PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1766215

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1766215

Thermoform Form-Fill-Seal Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

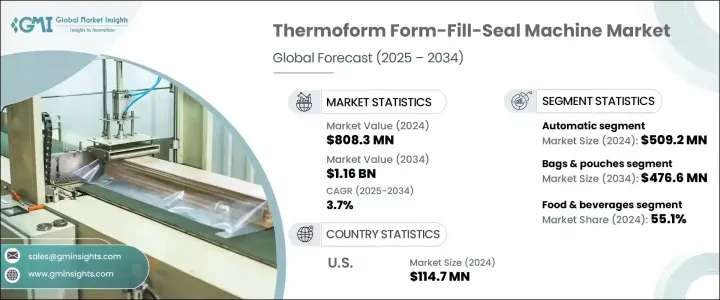

The Global Thermoform Form-Fill-Seal Machine Market was valued at USD 808.3 million in 2024 and is estimated to grow at a CAGR of 3.7% to reach USD 1.16 billion by 2034. This growth is fueled by rising global consumption and the urgent shift toward sustainability and eco-conscious manufacturing. With evolving plastic waste regulations, these machines are now designed to handle recyclable and biodegradable materials. Businesses are investing in next-generation equipment not only to stay compliant with environmental policies but also to align with growing consumer preferences for sustainable packaging. The push toward circular economy practices and smart factory initiatives is encouraging the adoption of innovative, automated packaging technologies.

In industries such as pharmaceuticals, food, and consumer goods, thermoform form-fill-seal machines are increasingly used to meet demands for improved safety, tamper resistance, and longer shelf life. The integration of sensors and IoT-enabled systems for predictive maintenance and process optimization is gaining momentum under Industry 4.0 standards. This evolution is reshaping packaging lines globally, making machines more efficient and adaptive to a wide variety of materials and product types while supporting cost-effective and environmentally friendly operations.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $808.3 million |

| Forecast Value | $1.16 billion |

| CAGR | 3.7% |

In 2024, the automatic thermoform form-fill-seal machine segment recorded USD 509.2 million and is expected to grow at a CAGR of 4.5% between 2025 and 2034. Automatic models are being widely adopted due to their ability to meet rising demands for fast, reliable, and sustainable packaging. The elimination of manual tasks reduces labor costs, enhances consistency, and increases throughput across manufacturing lines. These machines are equipped with advanced interfaces like real-time tracking, programmable logic controllers (PLCs), and intuitive touchscreen controls, which improve user experience and boost operational efficiency. Their adaptability to multiple formats and substrates makes them suitable for an expanding range of applications across sectors.

The bags and pouches packaging format led the global market in 2024, securing a 39.1% share and is forecasted to reach USD 476.6 million by 2034. The growing popularity of convenience foods and health-focused packaged goods is increasing demand for secure and hygienic packaging solutions. Form-fill-seal systems now offer controlled atmosphere sealing capabilities, ensuring freshness and extending shelf life. They are also evolving to support the use of compostable and environmentally safe materials. Regulations that prioritize food safety and packaging integrity continue to drive innovation in this category, as manufacturers seek tamper-proof and contamination-resistant solutions.

United States Thermoform Form-Fill-Seal Machine Market generated USD 114.7 million in 2024, with an anticipated CAGR of 3.9% through 2034. Growth in the U.S. is closely linked to expanding adoption of flexible packaging solutions and sustainable practices across the consumer goods, healthcare, and food and beverage sectors. Increasing demand for eco-friendly alternatives is also pushing companies to upgrade packaging lines with newer, more energy-efficient technologies.

Leading players in the Thermoform Form-Fill-Seal Machine Market include DS Smith, Anchor Packaging, Inc., Huhtamaki Oyj, ProMach, Amcor PLC, Winpak Ltd., Bosch Packaging Technology, Placon Corporation, Barry-Wehmiller Group, Paccor Packaging Corporation, Sealed Air Corporation, Syntegon, Mondi Group, Sonoco Products Company, and Coesia Group. To strengthen their position in the global thermoform form-fill-seal machine market, companies are focusing on integrating smart automation features and digital monitoring tools that enhance machine reliability and reduce operational downtime.

Many are investing in research and development to support the processing of recyclable and biodegradable materials in compliance with evolving environmental regulations. By incorporating flexible design features, these manufacturers are making machines compatible with various packaging formats and substrates. Strategic partnerships with raw material suppliers and OEMs are being formed to enhance supply chain capabilities and product innovation. Some are expanding their geographic presence by setting up regional service centers and technical support hubs to better serve localized markets and reduce lead times.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 End use industry

- 2.2.4 Packaging type

- 2.2.5 Material type

- 2.2.6 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By machine type

- 3.7 Regulatory landscape

- 3.7.1 standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Technology, 2021 - 2034, (USD Million)(Thousand Units)

- 5.1 Key trends

- 5.2 Manual

- 5.3 Semi-automatic

- 5.4 Fully automatic

Chapter 6 Market Estimates & Forecast, By Packaging Type, 2021 - 2034, (USD Million)(Thousand Units)

- 6.1 Key trends

- 6.2 Bags & pouches

- 6.3 Cups & trays

- 6.4 Bottles

- 6.5 Sachets

- 6.6 Cartons

- 6.7 Others

Chapter 7 Market Estimates & Forecast, By End Use Industry, 2021 - 2034, (USD Million)(Thousand Units)

- 7.1 Key trends

- 7.2 Food & beverages

- 7.3 Pharmaceuticals

- 7.4 Cosmetics & personal care

- 7.5 Chemicals

- 7.6 Others

Chapter 8 Market Estimates & Forecast, By Material Type, 2021 - 2034, (USD Million)(Thousand Units)

- 8.1 Key trends

- 8.2 Plastic

- 8.3 Paper

- 8.4 Aluminum foil

- 8.5 Multi-layer films

- 8.6 Biodegradable materials

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034, (USD Million)(Thousand Units)

- 9.1 Key trends

- 9.2 Direct

- 9.3 Indirect

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Million)(Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 Saudi Arabia

- 10.6.2 UAE

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Amcor PLC

- 11.2 Anchor Packaging, Inc.

- 11.3 Barry-Wehmiller Group

- 11.4 Bosch Packaging Technology

- 11.5 Coesia Group

- 11.6 DS Smith

- 11.7 Huhtamaki Oyj

- 11.8 Mondi Group

- 11.9 Paccor Packaging Corporation

- 11.10 Placon Corporation

- 11.11 ProMach

- 11.12 Sealed Air Corporation

- 11.13 Sonoco Products Company

- 11.14 Syntegon

- 11.15 Winpak Ltd.