PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1871108

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1871108

Shape Memory Ceramics for Actuator Applications Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

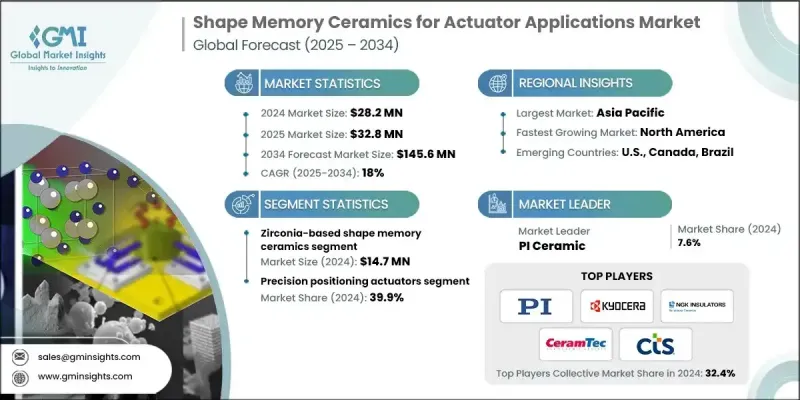

The Global Shape Memory Ceramics for Actuator Applications Market was valued at USD 28.2 million in 2024 and is estimated to grow at a CAGR of 18% to reach USD 145.6 million by 2034.

Shape memory ceramics are emerging as one of the most innovative smart materials in actuator technology, capable of changing and restoring their shape under specific external stimuli such as stress, temperature, or electric fields. Their ability to offer high reliability, excellent durability, and efficiency makes them vital in modern industries, including aerospace, automotive, defense, and healthcare. The rapid expansion of automation, robotics, and smart manufacturing technologies is amplifying the demand for actuators that are lightweight, corrosion-resistant, and capable of functioning under extreme conditions. Compared with conventional metallic actuators, these ceramics deliver superior mechanical and thermal performance, allowing consistent operation over extended lifecycles. Increasing R&D investments, supported by government initiatives focused on advanced materials and manufacturing, are fueling technological innovation. Furthermore, the integration of shape memory ceramics into emerging fields such as biomedical devices and MEMS-based components highlights their expanding role in next-generation engineering applications. Their significance continues to rise as industries seek efficient and high-performance actuator materials that deliver precision, repeatability, and resilience in demanding operational environments.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $28.2 million |

| Forecast Value | $145.6 million |

| CAGR | 18% |

The zirconia-based shape memory ceramics generated USD 14.7 million in 2024, accounting for the largest share of the market. Zirconia's superior tensile strength, high fracture toughness, and remarkable thermal stability make it a preferred choice for applications operating in extreme temperature and pressure conditions. These properties allow zirconia-based materials to retain shape memory characteristics while addressing the brittleness typically associated with ceramic materials, ensuring stable performance in aerospace, industrial, and energy applications.

The precision positioning actuator segment held a 39.9% share in 2024. This dominance is driven by their critical use in industries requiring sub-micrometer accuracy, such as semiconductor manufacturing, optical systems, and advanced instrumentation. The growing demand for actuators that provide consistent motion control and high accuracy under elevated temperatures continues to boost adoption. Ceramic-based actuators are also gaining prominence in high-temperature environments exceeding 300°C, where conventional metallic shape memory alloys tend to lose functionality, positioning them as the preferred solution for aerospace and industrial automation systems.

North America Shape Memory Ceramics for Actuator Applications Market will grow at a CAGR of 18.1% between 2025 and 2034. Regional growth is driven by the increasing need for precise and high-performance actuators across aerospace, automotive, and medical device manufacturing sectors. Technological advancements in ceramic compositions have improved their mechanical strength and response time, making them suitable for continuous operation in challenging environments. Additionally, the region's emphasis on automation, robotics, and smart manufacturing is accelerating the adoption of ceramic-based actuator systems that offer faster, more durable, and efficient performance.

