PUBLISHER: TrendForce | PRODUCT CODE: 1794792

PUBLISHER: TrendForce | PRODUCT CODE: 1794792

Glass Substrate Breakthroughs: Driving CoWoS and CPO Innovation

Glass substrates are emerging as a highly promising solution in advanced semiconductor packaging with recent breakthroughs in Through-Glass Via (TGV) technology. They are poised to drive innovation in CoWoS, CPO, and FOPLP technologies. Leveraging superior high-frequency performance, low coefficient of thermal expansion (CTE), and excellent dimensional stability, glass substrates significantly enhance I/O density and signal integrity. This makes them particularly well-suited for large interposers, multi-layer stacking, and high-frequency RF applications. As major players such as Intel, Samsung and TSMC actively invest in the development and adoption of glass substrates, the widespread application of TGV technology is set to profoundly accelerate the advancement of cutting-edge packaging technologies.

INFOGRAPHICS

Key Highlights:

- Glass substrates, driven by breakthroughs in TGV technology, are key emerging materials for advanced semiconductor packaging.

- They offer superior high-frequency performance, low thermal expansion, and excellent dimensional stability, boosting I/O density and signal integrity.

- Ideally suited for large interposers, multilayer stacking, and high-frequency RF scenarios.

- Major industry players are investing in glass substrate development, accelerating TGV technology adoption and cutting-edge packaging innovation.

Table of Contents

1. Global Packaging Trends and Substrate Material Market Overview

- Table 1: Materials, Technologies, and Key Specifications of FC-BGA and FC-CSP

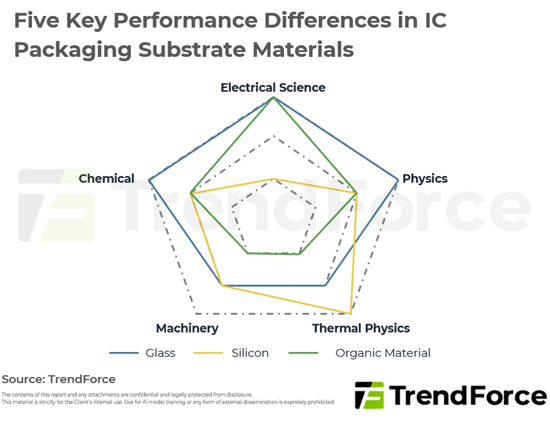

- Figure 1: Five Key Performance Differences in IC Packaging Substrate Materials

- Figure 2: Packaging Architectures Using Silicon, Organic, and Glass Materials

- Table 2: Progress of Substrate and Materials Suppliers in Glass Substrate Development (as of 1H25)

2. Glass Substrates Drive the Next Wave of 3D Integration, Challenging TSV in Cost and Performance

- Table 3: Cost-Effectiveness Comparison of TGV Fabrication Techniques

- Figure 3: Glass Substrates Can Be Applied at Scale in 2.5D/3D Packaging Types

3. Glass Substrates Empower CoWoS, CPO, and FOPLP, Unlocking New Market Potential

4. TRI's View