PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1773422

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1773422

Plastic Injection Molding Machine for MedTech Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

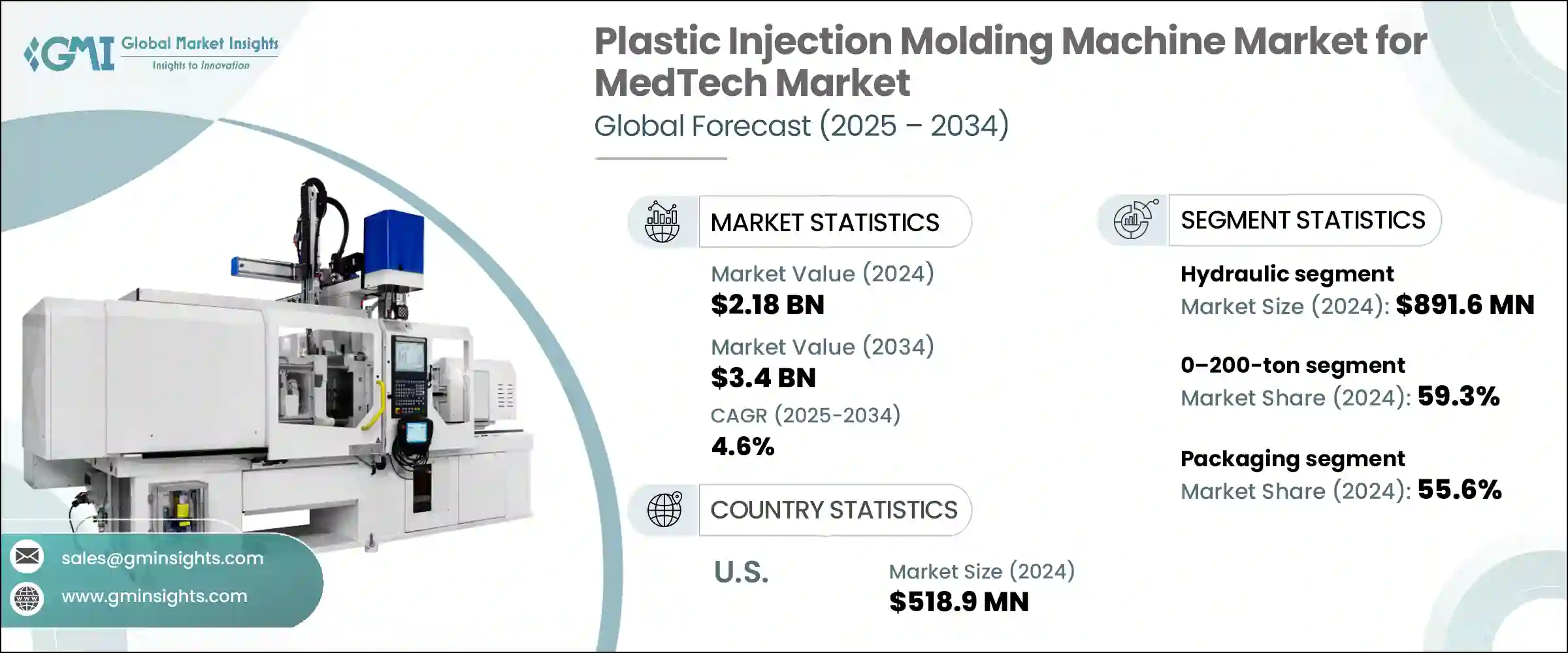

The Global Plastic Injection Molding Machine for MedTech Market was valued at USD 2.18 billion in 2024 and is estimated to grow at a CAGR of 4.6% to reach USD 3.4 billion by 2034. Demand is being driven by aging demographics and a surge in chronic diseases across the U.S. and Europe, resulting in increased requirements for high-quality, reliable medical devices. These devices often require intricate packaging components designed for long-term care and chronic disease management. Expansion in emerging market healthcare sectors presents compelling growth prospects for U.S. and European machine manufacturers, both through exports and through servicing domestic MedTech OEMs catering to these geographies. Additionally, rising healthcare expenditures in regions like Asia-Pacific, Latin America, Eastern Europe, and parts of the Middle East are elevating demand for cost-effective yet precise medical device production.

A broader trend toward onshoring and the rapid expansion of contract manufacturing networks is actively reshaping the global MedTech production landscape, creating new momentum for plastic injection molding machine suppliers. As manufacturers seek to reduce reliance on overseas supply chains and mitigate geopolitical and logistical risks, many are relocating production closer to key markets such as North America and Europe. This shift is fueling demand for highly automated, precision-focused molding machines that support lean manufacturing models and cleanroom compliance. Additionally, contract manufacturing partners are scaling up facilities to handle diverse product portfolios for MedTech OEMs, driving the need for versatile molding platforms capable of producing intricate components efficiently and at high volumes. These evolving dynamics are opening long-term growth avenues for machine makers specializing in medical-grade applications.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.18 Billion |

| Forecast Value | $3.4 Billion |

| CAGR | 4.6% |

The hydraulic segment generated USD 891.6 million in 2024 and is projected to grow at a CAGR of 3.9% through 2034. Though energy-intensive, their high injection pressures, exceptional clamping force, and durability suit large-batch production of complex biomedical components. Their consistent performance in molding high-viscosity materials under high temperatures makes them a dependable choice for critical medical parts production.

