PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1750299

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1750299

Aircraft Windows and Windshields Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

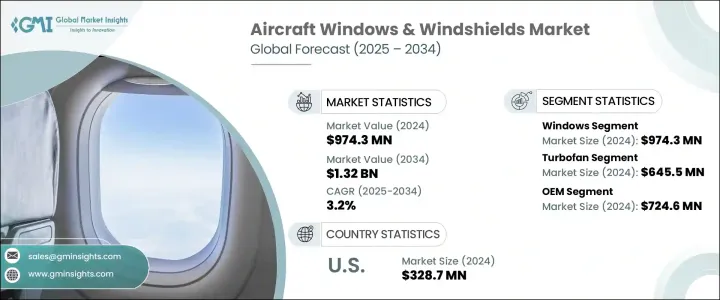

The Global Aircraft Windows and Windshields Market was valued at USD 974.3 million in 2024 and is estimated to grow at a CAGR of 3.2% to reach USD 1.32 billion by 2034, driven by the rising production and deployment of both commercial and business aircraft with sustained demand for advanced window systems. New aircraft platforms and retrofits are driving the shift toward lightweight, impact-resistant materials, while passenger comfort and energy efficiency remain essential considerations in new product development. As the industry adapts to stricter regulatory guidelines, material innovations and evolving aerodynamics are shaping next-generation designs.

Trade policies have influenced manufacturing strategies in recent years. The introduction of tariffs on critical raw materials like aluminium and specialty glass led to production cost hikes of up to 15%, particularly in North America. These shifts prompted a realignment of global supply chains and created cost advantages for some international manufacturers. Additionally, aftermarket vendors saw cost pressures due to their reliance on imported components. Such geopolitical tensions have intensified cost sensitivities across the supply and distribution network. Advancements in material science are propelling the development of superior aircraft windows and windshields. Technologies such as polycarbonate laminates, electrochromic dimming systems, and graphene-infused coatings are gaining prominence for enhancing performance in extreme conditions. Self-healing films, embedded sensors, and smart-tinting functions transform cabin experiences while optimizing energy use.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $974.3 Million |

| Forecast Value | $1.32 Billion |

| CAGR | 3.2% |

In the product category breakdown, the aircraft windows segment generated USD 974.3 million in 2024. These components are engineered not only for visibility but also to handle extreme pressure differentials, temperature shifts, and impact scenarios. The industry is steadily shifting toward advanced polycarbonate-based alternatives to lighten aircraft weight and enhance fuel efficiency, without compromising structural resilience. While the transition demands high R&D and certification costs due to strict aviation authority standards, these investments are justified by improvements in performance, lifecycle reliability, and regulatory compliance.

The turbofan segment in the aircraft windows & windshields market was valued at USD 645.5 million in 2024 as high-performance, multi-layered windows withstand severe thermal gradients, high-altitude pressures, and potential bird impacts. Many new-generation aircraft use advanced windshields with built-in de-icing and thermal regulation features to ensure pilot visibility and cockpit safety. As fleets expand, OEM shipments are gaining momentum, while the aftermarket remains active due to increasing demand for windshield replacements and upgrades in older airframes.

United States Aircraft Windows & Windshields Market reached USD 328.7 million in 2024, owing to key manufacturing hubs, large aircraft fleets, and a solid maintenance, repair, and overhaul (MRO) ecosystem. Military procurement programs, along with rigorous FAA compliance standards, continue to drive the demand for durable, lightweight, and technically advanced materials across both defense and commercial sectors.

Leading players in the Global Aircraft Windows & Windshields Market include Saint-Gobain Aerospace, The NORDAM Group LLC, GENTEX Corporation, GKN Aerospace, and PPG Industries, Inc. Key players in the aircraft windows & windshields market are strengthening their positions through technology partnerships, facility expansions, and material innovation. Companies invest heavily in smart window systems that enhance comfort and performance, especially in the premium and defense segments. Strategic collaborations with OEMs help ensure early integration of products into new platforms, while efforts to develop impact-resistant, lightweight solutions help meet strict FAA and EASA requirements. Major manufacturers localize supply chains to mitigate tariff impacts and improve lead times. R&D remains a core strategy, with firms focusing on electro-optic upgrades, anti-icing enhancements, and new composite structures that reduce lifecycle costs and weight.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.1.3 Impact on the industry

- 3.2.1.3.1 Supply-side impact

- 3.2.1.3.1.1 Price volatility

- 3.2.1.3.1.2 Supply chain restructuring

- 3.2.1.3.1.3 Production cost implications

- 3.2.1.3.2 Demand-side impact

- 3.2.1.3.2.1 Price transmission to end markets

- 3.2.1.3.2.2 Market share dynamics

- 3.2.1.3.2.3 Consumer response patterns

- 3.2.1.3.1 Supply-side impact

- 3.2.1.4 Key companies impacted

- 3.2.1.5 Strategic industry responses

- 3.2.1.5.1 Supply chain reconfiguration

- 3.2.1.5.2 Pricing and product strategies

- 3.2.1.5.3 Policy engagement

- 3.2.1.6 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.1.1 Increasing aircraft deliveries and fleet expansion

- 3.3.1.2 Technological advancements in materials and coatings

- 3.3.1.3 Rising defense and military aircraft modernization

- 3.3.1.4 Aftermarket demand driven by aging fleets and MRO growth

- 3.3.2 Industry pitfalls and challenges

- 3.3.2.1 High certification costs

- 3.3.2.2 Supply chain disruptions

- 3.3.1 Growth drivers

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.6 Technology landscape

- 3.7 Future market trends

- 3.8 Gap analysis

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategy dashboard

Chapter 5 Market Estimates & Forecast, By Product Type, 2021-2034 (USD Million & Units)

- 5.1 Key trends

- 5.2 Windows

- 5.3 Windshields

Chapter 6 Market Estimates & Forecast, By Aircraft Type, 2021-2034 (USD Million & Units)

- 6.1 Key trends

- 6.2 Turboprop

- 6.3 Turbofan

- 6.4 Turbojet

- 6.5 Turboshaft

Chapter 7 Market Estimates & Forecast, By End Use, 2021-2034 (USD Million & Units)

- 7.1 Key trends

- 7.2 OEM

- 7.3 Aftermarket

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Million & Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Netherlands

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 Control Logistics Inc

- 9.2 GENTEX CORPORATION

- 9.3 GKN Aerospace

- 9.4 Lee Aerospace

- 9.5 Llamas Plastics Inc.

- 9.6 LP Aero Plastics Inc.

- 9.7 Perkins Aircraft Windows

- 9.8 PPG Industries, Inc.

- 9.9 Saint-Gobain Aerospace

- 9.10 The NORDAM Group LLC