PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1721496

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1721496

Gas Turbine Component Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

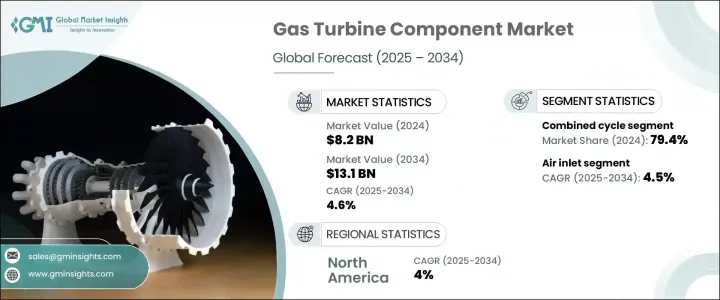

The Global Gas Turbine Component Market was valued at USD 8.2 billion in 2024 and is estimated to grow at a CAGR of 4.6% to reach USD 13.1 billion by 2034. This growth is primarily fueled by the shift toward lower-emission technologies, increasing the demand for efficient turbine components, particularly in peaker plants and combined-cycle systems. The modernization and retrofitting of existing gas turbine infrastructure across industrial and utility sectors are expected to drive the adoption of advanced parts, enhancing turbine efficiency and performance. The continued innovation in materials and design, specifically in combustors, nozzles, and blades, plays a critical role in meeting evolving emission standards, while also improving overall turbine performance. As the world increasingly prioritizes cleaner, more flexible power generation, gas turbine components are becoming integral to the modernization of energy infrastructure.

The demand for high-performance turbine components is further strengthened by advancements driven by the aerospace industry, where the need for single-crystal blades and heat-resistant alloys continues to rise. The increasing importance of decentralized energy systems and backup power solutions, particularly in remote or off-grid locations, also fuels the need for reliable turbine components. These systems, often integrated with renewable energy sources, are vital to the development of modern hybrid power infrastructure. As energy producers seek to meet both environmental and operational demands, the importance of high-quality turbine components grows, making them essential to the broader energy transition.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $8.2 Billion |

| Forecast Value | $13.1 Billion |

| CAGR | 4.6% |

The air inlet component segment is expected to grow at a CAGR of 4.5% through 2034, owing to its vital role in safeguarding turbines from environmental contaminants such as dust, moisture, and industrial pollutants. These components are crucial in preserving turbine integrity, improving combustion efficiency, and reducing maintenance needs, ultimately lowering operational costs. As natural gas infrastructure expands in both developed and emerging markets, particularly in areas focused on clean energy transitions, reliable filtration systems are in high demand to support the evolving energy landscape.

The open-cycle turbine component segment is projected to grow at a CAGR of 4% through 2034, driven by innovations in fuel flexibility and emissions control. These systems offer flexibility, enabling them to support hybrid applications with renewable inputs while complying with stringent carbon reduction regulations. Open-cycle turbines continue to play a significant role in balancing intermittent renewable energy sources, making them vital to large-scale utility projects. Governments' policies supporting clean energy further enhance the relevance of these systems in the evolving energy mix.

In 2024, the U.S. Gas Turbine Component Market generated USD 576.9 million, fueled by the country's ongoing transition to cleaner, more efficient gas turbine technologies. Gas turbines are preferred for their ability to rapidly respond to demand changes, ensuring grid stability while integrating seamlessly with renewable energy sources like solar and wind.

Key players in the Global Gas Turbine Component Market include MAN Energy Solutions, Solar Turbines, Ansaldo Energia, Woodward, Rolls-Royce, Mitsubishi Power, Suzler, Parker Hannifin, IHI Corporation, GE Vernova, Baker Hughes, Siemens Energy, MTU Aero Engines, Wartsila, Doncasters Group, Chromalloy Gas Turbine, Doosan, Kawasaki Heavy Industries, Precision Castparts, and Bharat Heavy Electricals Limited. To maintain market leadership, these companies focus on developing advanced alloys, cooling technologies, and additive manufacturing solutions, boosting turbine durability and operational efficiency.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Impact of trump administration tariffs on trade & overall industry

- 3.4 Industry impact forces

- 3.4.1 Growth drivers

- 3.4.2 Industry pitfalls & challenges

- 3.5 Growth potential analysis

- 3.6 Porter's analysis

- 3.6.1 Bargaining power of suppliers

- 3.6.2 Bargaining power of buyers

- 3.6.3 Threat of new entrants

- 3.6.4 Threat of substitutes

- 3.7 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Strategic outlook

- 4.3 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Component Type, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Air inlet

- 5.3 Compressor

- 5.4 Combustor

- 5.5 Turbine

- 5.6 Fuel nozzle

- 5.7 Exhaust

- 5.8 Auxiliary systems

- 5.9 Others

Chapter 6 Market Size and Forecast, By Technology, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 Open cycle

- 6.3 Combined cycle

Chapter 7 Market Size and Forecast, By Product, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 Aero-derivative

- 7.3 Heavy duty

Chapter 8 Market Size and Forecast, By Application, 2021 - 2034 (USD Million)

- 8.1 Key trends

- 8.2 Power plant

- 8.3 Oil & gas

- 8.4 Process plant

- 8.5 Aviation

- 8.6 Marine

- 8.7 Others

Chapter 9 Market Size and Forecast, By Service Provider, 2021 - 2034 (USD Million)

- 9.1 Key trends

- 9.2 OEM

- 9.3 Non-OEM

Chapter 10 Market Size and Forecast, By Region, 2021 - 2034 (USD Million)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.2.3 Mexico

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 France

- 10.3.3 Germany

- 10.3.4 Russia

- 10.3.5 Italy

- 10.3.6 Netherlands

- 10.3.7 Greece

- 10.3.8 Poland

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 Australia

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Indonesia

- 10.4.6 Thailand

- 10.4.7 Malaysia

- 10.5 Middle East & Africa

- 10.5.1 Saudi Arabia

- 10.5.2 UAE

- 10.5.3 Qatar

- 10.5.4 Oman

- 10.5.5 Egypt

- 10.5.6 Turkey

- 10.5.7 Bahrain

- 10.5.8 Iraq

- 10.5.9 South Africa

- 10.5.10 Algeria

- 10.6 Latin America

- 10.6.1 Brazil

- 10.6.2 Argentina

- 10.6.3 Peru

Chapter 11 Company Profiles

- 11.1 Ansaldo Energia

- 11.2 Baker Hughes

- 11.3 Bharat Heavy Electricals Limited (BHEL)

- 11.4 Chromalloy Gas Turbine LLC

- 11.5 Doncasters Group

- 11.6 Doosan

- 11.7 GE Vernova

- 11.8 IHI Corporation

- 11.9 Kawasaki Heavy Industries

- 11.10 MAN Energy Solutions

- 11.11 Mitsubishi Power

- 11.12 MTU Aero Engines

- 11.13 Parker Hannifin

- 11.14 Precision Castparts

- 11.15 Rolls-Royce

- 11.16 Siemens Energy

- 11.17 Solar Turbines

- 11.18 Sulzer

- 11.19 Wartsila

- 11.20 Woodward