

- 29.1. Leading Player 1

- 29.2. Leading Player 2

- 29.3. Leading Player 3

- 29.4. Leading Player 4

- 29.5. Leading Player 5

- 29.6. Leading Player 6

- 29.7. Leading Player 7

- 29.8. Leading Player 8

30. ADJACENT MARKET ANALYSIS

SECTION VII: STRATEGIC TOOLS

31. KEY WINNING STRATEGIES

32. PORTER'S FIVE FORCES ANALYSIS

33. SWOT ANALYSIS

34. VALUE CHAIN ANALYSIS

35. ROOTS STRATEGIC RECOMMENDATIONS

- 35.1. Chapter Overview

- 35.2. Key Business-related Strategies

- 35.2.1. Research & Development

- 35.2.2. Product Manufacturing

- 35.2.3. Commercialization / Go-to-Market

- 35.2.4. Sales and Marketing

- 35.3. Key Operations-related Strategies

- 35.3.1. Risk Management

- 35.3.2. Workforce

- 35.3.3. Finance

- 35.3.4. Others

SECTION VIII: OTHER EXCLUSIVE INSIGHTS

36. INSIGHTS FROM PRIMARY RESEARCH

37. REPORT CONCLUSION

SECTION IX: APPENDIX

38. TABULATED DATA

39. LIST OF COMPANIES AND ORGANIZATIONS

40. CUSTOMIZATION OPPORTUNITIES

41. ROOTS SUBSCRIPTION SERVICES

42. AUTHOR DETAILS