PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1755390

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1755390

Panel Mounted Industrial Disconnect Switch Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

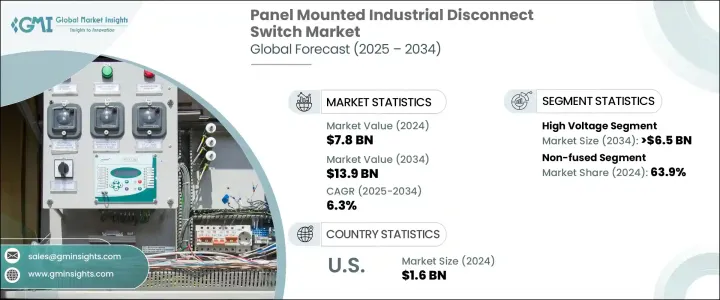

The Global Panel Mounted Industrial Disconnect Switch Market was valued at USD 7.8 billion in 2024 and is estimated to grow at a CAGR of 6.3% to reach USD 13.9 billion by 2034, driven by the increasing demand for reliable electrical equipment, combined with stricter safety regulations. Additionally, the growing trend of automation in industrial facilities, coupled with the need for efficient control panels. A panel mounted industrial disconnect switch is a key electrical device used within industrial control panels or distribution boards to ensure the safe isolation of equipment from power sources. The rise in the adoption of smart disconnect switches, integrated with IoT for real-time monitoring and remote control, is fueling market growth.

As urban and industrial areas grow, the demand for more efficient and reliable electrical systems intensifies. The ongoing push for reducing energy consumption, coupled with a growing focus on operational efficiency, is driving the widespread adoption of low-voltage panel-mounted industrial disconnect switches. These switches help in enhancing safety, ensuring compliance with safety regulations, and improving energy management in diverse industrial settings. In addition, the increasing reliance on automation, digital control systems, and the integration of advanced technology into industrial operations is fueling the need for these switches. With stricter safety standards and an emphasis on preventive maintenance, industries invest in higher-quality and more durable disconnect switches to safeguard electrical systems and minimize downtime.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $7.8 Billion |

| Forecast Value | $13.9 Billion |

| CAGR | 6.3% |

The low voltage segment is anticipated to grow at a robust CAGR of 6.5% by 2034, driven by these evolving industry demands. As automation and energy efficiency become central to modern industries, the need for reliable disconnect switches in applications like control cabinets, machine panels, and building automation systems is expected to surge. This trend is supported by a rising emphasis on safety protocols, regulatory compliance, and maintenance practices across various sectors, including manufacturing, construction, and energy.

The non-fused panel mounted disconnect switch segment held 63.9% in 2024. These switches offer simplified maintenance and reduced downtime by eliminating the need for fuse replacement, making them ideal for modern industrial setups. The ongoing modernization of industrial facilities and the adoption of advanced electrical systems drive demand. Furthermore, the push for compliance with international standards like UL, IEC, and ISO, along with expanding industrial automation, will contribute to market growth.

United States Panel Mounted Industrial Disconnect Switch Market generated USD 1.6 billion by 2024. Stringent safety regulations are encouraging the adoption of efficient, compact, and smart fused disconnect switches. Integrating advanced technologies such as automatic fault detection and diagnostics, combined with efforts to upgrade aging electrical infrastructure, enhances market potential. Investments from key manufacturers to expand production capabilities will further support industry growth in the U.S.

Key players involved in the Panel Mounted Industrial Disconnect Switch Market include Schneider Electric, Mersen, Siemens, Richards Manufacturing, Havells, Lovato Electric, Mersen, Eaton, Socomec, Rockwell Automation, Giovenzana International, Rittal, c3controls, Emerson Electric, Hubbell, Salzer, GE Vernova, Littelfuse, WEG, EMSPEC. To strengthen their market presence, companies in the panel-mounted industrial disconnect switch industry are adopting several key strategies. One of the primary approaches is innovation in product design, with manufacturers focusing on creating more efficient, durable, and compact disconnect switches that meet the growing demand for safety and performance in industrial environments. Companies are increasingly integrating smart technologies into their products, such as IoT connectivity, enabling real-time monitoring and predictive maintenance.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw material)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw material)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Regulatory landscape

- 3.4 Industry impact forces

- 3.4.1 Growth drivers

- 3.4.2 Industry pitfalls & challenges

- 3.5 Growth potential analysis

- 3.6 Porter's analysis

- 3.6.1 Bargaining power of suppliers

- 3.6.2 Bargaining power of buyers

- 3.6.3 Threat of new entrants

- 3.6.4 Threat of substitutes

- 3.7 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic dashboard

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Voltage, 2021 - 2034 (USD Million & Units)

- 5.1 Key trends

- 5.2 Low

- 5.3 Medium

- 5.4 High

Chapter 6 Market Size and Forecast, By Product, 2021 - 2034 (USD Million & Units)

- 6.1 Key trends

- 6.2 Fused

- 6.3 Non-fused

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million & Units)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 UK

- 7.3.2 Germany

- 7.3.3 France

- 7.3.4 Russia

- 7.3.5 Italy

- 7.3.6 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 Australia

- 7.4.3 India

- 7.4.4 Japan

- 7.4.5 South Korea

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 Qatar

- 7.5.4 Oman

- 7.5.5 South Africa

- 7.5.6 Egypt

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Peru

- 7.6.3 Argentina

Chapter 8 Company Profiles

- 8.1 ABB

- 8.2 c3controls

- 8.3 Eaton

- 8.4 Emerson Electric

- 8.5 EMSPEC

- 8.6 GE Vernova

- 8.7 Giovenzana International

- 8.8 Havells

- 8.9 Hubbell

- 8.10 Littelfuse

- 8.11 Lovato Electric

- 8.12 Mersen

- 8.13 Richards Manufacturing

- 8.14 Rittal

- 8.15 Rockwell Automation

- 8.16 Salzer

- 8.17 Schneider Electric

- 8.18 Siemens

- 8.19 Socomec

- 8.20 WEG