PUBLISHER: Aviation & Defense Market Reports (A&D) | PRODUCT CODE: 1936047

PUBLISHER: Aviation & Defense Market Reports (A&D) | PRODUCT CODE: 1936047

Global Defense Afterburner / Reheat Systems Market 2026-2036

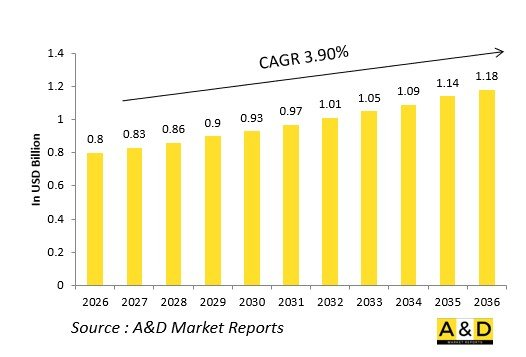

The Global Defense Afterburner / Reheat Systems Market is estimated at USD 0.8 billion in 2026, projected to grow to USD 1.18 billion by 2036 at a Compound Annual Growth Rate (CAGR) of 3.90% over the forecast period 2026-2036.

Introduction

The global Defense Afterburner / Reheat Systems market powers tactical aircraft through controlled post-turbine combustion, multiplying dry thrust for beyond-visual-range engagements and short takeoffs. Annular flame holders stabilize kerosene spray amid supersonic flows, while cooled liners protect turbine faces from thermal shock.

Market evolution tracks sixth-generation requirements, where afterburners balance peak power with infrared suppression for penetrating defenses. Core technologies include fuel spray rings, V-gutter stabilizers, and variable throat nozzles optimizing pressure for maximum augmentation. Emphasis on staged injection reduces smoke signatures.

Geopolitical air superiority competitions drive development, prioritizing integration with adaptive cycle cores and FADEC controls. Modular designs enable retrofits across legacy platforms. Supply chains focus on high-temperature alloys and ceramic coatings. Competition features Pratt & Whitney, Rolls-Royce, and Safran pioneering low-NOx reheat.

This market fuels combat edge through thermodynamic bursts.

Technology Impact in Defense Afterburner / Reheat Systems

Low-emission combustors with rich-quench-lean zones slash visible signatures while maximizing augmentation, critical for day intercepts. Cooled petal nozzles vector thrust without hot edges betraying stealth platforms, using transpiration air to film-cool petals.

Variable geometry throats adjust backpressure across flight envelopes, preventing blowout during climb or unstart in maneuvering combat. Plasma ignition systems light instantly under crosswinds, eliminating pyrotechnic cartridges. Staged fuel injection-pilot then main-stabilizes flame across Mach regimes.

Thermal barrier coatings on liners withstand sustained reheat, extending intervals between overhauls. Integrated FADEC sequences injection with turbine speeds, preventing overtemperature. Hollow flameholders reduce weight while maintaining stability. Augmented thrust links with super cruise cores for seamless dry-to-wet transitions.

Digital twins optimize spray patterns against inlet distortion, while ceramic matrix liners enable higher turbine inlet temperatures. These innovations extend no-escape zones and enable deep strikes against mobile SAMs.

Key Drivers in Defense Afterburner / Reheat Systems

Sixth-generation air dominance mandates sustained afterburning for super cruise intercepts against hypersonic threats. Carrier aviation demands reliable wet thrust for catapult strokes and arrested recoveries under max loads.

Sustainment economics favor durable liners minimizing hot-section inspections. Export markets require smoke-free operation for neutral airspace transit. Stealth integration drives cooled nozzle petals blending with aircraft skins.

Budget pressures prioritize modular reheat over full engine redesigns. Supply chain resilience counters refractory metal shortages. Interoperability standards enable common fuel controls across coalitions.

Urban combat needs precise thrust bursts avoiding overshoot. These imperatives position afterburners as mission differentiators.

Regional Trends in Defense Aircraft Afterburner / Reheat Systems

North America pioneers adaptive reheat for NGAD, emphasizing variable geometry.

Europe upgrades Typhoon and Rafale nozzles for dispersed basing.

Asia-Pacific accelerates indigenous development-India's Kaveri wet variant, China's WS-15-tailored to carrier ops.

Middle East pursues smoke-free systems for day operations.

Russia advances high-temperature alloys for Su-57 sustainment.

South Korea integrates with KF-21 export packages.

Trends favor ceramic liners; Asia-Pacific gains production share.

Key Defense Afterburner / Reheat Systems Programs

F135 afterburner powers F-35 across STOVL, CTOL, CV variants with stealthy petals.

NGAD variable cycle reheat enables super cruise without wet thrust.

EJ200 upgrades deliver dry super cruise with optimized nozzles.

India's Kaveri wet testing validates hollow reheat integration on Tejas.

WS-15 equips J-20 with indigenous augmentation.