Machines with 0-200-ton clamping force segment held a 59.3% share in 2024 and are forecast to grow at a CAGR of 5.1% through 2034. These compact systems enable precise molding of small, disposable components-such as surgical and dental devices-within cleanroom settings. Their energy efficiency, shorter cycle times, and ability to produce high volumes of precision parts make them indispensable for the MedTech sector.

U.S. Plastic Injection Molding Machine for MedTech Market generated USD 518.9 million in 2024 and is expected to grow at a 3.1% CAGR through 2034. Domestic preference for hydraulic machines is strong due to their cost-effectiveness and capability for large-shot, complex part production, especially in contract manufacturing. Electric machines are also gaining traction in SMEs and research labs for their fast cycles, low noise, and minimal upkeep. U.S. MedTech firms increasingly value energy efficiency, clean operation, and precision, driving a balanced market between hydraulic and electric platforms.

Leading manufacturers in the Global Plastic Injection Molding Machine for MedTech Market include Million, JSW, Sumitomo Demag, Nissei Plastic Industrial Co., Ltd., Tederic Machinery, Wittmann Battenfeld, Arburg, Netstal, Ferromatik Milacron, Bohle Machinery, Negri Bossi, Chen Hsong Holdings Limited, Engel, Battenfeld, and Husky Injection Molding Systems. Companies operating in this specialized equipment market are employing strategic initiatives to reinforce their competitive positions. They focus on developing precision-engineered machines designed for medical-grade components while investing in R&D to improve energy efficiency and cycle speed.

Collaborations with MedTech OEMs help validate machine performance for demanding applications, while global service networks ensure rapid support and maintenance. Furthermore, manufacturers are customizing products to match regional cleanroom standards and regulatory needs and are enhancing digital capabilities through smart manufacturing features like predictive maintenance and remote monitoring.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 Technology

- 2.2.4 Clamping Force

- 2.2.5 Application

- 2.2.6 End Use

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for medical devices

- 3.2.1.2 Technological advancements in healthcare

- 3.2.1.3 Aging population and chronic diseases

- 3.2.1.4 Shift towards minimally invasive procedures

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment costs

- 3.2.2.2 Regulatory compliance challenges

- 3.2.3 opportunities

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By machine type

- 3.7 Regulatory framework

- 3.7.1 Standards and certifications

- 3.7.2 Environmental regulations

- 3.7.3 Import export regulations

- 3.8 Trade statistics (HS code 847710)

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's five forces analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021 - 2034, (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Hydraulic machines

- 5.3 Electric machines

- 5.4 Hybrid machines

- 5.5 Micro machines

Chapter 6 Market Estimates & Forecast, By Technology, 2021 - 2034, (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Hot runner systems and cold runner systems

- 6.3 Multi-cavity and family mold designs

- 6.4 Stack mold technology

- 6.5 Servo-actuated mold systems

- 6.6 High-precision mold technologies

Chapter 7 Market Estimates & Forecast, By Clamping Force, 2021 - 2034, (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 0-200 ton force

- 7.3 201-500 ton force

- 7.4 Above 500 ton force

Chapter 8 Market Estimates & Forecast, By Application, 2021 - 2034, (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Packaging

- 8.2.1 Sterile packaging components

- 8.2.2 Caps and closures

- 8.2.3 Protective packaging

- 8.2.4 Others

- 8.3 Diagnostic

- 8.4 Surgical

- 8.5 Others

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034, (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 B2B MedTech Companies

- 9.2.1 Large

- 9.2.2 SME

- 9.3 Pharmaceutical and Combination Product Manufacturers

- 9.4 Contract Manufacturing Organizations (CMOs)

- 9.5 Research and Development Organizations

- 9.5.1 Medical Research Institutions

- 9.5.2 Medical Incubators and Innovation Centers

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 Saudi Arabia

- 10.6.2 UAE

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Arburg

- 11.2 Billion

- 11.3 BOLE Machinery

- 11.4 Chen Hsong Holdings Limited

- 11.5 Engel

- 11.6 Ferromatik Milacron

- 11.7 Husky Injection Molding Systems

- 11.8 JSW

- 11.9 KraussMaffei

- 11.10 Negri Bossi

- 11.11 Nissei Plastic Industrial Co., Ltd.

- 11.12 Netstal

- 11.13 Sumitomo Demag

- 11.14 Tederic Machinery

- 11.15 Wittmann Battenfeld