Key players operating in the Global Shape Memory Ceramics for Actuator Applications Market include Kyocera Corporation, FUJI CERAMICS CORPORATION, CeramTec Group, Morgan Advanced Materials, CTS Corporation, TAIYO YUDEN CO., LTD., Tosoh Corporation, Advanced Ceramic Material, NGK Insulators, Niterra Co., Ltd., PI Ceramic, and Piezo Direct. Companies in the Global Shape Memory Ceramics for Actuator Applications Market are implementing diverse strategies to reinforce their market foothold and competitive edge. Many are channeling significant investments into R&D to develop advanced zirconia and alumina-based formulations with enhanced thermal endurance and mechanical strength. Partnerships and collaborations with aerospace, medical, and industrial manufacturers are helping broaden application portfolios. Firms are also emphasizing capacity expansion to meet the growing demand for precision actuators across critical industries.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Product trends

- 2.2.2 Application trends

- 2.2.3 End use industry trends

- 2.2.4 Regional trends

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Aerospace industry demand for high-performance actuators

- 3.2.1.2 Miniaturization trends in mems & microactuator systems

- 3.2.1.3 Superior chemical & corrosion resistance properties

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High manufacturing costs & complex processing requirements

- 3.2.2.2 Brittleness & fracture toughness limitations

- 3.2.3 Market opportunities

- 3.2.3.1 Hybrid metal-ceramic composite development

- 3.2.3.2 Lead-free ferroelectric systems for environmental compliance

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and Innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By product

- 3.9 Future market trends

- 3.10 Technology and Innovation landscape

- 3.10.1 Current technological trends

- 3.10.2 Emerging technologies

- 3.11 Patent Landscape

- 3.12 Trade statistics (HS code)

( Note: the trade statistics will be provided for key countries only

- 3.12.1 Major importing countries

- 3.12.2 Major exporting countries

- 3.13 Sustainability and environmental aspects

- 3.13.1 Sustainable practices

- 3.13.2 Waste reduction strategies

- 3.13.3 Energy efficiency in production

- 3.13.4 Eco-friendly initiatives

- 3.14 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Product, 2021-2034 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Zirconia-based shape memory ceramics

- 5.2.1 Ceria-doped zirconia (CeO2-ZrO2)

- 5.2.2 Yttria-stabilized tetragonal zirconia

- 5.2.3 Modified zirconia with aliovalent dopants

- 5.3 Ferroelectric shape memory ceramics

- 5.3.1 Lead zirconate titanate (PZT)

- 5.3.2 Lead-free ferroelectric ceramics

- 5.3.3 Hafnium oxide (HfO2) thin film

- 5.4 Composite shape memory ceramics

- 5.4.1 Metal matrix composites

- 5.4.2 Zirconia-toughened alumina (ZTA)

- 5.4.3 Hybrid organic-inorganic composites

- 5.5 Others

Chapter 6 Market Estimates and Forecast, By Application, 2021-2034 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Precision positioning actuators

- 6.2.1 Nanometer-scale optical positioning systems

- 6.2.2 MEMS & microactuator applications

- 6.2.3 Fast-steering mirrors & optical pointing

- 6.3 High-temperature actuators

- 6.3.1 Aerospace engine control systems

- 6.3.2 Deep borehole & extreme environment applications

- 6.3.3 Industrial high-temperature process control

- 6.4 RF & microwave actuators

- 6.4.1 Reconfigurable antenna systems

- 6.4.2 Metamaterial & metasurface applications

- 6.4.3 CubeSat & space communication systems

- 6.5 Microfluidic & lab-on-chip actuators

- 6.5.1 Microvalves & micropump systems

- 6.5.2 Microrobotic applications

- 6.5.3 Biomedical device integration

- 6.6 Others

Chapter 7 Market Estimates and Forecast, By End Use Industry, 2021-2034 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Aerospace & defense

- 7.2.1 Aircraft morphing wing structures

- 7.2.2 Spacecraft deployable mechanisms

- 7.2.3 Military precision optical systems

- 7.3 Automotive

- 7.3.1 Engine thermal management systems

- 7.3.2 Adaptive suspension & vibration control

- 7.3.3 Battery thermal management

- 7.4 Industrial automation & robotics

- 7.4.1 Precision manufacturing equipment

- 7.4.2 Robotic system actuators

- 7.4.3 Process control & flow management

- 7.5 Electronics & semiconductors

- 7.5.1 MEMS & microelectromechanical systems

- 7.5.2 Optical switching & fiber positioning

- 7.5.3 Semiconductor processing equipment

- 7.6 Medical & biomedical

- 7.6.1 Surgical instrument actuators

- 7.6.2 Lab-on-chip diagnostic devices

- 7.6.3 Biocompatible actuation systems

- 7.7 Others

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 Advanced Ceramic Material

- 9.2 CeramTec Group

- 9.3 CTS Corporation

- 9.4 FUJI CERAMICS CORPORATION

- 9.5 Kyocera Corporation

- 9.6 Morgan Advanced Materials

- 9.7 NGK Insulators

- 9.8 Niterra Co., Ltd.

- 9.9 PI Ceramic

- 9.10 Piezo Direct

- 9.11 TAIYO YUDEN CO., LTD.

- 9.12 Tosoh Corporation