Rafale M88 reheat sustains carrier operations.

T-50 FADEC-driven injection sequences wet thrust.

Table of Contents

Defense Afterburner / Reheat Systems Market - Table of Contents

Defense Afterburner / Reheat Systems Market Report Definition

Defense Afterburner / Reheat Systems Market Segmentation

By Platform

By Nozzle Type

By Actuation

Defense Afterburner / Reheat Systems Market Analysis for next 10 Years

The 10-year Defense Afterburner / Reheat Systems market analysis would give a detailed overview of Defense Afterburner / Reheat Systems market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Defense Afterburner / Reheat Systems Market

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Defense Afterburner / Reheat Systems Market Forecast

The 10-year Defense Afterburner / Reheat Systems market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Defense Afterburner / Reheat Systems Market Trends & Forecast

The regional counter drone market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Defense Afterburner / Reheat Systems Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Defense Afterburner / Reheat Systems Market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Defense Afterburner / Reheat Systems Market Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2026-2036

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2026-2036

- Table 18: Scenario Analysis, Scenario 1, By Platform, 2026-2036

- Table 19: Scenario Analysis, Scenario 1, By Integration, 2026-2036

- Table 20: Scenario Analysis, Scenario 2, By Region, 2026-2036

- Table 21: Scenario Analysis, Scenario 2, By Platform, 2026-2036

- Table 22: Scenario Analysis, Scenario 2, By Integration, 2026-2036

List of Figures

- Figure 1: Global Afterburner / Reheat Systems Market Forecast, 2026-2036

- Figure 2: Global Afterburner / Reheat Systems Market Forecast, By Region, 2026-2036

- Figure 3: Global Afterburner / Reheat Systems Market Forecast, By Platform, 2026-2036

- Figure 4: Global Afterburner / Reheat Systems Market Forecast, By Integration, 2026-2036

- Figure 5: North America, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 6: Europe, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 7: Middle East, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 8: APAC, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 9: South America, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 10: United States, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 11: United States, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 12: Canada, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 13: Canada, Afterburner / Reheat Systems Market , Forecast, 2026-2036

- Figure 14: Italy, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 15: Italy, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 16: France, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 17: France, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 18: Germany, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 19: Germany, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 20: Netherlands, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 21: Netherlands, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 22: Belgium, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 23: Belgium, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 24: Spain, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 25: Spain, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 26: Sweden, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 27: Sweden, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 28: Brazil, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 29: Brazil, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 30: Australia, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 31: Australia, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 32: India, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 33: India, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 34: China, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 35: China, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 36: Saudi Arabia, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 37: Saudi Arabia, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 38: South Korea, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 39: South Korea, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 40: Japan, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 41: Japan, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 42: Malaysia, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 43: Malaysia, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 44: Singapore, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 45: Singapore, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 46: United Kingdom, Afterburner / Reheat Systems Market , Technology Maturation, 2026-2036

- Figure 47: United Kingdom, Afterburner / Reheat Systems Market , Market Forecast, 2026-2036

- Figure 48: Opportunity Analysis, Afterburner / Reheat Systems Market , By Region (Cumulative Market), 2026-2036

- Figure 49: Opportunity Analysis, Afterburner / Reheat Systems Market , By Region (CAGR), 2026-2036

- Figure 50: Opportunity Analysis, Afterburner / Reheat Systems Market , By (Cumulative Market), 2026-2036

- Figure 51: Opportunity Analysis, Afterburner / Reheat Systems Market , By Platform(CAGR), 2026-2036

- Figure 52: Opportunity Analysis, Afterburner / Reheat Systems Market , By Integration (Cumulative Market), 2026-2036

- Figure 53: Opportunity Analysis, Afterburner / Reheat Systems Market , By Integration (CAGR), 2026-2036

- Figure 54: Scenario Analysis, Afterburner / Reheat Systems Market , Cumulative Market, 2026-2036

- Figure 55: Scenario Analysis, Afterburner / Reheat Systems Market , Global Market, 2026-2036

- Figure 56: Scenario 1, Afterburner / Reheat Systems Market , Total Market, 2026-2036

- Figure 57: Scenario 1, Afterburner / Reheat Systems Market , By Region, 2026-2036

- Figure 58: Scenario 1, Afterburner / Reheat Systems Market , By Platform, 2026-2036

- Figure 59: Scenario 1, Afterburner / Reheat Systems Market , By Integration, 2026-2036

- Figure 60: Scenario 2, Afterburner / Reheat Systems Market , Total Market, 2026-2036

- Figure 61: Scenario 2, Afterburner / Reheat Systems Market , By Region, 2026-2036

- Figure 62: Scenario 2, Afterburner / Reheat Systems Market , By Platform, 2026-2036

- Figure 63: Scenario 2, Afterburner / Reheat Systems Market , By Integration, 2026-2036

- Figure 64: Company Benchmark, Afterburner / Reheat Systems Market , 2026-2036